Patents

Literature

43results about How to "Grouting pressure is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

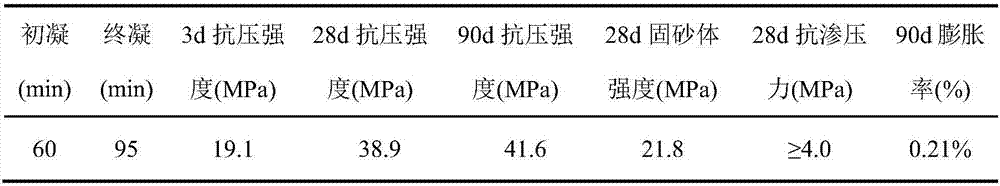

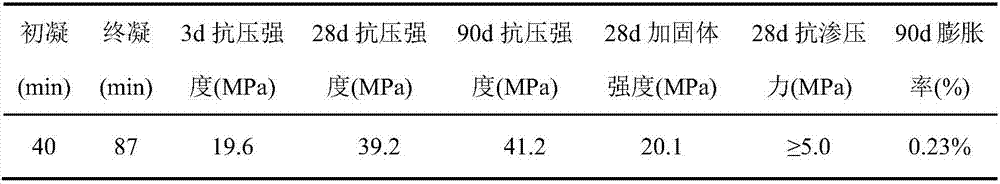

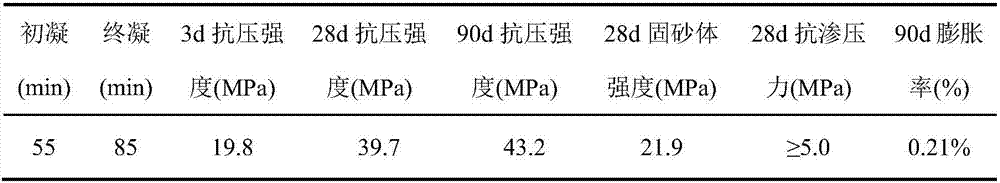

Efficient superfine cement based composite grouting material for grouting treatment of water-rich sand layer, preparation process and application

ActiveCN107572994AEasy to operateImprove applicabilityDrilling compositionSealing/packingMicrofine cementAluminate

The invention discloses an efficient superfine cement based composite grouting material for grouting treatment of a water-rich sand layer, a preparation process and application. The efficient superfine cement based composite grouting material is prepared from the following components in parts by weight: 40 to 80 parts of portland cement clinker, 10 to 45 parts of coal ash, 5 to 30 parts of superfine slag micro powder, 2 to 6.5 parts of desulphurization gypsum, 1 to 10 parts of silica fume, 0.51 to 2.10 parts of first mixed composite modifier, 0.4 to 2.4 parts of second mixed composite modifierand 5.5 to 8.9 parts of third mixed composite modifier; the coal ash is prepared from the following components in parts by weight: 50 to 100 parts of high-calcium coal ash and 0 to 50 parts of low-calcium coal ash; the first mixed composite modifier is prepared from the following components in parts by weight: 96 to 99 parts of super plasticizer and 1 to 4 parts of hydroxypropyl methyl cellulose;the second mixed composite modifier is prepared from the following components in parts by weight: 20 to 32 parts of sodium hydroxide, 21 to 28 parts of sodium carbonate, 18 to 32 parts of sodium sulfate and 18 to 36 parts of sodium metaaluminate; the third mixed composite modifier is prepared from the following components in parts by weight: 12 to 25 parts of calcium chloride, 8 to 21 parts of lithium chloride, 10 to 23 parts of triethanolamine and 32 to 68 parts of sulphoaluminate cement clinker.

