Energy-saving metal finish integral plate and technology for processing same

A processing technology and energy-saving technology, which is applied in the field of energy-saving metal veneer integrated board and its processing technology, can solve the problems of substandard waterproof performance of the system, easy cracking and falling off of the veneer layer, complicated construction technology, etc., and achieve the goal of overcoming quality problems. The effects of poor control, ingenious structural design, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

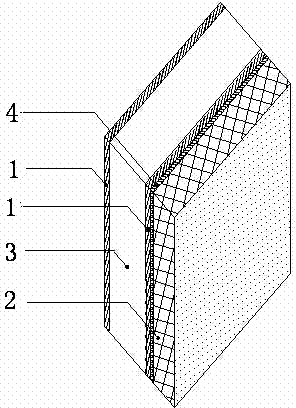

[0018] The energy-saving metal-decorated integrated board of this embodiment includes a polyurethane board for interface enhancement, fire protection, and heat preservation, a decorative layer 2 for decoration and fire protection, and an adhesive layer 4. The polyurethane board passes through the adhesive layer. 4 Combined with the decorative layer 2, the polyurethane sheet includes coiled material layer 1, insulation layer 3, and coiled material layer 1; Any one of galvanized steel sheets, etc.; coil layer 1 is an interface sheet prepared from flame-retardant polymer glue, and the base material of coil layer 1 is glass fiber, mesh cloth, non-woven fabric Any one of them, wherein, the coiled material layer 1 made of glass fiber as the base material is a glass fiber coiled material, and the glass fiber coiled material is made of flame-retardant polymer glue as the base cloth, and a plurality of strips are added on the base cloth Glass fiber acts as a reinforcing rib to strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com