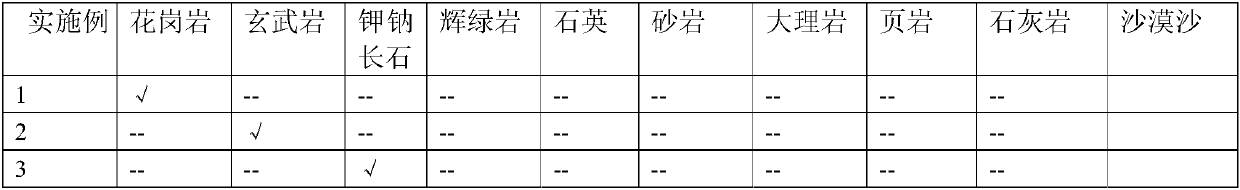

Patents

Literature

100results about How to "The construction process is simple and fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

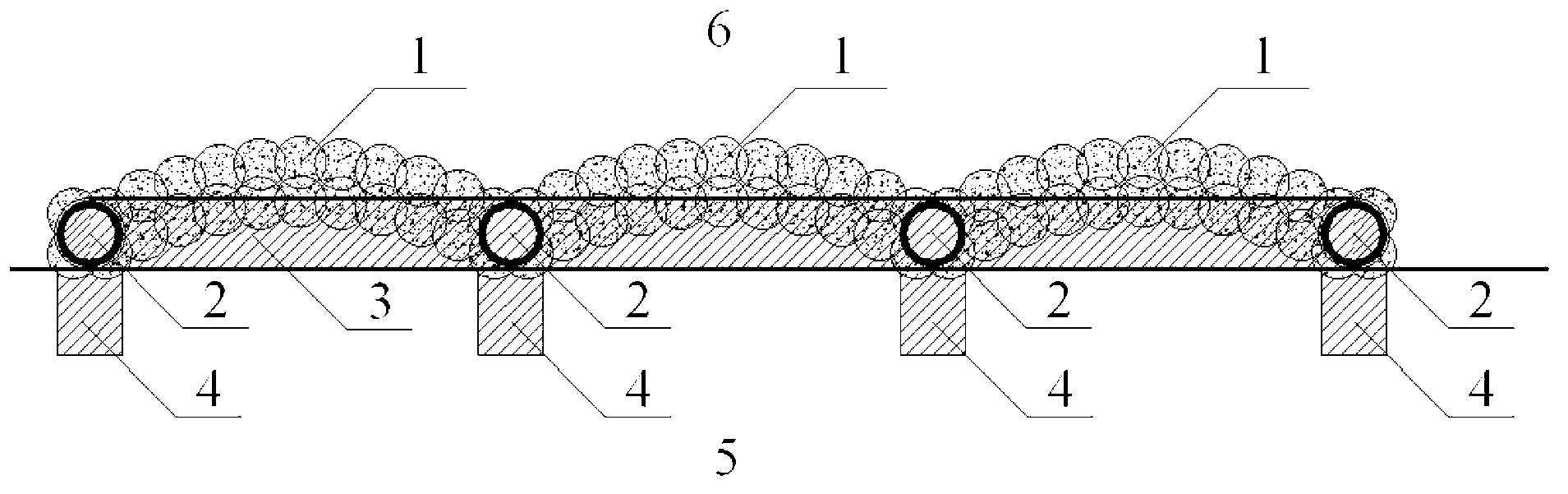

Construction method for two-block unballasted track bed board

InactiveCN101503870AAchieve precise positioningTooling system is simpleRailway track constructionEngineeringRebar

The invention relates to a construction method for a double-block-type ballastless track bed slab, which comprises the following steps: 1, clearing a base surface and performing construction lofting; 2, placing a bottom layer of reinforcing steel bars, and laying sleepers; 3, mounting a tool track and adjusting the sleepers; 4, assembling track panels; 5, coarsely adjusting the track panels; 6, binding the reinforcing steel bars and performing earthing welding; 7, mounting templates and finely adjusting the track; 8, casting concrete into the track bed slab; 9, loosening adjusting devices and fasteners, and curing the concrete; and 10, relocking the tool track and completing the measurement. The construction method has the advantages that: the tool track is adopted as a detection standard, so the precise positioning of the track is realized; a frock system is simple, is easy to process and manufacture, has wide commonality, and is not only suitable for construction of the track bed slab in a subgrade section but also suitable for construction of the track bed slab in a bridge section; the construction process is simple and quick, and various working procedures are easily carried out by flow construction; and the construction cost is low, so the construction investment is effectively saved.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

