A kind of article for travertine geological restoration and its preparation method and application

A geological and travertine technology, applied in application, chemical instruments and methods, manufacturing tools, etc., can solve problems such as the inability to meet the needs of rapid repair of travertine geology, and achieve the effect of accelerating strength repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

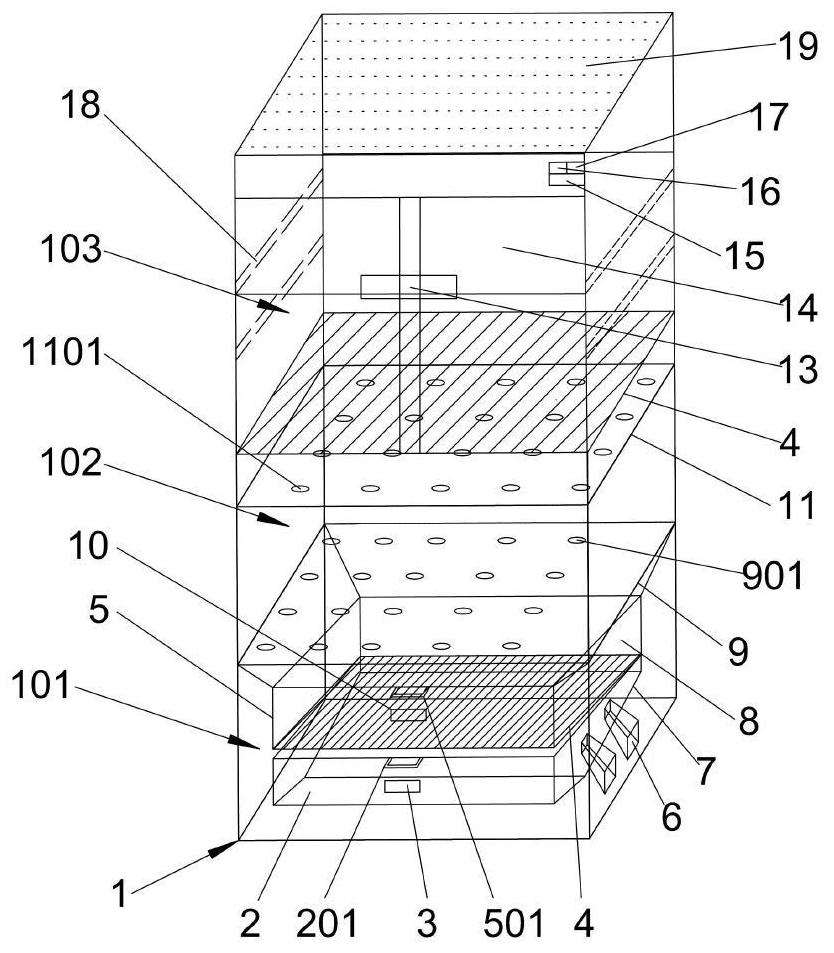

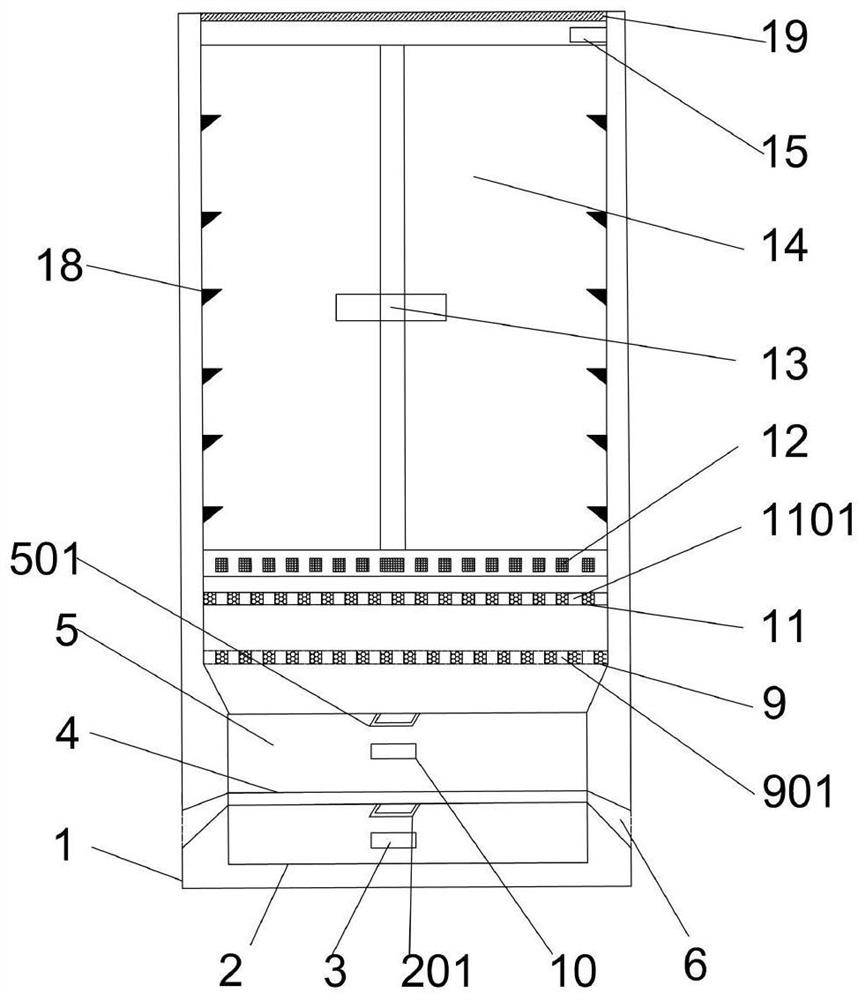

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a piece for travertine geological restoration, comprising the following steps:

[0026] (1) Mixing and aging waste travertine granules, calcium-based additives and water in sequence to obtain a pouring material;

[0027] (2) pouring and molding the pouring material obtained in the step (1) to obtain a molding;

[0028] (3) Carrying out gas-thermal curing to the molded blank obtained in the step (2) to obtain a workpiece for travertine geological restoration; the gas used for the gas-thermal curing is carbon dioxide.

[0029] In the invention, waste travertine granules, calcium-based additives and water are sequentially mixed and aged to obtain pouring materials. In the present invention, the particle size of the waste travertine granular material is preferably 0.1-2 mm, more preferably 0.2-1.5 mm, more preferably 0.5-1.0 mm.

[0030] In the present invention, the waste travertine granular material is preferably obtained by...