Owner:SHANDONG UNIV

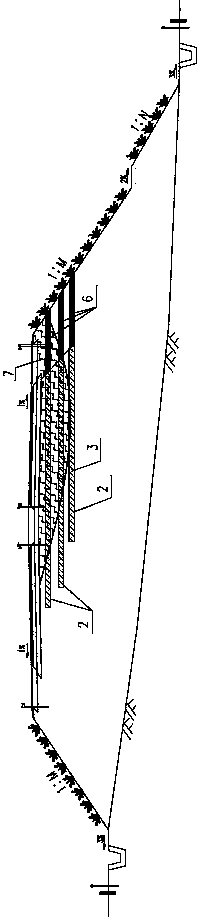

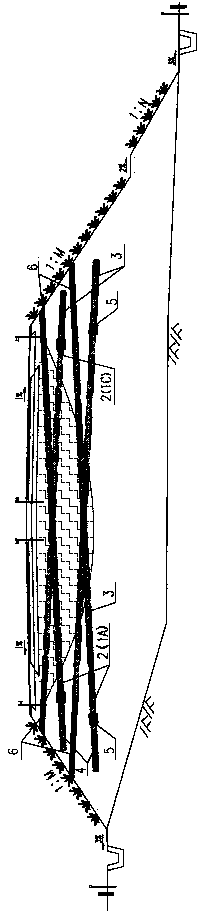

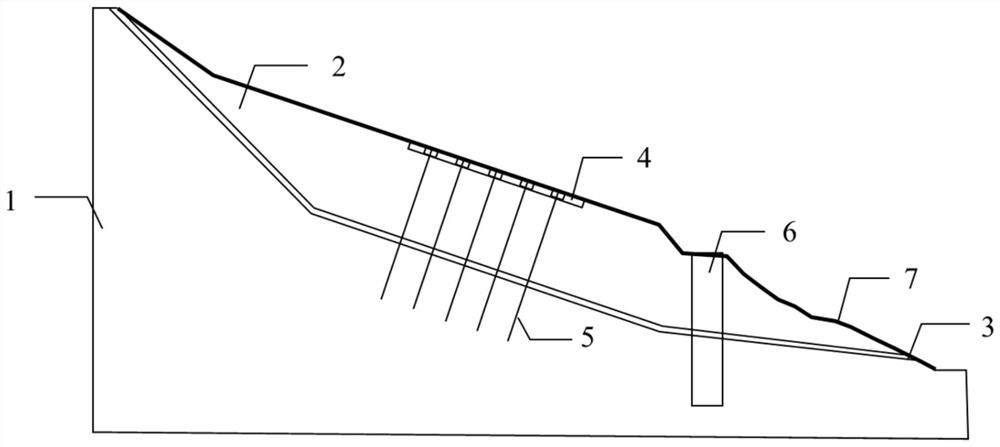

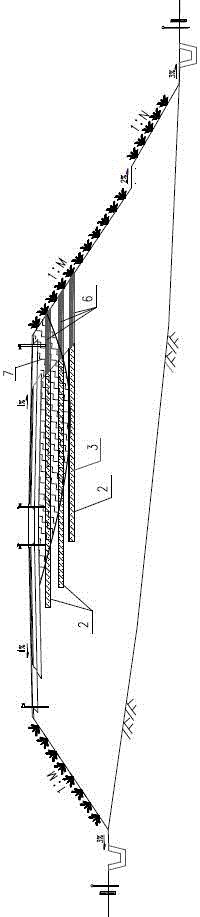

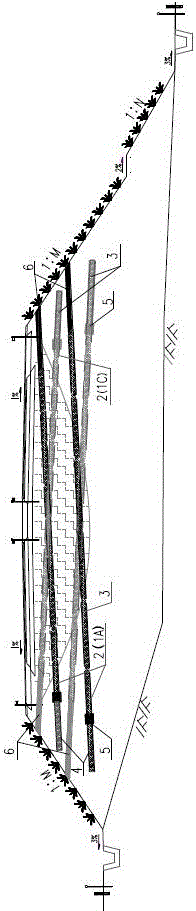

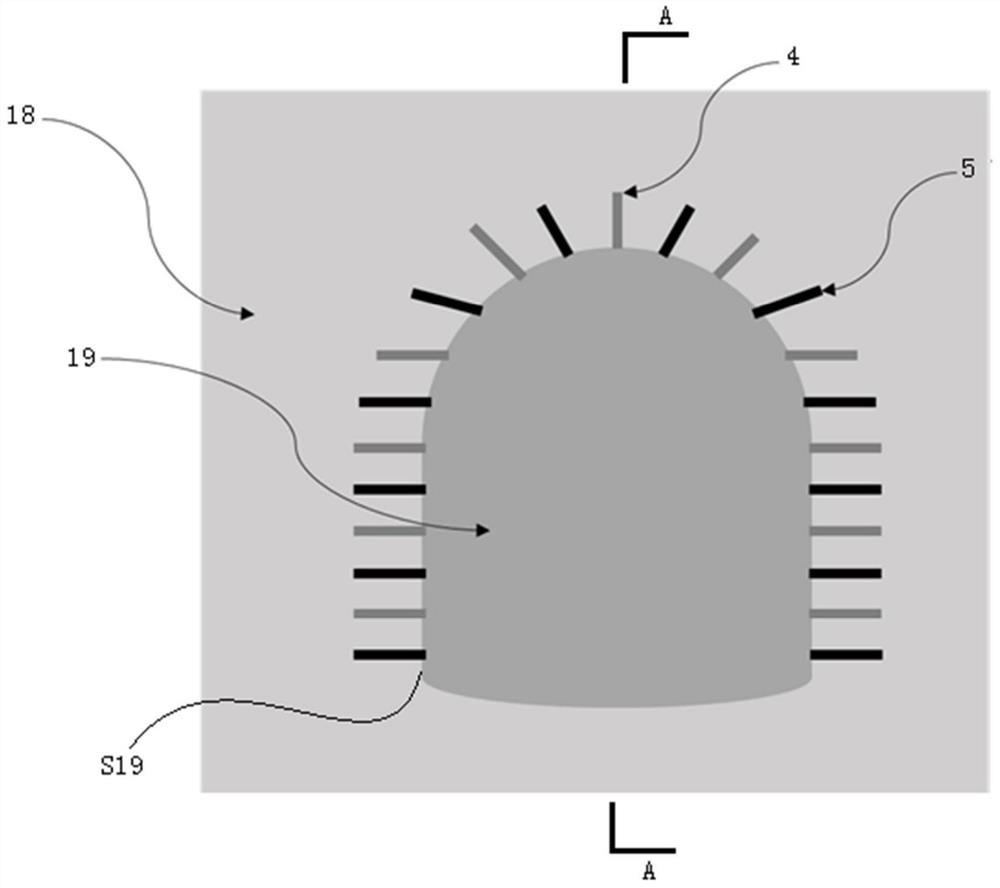

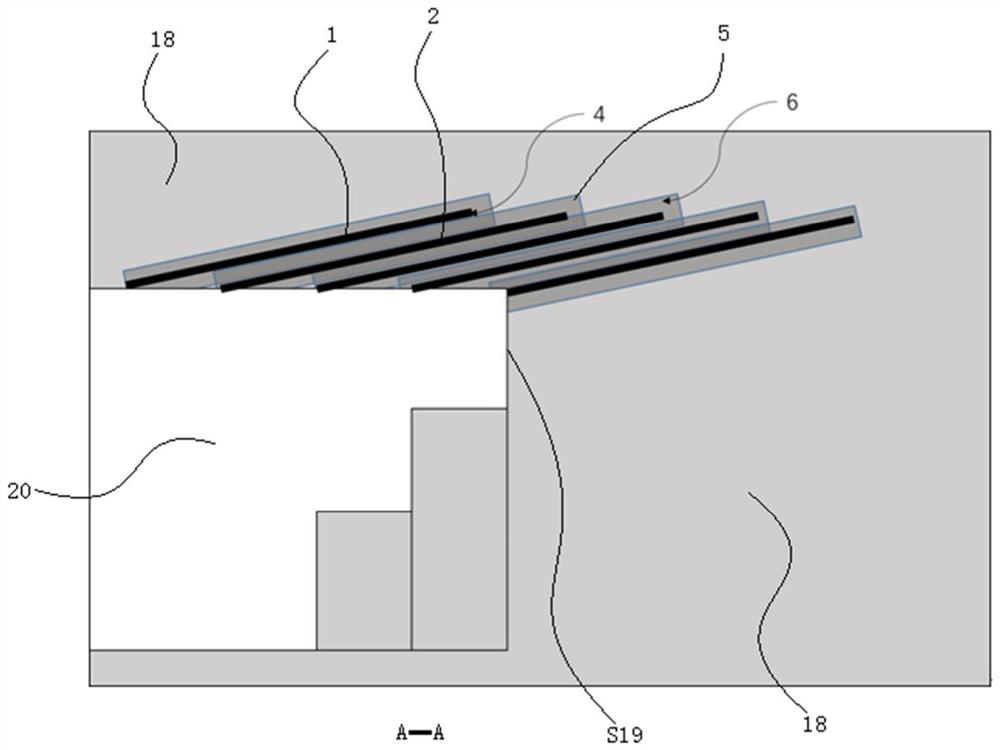

Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

ActiveCN103981782AGuaranteed integrityAvoid damageRoadwaysSoil preservationStructural engineeringCement grout

The invention discloses a method and a structure for reinforcing flat hole grouting roadbed without damaging road surface. The method comprises the following steps of A. determining the positions of grouting holes; B. drilling horizontal or slant grouting holes to ensure that the drilling angle is orthogonal to the main damaging direction of the roadbed; C. striking the grouting holes in an interlaced mode; D. drilling and grouting from the periphery of the damaged roadbed to the inside; E. arranging grouting floral pipes; F. arranging seamless grouting outer pipes at the front ends of the grouting holes which penetrate through the cross section