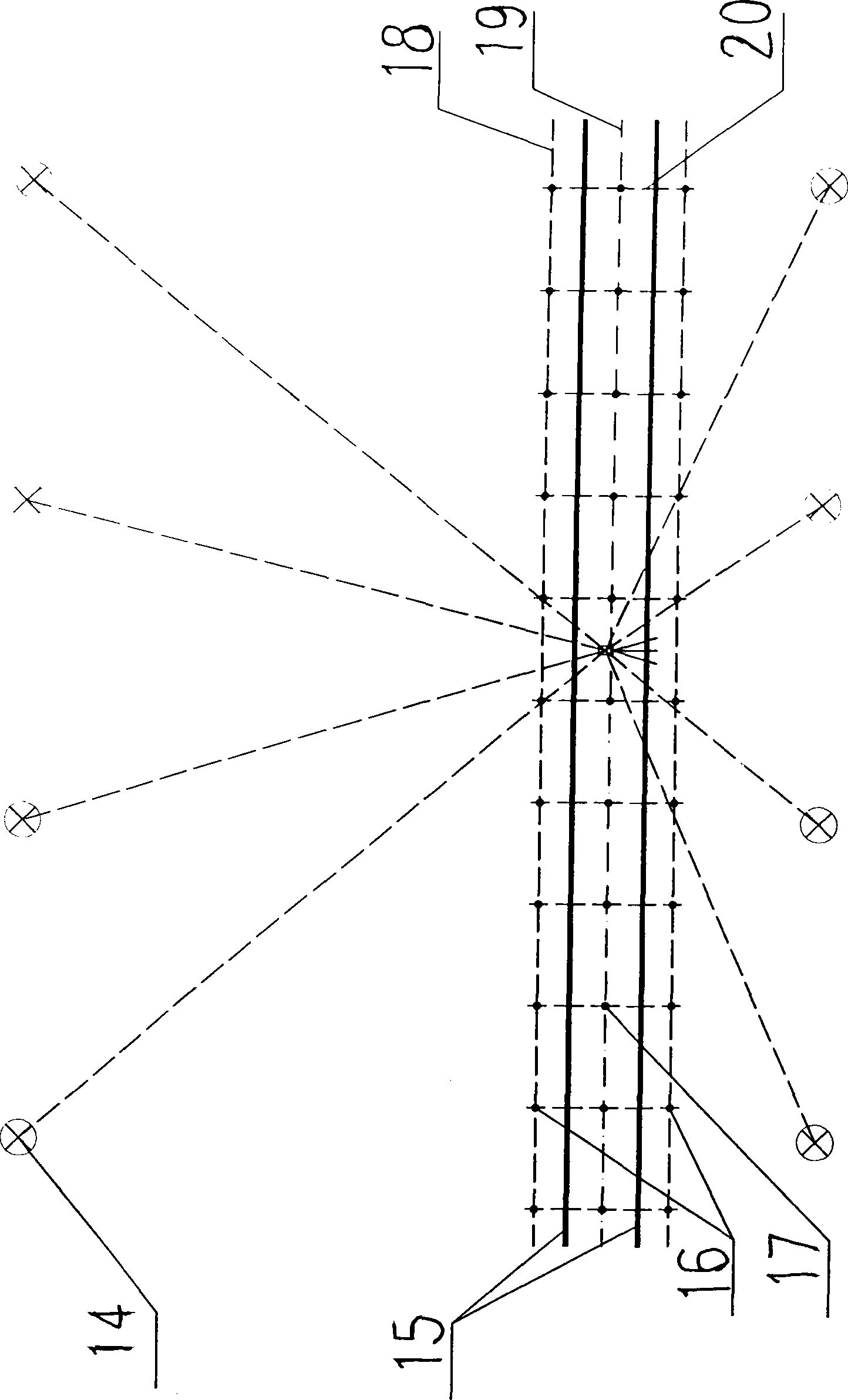

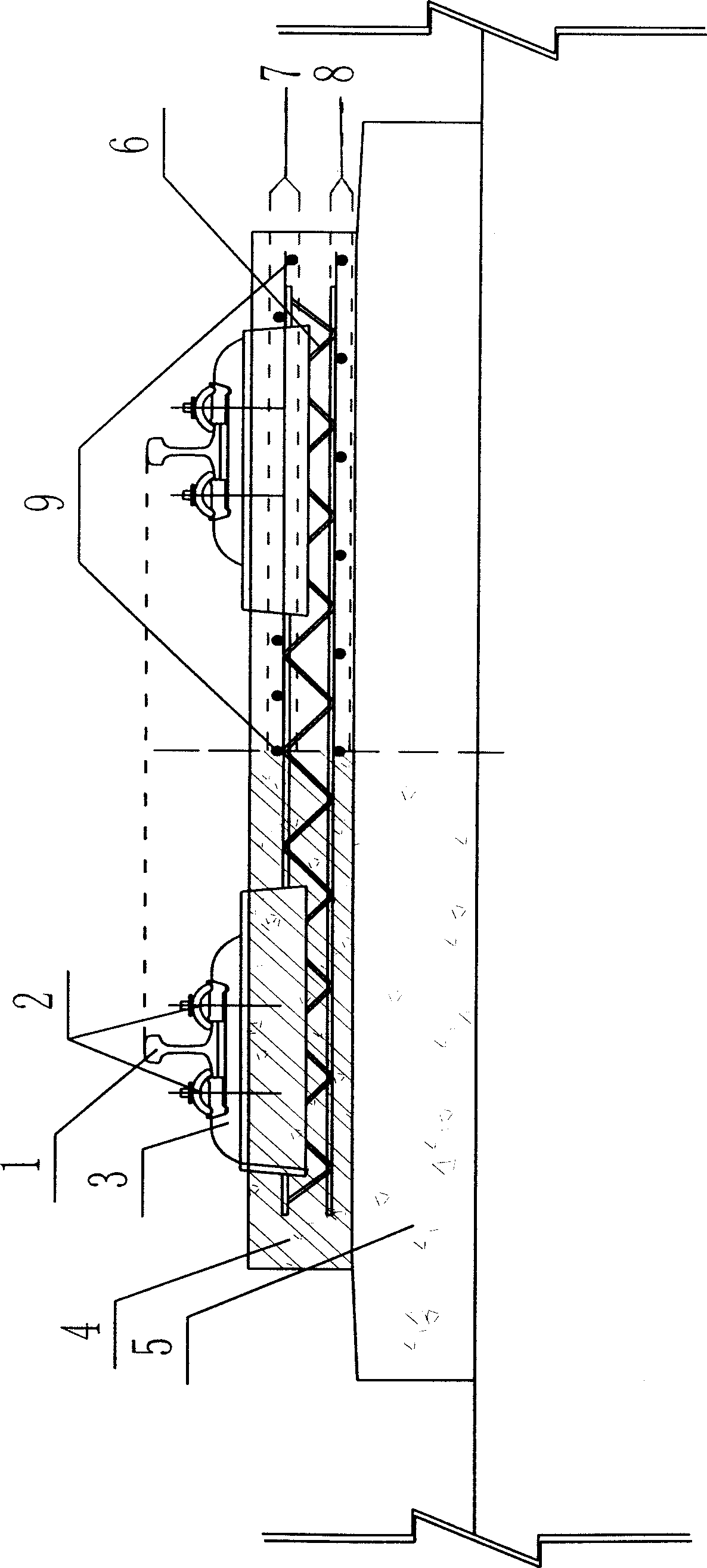

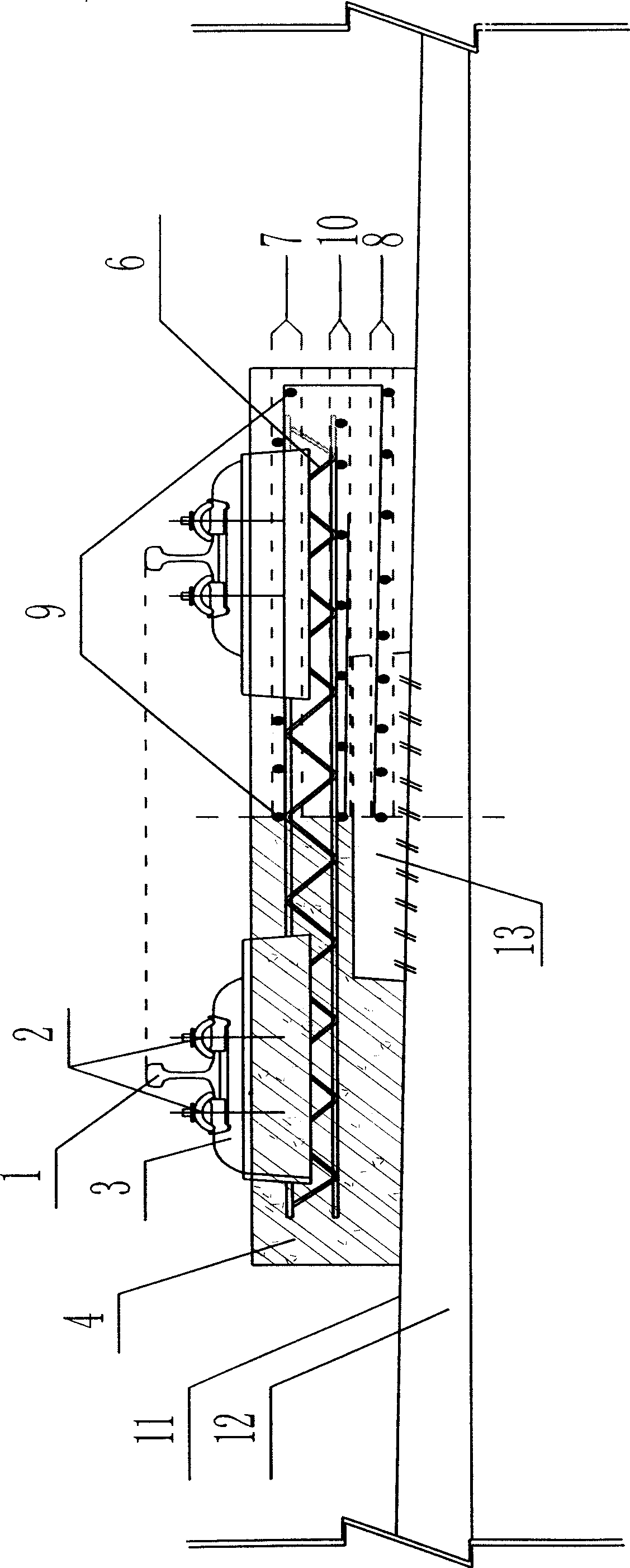

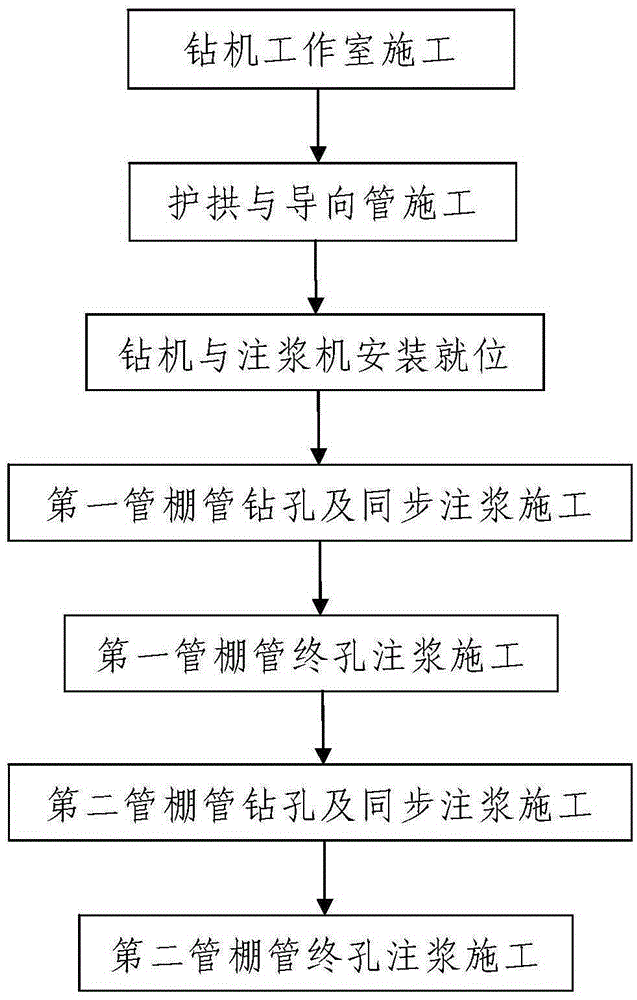

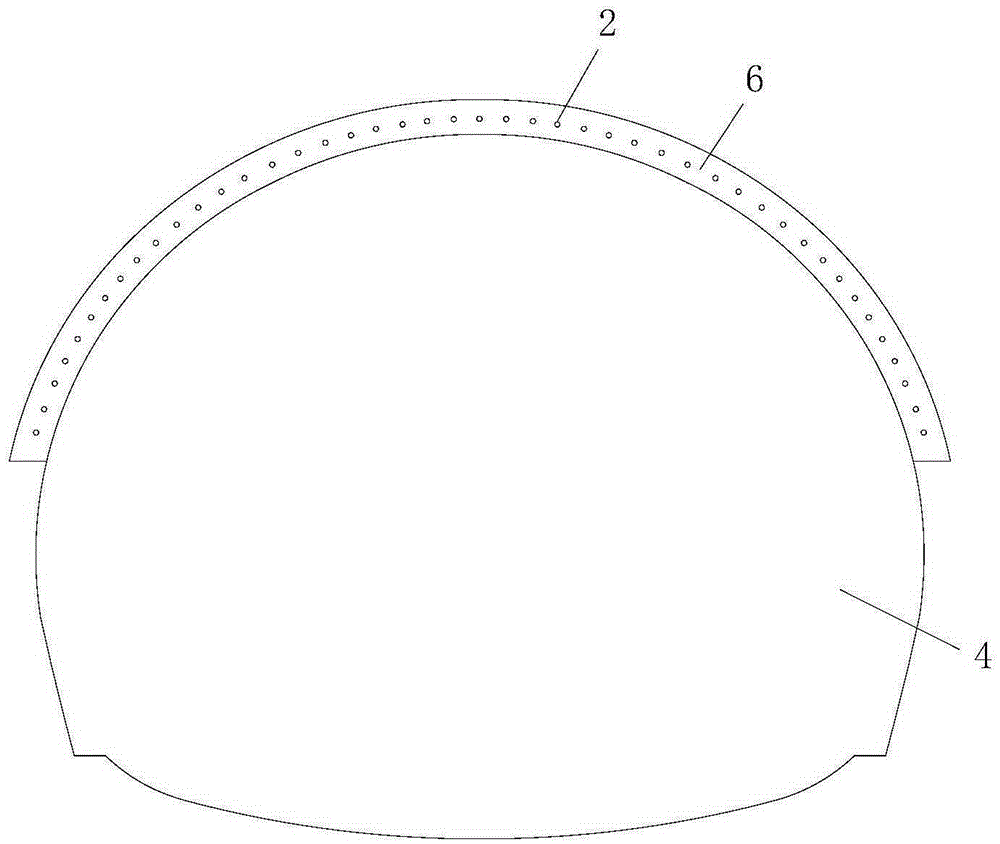

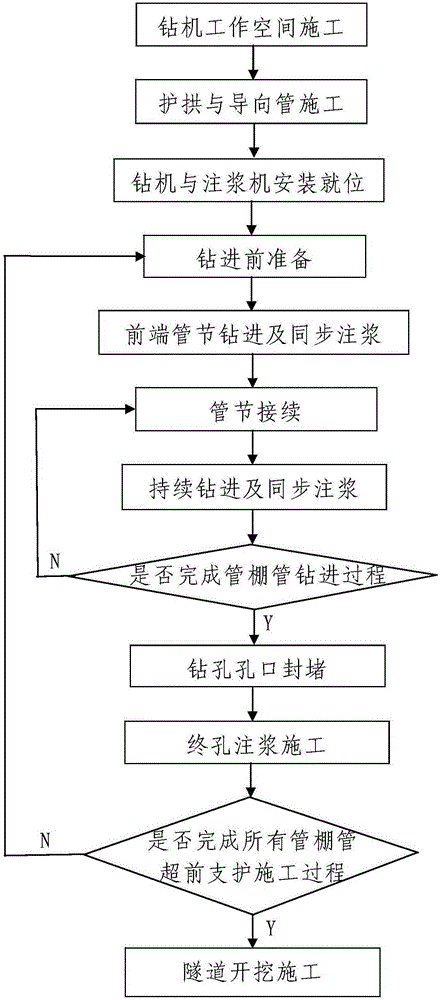

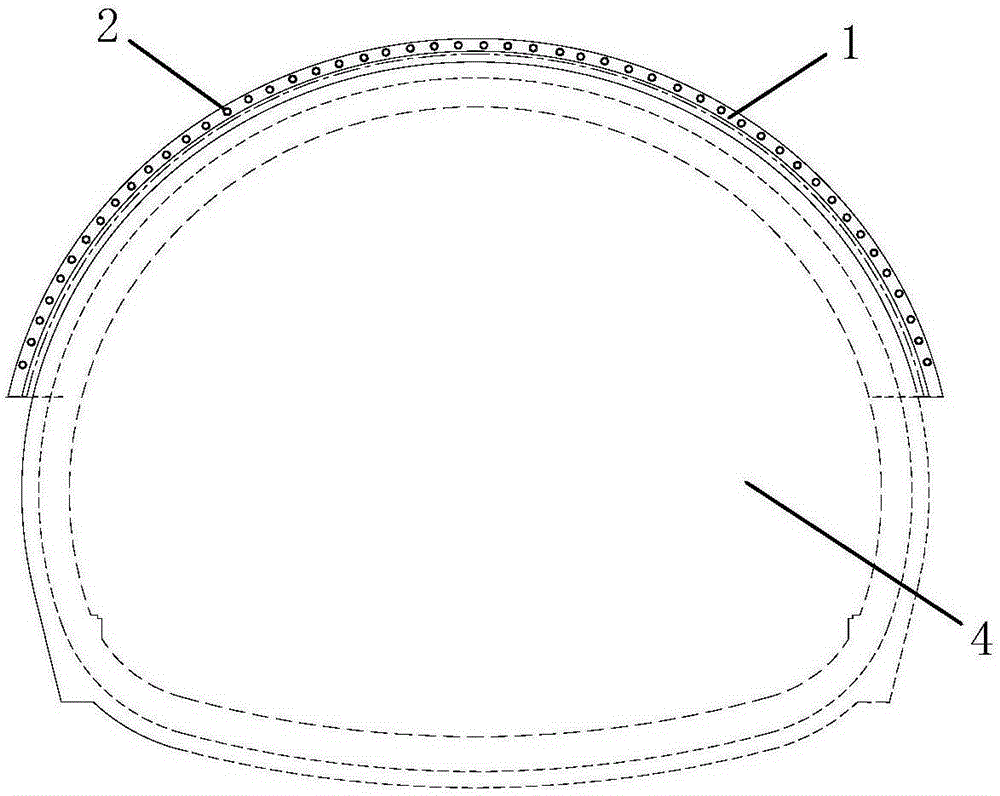

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

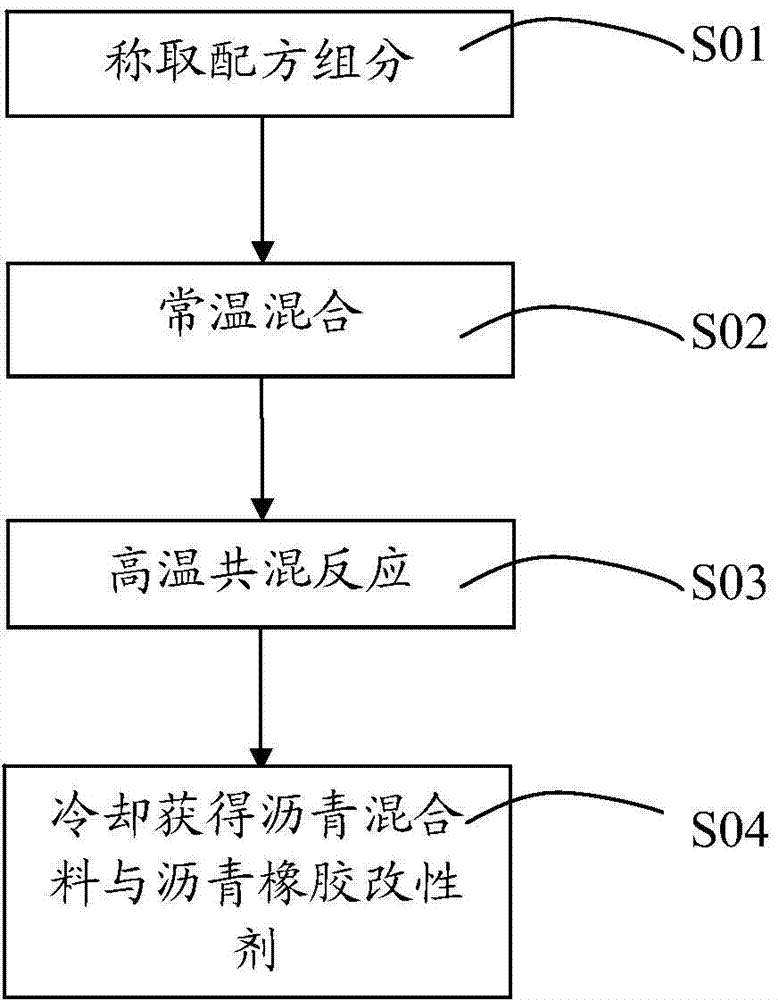

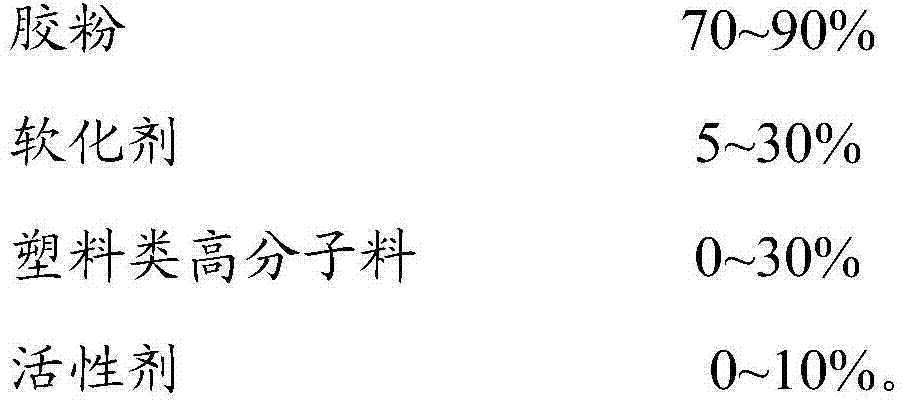

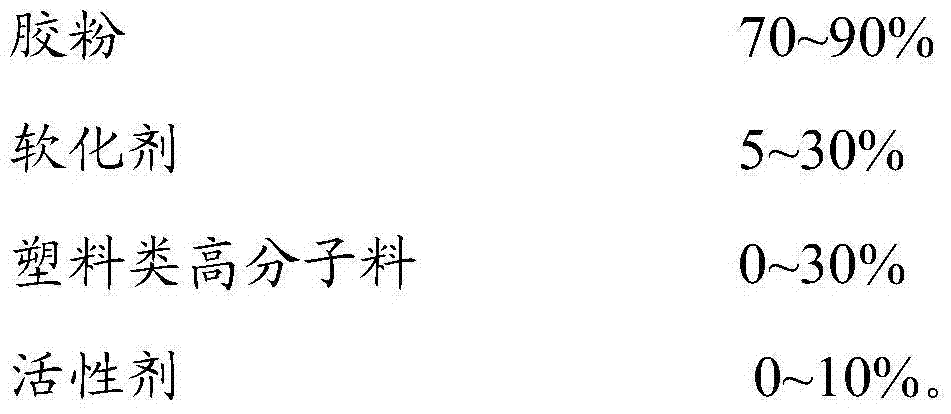

Rubber modifier, preparation method of rubber modifier, rubber asphalt mixture and rubber asphalt

The invention relates to a rubber modifier and an application method thereof. The rubber modifier comprises the following components by mass percent: 70-90% of rubber powder, 5-30% of softener, 0-30% of plastic polymer materials and 0-10% of active agent. The rubber modifier works together with no less than 70% of rubber powder to consume a large quantity of waste rubber; since the softener is added to the rubber powder, rubber material becomes soft and the rubber powder and / or plastic polymer materials can be better swelled and dispersed into the asphalt mixture or asphalt; the rubber powder, the softener and / or the plastic polymer materials, and the active agent generate synergistic effects; the rubber modifier disclosed by the invention has excellent ageing resistance and low viscous flow temperature, can be used for preparing the rubber asphalt mixture by a dry method and also can be used for preparing the rubber asphalt by a wet method; the heating temperature of the asphalt and the asphalt mixture can be reduced. Thus, high-temperature aging of the asphalt is prevented and energy consumption and carbon emission are greatly reduced. The product disclosed by the invention is easy to store; the blending. Transportation and storage costs are effectively saved and the production cost is greatly reduced.

Owner:翁晓娜

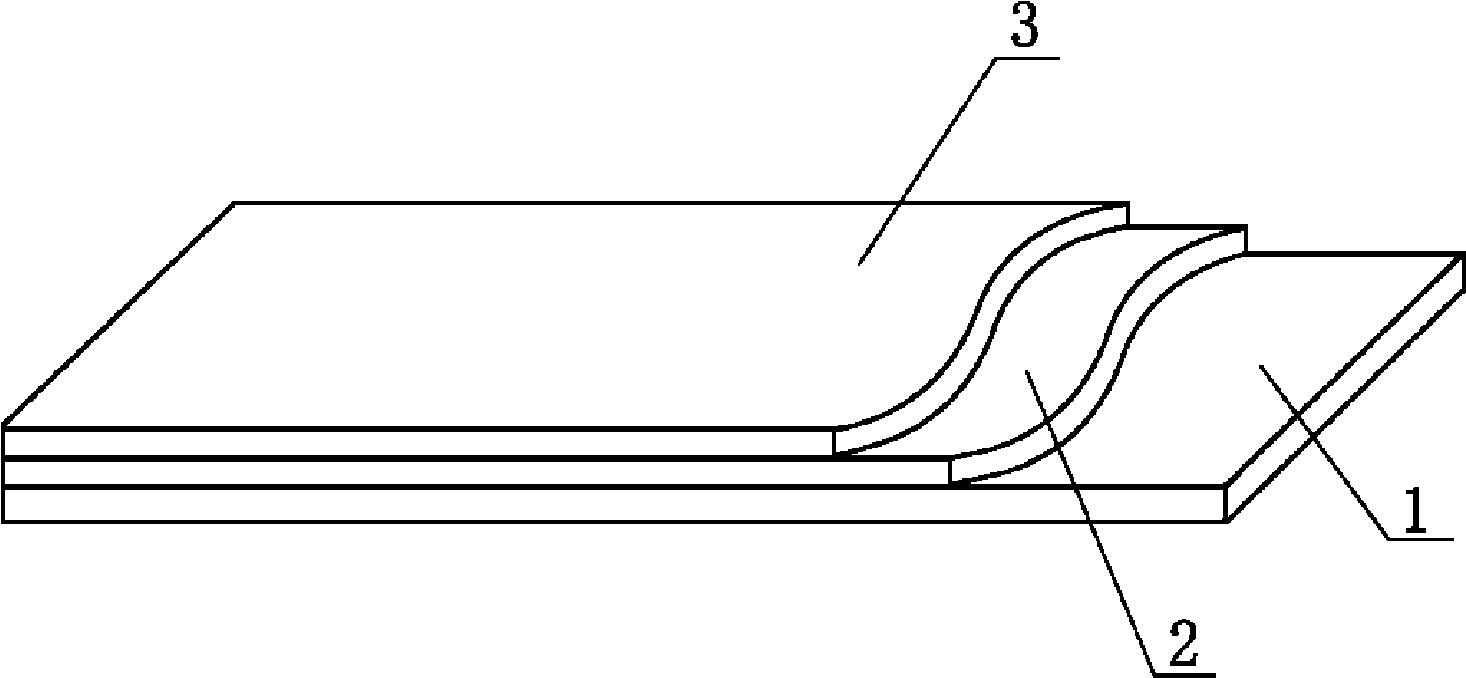

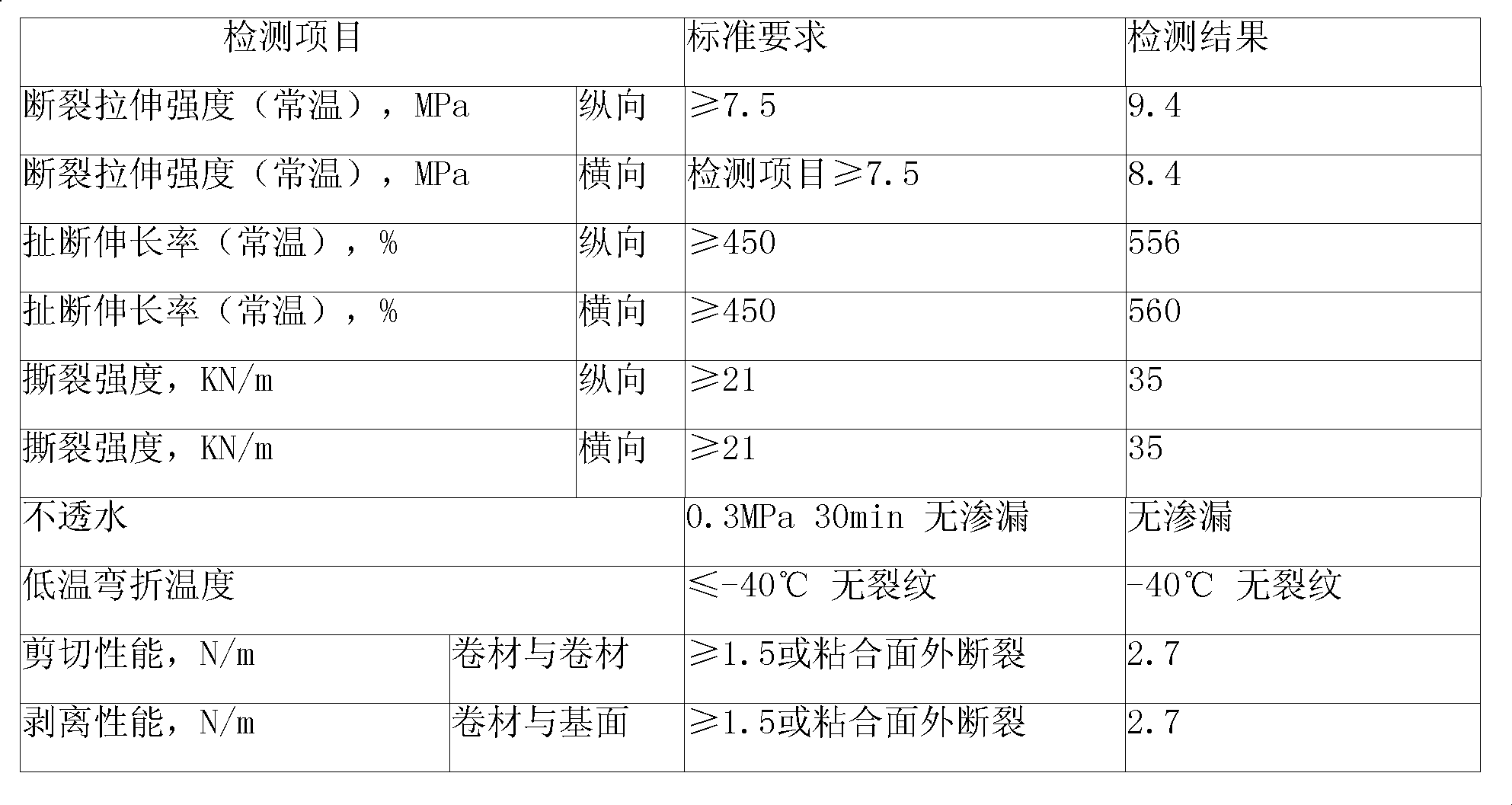

Self-adhering rubber water-proof coiled material and method for preparing same

InactiveCN101545285AUnique "self-locking water" functionSolve the problem of water leakageProtective foundationMarine site engineeringGlass fiberEngineering

A self-adhering rubber water-proof coiled material and a method for preparing the same composed of a rubber water-proof coiled material basal layer, a glue spreading reinforcement layer and a self-adhering rubber waterproof layer on the glue spreading reinforcement layer. The glue spreading reinforcement layer is glue spreaded nonwoven cloth or glue spreaded glass-fiber cloth. The self-adhering rubber waterproof layer is produced by mixing the following materials in proportion by weight: 60-70 portions of ethylene propylene terpolymer (PET); 10-26 portions of butyl rubber; 4-25 portions of chloroprene rubber; 50-70 portions of black carbon; 50-70 portions of fine particle calcium carbonate; 2-7 portions of coumarone; 10-20 portions of naphthenic oil; 5-10 portions of zinc oxide and 0.7-1.2 portions of stearic acid. The construction art is simple and fast. Because the self-adhering base material contains hydrophilic material, the basal layer can be in wet lay up if the basal layer has no water. The method has no glue brushing and glue shining process so as to save time limit for a project and the cost, effectively avoid hollow casing and burst phenomenon and form a whole a complete waterproof sealing system.