Embodiment 1

[0069] Remove impurities, grind and sieve the waste travertine to obtain waste calcified granules with a particle size of 1 mm; sieve calcium hydroxide to obtain a calcium-based additive with a particle size of 100 mesh; mix 40 parts of waste calcified granules with 60 1 part of calcium hydroxide is put into the mixer, first dry stir for 10min and mix evenly, then add water according to the solid-to-liquid ratio of 80:20, wet stir for 20min, and after aging for 24h, the pouring material is obtained;

[0070] Apply engine oil to the inner wall of the mould, pour the pouring material into the mould, hold the pressure at 15MPa for 1 hour, and then release the mold to obtain a molded body;

[0071] Carry out gas heat curing under the following conditions. The curing conditions are temperature of 150°C and supply concentration of carbon dioxide of 20m 3 / h, curing for 24h, and the parts for travertine geological restoration are obtained after natural cooling.

[0072] The obtained...

Embodiment 2~11

[0075] According to the method of Example 1, the article for travertine geological restoration is prepared. The amount of raw materials is listed in Table 1, and the preparation parameters are listed in Table 2. Others are the same as in Example 1.

[0076] Table 1 Embodiment 1~11 raw material and consumption thereof

[0077]

[0078] Table 2 Embodiment 1~11 preparation process parameters

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com