A kind of rapid repair material for expansion joint and preparation method thereof

A technology for repairing materials and expansion joints, applied in the field of pavement repair, can solve the problems of high brittleness, low bonding strength, poor tensile strength and interfacial adhesion, etc., and achieve large surface structure depth, high early strength, and road performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Rapid repair material for expansion joints, made from the following components:

[0035] A component: epoxy resin E51100 parts by mass;

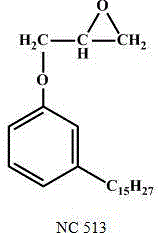

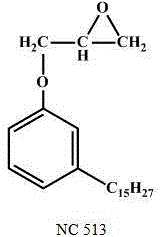

[0036] NC51312 parts by mass;

[0037] 20 parts by mass of diatomaceous earth;

[0038] Component B: 80 parts by mass of phenalkamine curing agent;

[0039] UV3291.5 parts by mass;

[0040] Component C: aggregate, the ratio of its mass to the sum of the mass of components A and B is 4:1. The aggregate is wear-resistant stone with a particle size of 0.6mm-3.3mm. It is made from copper ore, crushed and fired at a high temperature of 3000°C. The Mohs hardness is above 5.

[0041] Put epoxy resin E51, reactive diluent NC513, diatomaceous earth, phenalkamine curing agent, and ultraviolet light absorber UV329 into the mixing tank in turn, stir evenly to form a glue, and then mix with aggregate evenly to obtain expansion joints. Quick patch material.

Embodiment 2

[0043] Rapid repair material for expansion joints, made from the following components:

[0044] A component: epoxy resin E51100 parts by mass;

[0045] NC51312 parts by mass;

[0046] 20 parts by mass of active silica powder;

[0047] Component B: 80 parts by mass of phenalkamine curing agent;

[0048] UV3291.5 parts by mass;

[0049] Component C: aggregate, the ratio of its mass to the sum of the mass of components A and B is 5:1. The aggregate is wear-resistant stone with a particle size of 0.6mm-3.3mm. It is made from iron ore tailings and fired at 3000°C after crushing. The Mohs hardness is above 5.

[0050] Put epoxy resin E51, active diluent NC513, active silicon micropowder, phenalkamine curing agent, and ultraviolet light absorber UV329 into the mixing tank in turn, stir evenly to form a glue, and then mix with aggregate evenly to obtain the expansion joint. Quick patch material.

Embodiment 3

[0052] A quick repair material for expansion joints, made from the following components:

[0053] A component: epoxy resin E51100 parts by mass;

[0054] NC51315 parts by mass;

[0055] 30 parts by mass of diatomaceous earth;

[0056] Component B: 80 parts by mass of phenalkamine curing agent;

[0057] UV3291.5 parts by mass;

[0058] Component C: aggregate, the ratio of its mass to the sum of the mass of components A and B is 6:1. The aggregate is wear-resistant stone with a particle size of 0.6mm-3.3mm. It is made from copper ore, crushed and fired at a high temperature of 3000°C. The Mohs hardness is above 5.

[0059] Put epoxy resin E51, reactive diluent NC513, diatomaceous earth, phenalkamine curing agent, and ultraviolet light absorber UV329 into the mixing tank in turn, stir evenly to form a glue, and then mix with aggregate evenly to obtain expansion joints. Quick patch material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com