Owner:北京立高科技股份有限公司

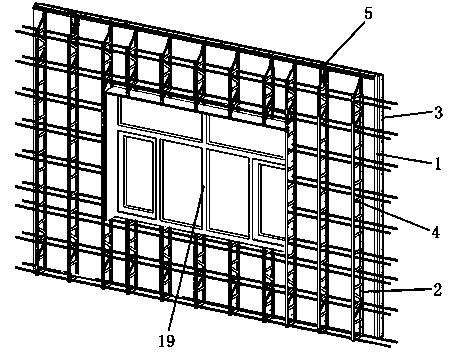

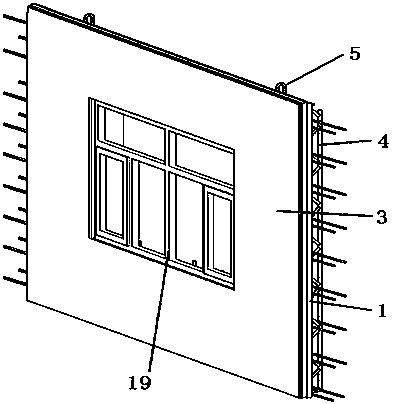

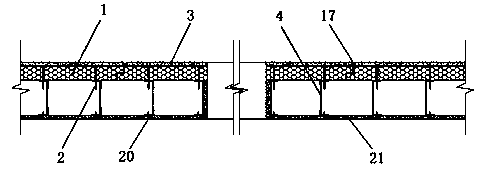

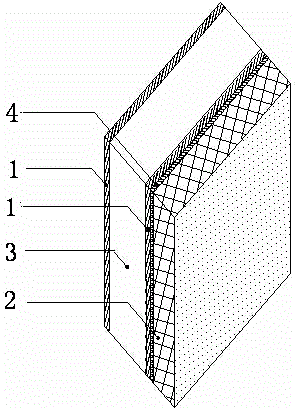

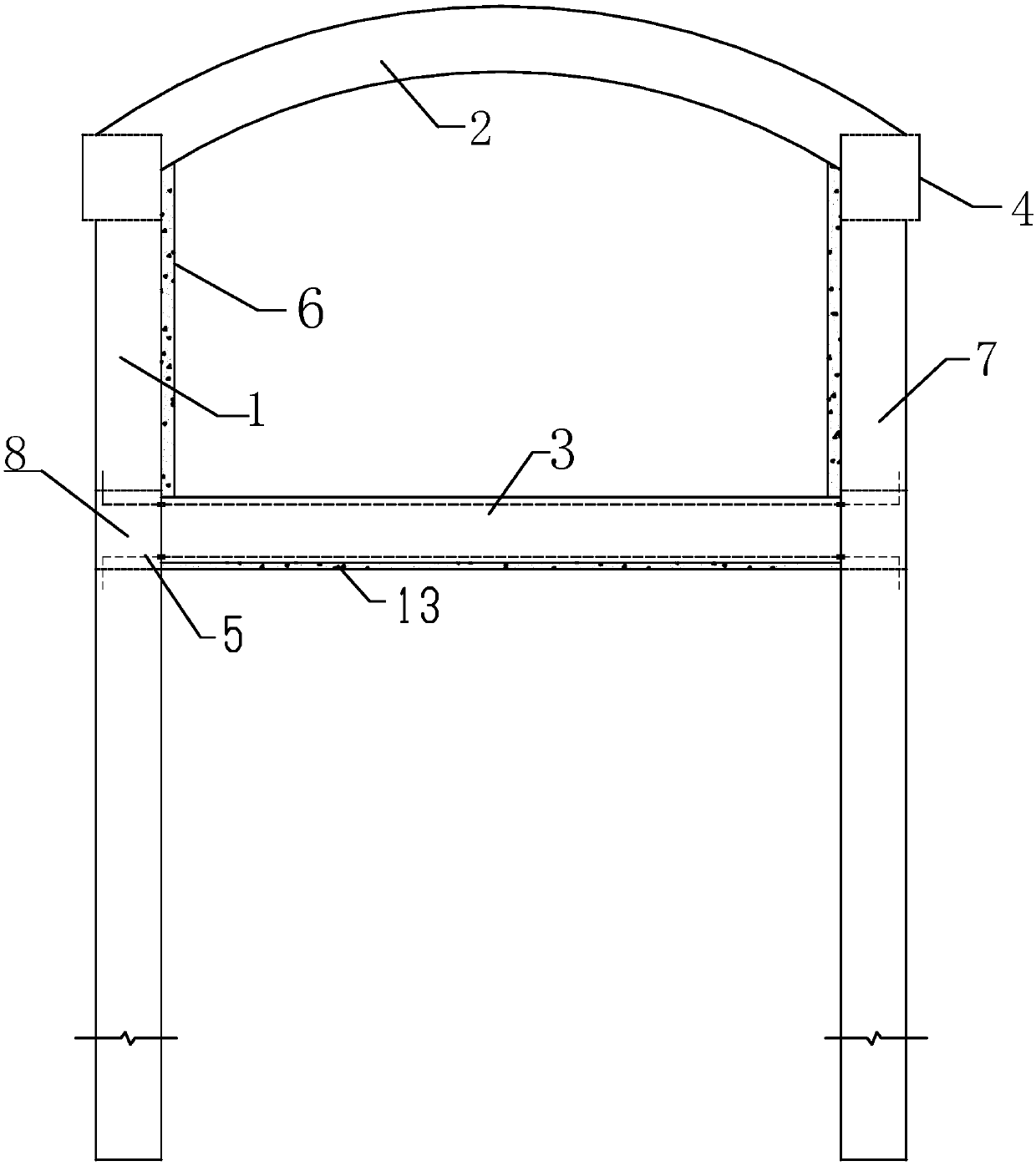

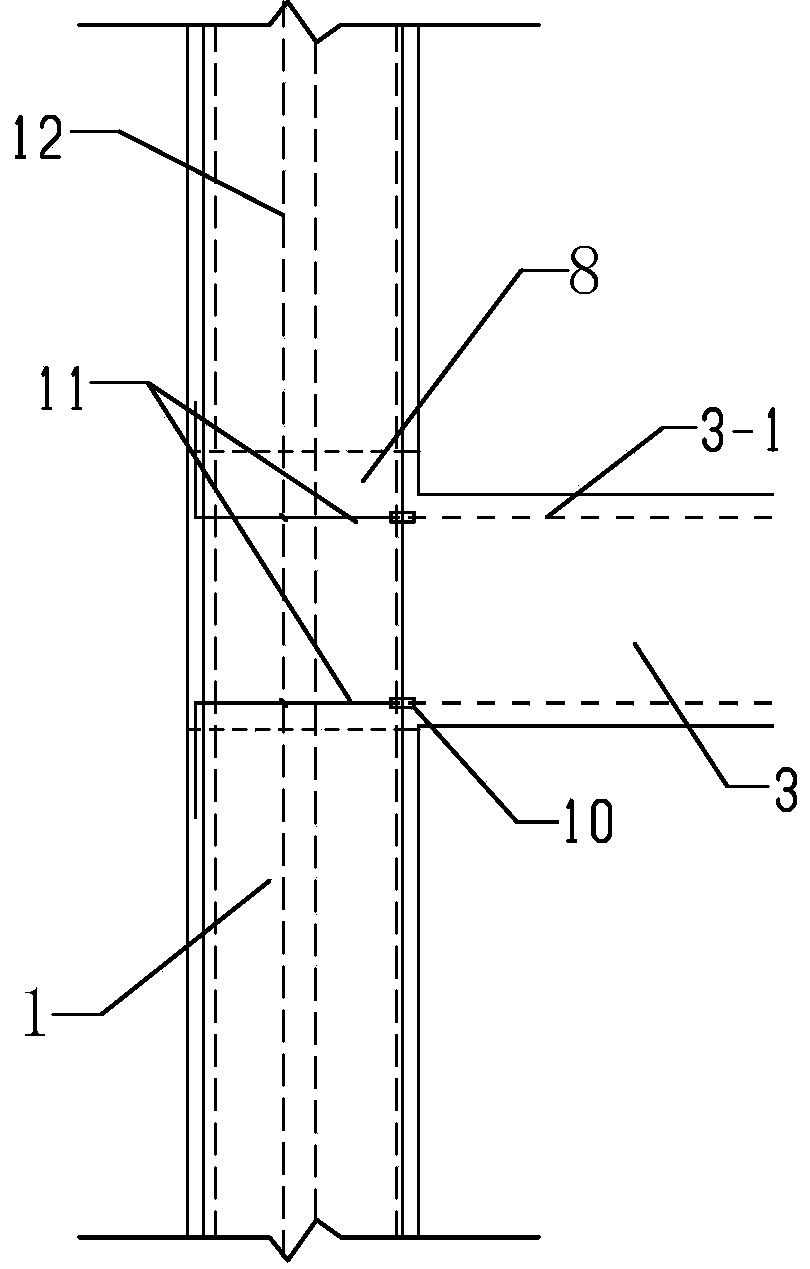

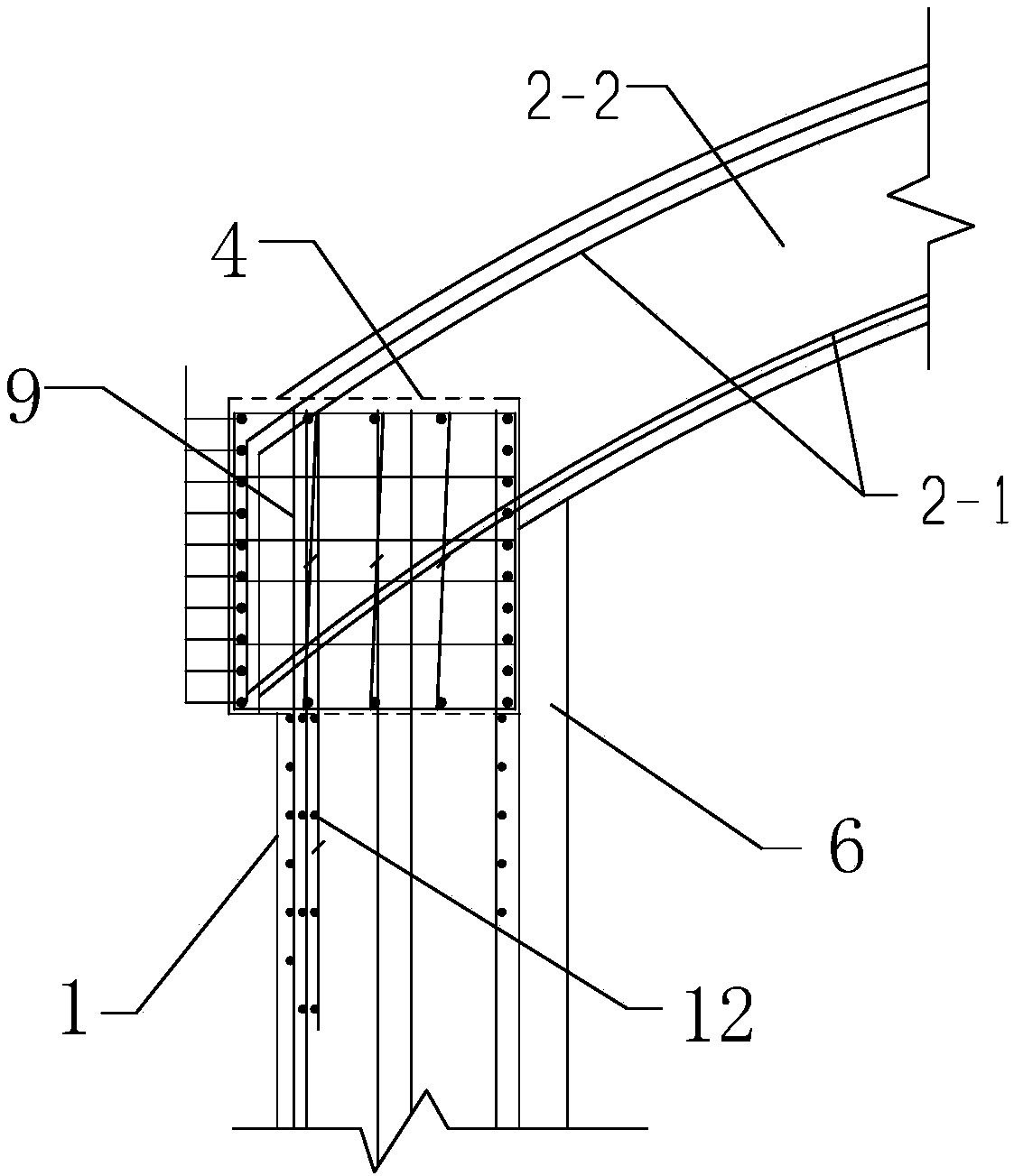

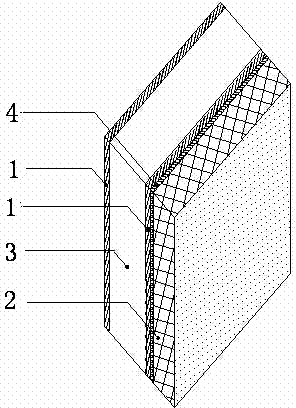

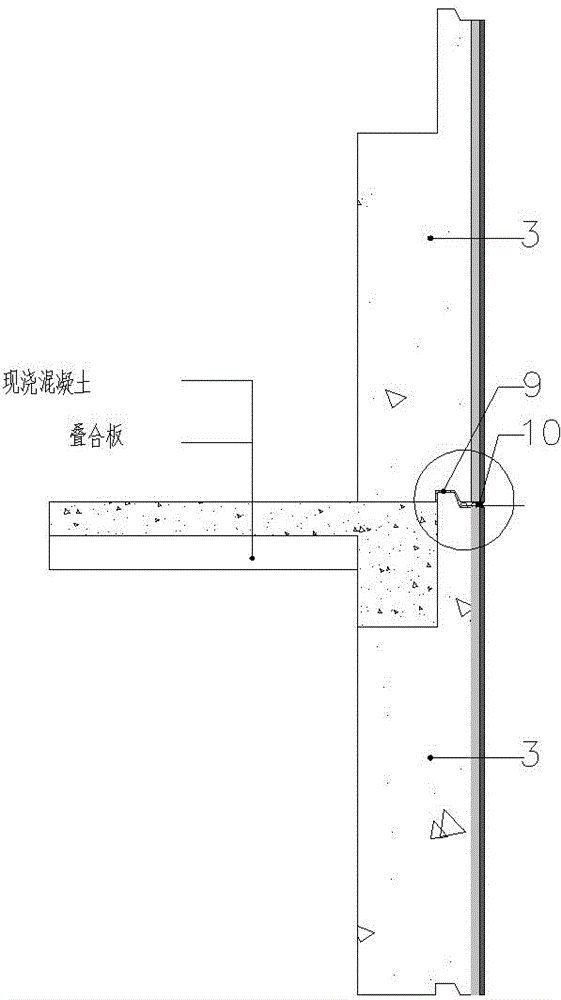

Assembly type cast-in-place concrete exterior thermal insulation wall steel skeleton framework system and connecting piece

PendingCN106522406AGuarantee the construction qualityStable supportWallsInsulation layerThermal insulation

The invention provides an assembly type cast-in-place concrete exterior thermal insulation wall steel skeleton framework system and a connecting piece. The system comprises a thermal insulation layer, a thin layer plastering protective layer, connecting bolts, trusses, horizontal steel bars and door and window frames. Thermal insulation plates are subjected to mutual tongue-and-groove inserted connection to form the thermal insulation layer and fixed to one side of the rigid trusses through connecting pieces. Construction parts can be assembled and formed on the ground and integrally hoisted, and the trusses can take the place of a part of bearing wall steel bars. The other sides of the trusses are connected through the horizontal steel bars which are connected with pre-cast vertical steel bars on the wall. Free-disassembly cement boards are then fixed to the trusses to form the system, and concrete of the bearing wall is poured in cavities of the system so that the system and the concrete of the bearing wall can be integrated to form an exterior thermal insulation concrete composite wall. According to the assembly type cast-in-place concrete exterior thermal insulation wall steel skeleton framework system and the connecting piece, the overall construction speed of an energy-saving building can be greatly improved, the construction safety risk is reduced, construction accuracy is effectively improved, the project quality is ensured, and meanwhile, a technical support is provided for building industrialization.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

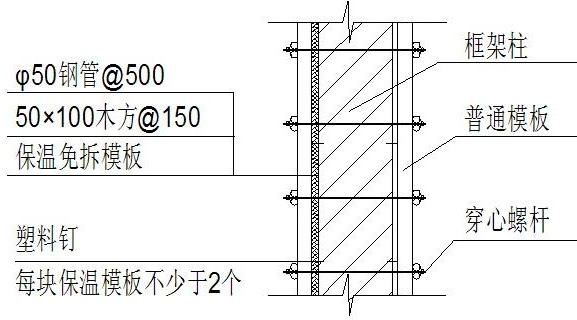

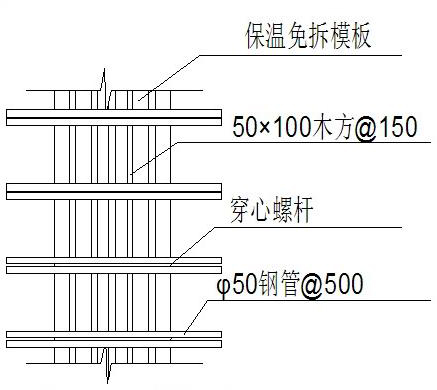

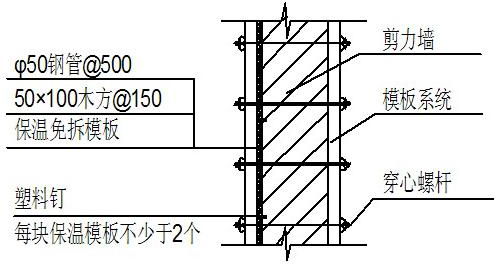

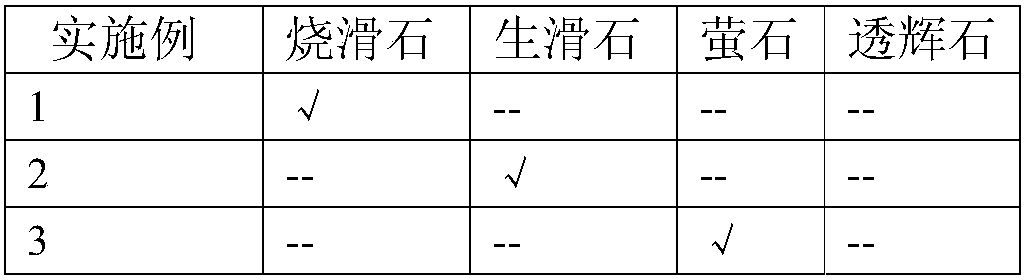

Method for same-body pouring of thermal insulation stay-in-place mould

InactiveCN102433987ASave resourcesThe construction process is simple and fastForms/shuttering/falseworksThermal insulationSteel tube

The invention discloses a method for same-body pouring of a thermal insulation stay-in-place mould, which comprises the following steps of: 1) selecting the thermal insulation stay-in-place mould; 2) performing interface treatment on one surface of the thermal insulation stay-in-place mould; 3) providing a support for the bottom layer, and placing the thermal insulation stay-in-place mould on the outer side of a to-be-placed member which requires thermal insulation treatment, wherein the surface subjected to the interface treatment faces towards the surface of the to-be-placed member; 4) adopting vertical arrangement on the outer side of the thermal insulation stay-in-place mould, taking a flitch as a back ridge, and fixedly connecting the thermal insulation stay-in-place mould with the flitch; 5) arranging a steel pipe in the horizontal direction, and adopting a split bolt punched hole to ensure that the steel pipe is in pull fixation with a template on the inner side of the member; 6) pouring concrete; 7) before the strength of the concrete is not formed, penetrating an anchoring member into the concrete; and 8) when the concrete reaches a standard strength, dismounting the back ridge and a supporting frame on the outer side of the thermal insulation stay-in-place mould. In the technology for the same-body pouring of the thermal insulation stay-in-place mold, a thermal insulation plate is used as a template for same-body pouring, so that a wood mould or a steel mould is replaced, resources are saved, a construction process is simple and direct, and construction cost and safety risk factor are reduced.

Owner:江苏华伟佳建材科技有限公司 +1

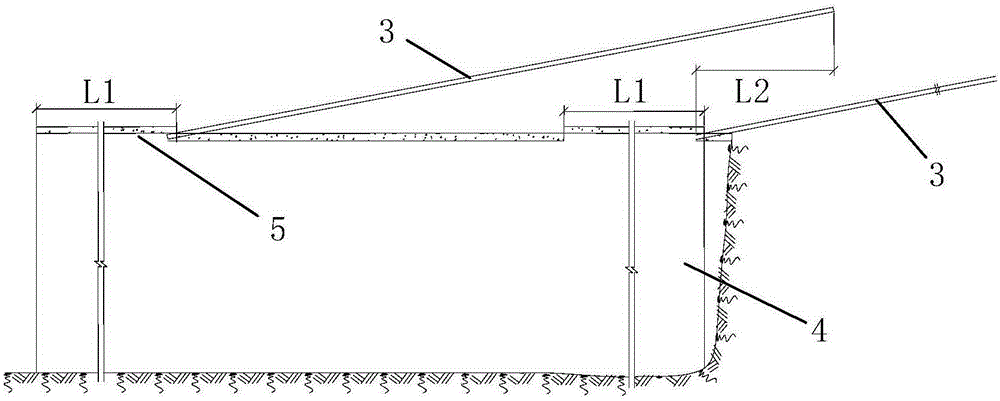

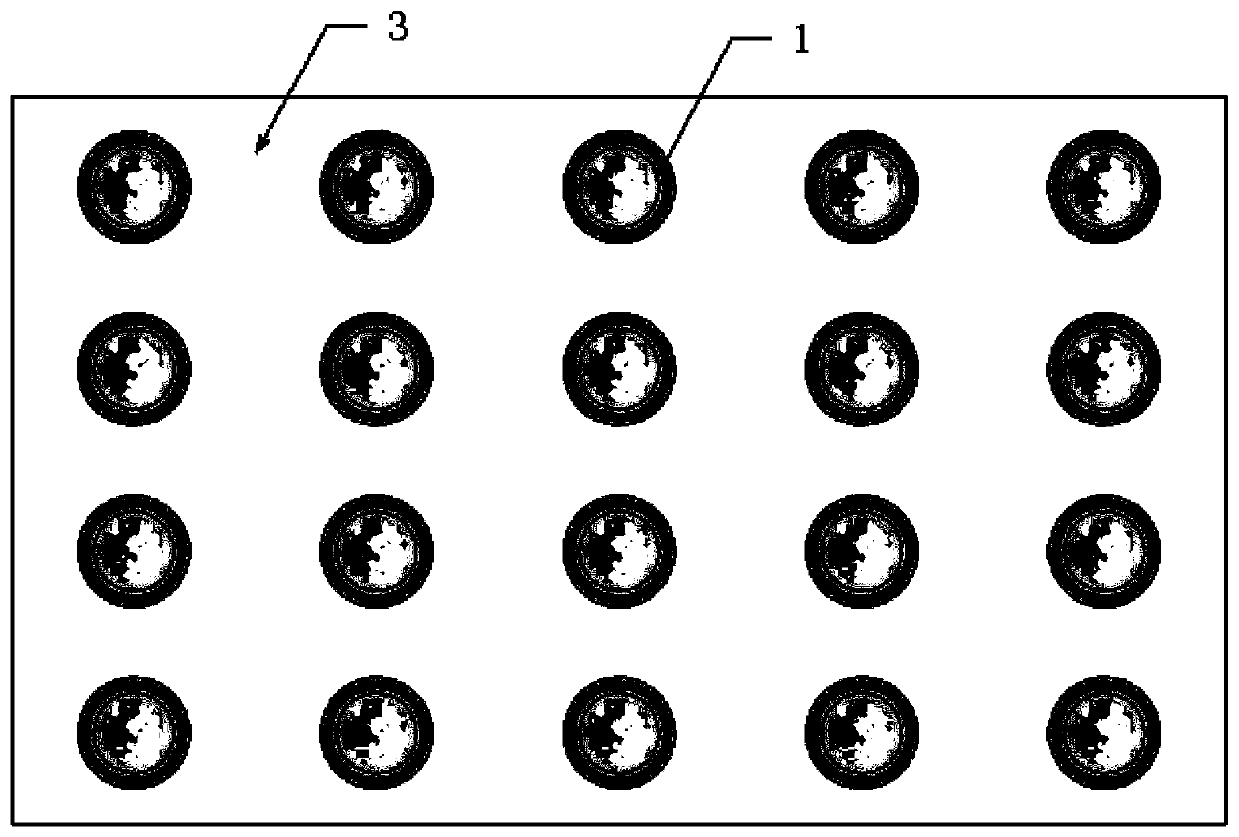

Arch combination foundation pit retaining and protection system and construction method thereof

InactiveCN103290850APlay the role of water stopGive full play to the resistance to pressureExcavationsHigh strength concreteSoil mixing

The invention relates to an arch combination foundation pit retaining and protection system and a construction method of the arch combination foundation pit and protection system, and provides a combination foundation pit retaining and protection system which is simple in structural style, fast in construction method, capable of sufficiently utilizing property advantages of materials and combining the soil blocking function and waterproof function, and suitable for an arch-shaped cement soil mixing pile large in excavating depth and prefabrication of a high-strength concrete thin-wall steel tube pile, and the construction method of the combination foundation pit retaining and protection system. The arch combination foundation pit retaining and protection system comprises arch-shaped cement soil mixing pile walls (1), high-strength concrete thin-wall steel pipe piles (2), pile top beams (3) and inner supports (4), wherein the high-strength concrete thin-wall steel pipe piles (2) are arranged inside the foundation pit in a scattered mode, the pile top beams (3) connect the high-strength concrete thin-wall steel pipe piles into a whole, each inner support (4) is arranged on the outer side of each high-strength concrete thin-wall steel pipe pile (2), each arch-shaped cement soil mixing pile wall (1) is arranged between two high-strength concrete thin-wall steel pipe pile (2) and the arch-shaped cement soil mixing pile walls (1) to be connected into a whole, and the arch-shaped foundation pit retaining and protection system is formed.

