Quick-setting and quick-hardening early-strength and high-strength pavement patching material and preparation method thereof

A pavement repair and high-strength technology, applied in the field of building materials, can solve the problems of inability to meet the requirements of rapid repair of the pavement, unstable crystal forms of hydration products, and high cost of aluminate cement, so as to enhance the repair and use performance of the pavement, and the construction process is simple. Convenience, high strength and the effect of stable growth in later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

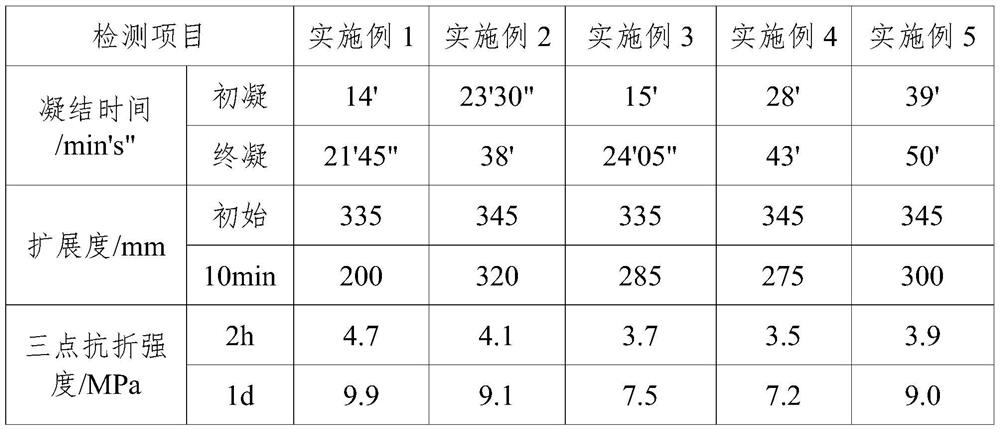

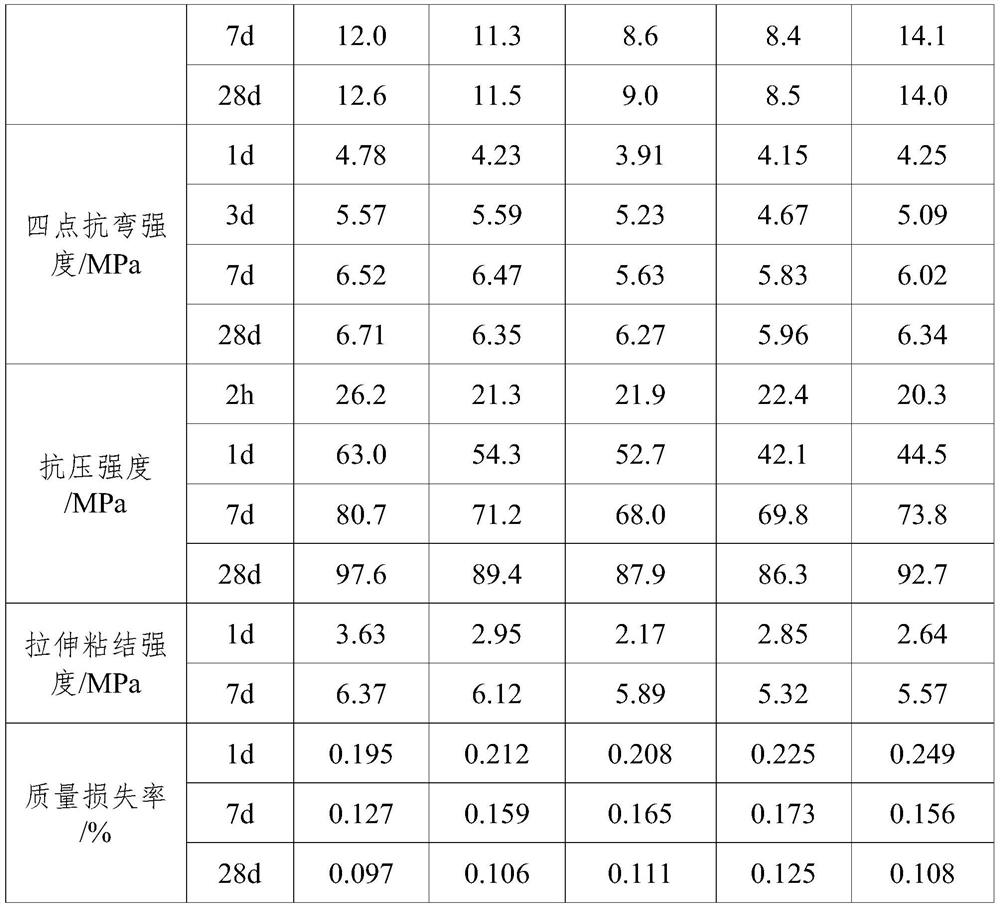

Examples

Embodiment 1

[0031] The fast-setting, rapid-hardening, early-high-strength pavement repair material of the present embodiment is prepared by the following components in parts by mass: 4.8 parts of ordinary Portland cement, 38.4 parts of rapid-hardening sulfoaluminate cement, and 4.8 parts of fly ash, which can be dispersed 0.5 part of latex powder, 0.5 part of modified fiber, 1.2 parts of water reducer, 11.5 parts of water, 38.4 parts of sand; the dispersible latex powder is a copolymer of ethylene / vinyl acetate; the preparation process of the modified fiber is : Put the polypropylene fiber in the silane coupling agent solution for 12 hours at 60°C, then wash it with deionized water, filter it, and dry it in a vacuum oven at 60°C for 8 hours, then cool it to room temperature, and put it in a dry place. Dried in a dish to constant weight to obtain modified polypropylene fibers, wherein the silane coupling agent solution is ultrasonically mixed with deionized water, absolute ethanol, and KH-5...

Embodiment 2

