Method for carrying out microwave-assisted chemical leaching and restoring on soil in heavy metal pollution site

A microwave-assisted, chemical leaching technology, applied in the field of microwave-enhanced chemical leaching repair, to reduce the repair time and meet the effect of rapid repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Remediation Effect of EDDS Washing Treatment on Heavy Metal Contaminated Site Soil

[0030] The remediation test contaminated site is located in a certain place in Yuhua District, Nanjing City, Jiangsu Province. It is the surface soil near the heavily polluting enterprise Meishan Iron and Steel Plant. The soil samples were air-dried, ground, passed through a 2 mm sieve, and stored in a desiccator in a dark place. Part of the soil sample was ground by the quartering method and passed through a 0.125 mm sieve for full analysis of heavy metals. Weigh 0.50 g of the above 2 mm sieved soil samples and place them in a series of 50 ml polyethylene plastic bottles with a water-to-soil ratio of 30. Ratio of 2 (the ratio of water to soil and the molar ratio of eluent were determined through pre-experiments), and the shaker was shaken for a certain period of time (0.2, 0.5, 1, 3, 4, 6 h) under the conditions of 25 °C and 180 r / min.

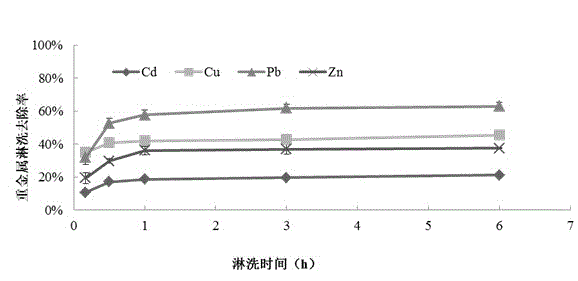

[0031] Figure 1 shows the change o...

Embodiment 2

[0033] Remediation Effect of Microwave Enhanced EDDS Washing on Heavy Metal Contaminated Site Soil

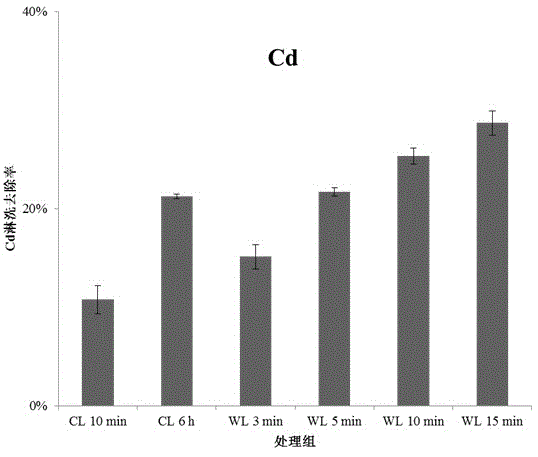

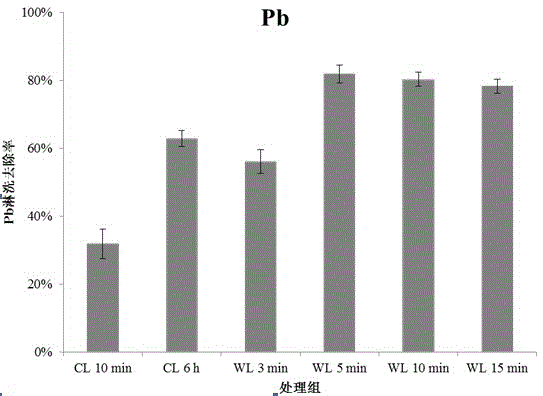

[0034] The basic steps are the same as those in Embodiment 1, except that microwaves are introduced, and the treatment groups include microwave time group and microwave power group. Figure 2-5 shows the change of heavy metal concentration in soil with time (3-15 min) under microwave (power 500 W) enhanced EDDS leaching treatment. It can be seen from the figure that after 3 min of microwave irradiation, the leaching removal rate of various metals in soil samples increased significantly. With the prolongation of microwave irradiation time, the leaching removal rates of heavy metals in soil samples showed an overall upward trend. Among them, Cd The removal rate of Zn continued to increase with the extension of the irradiation time, the removal rate of Zn slowed down after 10 min, and the removal of Pb hardly changed with the irradiation time after 5 min of microwave irradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com