Owner:THE CITY VOCATIONAL COLLEGE OF JIANGSU

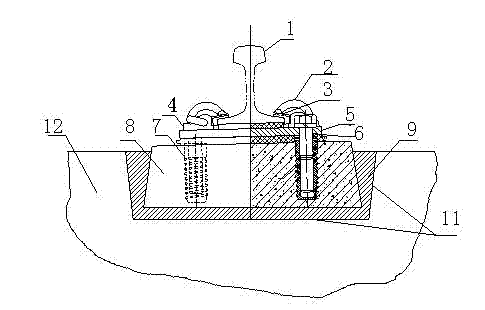

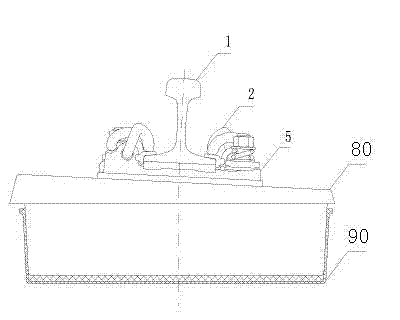

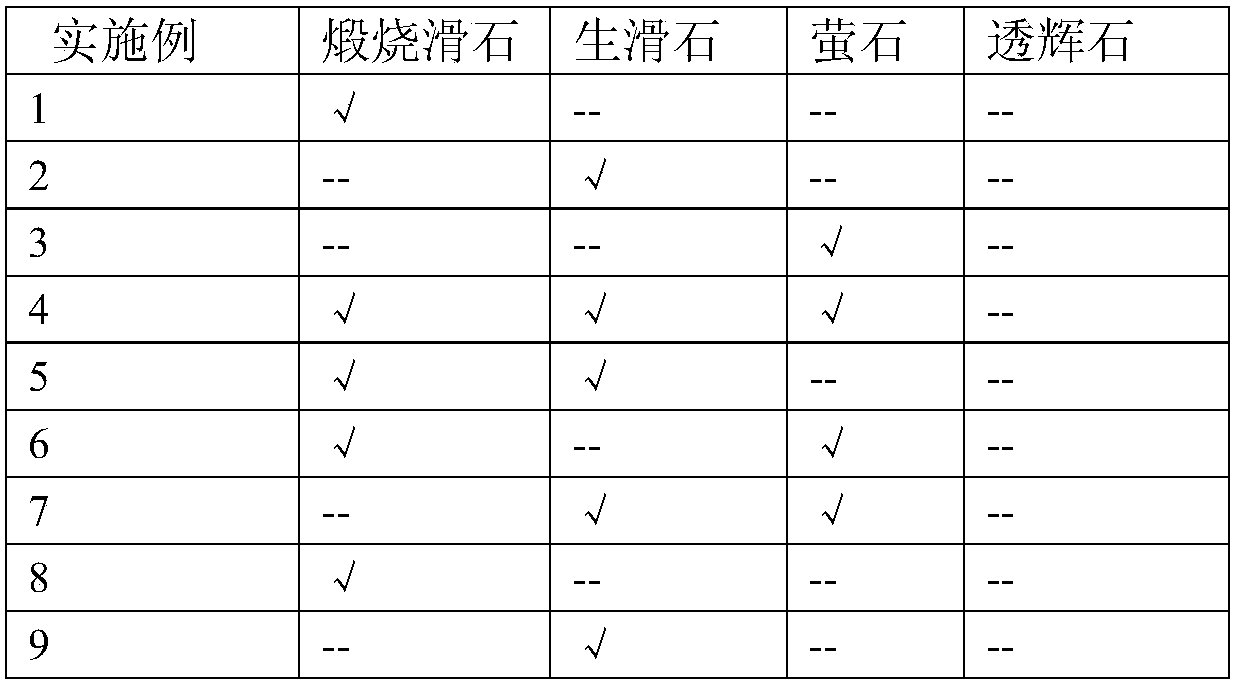

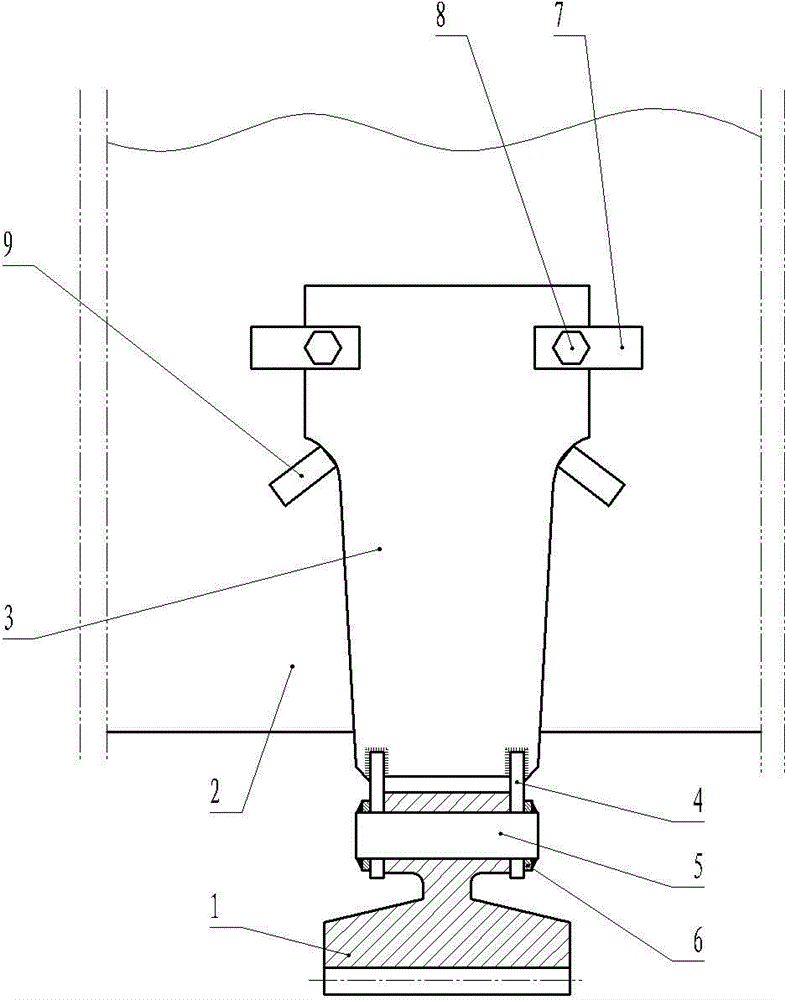

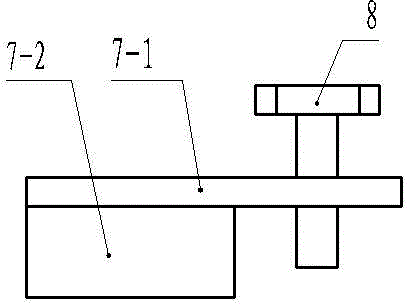

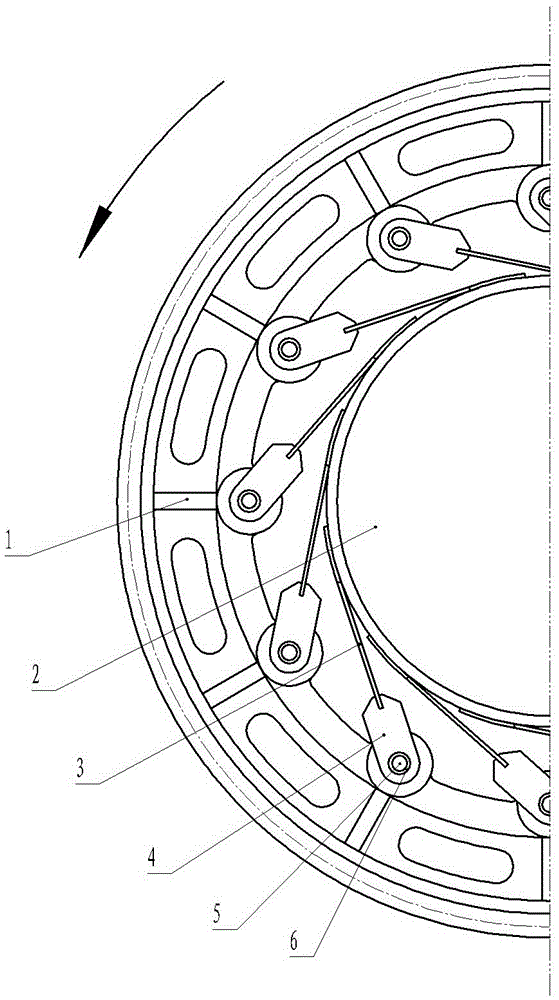

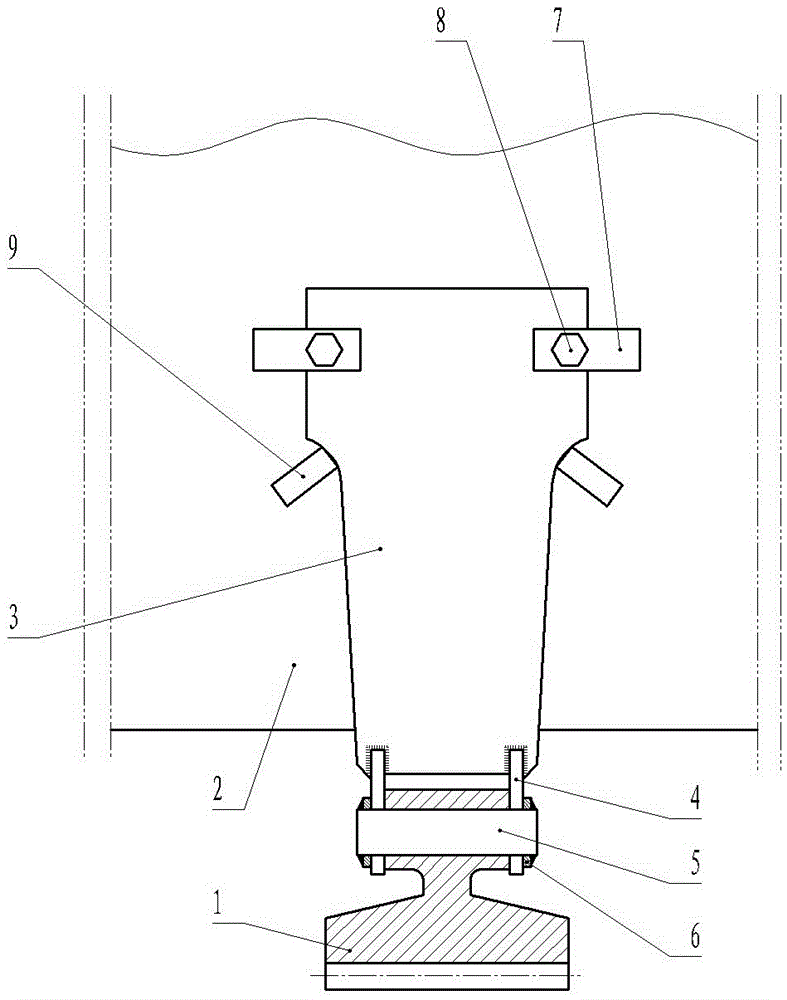

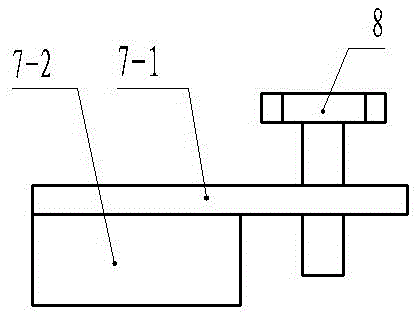

Construction technology of short sleeper vibration attenuation fastener with improved structure replacing elasticity short sleeper

ActiveCN103174071ADoes not affect normal safe operationExtend your lifeBallastwayRail fastenersVibration attenuationArchitectural engineering

The invention belongs to the technical field of rails, and particularly relates to a construction technology of a short sleeper vibration attenuation fastener with an improved structure replacing an elasticity short sleeper. Testing and recording are carried out on rail position where a section needs rebuilding and replacing and geometric parameters, and staging construction is carried out on the section which needs rebuilding and replacing combined with the characteristics of railway construction. Each period of construction section which needs rebuilding and replacing is determined according to the time of the construction. A construction technology by root of rails is carried out on old short sleepers (80) on two rails (1) and fasteners (5) placed on the old short sleepers (80) in each period of construction; each period of construction adopts a way of construction for multiple times, and the old short sleeper (80) on one root of rails and the fastener (5) placed on the old short sleeper (80) are replaced in the construction at each time, and each time of construction adopts a construction technology of 'pulling one at multiple intervals'. The construction technology is simple and rapid, low in maintenance and construction cost.

