Pulse type grouting machine and double-liquid grouting construction method

A construction method and double-liquid grouting technology, which can be used in infrastructure engineering, roads, tracks, etc., and can solve problems such as low strength, poor underwater dispersion resistance, and slow coagulation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

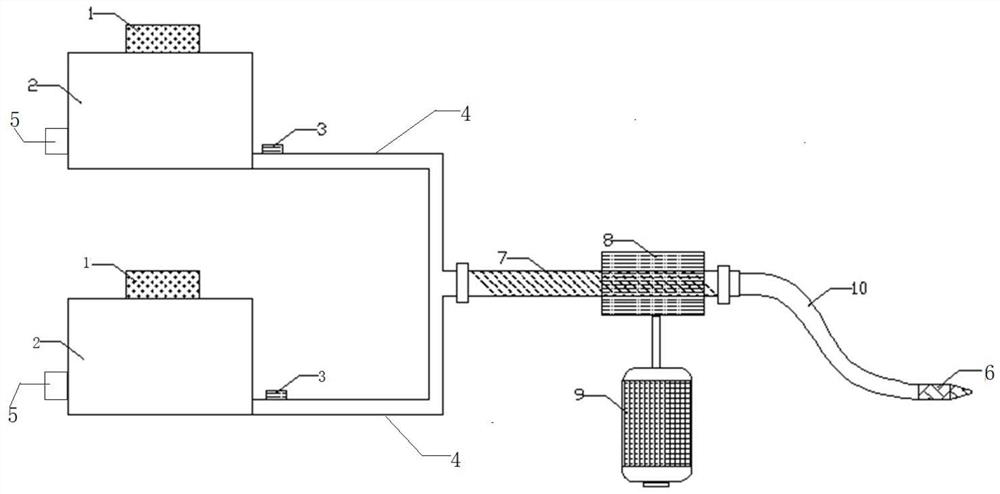

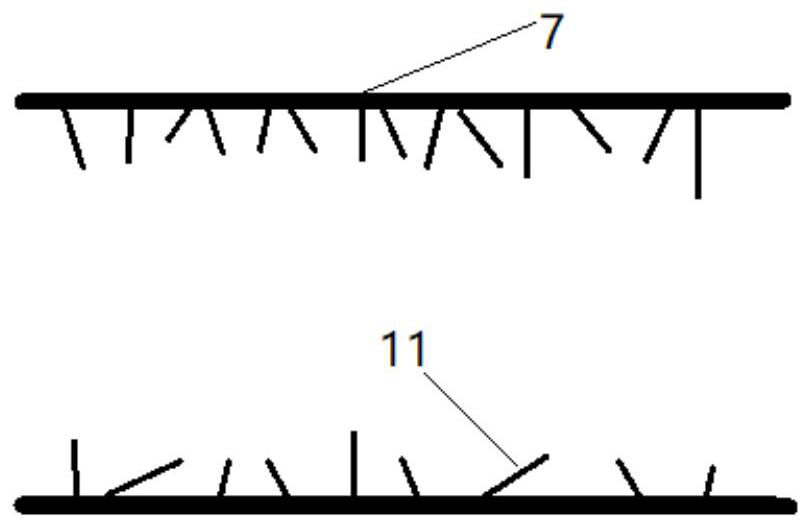

[0087] A pulse type grouting machine, the pulse type grouting machine according to the present invention, includes a plurality of storage tanks 2, each storage tank 2 is respectively provided with a pressure device 1, and each storage tank 2 is respectively connected to one end of the mixing pipe 7 , a vibrator 8 is set on the mixing tube 7, the vibrator (8) is connected with the motor frequency regulator 9, a flow control valve 3 is respectively set between each storage tank 2 and the mixing tube 7, and the other end of the mixing tube 7 is grouted with the mixed slurry Tube 10 communicates.

[0088] Each storage tank 2 communicates with one end of the mixing tube 7 through a pipeline 4 , and the single liquid enters the mixing tube 7 from the storage tank 2 through the pipeline 4 .

[0089] The pressure device 1 and the flow control valve 3 are respectively connected with the control part 5 .

[0090] The mixed slurry grouting pipe 10 is connected to the grouting gun head 6...

Embodiment 2

[0100] A double liquid grouting construction method, comprising the following steps:

[0101] S1. After determining the grouting filling area where the foundation is voided, locate the borehole and clean it. The borehole is determined by the elastic wave radar after the void area and its depth of the foundation, according to the size of the area, according to the size of the area, the plum blossom pile type positioning borehole is carried out according to a certain density, and the hole is cleared with a high-pressure water gun, so that each grouting hole and The void area is connected. The diameter of the grouting hole is 25-35mm, and the hole density is 8-12 pcs / m 2 , the hole spacing is 0.30-0.35m, and the drilling depth should be such that the grouting hole is connected to the void area; the plum blossom pile type grouting holes connected to the void area are set for grouting. Compared with single-row hole grouting, it can The slurry is evenly distributed in the cavity l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com