Cement concrete pavement patching material and cement concrete pavement patching method

A technology for repairing cement concrete and pavement, which is applied in the field of cement concrete pavement repairing materials and cement concrete pavement repairing. It can solve the problems of unsatisfactory repairing effect, low compressive strength, low tensile strength, and low bond strength, and achieve good frost resistance. Improve the destructive ability of melting cycle, improve the interfacial bond strength, and improve the effect of anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

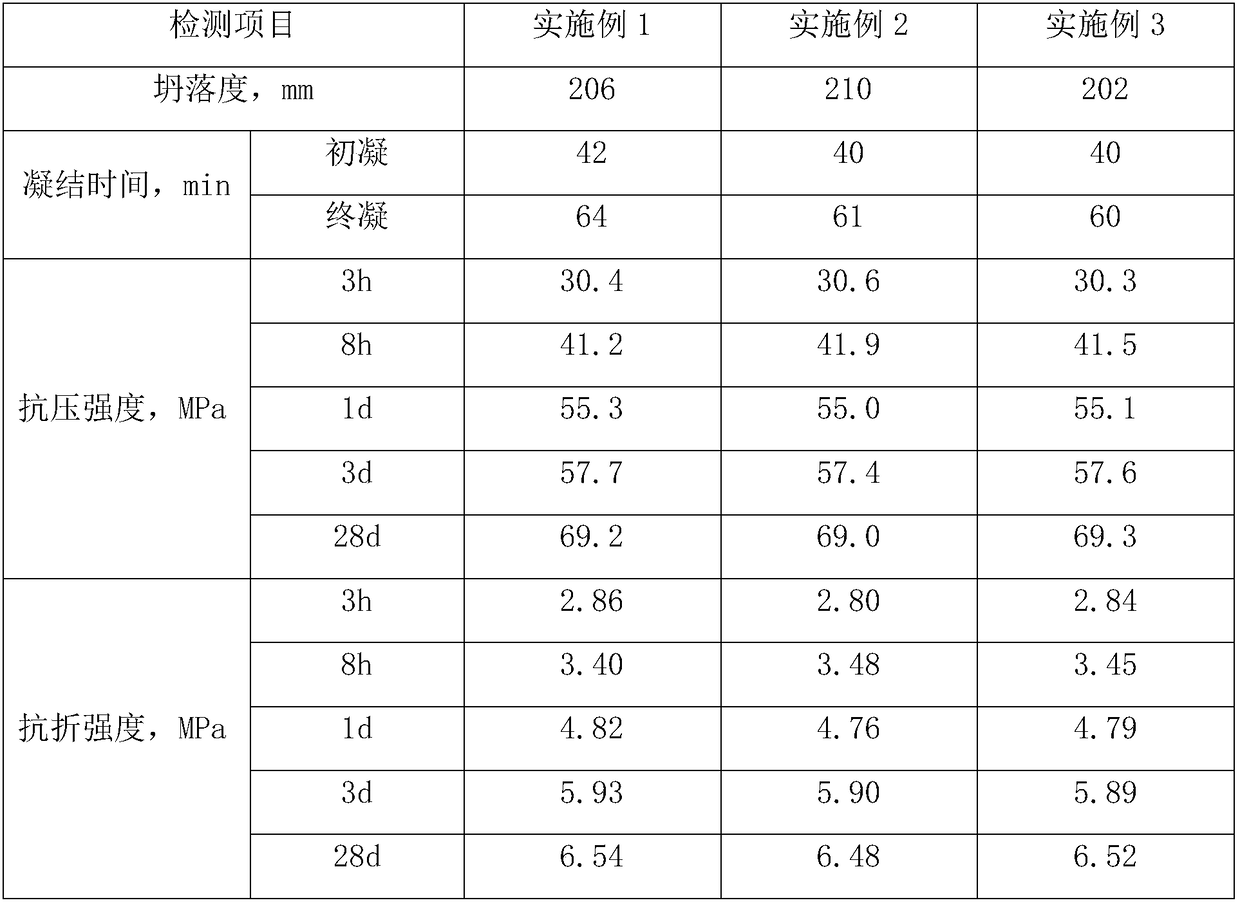

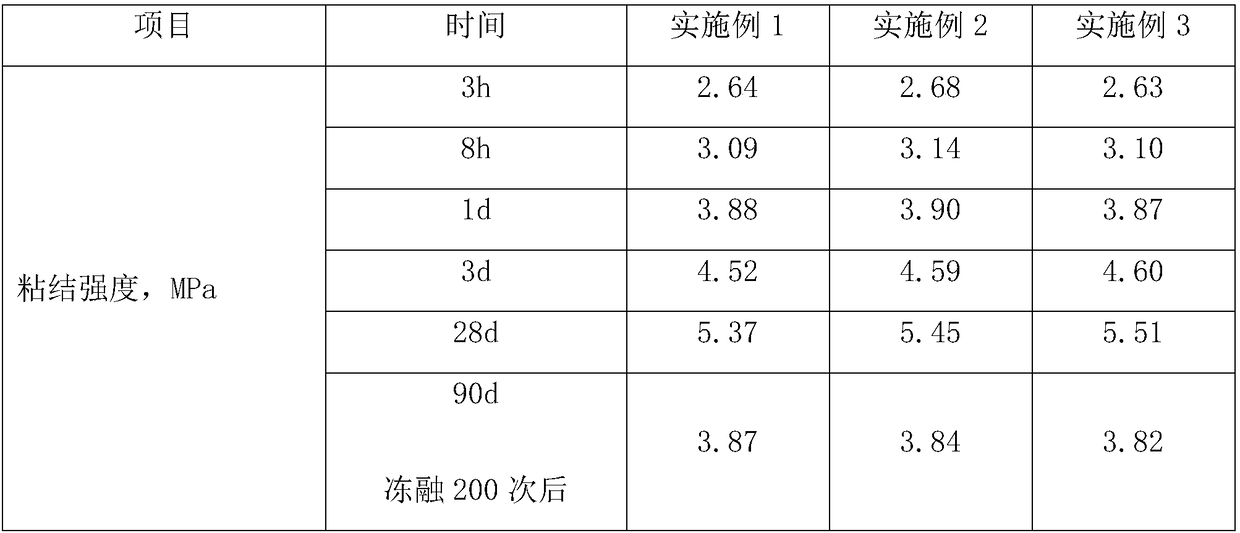

Embodiment 1

[0029] The cement concrete pavement repair material of the present embodiment is made up of water and the following components in parts by weight: 48 parts of Portland cement, 22 parts of sulphoaluminate cement, 22 parts of metakaolin, 8 parts of fly ash, alkali-activated 25 parts of agent, 145 parts of fine aggregate, 280 parts of coarse aggregate, 1.5 parts of polycarboxylate superplasticizer, 2.0 parts of polyethylene oxide rubber powder, 1.0 parts of ethylene-vinyl acetate copolymer rubber powder, 2 parts of organic-inorganic composite fiber , Coagulation regulator 0.23 parts; the amount of water used to control the water-binder ratio is 0.35.

[0030] Wherein, the fine aggregate is medium sand with a fineness modulus of 2.6; the coarse aggregate is continuously graded gravel with a particle size of 4-10mm; the organic-inorganic composite fiber is polypropylene fiber and steel fiber The mass ratio is a mixture of 4:1; the length of the polypropylene fiber is 10mm, and the ...

Embodiment 2