Owner:洛阳双瑞橡塑科技有限公司

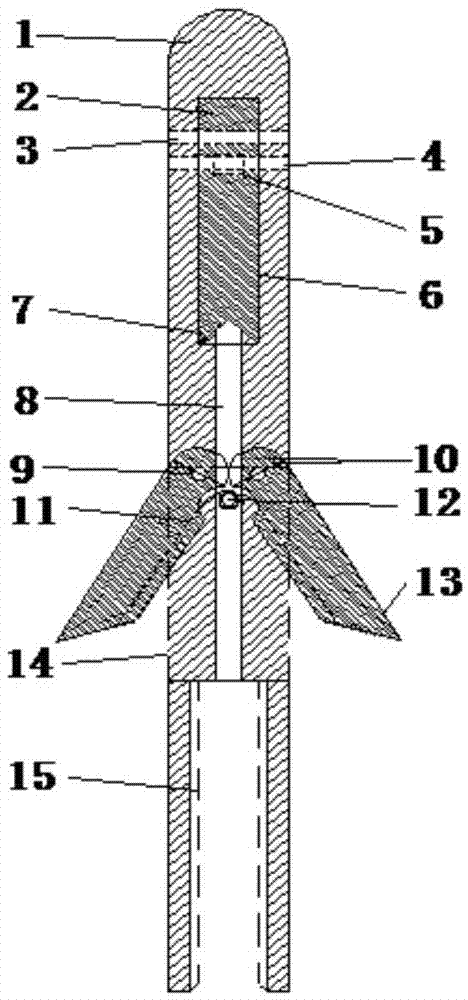

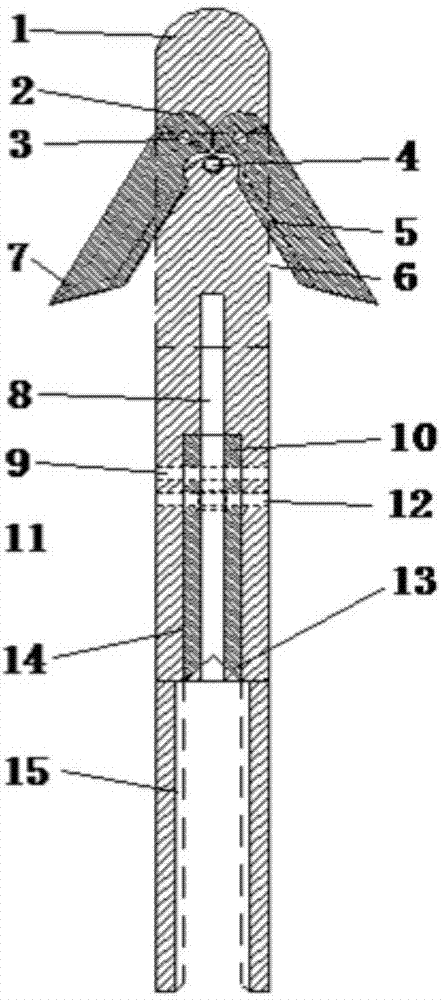

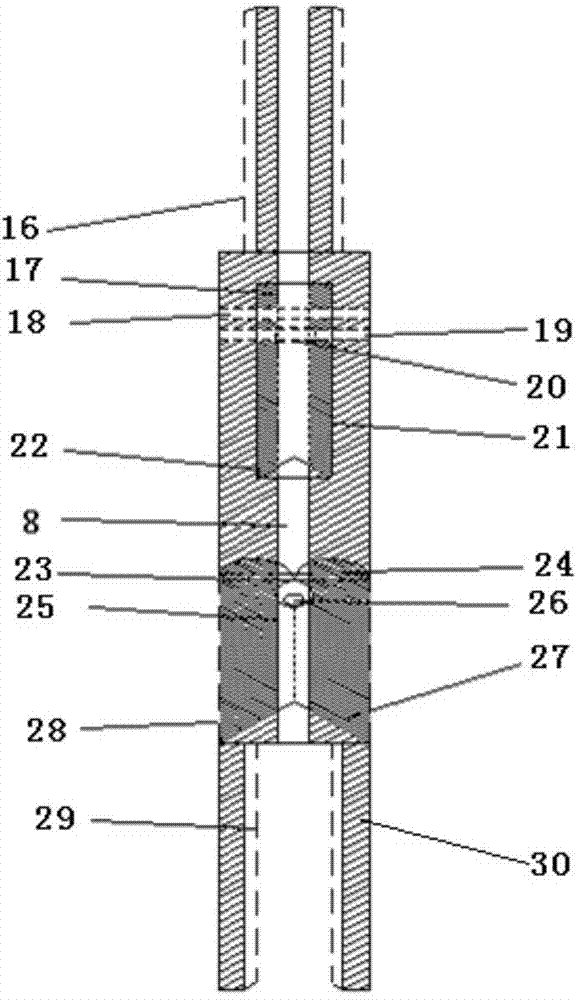

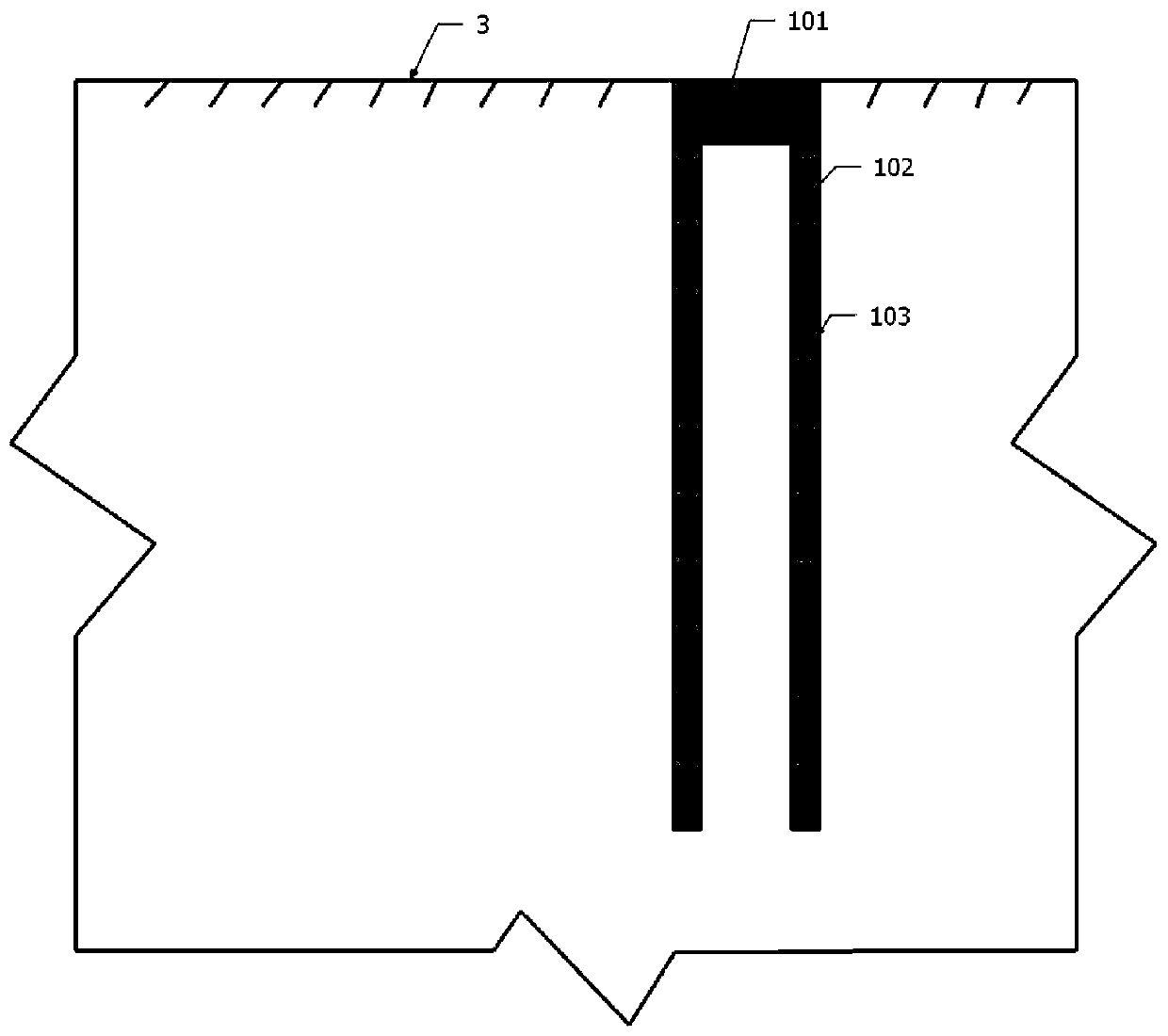

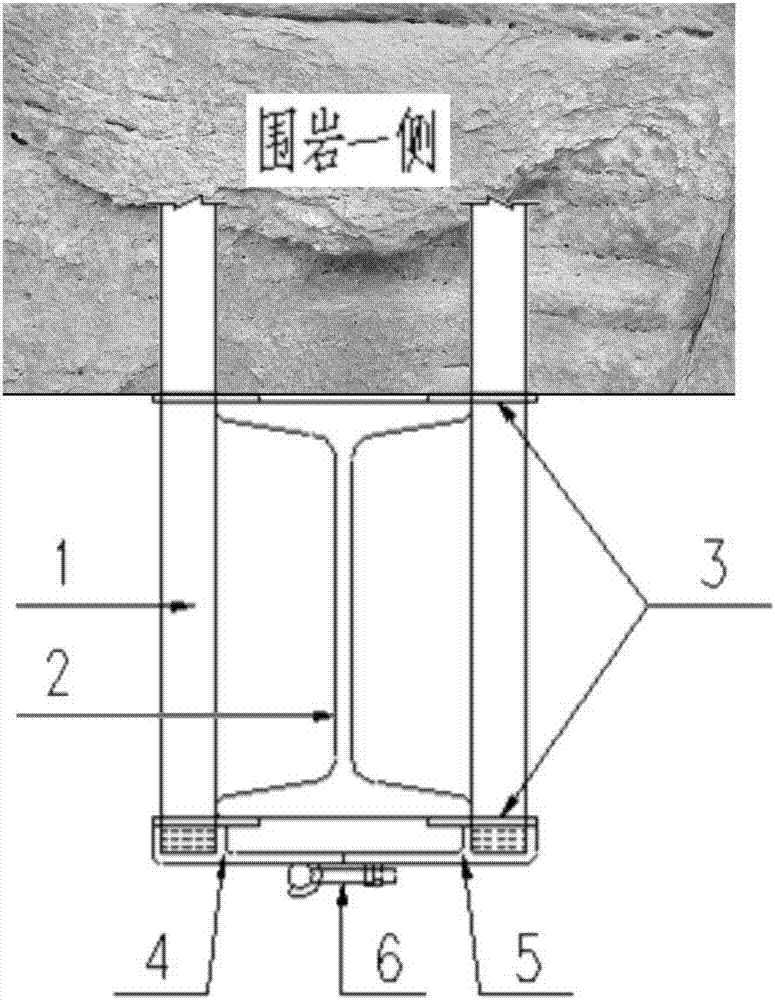

Multi-joint self-expansion anchor rod

InactiveCN103939120AEasy to installControl deformationAnchoring boltsUltimate tensile strengthSelf expansion

The invention relates to a multi-joint self-expansion anchor rod for tunnel engineering construction. The multi-joint self-expansion anchor rod comprises an anchoring head and one or more anchor rod bodies, strip-shaped square holes orthogonal in space position are respectively formed in the head portions and the middle portions of the anchoring head and the anchor rod bodies, a group of elastic self-expansion wedge blocks are respectively installed in the strip-shaped square holes through pins and comprises an inverted V-shaped spring and two wedge blocks symmetrically attached to the outer edge of a spring reed. In the actual construction, the wedge blocks attached to the outer edge of the spring reed are always open and tightly in contact with a surrounding rock in the anchor rod feeding process, and after the anchor rods are fed to the bottom, the anchor rods are embedded into a pore wall rock to play an anchoring effect of the anchor rods. After anchoring is finished, reinforcement can be achieved through grouting holes or the designed anchoring effect can be achieved without the anchor rod grouting construction process. The multi-joint self-expansion anchor rod for tunnel engineering construction is reasonable in structure, convenient to construct, quick, high in efficiency, good in anchoring strength and supporting effect and capable of keeping the integrity and stability of the surrounding rock to the most extent.

Owner:罗宗帆

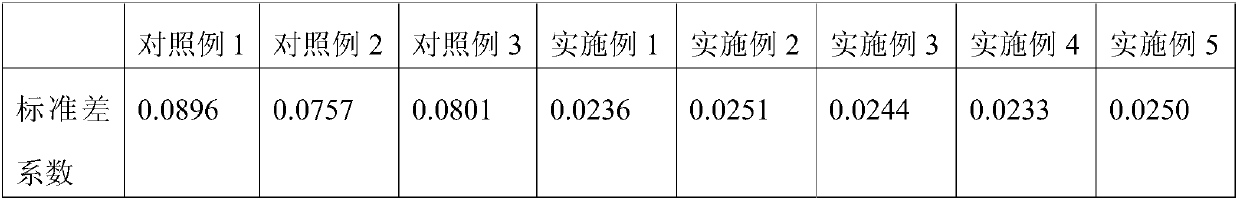

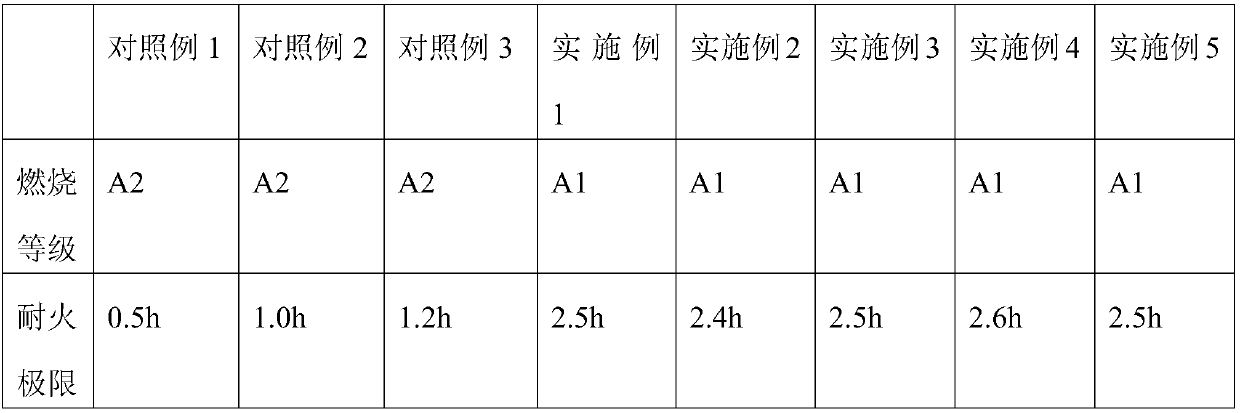

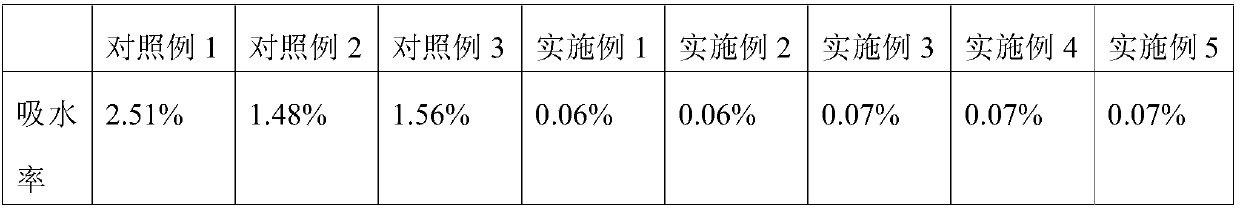

Graphene-based foamed lightweight refractory thermal insulating decoration board and preparation method thereof

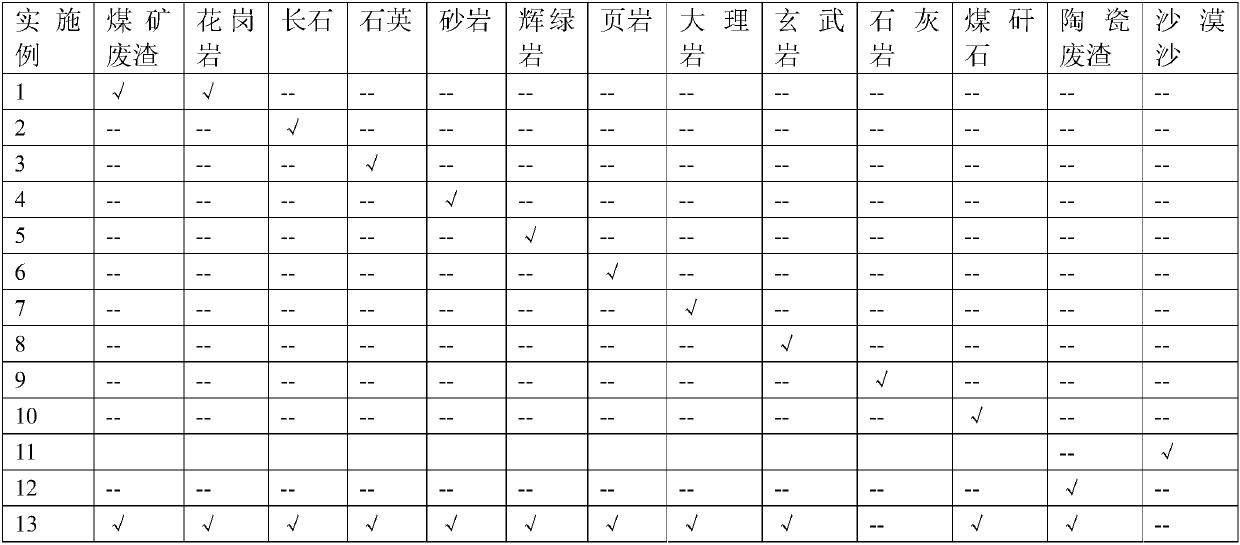

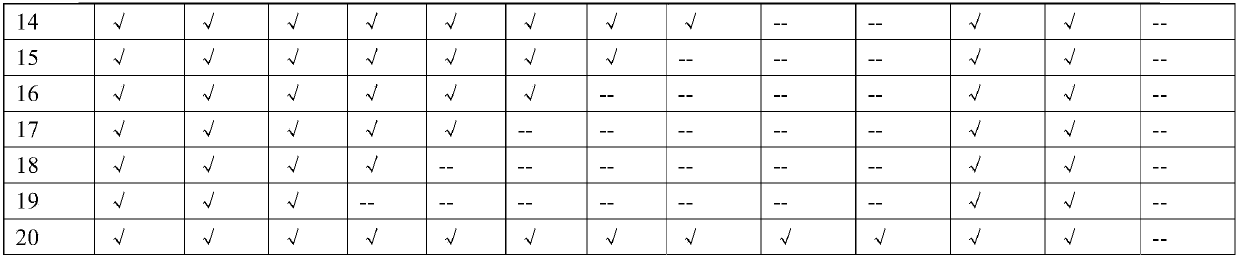

The invention discloses a graphene-based foamed lightweight refractory thermal insulating decoration board which comprises a matrix foamed lightweight refractory thermal insulating material layer anda decorative surface layer, wherein after sprayed to the surface of the matrix foamed lightweight refractory thermal insulating material layer, the decorative surface layer and the matrix foamed lightweight refractory thermal insulating material layer are adhered together by virtue of one-step sinter molding; the matrix foamed lightweight refractory thermal insulating material layer comprises thefollowing raw materials in percentage by weight: graphene, inorganic high-temperature-resistant fibers, non-metallic tailings, expanded vermiculite, expanded perlite, zirconia, a high-temperature cosolvent, a water repellent, an inorganic high-temperature-resistant adhesive and a flame retardant; and the decorative surface layer comprises the following raw materials in percentage by weight: graphene, feldspar, quartz, alumina, wollastonite, calcium carbonate and pigments. According to the prepared finished product in the invention, the materials are uniformly dispersed; and moreover, the prepared board has the advantages of being lightweight, high in strength, fire-resistant, flame-retardant, resistant to water seepage, difficult to age, excellent in mechanical property, green, saving in energy and environmentally friendly and has wide market popularization value.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

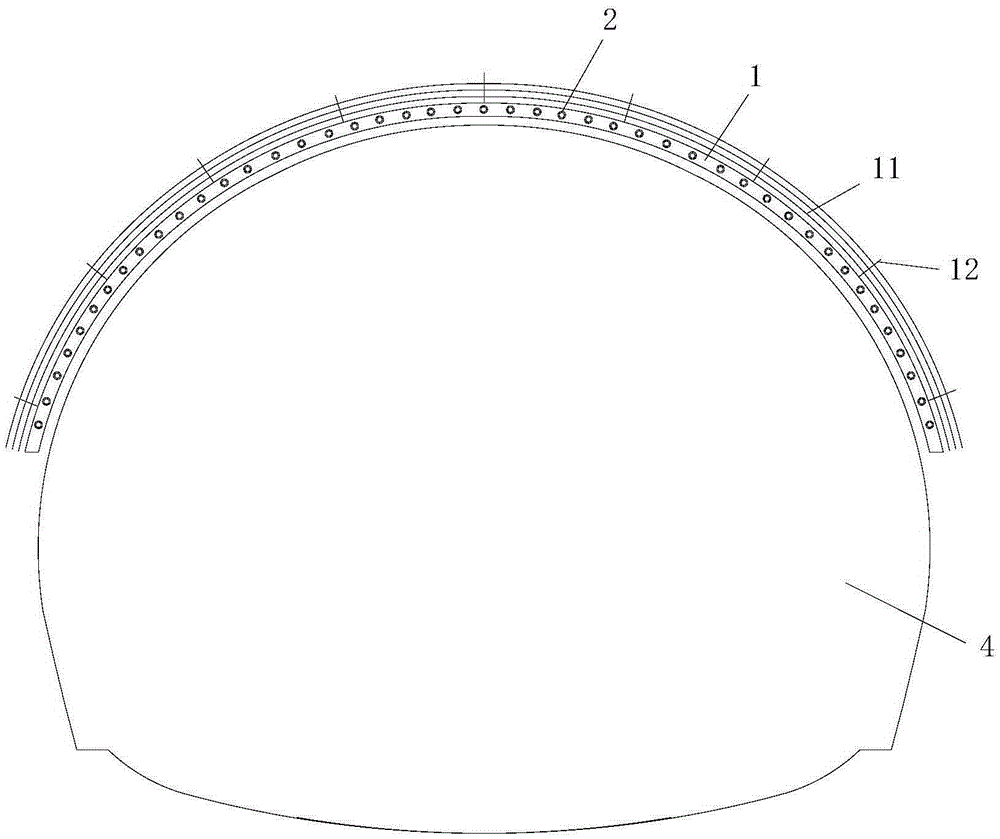

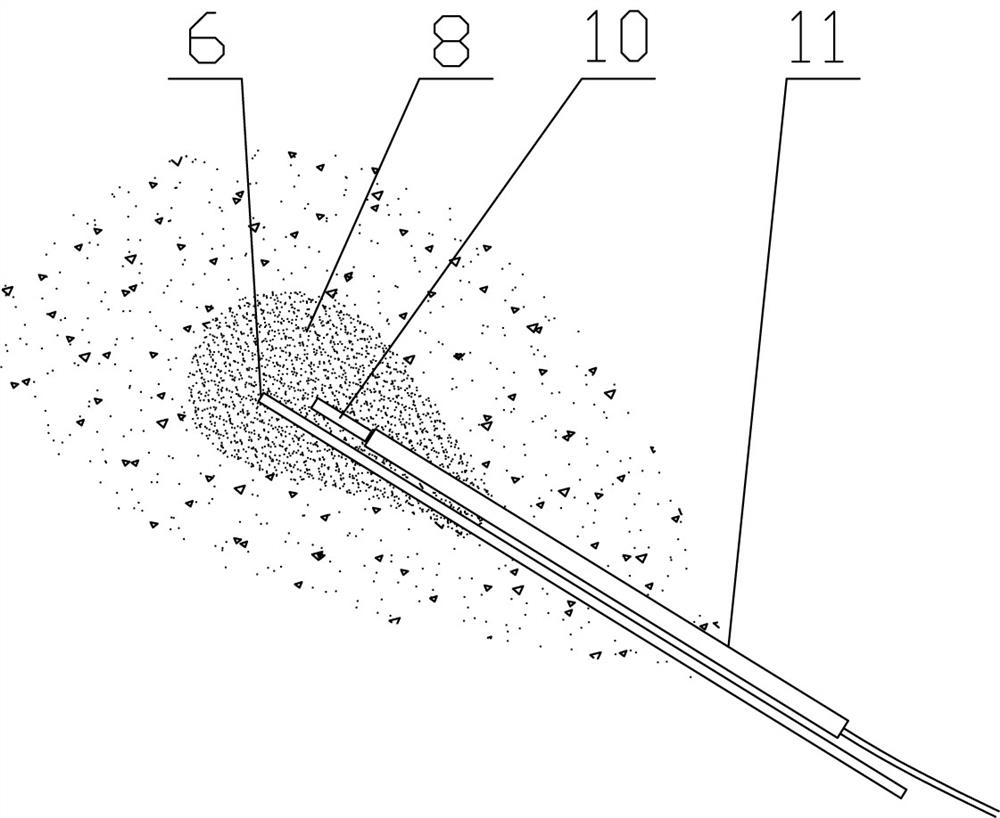

Advance support construction method for high-strength pipe shed of tunnel

InactiveCN105201517AShort construction periodImprove construction efficiencyUnderground chambersTunnel liningDrill holeHigh intensity