of the roadbed and are dimensionally and crossly distributed; G. uniformly filling cement grouts and determining grouting pressure through tests and areas; and H. performing sedimentation, inclination, deformation and displacement observation on the roadbed surfaces, structures and surrounding buildings during grouting. Horizontal or inclined drilling is carried out on roadbed slopes in the affected area for forming the grouting holes, the grouting floral pipes and the seamless grouting outer pipes are arranged, and the grouting floral pipes are connected with the seamless grouting outer pipes by virtue of joint by screws. The method is feasible and convenient to carry out; because of no-damage road surface structure, the bearing capacity and the stability of the roadbed structure in the affected area are obviously improved, and the reinforcement effect is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Method for preparing geopolymer grouting material and method for applying geopolymer grouting material to static pressure grouting

ActiveCN106587782AReduce labor intensityLow viscosityCement productionRoads maintainenceSilica fumeSodium silicate

The invention provides a method for preparing a geopolymer grouting material and a method for applying the geopolymer grouting material to static pressure grouting. Raw materials for preparing the geopolymer grouting material include steel slag, mineral slag, sodium silicate, silica fume, calcium bentonite, softened water and a composite alkali activator. The method for preparing the geopolymer grouting material comprises the steps that 1, a component A is prepared; 2, a component B is prepared; 3, a component C is prepared; and 4, the geopolymer grouting material is prepared. The method for static pressure grouting comprises the steps of 1, survey; 2, assessment; 3, pit sounding; 4, hollowing general survey; 5, deflection value check; 6, comprehensive evaluation; 7, measurement and hole arrangement; 8, drilling; 9, grouting; 10, check; 11, grouting hole sealing; and 12, recheck to complete static pressure grouting. The methods have the advantages of environmental friendliness, low viscosity, high elasticity modulus, high cohesiveness, low cost, high efficiency and high durability.