[0038] The cement concrete pavement repair material of the present embodiment is made up of water and the following components in parts by weight: 50 parts of Portland cement, 20 parts of sulphoaluminate cement, 20 parts of metakaolin, 10 parts of fly ash, alkali-activated 28 parts of agent, 150 parts of fine aggregate, 275 parts of coarse aggregate, 1.2 parts of polycarboxylate superplasticizer, 2.3 parts of polyethylene oxide rubber powder, 0.9 parts of ethylene-vinyl acetate copolymer rubber powder, and 3 parts of organic-inorganic composite fiber , Coagulation regulator 0.28 parts; the amount of water used to control the water-binder ratio is 0.38.

[0039] Wherein, the fine aggregate is medium sand with a fineness modulus of 2.7; the coarse aggregate is continuously graded gravel with a particle size of 4-10mm; the organic-inorganic composite fiber is polypropylene fiber and steel fiber The mass ratio is a mixture of 4:1; the length of the polypropylene fiber is 15mm, and...

Embodiment 3

[0043] The cement concrete pavement repair material of the present embodiment is made up of water and the following components in parts by weight: 52 parts of Portland cement, 18 parts of sulphoaluminate cement, 18 parts of metakaolin, 12 parts of fly ash, alkali-activated 30 parts of agent, 158 parts of fine aggregate, 270 parts of coarse aggregate, 1.0 part of polycarboxylate superplasticizer, 2.5 parts of polyethylene oxide rubber powder, 0.8 parts of ethylene-vinyl acetate copolymer rubber powder, 4 parts of organic-inorganic composite fiber , 0.31 parts of coagulation regulator; the amount of water used to control the water-binder ratio is 0.36.

[0044] Wherein, the fine aggregate is medium sand with a fineness modulus of 2.8; the coarse aggregate is continuously graded gravel with a particle size of 4-10 mm; the organic-inorganic composite fiber is polypropylene fiber and steel fiber The mass ratio is a mixture of 4:1; the length of the polypropylene fiber is 15mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com