The invention discloses an advance support construction method for a high-strength pipe shed of a tunnel. A process for carrying out advance support construction on a pipe shed of one segment of a constructed tunnel comprises the following steps: (1) constructing support arches and guide pipes; (2) installing a drilling machine and a grouting machine in place; (3) carrying out advance support construction on the pipe shed: (301) preparing before drilling; (302) drilling pipe joints at front ends and synchronously grouting; (303) connecting the pipe joints; (304) continuously drilling and synchronously grouting; (305) repeating the steps (303) and (304) many times until the drilling processes of pipes of the current constructed pipe shed are finished; (306) blocking drill holes; (307) carrying out grouting construction on final holes; (308) repeating the steps (301) to (307) many times until all advance support construction processes of the pipes of the pipe shed are finished; and (4) carrying out excavation construction on the tunnel. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient in construction and good in support effect; and by adopting automatic drilling type high-strength pipes of the pipe shed, the advance support process of the tunnel can be simply, conveniently and quickly finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

Energy-saving integrated board with inorganic synthesis finish and processing technology thereof

InactiveCN104831890AImprove securityImprove adhesionCovering/liningsSynthetic resin layered productsPolyurethane adhesiveThermal insulation

The invention relates to an energy-saving integrated board with an inorganic synthesis finish and a processing technology thereof, and belongs to the technical field of building board structures. The processing technology includes the steps that step1, a polyurethane board is cut according to the size of a finish coat; step2, polyurethane adhesive and polyaryl polymethylene isocyanate are mixed according to the mass ratio of 1:1-2, the temperature of a mixed material is controlled within 15 DEG C-50 DEG C, and then the mixed material is evenly poured between the polyurethane board and the finish coat; step3, a board obtained through the step2 is placed into a press machine, and pressure of 0.02 MPa-0.1 MPa is exerted on the board through the press machine so that the polyurethane board and the finish coat can be combined integrally; step4, after compositing is performed in the press machine for 1-1.5 hours, the obtained composite integrated board with the inorganic synthesis finish can be taken out. The energy-saving integrated board is excellent in thermal insulation and waterproof performance and convenient and rapid to construct, and the finish coat is not prone to cracking and falling.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

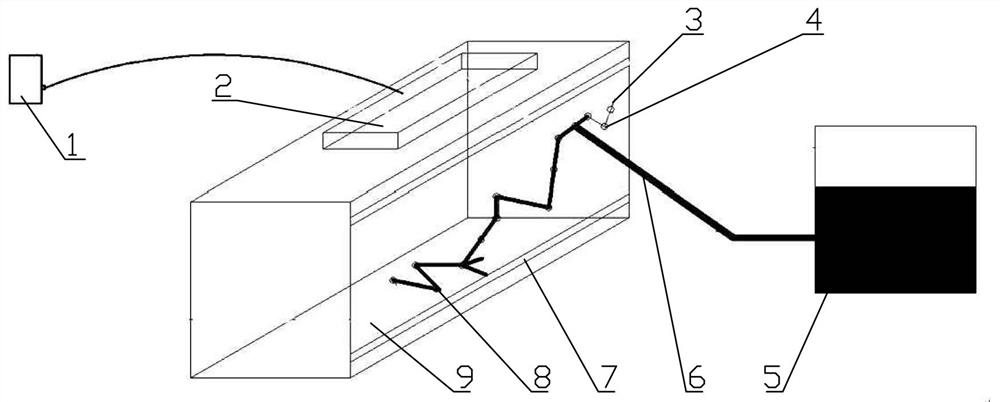

Method for repairing dam crack defect by using magnetic mortar

A method for repairing dam crack defects by using magnetic mortar comprises the following steps: Step 1, detecting concrete dam cracks by using ultrasonic waves, and determining the specific position, size and trend of the cracks needing to be repaired; 2, a construction working face is cleaned and repaired, and precipitates on the concrete surface of the dam are chiseled away; 3, the number, the position, the depth, the diameter and the distance of grouting holes are determined according to the specific position, the size and the trend of the crack, and the grouting holes are drilled through a drilling machine; 4, a grouting nozzle is embedded in the drilled grouting hole, a grouting pipe is inserted, a power source is arranged outside the working face, and a movable electromagnet with the magnetic force capable of being adjusted and controlled is placed; 5, the magnetic mortar is placed in a grouting machine, and the grouting machine is used for sequentially injecting the magnetic mortar into grouting nozzles through grouting pipes; the crack repairing method is used for solving the problem that in an existing crack repairing method, the mortar filling rate in a crack can not be well increased possibly due to water flow or gravity and the like.

Owner:CHINA THREE GORGES UNIV

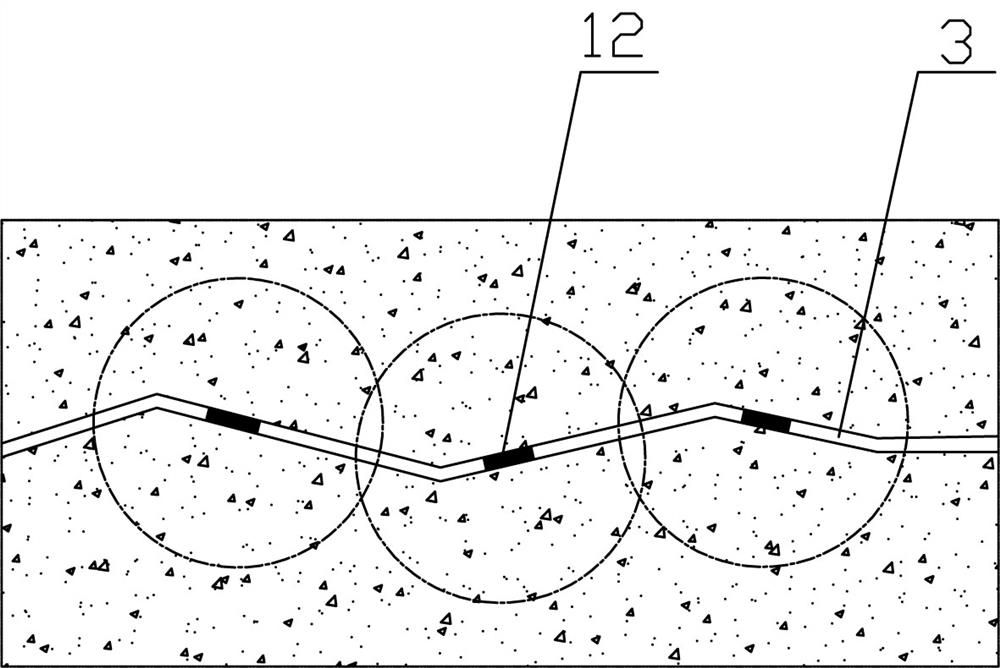

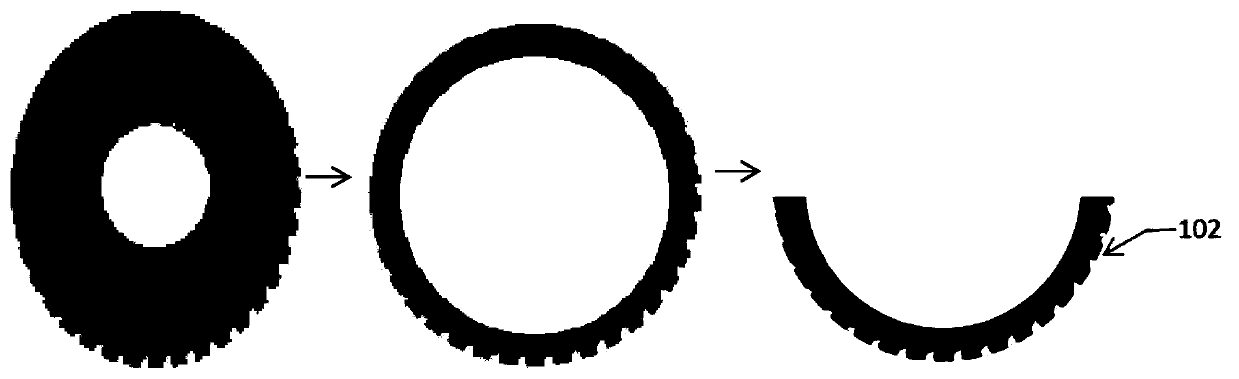

Waste tire thin-wall hollow pile for treating soft foundation and construction method thereof

PendingCN110952524ALow costImprove economyBulkheads/pilesSoil preservationReinforced concreteArchitectural engineering

The invention discloses a waste tire thin-wall hollow pile for treating soft foundation and a construction method thereof. The waste tire thin-wall hollow pile for treating the soft foundation comprises a hollow pile and a soft foundation; the hollow pile is pressed into the soft foundation through a tire sleeve mold and a piston at intervals; the hollow pile comprises a hollow pile top cover, a waste tire crown and a cement slurry, the waste tire crown is stacked one by one and is fixedly connected with the cement slurry, and a hollow pile top cover is arranged at the top of the hollow pile.The construction method comprises the following steps of prefabricating a geological survey, a crown and a sleeve mold, arranging the tire sleeve mold, pulling out the tire sleeve mold, filling the pile top hollow backfill concrete, and repeating the above steps at intervals of 2 to 4.5m. The waste tires are used as main materials of the hollow pile, compared with a traditional method for treatinga soft soil foundation through steel bars, concrete and other materials, the cost of the engineering material is reduced, and the method has economic and environmental protection benefits.

Owner:JIANGSU UNIV OF SCI & TECH

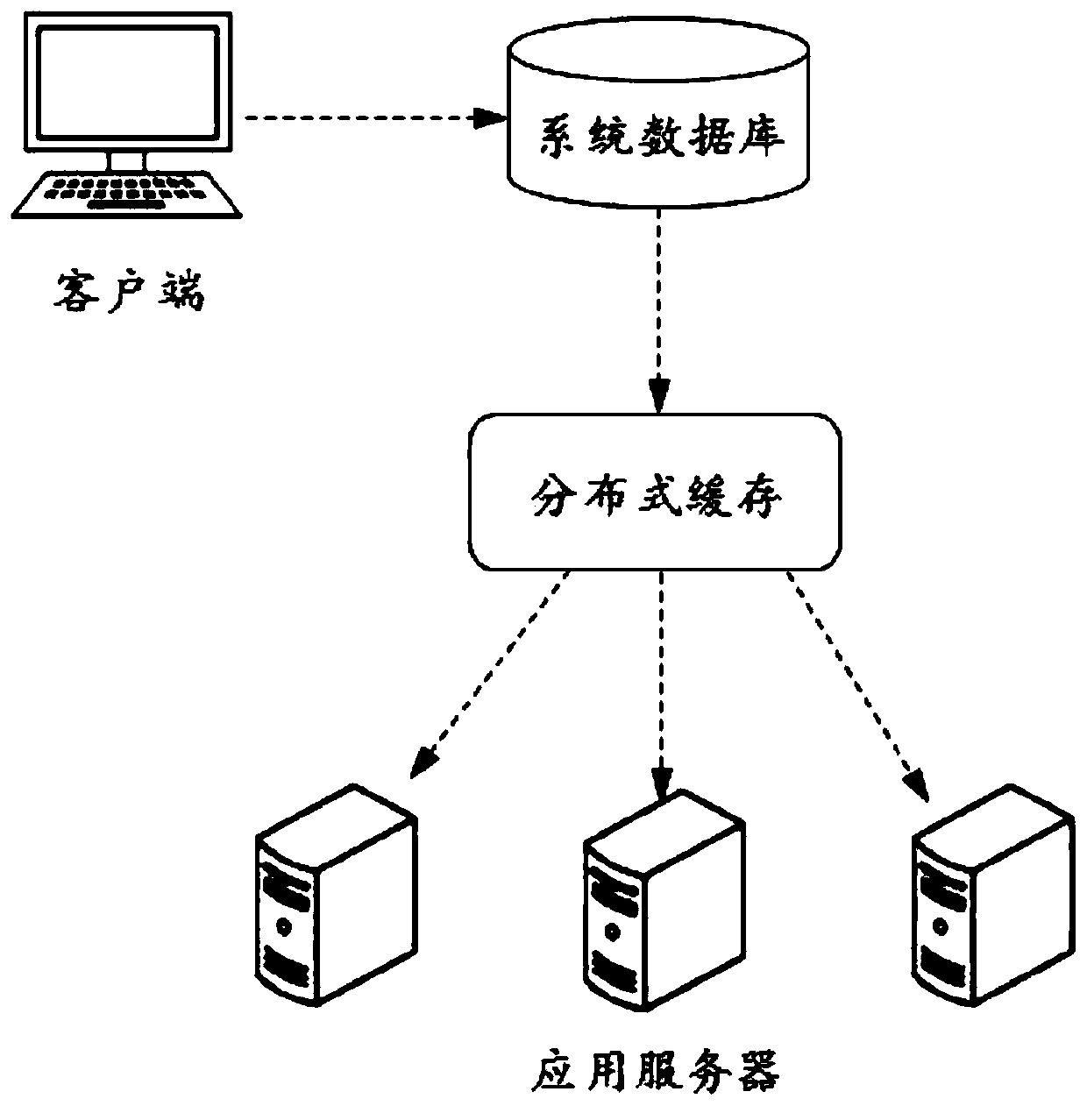

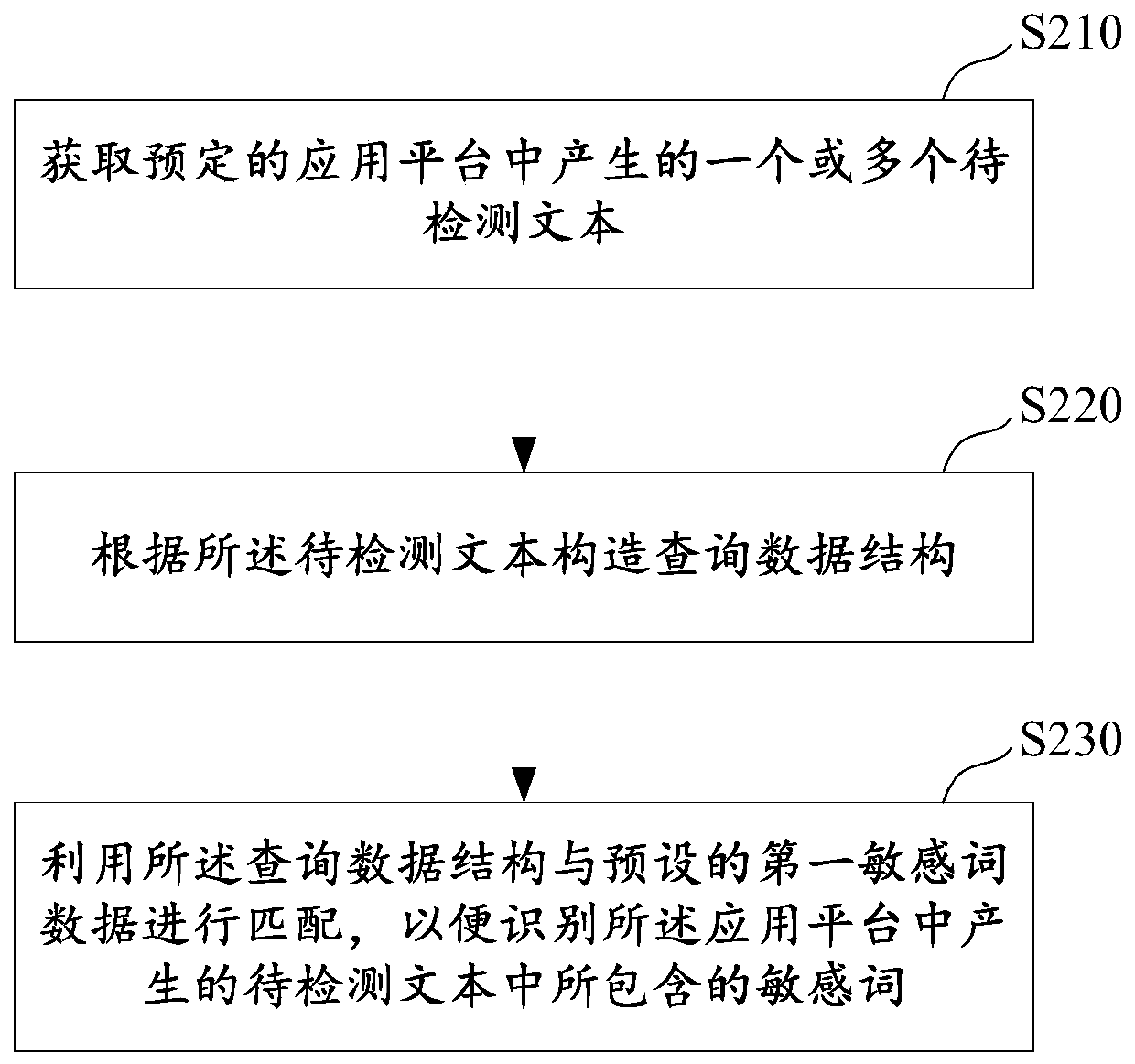

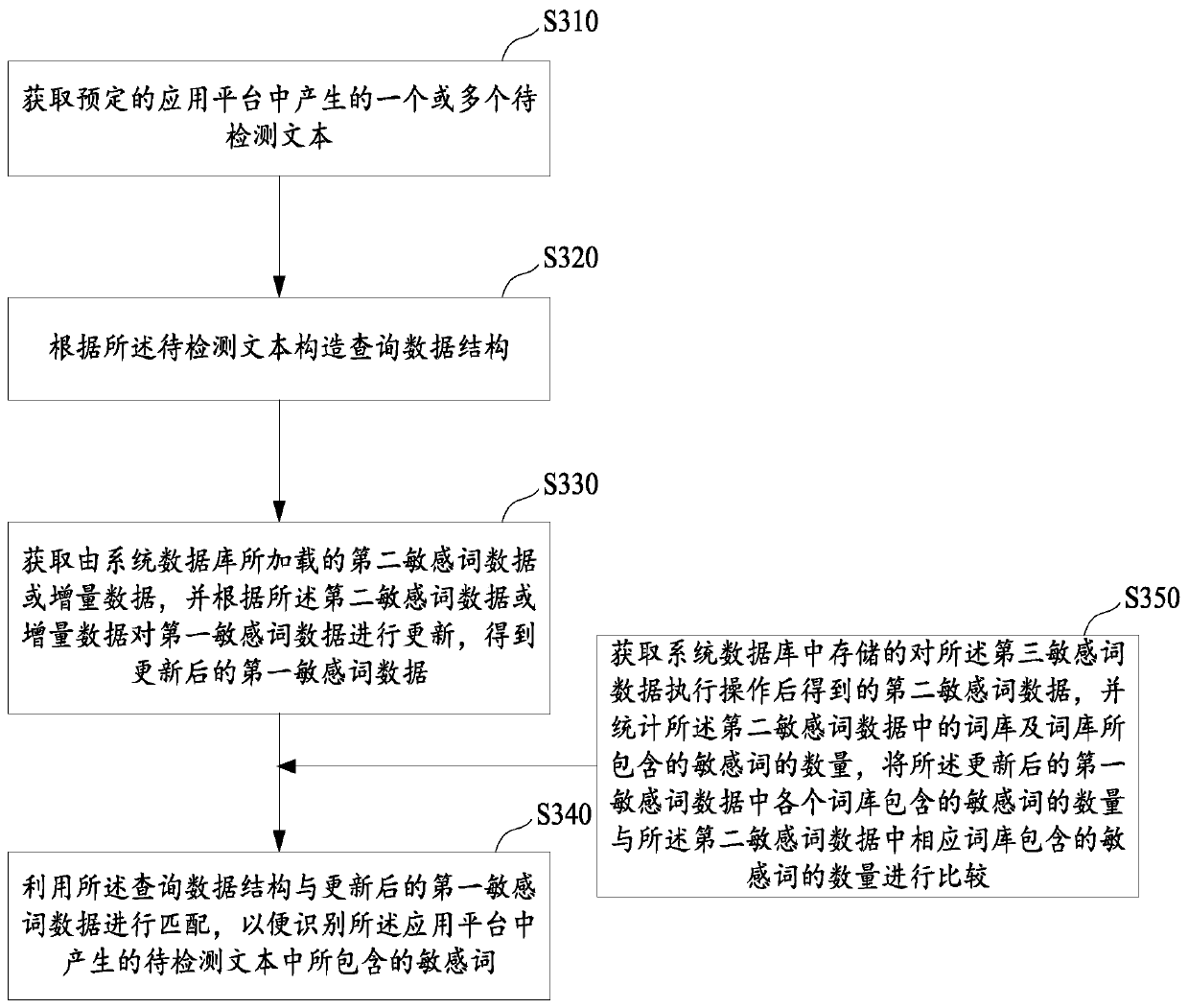

Sensitive word recognition method and device and electronic device

PendingCN111143513AQuick changeQuick response to changesText database indexingText database queryingEngineeringData structure