Owner:中能化江苏矿山生态研究院有限公司

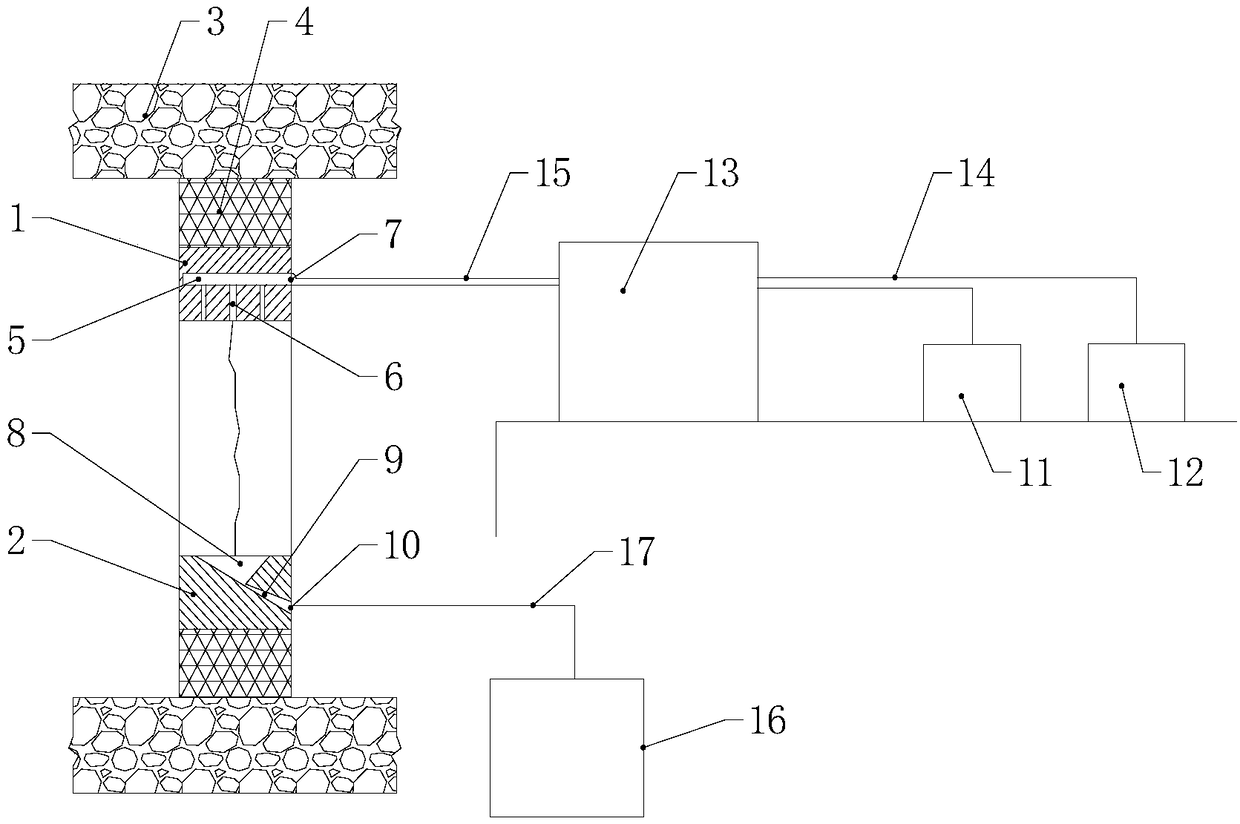

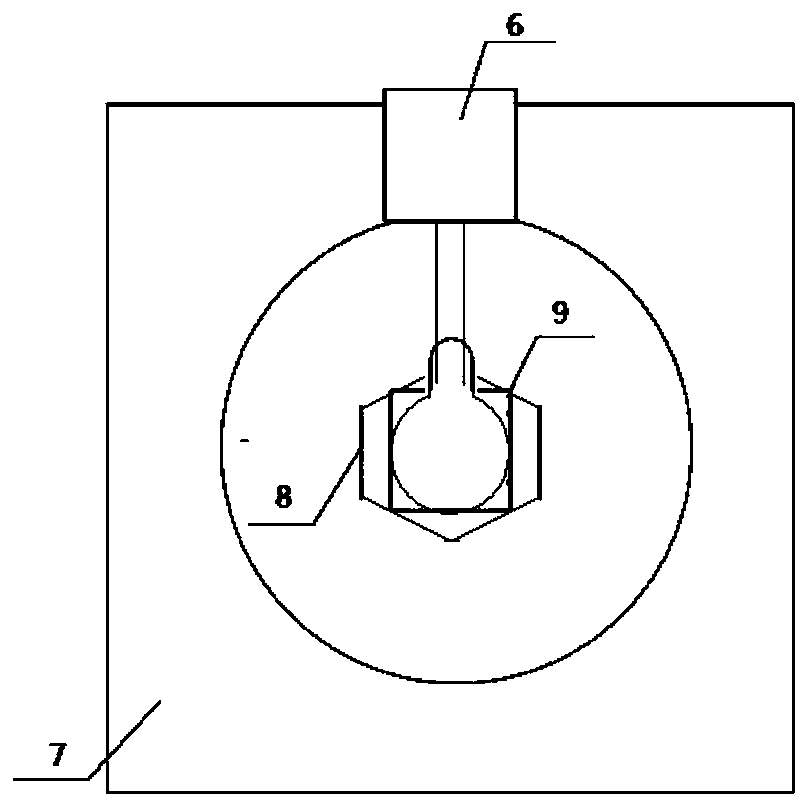

Novel grouting experiment device for fractured rock mass microorganism and experiment method thereof

InactiveCN109270211ASimple structureEasy to manufactureChemical analysis using titrationTitrationRock body

The invention discloses a novel grouting experiment device for fractured rock mass microorganism and an experiment method thereof. The experiment device comprises a grouting top cover, a grouting bottom cover, a grouting device and a waste liquid collecting device, RSM ultrasonic rebound detector receiving probes are respectively arranged between the grouting top cover and a corresponding fixed device and the grouting bottom cover and a corresponding fixed device, and a grouting cavity and an upper flow guiding hole are formed in the grouting top cover; a liquid inlet is formed in the side wall of the grouting top cover, a liquid receiving groove and a lower flow guiding hole are formed in the grouting bottom cover, and a liquid outlet communicated with the lower flow guiding hole and thewaste liquid collecting device is formed in the side wall of the grouting bottom cover. The experiment method comprises the steps of grouting liquid preparation, test piece installment, setting of titration speed and experiment result measuring after different parameters are changed. By adopting the experiment device and the experiment method, the purposes that the experiment result is improved, the experiment cost is reduced, and the device and method are suitable for popularization to conduct experiment study are achieved.