[0038] The fast-setting, rapid-hardening, early-high-strength pavement repair material of the present embodiment is prepared by the following components in parts by mass: 2.4 parts of ordinary Portland cement, 31.1 parts of rapid-hardening sulfoaluminate cement, 10.8 parts of mineral powder, and fly ash 3.6 parts, 0.5 parts of dispersible latex powder, 0.2 part of modified fiber, 1.4 parts of water reducer, 11.7 parts of water, 38.3 parts of sand; the dispersible latex powder is a copolymer of ethylene / vinyl acetate and styrene and butyl The mixture of diene copolymerized rubber powder mixed at a mass ratio of 1:1; the preparation process of the modified fiber is as follows: the polypropylene fiber is placed in the silane coupling agent solution for 12 hours at 60 ° C, and then deionized Wash with water, filter and place in a vacuum oven at 60°C to dry for 8 hours, then cool to room temperature, and put in a drying dish to dry to constant weight to obtain modified polypropylene...

Embodiment 3

[0045] The fast-setting, rapid-hardening, early-high-strength pavement patching material of the present embodiment is made of the following components in parts by mass: 14.2 parts of ordinary Portland cement, 23.7 parts of rapid-hardening sulfoaluminate cement, 2.4 parts of mineral powder, and fly ash 7.1 parts, 0.5 parts of dispersible latex powder, 0.5 part of modified fiber, 1.4 parts of water reducer, 12.3 parts of water, 37.9 parts of sand; the dispersible latex powder is a copolymer of ethylene / vinyl acetate, styrene and butyl The mixture of diene copolymer rubber powder and acrylate and styrene copolymer rubber powder mixed in a mass ratio of 1:1:1; the preparation process of the modified fiber is: put the polypropylene fiber into the silane coupling at 60°C Treated in the joint agent solution for 12 hours, then washed with deionized water, filtered, placed in a vacuum oven at 60°C, dried for 8 hours, cooled to room temperature, and dried to constant weight in a drying d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com