The embodiment of the invention provides a sensitive word recognition method and device and an electronic device. The method comprises the steps of obtaining one or more to-be-detected texts generatedin a predetermined application platform; constructing a query data structure according to the to-be-detected text; and matching the query data structure with the preset first sensitive word data so as to identify the sensitive words contained in a to-be-detected text generated in the application platform, thereby realizing the identification of the sensitive words.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

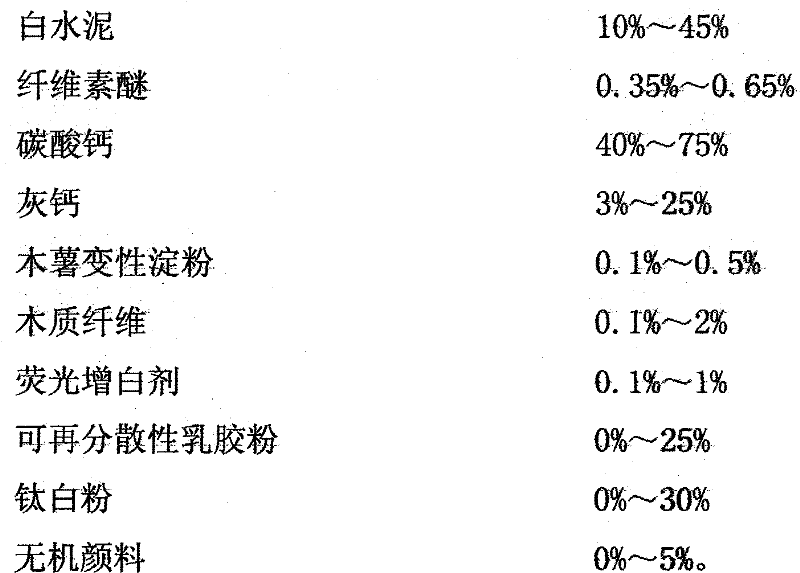

Novel dry powder emulsion paint

The invention discloses novel dry powder emulsion paint. The novel dry powder emulsion paint consists of the flowing substances in percentage by weight: 5 to 50 percent of white cement, 0.3 to 1 percent of cellulose ether, 35 to 75 percent of calcium carbonate, 0 to 30 percent of sierozem, and 0 to 10 percent of inorganic or organic pigment. All the substances are fed into a stirrer in a weight ratio, mixed uniformly and packaged to form a finished product; and water is added into the finished product so as to obtain a mixture which can used after being stirred uniformly, and the mixture is formed from bottom to top at one time. The novel dry powder emulsion paint has the characteristics of high intensity, bright color, scrubbing resistance, mould proofing, low cost, simple package, and convenience in transportation, is not easy to crack and construct, does not fall and pollute environment and can be widely applied to decoration of inner and outer walls of buildings; scale and hollowing are avoided; and by using paint, the wall can be dyed easily, and the color is not easy to fade.

Owner:倪建东

Prefabricated type tunnel foot-lock anchors rod and steel frame connecting member

PendingCN106968695AAchieve standardizationImprove stabilityUnderground chambersTunnel liningSteel frameRock bolt

The invention discloses are prefabricated type tunnel foot-lock anchor rods and a steel frame connecting member and belongs to the technical filed of tunnel engineering. The steel frame connecting member are composed of the foot-lock anchor rods, a support steel frame, positioning annular pieces, a left bolt sleeve, a right bolt sleeve and a bolt buckle. In the preparation stage, firstly, the ends (on the side where the ends are connected with the steel frame) of the foot-lock anchor rods are subjected to thread machining pretreatment; and secondly, according to the designed positions and construction angles of the foot-lock anchor rods, the positioning annular pieces are welded to the corresponding positions of the support steel frame. In the construction stage, the foot-lock anchor rods are subjected to precise positioning construction through the front and rear positioning annular pieces of the support steel frame; and then the foot-lock anchor rods on the two sides of the support steel frame are connected to be a whole in an anchoring mode through the prefabricated left bolt sleeve, the right bolt sleeve and a bolt fastener. By adopting the structure, the foot-lock anchor rods can be constructed precisely and stably connected with the support steel frame, the overall stability of a tunnel primary supporting structure is improved, and the difficult problem of tunnel engineering construction is effectively solved.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Graphene and nonferrous metal tailings-based foamed light wallboard and preparation method thereof

ActiveCN108996987AIncrease the areaHigh strengthCeramic materials productionCeramicwareFiberAluminum silicate

The invention belongs to the field of enclosure wall materials of buildings, and particularly relates to a graphene and nonferrous metal tailings-based foamed light wallboard and a preparation methodthereof. The graphene and nonferrous metal tailings-based foamed light wallboard comprises a main material and an auxiliary material. The main material comprises the following component in parts by weight: 70-90 parts of nonferrous metal tailings; and the auxiliary material comprises the following components in parts by weight: 0.5-8 part of graphene, 1-15 parts of vermiculite, 2-10 parts of aluminum fluoride, 3-8 parts of aluminum silicate fibers, 5-15 parts of montmorillonite, 1-10 parts of clay, 5-20 parts of a cosolvent, 0.1-5 parts of a foamer and 0.1-5 parts of a stabilizer. The foamed light wallboard provided by the invention has the characteristics of being light, high in strength, light, high in toughness, fireproof, high-temperature-resistant, waterproof, anti-seepage, green, environmentally-friendly and the like.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

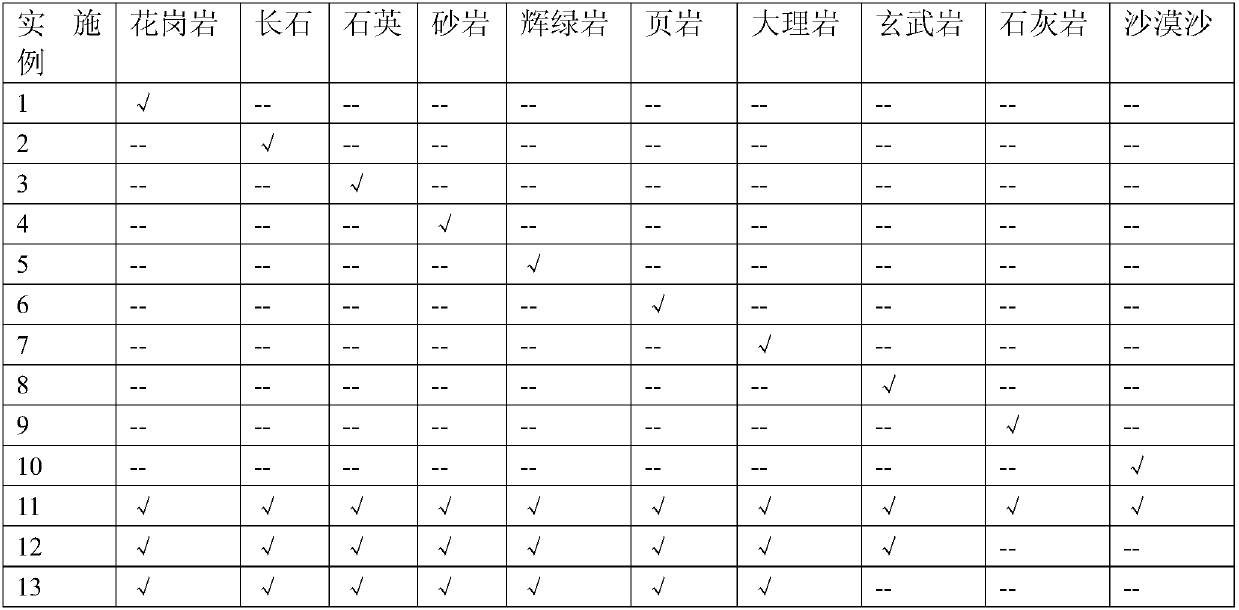

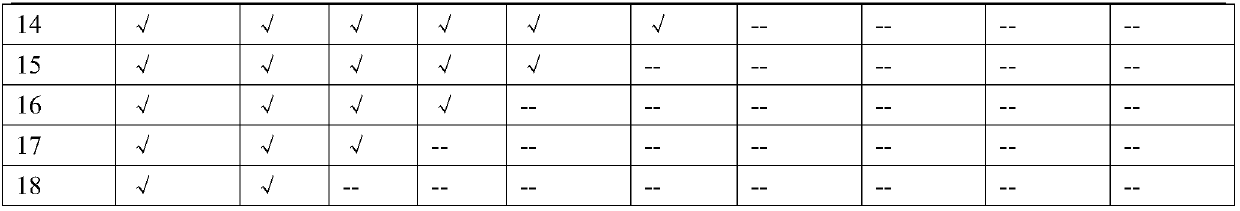

Graphene and nonmetallic tailing based foamed lightweight wallboard and preparation method thereof

InactiveCN107746250AIncrease the areaHigh strengthCeramic materials productionCeramicwareFiberFire resistance

The invention belongs to the field of building enclosure wall materials, and particularly relates to a graphene and nonmetallic tailing based foamed lightweight wallboard and a preparation method thereof. The graphene and nonmetallic tailing based foamed lightweight wallboard comprises the following components in percentage by weight: 55-75% of nonmetallic tailings, 0.05-15% of graphene, 1-15% ofvermiculite, 0.05-15% of a high-temperature cosolvent, 5-20% of high-temperature-resistant fiber, 0.05-5% of a foaming agent, 1-20% of zirconia, 1-10% of clay, 0.05-5% of a stabilizing agent and 0.05-5% of a peptizing agent. The invention has the advantages that the graphene and nonmetallic tailing based foamed lightweight wallboard has the comprehensive properties of obvious aging resistance, corrosion resistance, heat insulation, sound insulation, water resistance, permeation resistance, fire resistance, light weight, high strength, no cracking, environmental protection and the like, and isprepared by adopting a production preparation method which is green and low-carbon, high in efficiency, energy-saving, consumption-reducing, and simple and convenient in operation.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Kiln turning method for rotary kiln large-gear precise alignment

ActiveCN104390452AThe construction process is simple and fastLow costRotary drum furnacesTime efficientGear wheel

The invention discloses a kiln turning method for rotary kiln large-gear precise alignment and relates to the technical field of rotary kiln large-gear installation. A rotary kiln comprises a large gear installed outside a barrel body in a sleeving mode, wherein multiple pin holes are distributed in the inner edge position of the large gear, the large gear is in meshed connection with a small gear, and the small gear is connected with an auxiliary motor through a speed reducer. The kiln turning method comprises the following steps of (A) using multiple spring connecting plates to enable the large gear 1 and the barrel body to be connected; (B) using press wires to fix the long side edges of the spring plates to the barrel body, wherein the arc-shaped concave faces of the spring plates mutually abut against limiting blocks; (C) starting the auxiliary motor to drive the barrel body to rotate and measuring the radial and axial run-out amounts of the large gear; (D) adjusting the large gear; (E) repeating the step B and the step C till the measured radial and axial run-outs of the large gear are qualified; (F) dismounting the press wires and the limiting blocks and enabling the spring plates to be welded with the barrel body. Compared with the prior art, the kiln turning method does not need to dismount spring plates and does not need to repeatedly adjust the press wires and the limiting blocks as well when the large gear is adjusted, and the time and cost are saved.

Owner:GUANGXI YUFENG CEMENT

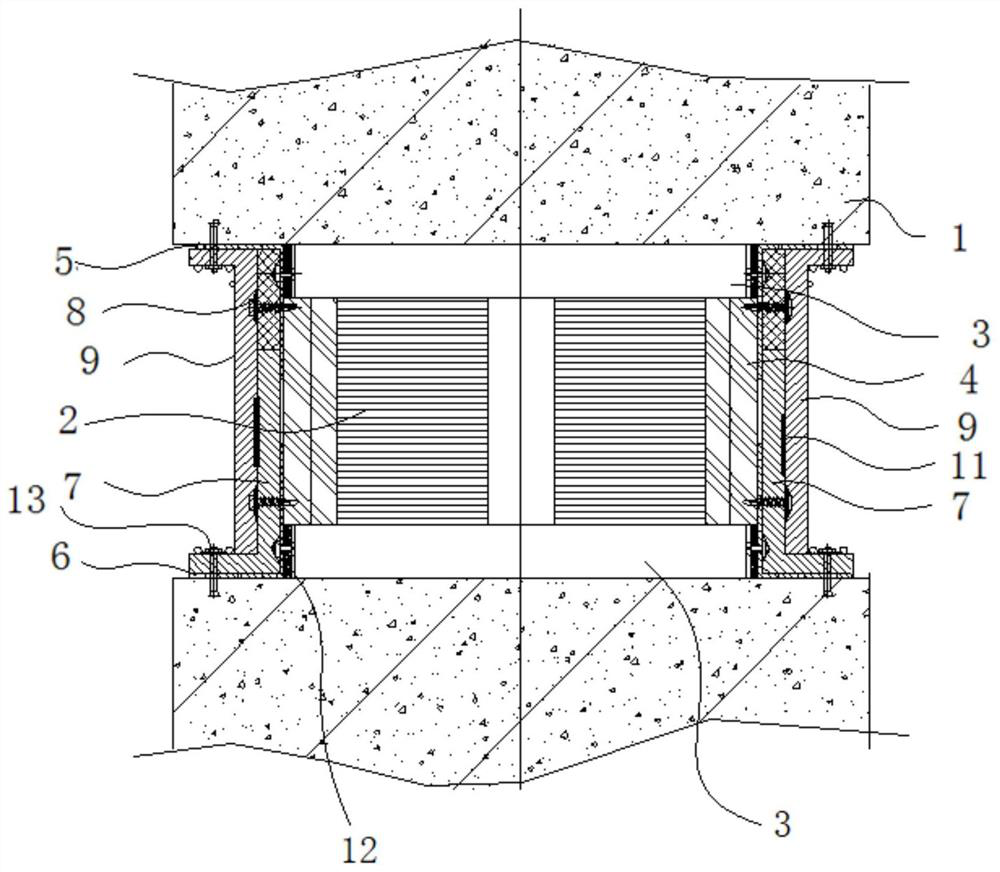

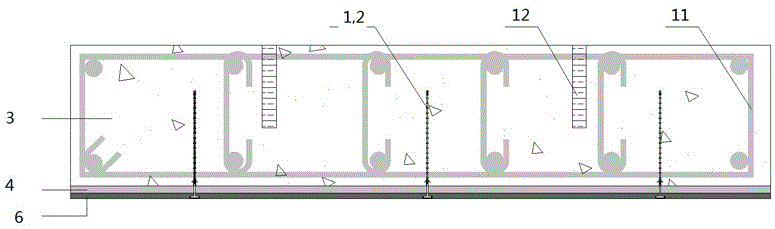

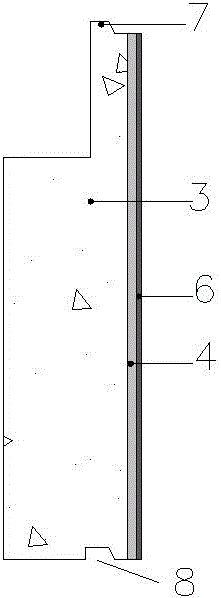

Underground comprehensive pipe gallery structure deeply buried in soft soil and construction method of underground comprehensive pipe gallery structure

PendingCN107794946AReduce support costsThe construction process is simple and fastArtificial islandsUnderwater structuresRebarReinforced concrete

The invention provides an underground comprehensive pipe gallery structure deeply buried in soft soil and a construction method of the underground comprehensive pipe gallery structure. The undergroundcomprehensive pipe gallery structure is a reinforced concrete box type structure with underground diaphragm walls buried in deep and thick soft soil 10 m below as side walls, hidden beams, top beamsand steel bar connectors are arranged on the underground diaphragm walls to be connected with a bottom plate and a top plate of a pipe gallery, and lining walls arranged in the underground diaphragm walls and the underground diaphragm walls are combined to be used as the side walls of the comprehensive pipe gallery. The elevation of the wall tops of the underground diaphragm walls is the same as that of the bottom of the top plate of the underground comprehensive pipe gallery, load-bearing bars of the top plate and wall top anchoring bars of the underground diaphragm walls are connected through the top beams, and the top plate of the comprehensive pipe gallery is formed. The hidden beams are arranged on the portions, corresponding to the bottom plate of the comprehensive pipe gallery, of the underground diaphragm walls and are connected through the steel bar connectors, and the bottom plate of the comprehensive pipe gallery is formed. According to the underground comprehensive pipe gallery structure, the problem that differential settlement is prone to being generated when the underground comprehensive pipe gallery passes through the deep and thick soft soil is solved, the foundation pit support cost is reduced, the construction process of the structure is simple, convenient and fast, and the structure is economical and reasonable.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Energy-saving metal finish integral plate and technology for processing same

InactiveCN104847071AImprove flame retardant performanceImprove waterproof performanceCovering/liningsSynthetic resin layered productsPolyurethane adhesiveMass ratio

The invention relates to an energy-saving metal finish integral plate and a technology for processing the same, and belongs to the technical field of building plate structures. The technology includes technological steps of 1, cutting polyurethane plates according to the sizes of finish layers 2; 2, mixing polyurethane adhesive with polymethylene poly-phenyl polyisocyanate according to a mass ratio of 1:(1-2) to obtain mixed materials, controlling the temperatures of the mixed materials in the range of 18-42 DEG C and then uniformly pouring the mixed materials between the polyurethane plates and the finish layers to obtain plates; 3, placing the plates obtained in the step 2 in pressure machines, exerting pressures of 0.02-0.1MPa on the plates by the aid of the pressure machines and integrally combining the polyurethane plates with the finish layers; 4, combining the polyurethane plates and the finish layers in the pressure machines for 1-1.5 hours and taking out the energy-saving metal finish integral plate. The energy-saving metal finish integral plate and the technology have the advantages that the energy-saving metal finish integral plate is excellent in heat-insulation and waterproof performance, the construction technology is convenient and speedy, and the finish layers are difficult to crack and fall off.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

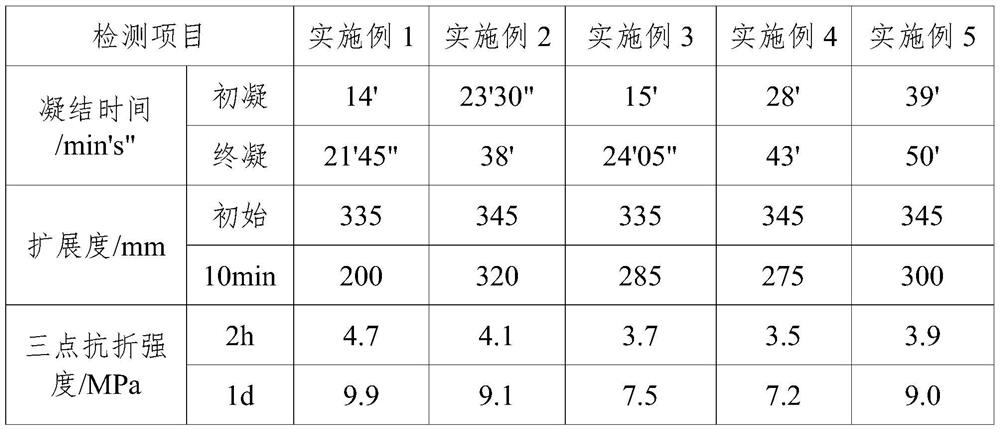

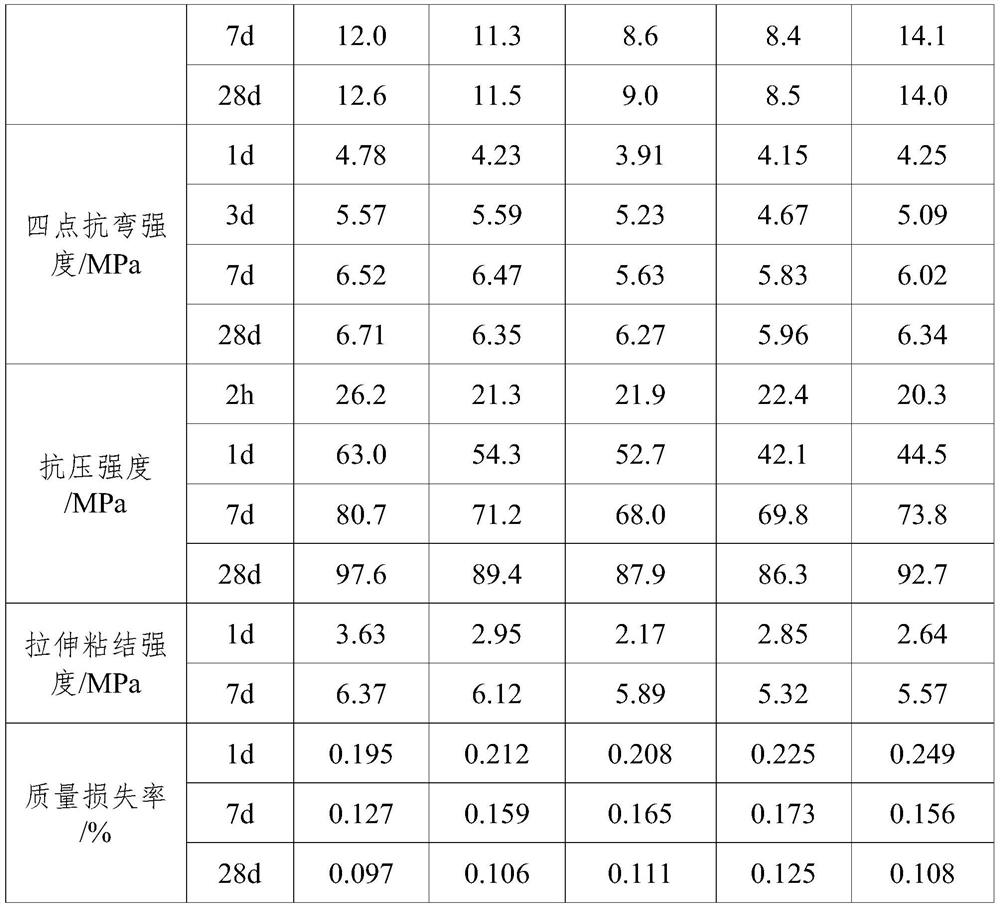

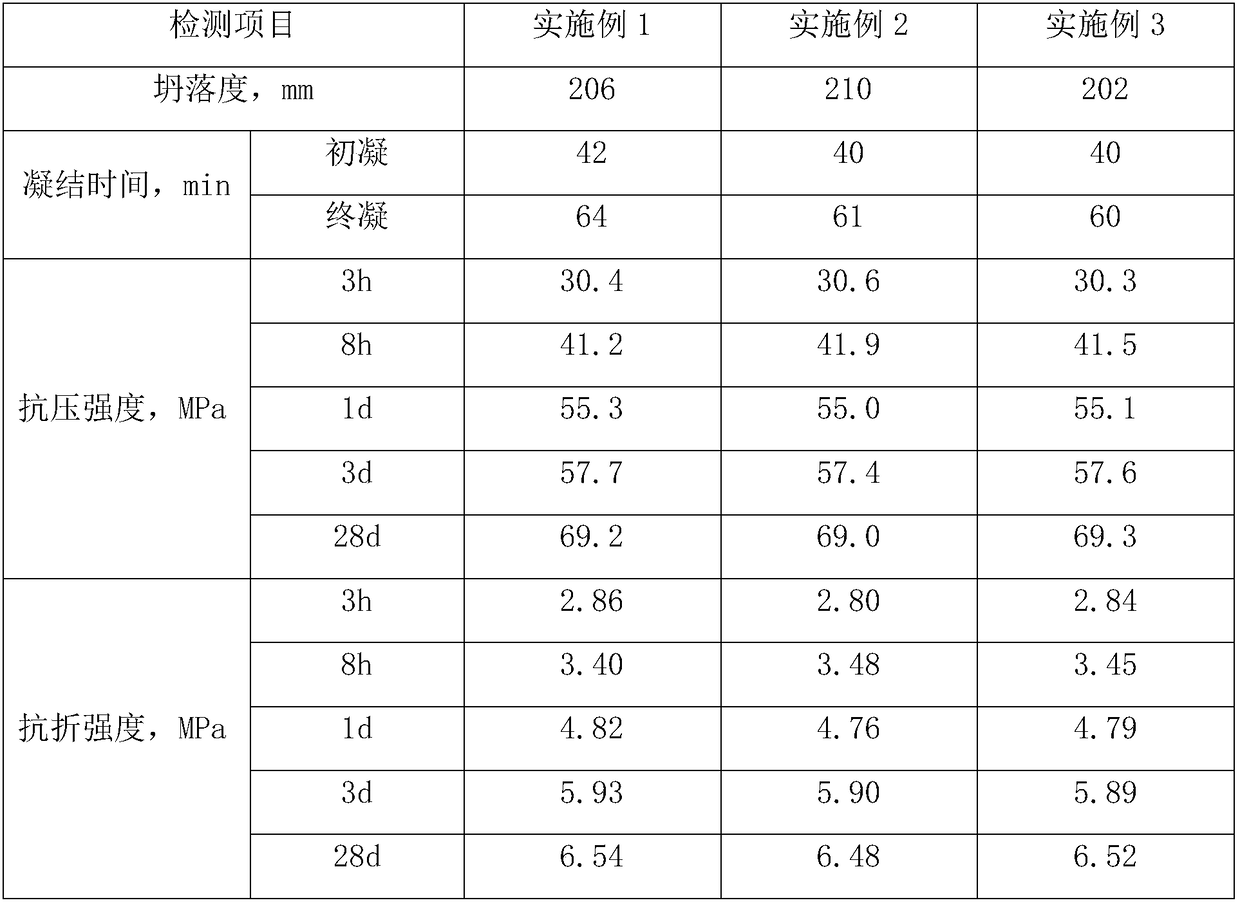

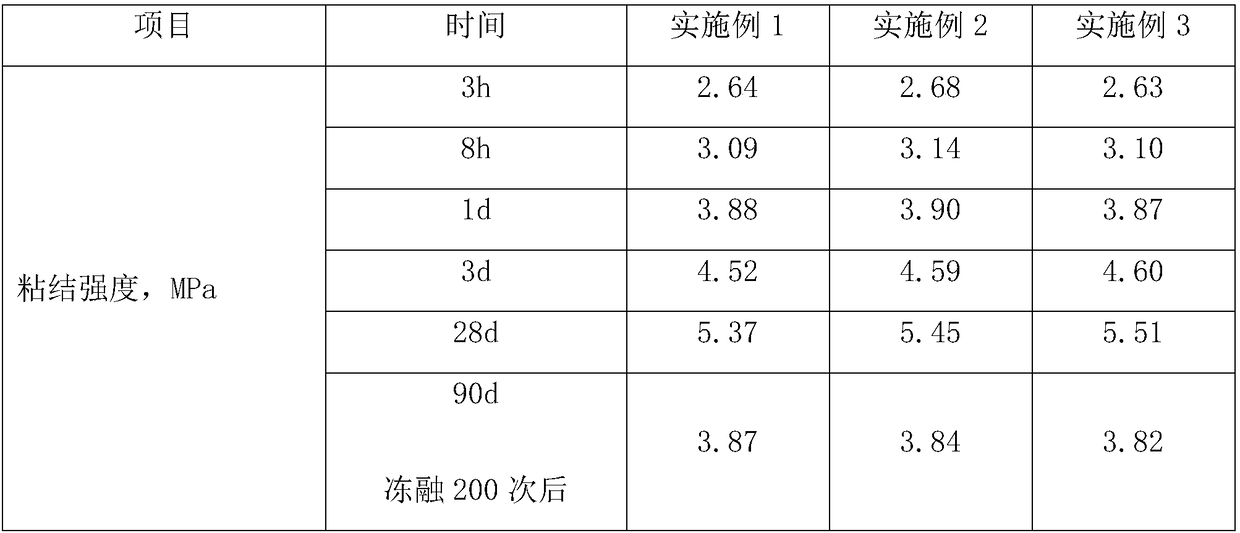

Quick-setting and quick-hardening early-strength and high-strength pavement patching material and preparation method thereof

The invention discloses a quick-setting and quick-hardening early-strength pavement patching material, which is prepared from the following components in parts by mass: 2.4 to 33.7 parts of ordinary Portland cement, 9.6 to 38.4 parts of quick-hardening sulphoaluminate cement, 0 to 10.8 parts of mineral powder, 0 to 7.1 parts of fly ash, 0.2 to 0.5 part of dispersible latex powder, 0.2 to 0.5 part of modified fiber, 1.1 to 1.4 parts of water reducing agent, 11.1 to 12.3 parts of water and 37.9 to 38.6 parts of sand. The invention also discloses a method for preparing the quick-setting, quick-hardening, early-strength and high-strength pavement patching material, which comprises the following steps: stirring a part of raw materials, adding water and a water reducing agent, adding modified fibers, and stirring to obtain the quick-setting, quick-hardening, early-strength and high-strength pavement patching material. According to the invention, the advantages of the components are integrated, the respective defects are made up, rapid setting, rapid hardening and high strength are realized, and the requirement of rapid pavement repair is met; the preparation process is simple, and rapid construction is realized.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

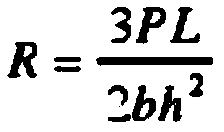

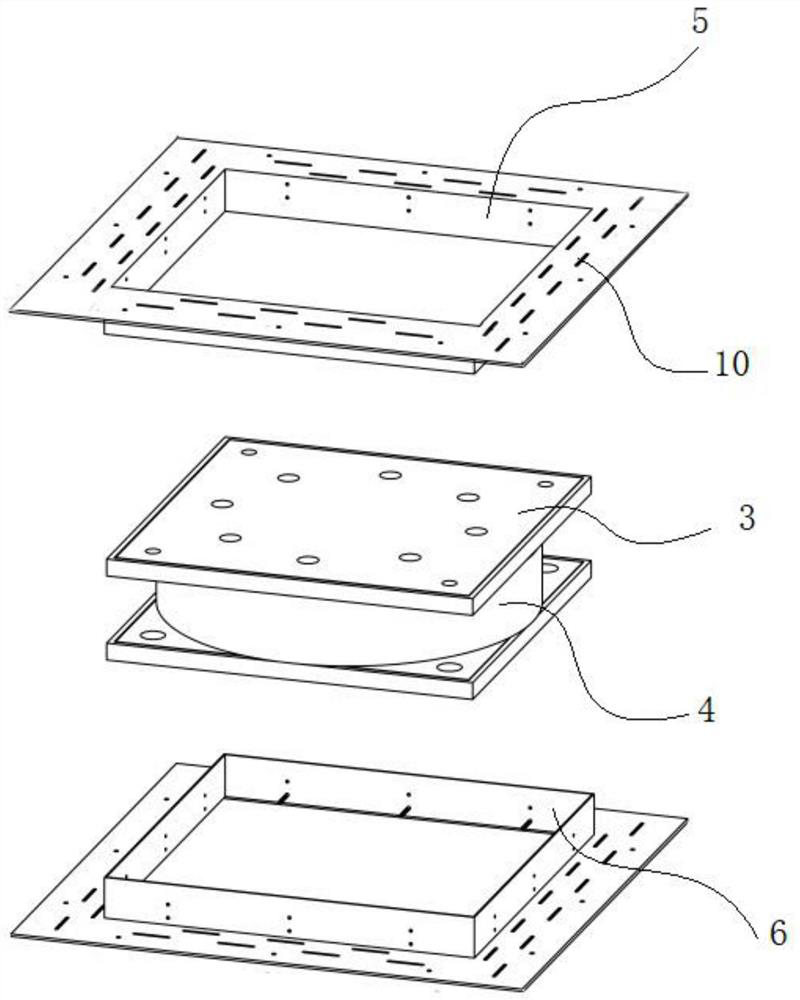

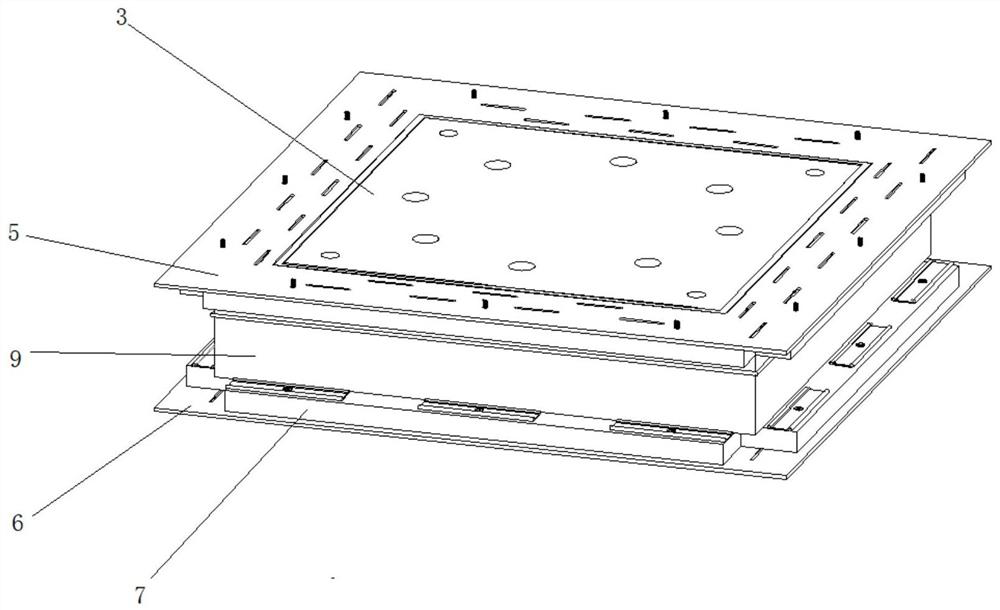

High-ductility seismic insulation rubber support fireproof protection structure and construction process thereof

PendingCN112502304AAchieve fire performanceImprove ductilityProtective buildings/sheltersFire proofingInsulation layerThermal break

The invention discloses a high-ductility seismic insulation rubber support fireproof protection structure and a construction process thereof. The periphery of a seismic insulation rubber support and the periphery of a flexible fireproof heat insulation material are further provided with a high-ductility fireproof structure layer, and the high-ductility fireproof structure layer comprises a connecting fixing plate and an extensible fireproof heat insulation layer; two fireproof composite layers are formed by the extensible fireproof heat insulation layer in the normal state to achieve fireproofprotection, when large deformation stretching displacement is generated during medium and violent earthquakes, the outer fireproof composite layer obliquely stretches relative to the inner fireproofcomposite layer, and due to the fact that the outer fireproof composite layer and the inner fireproof composite layer have an overlapping area, even if the stretching displacement is too large, the outer fireproof composite layer and the inner fireproof composite layer cannot fall off or be disconnected; adaptive extension is effectively carried out according to the deformation displacement degree, and the seismic insulation rubber support on the inner side is still wrapped in the whole process. Due to the improvement of the ductility, it is guaranteed that the fireproof composite layer on theouter side is not deformed, torn and damaged when the medium and violent earthquakes and large displacement offset occur, complete fireproof protection is continuously provided, and the fireproof effect under extreme conditions is achieved.

Owner:YUNNAN QUAKESAFE SEISMIC ISOLATION TECH

Graphene-based stone foamed lightweight wall plate and preparation method thereof

InactiveCN107759243AIncrease the areaHigh strengthCeramic materials productionCeramicwareCrack resistanceFire resistance

The invention belongs to the field of building enclosure wall materials and in particular relates to a graphene-based stone foamed lightweight wall plate and a preparation method thereof. The stone foamed lightweight wall plate contains the following components in percentage by weight: 45-90% of stone tailings, 0.05-10% of a high-temperature cosolvent, 0.05-15% of graphene, 0.05-5% of expanded graphite, 1-20% of zirconia, 0.05-10% of calcium carbonate, 1-10% of clay, 0.05-5% of a stabilizer, 0.05-5% of a dispergator and 0.05-5% of inorganic colors. The stone foamed lightweight wall plate has the advantages of integrating overall performances such as obvious aging resistance, corrosion resistance, heat insulation, sound insulation, water seepage resistance, fire resistance, lightweight, high strength, cracking resistance, greening and environment friendliness, the preparation method is simple and easy to operate, and the production process is green, low-carbon, high-efficiency, energy-saving and consumption-reducing.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Reverse hitting preparation technology of non-facing layer prefabricated wall body

ActiveCN106671267ASimple production processReduce weightCeramic shaping apparatusBuilding componentsCement mortarMaterials science

The invention discloses a reverse hitting preparation technology of a prefabricated self-insulation wall body. The wall body comprises a concrete wall body, an insulation board and a cement mortar layer protective layer, wherein the insulation board is arranged at the outer part of the concrete wall body; the insulation board is provided with a protective layer; and the cement mortar layer protective layer is arranged at the outer part of the insulation board. The prefabricated self-insulation wall body is produced through an insulation board reverse hitting construction technology, and connecting pieces of outer hinge plates in an original sandwich structure and the interior and exterior are discarded, so that the cost is greatly reduced, the production efficiency is improved, selfweight of buildings is decreased, and large-scale popularization of the prefabricated buildings is guaranteed.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Graphene and stone tailing-based foamed lightweight high-temperature-resistant wallboard and preparation method thereof

InactiveCN107602080AIncrease the areaHigh strengthCeramic materials productionCeramicwareFiberPolymer science

The invention belongs to the field of building enclosure wall materials, and particularly relates to a graphene and stone tailing-based foamed lightweight high-temperature-resistant wallboard and a preparation method thereof. The wallboard comprises the following raw materials in percentage by weight: 40-65% of stone tailings, 0.05-15% of graphene, 1-30% of aluminum oxide, 1-15% of vermiculite, 0.05-10% of calcium carbonate, 0.05-15% of high temperature solvent, 5-30% of high-temperature resistance fiber grains, 0.05-5% of vesicant, 0.05-5% of stabilizer, 0.05-5% of dispergator, 1-10% of clay,and additional 0-5% of pigment. The wallboard has the advantages of integrating comprehensive anti-ageing, anti-corrosion, heat-insulation, soundproof, waterproof and anti-seepage, fireproof, 1000DEGC high-temperature-resistant properties, light weight and high strength and toughness, no cracking, environment protection and the like, and the preparation method is simple and easy to operate, theproduction process is green and low-carbon, high-efficiency, energy-saving and consumption-reducing, and high in automation.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Cement concrete pavement patching material and cement concrete pavement patching method

ActiveCN107324738BExtended service lifeHigh bonding strengthSolid waste managementRoads maintainenceFiberSuperplasticizer

Owner:呼和浩特市政公路工程有限责任公司

A kind of environment-friendly dry powder latex paint and preparation method thereof

Owner:安徽三力装饰材料科技有限公司

Rotary Kiln Method for Fine Alignment of Large Gear in Rotary Kiln

ActiveCN104390452BThe construction process is simple and fastLow costRotary drum furnacesTime efficientGear wheel

The invention discloses a kiln turning method for rotary kiln large-gear precise alignment and relates to the technical field of rotary kiln large-gear installation. A rotary kiln comprises a large gear installed outside a barrel body in a sleeving mode, wherein multiple pin holes are distributed in the inner edge position of the large gear, the large gear is in meshed connection with a small gear, and the small gear is connected with an auxiliary motor through a speed reducer. The kiln turning method comprises the following steps of (A) using multiple spring connecting plates to enable the large gear 1 and the barrel body to be connected; (B) using press wires to fix the long side edges of the spring plates to the barrel body, wherein the arc-shaped concave faces of the spring plates mutually abut against limiting blocks; (C) starting the auxiliary motor to drive the barrel body to rotate and measuring the radial and axial run-out amounts of the large gear; (D) adjusting the large gear; (E) repeating the step B and the step C till the measured radial and axial run-outs of the large gear are qualified; (F) dismounting the press wires and the limiting blocks and enabling the spring plates to be welded with the barrel body. Compared with the prior art, the kiln turning method does not need to dismount spring plates and does not need to repeatedly adjust the press wires and the limiting blocks as well when the large gear is adjusted, and the time and cost are saved.

Owner:GUANGXI YUFENG CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com