Owner:CENT SOUTH UNIV

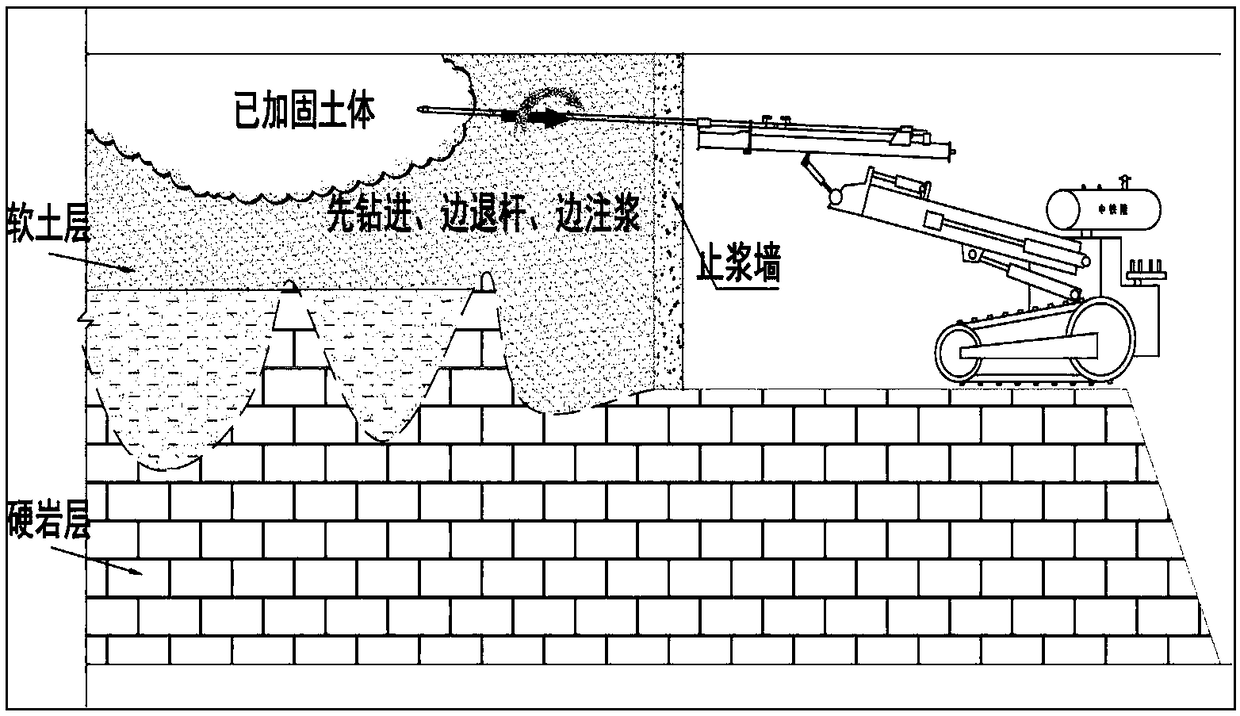

Construction method for undercrossing of urban shallow tunnel through soft-flow plastic red clay layer

ActiveCN108252719AEasy to reinforceSolve the problem of difficult groutingUnderground chambersTunnel liningRebarGrout

The invention discloses a construction method for undercrossing of an urban shallow tunnel through a soft-flow plastic red clay layer. The construction method comprises the following steps that 1, a simple grout-preventing wall is built, concrete is sprayed through a reinforcing mesh, and meanwhile annular implemented anchor bars are preliminarily erected on a tunnel face and connected with the reinforcing mesh into a whole; and 2, retrograde grouting is conducted, specifically, a down-the-hole drill drills in the tunnel face to drill forwards till the preset depth is reached, grouting work isconducted through a hollow drill rod, meanwhile the drill rod rotates and retreats, and the grouting pressure is controlled to be 0.5-1 Mpa. According to the construction method, low-pressure grouting processing operation of the soft-flow plastic red clay layer can be effectively achieved, the construction safety and urban pipe network road safety are guaranteed, and the construction schedule isaccelerated.

Owner:RANKEN RAILWAY CONSTR GROUP

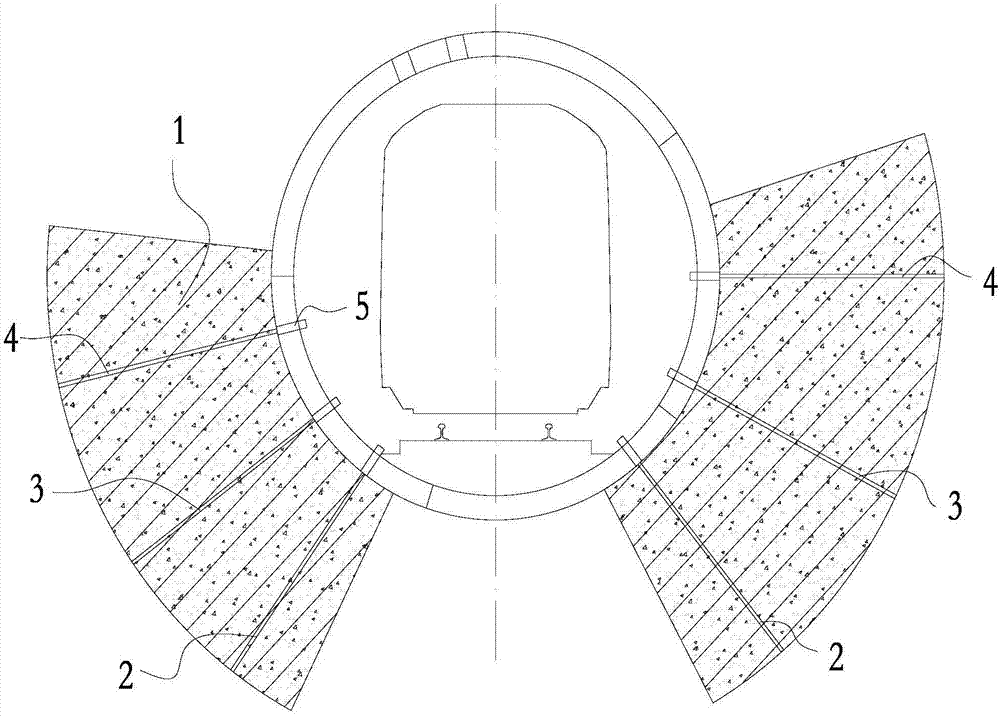

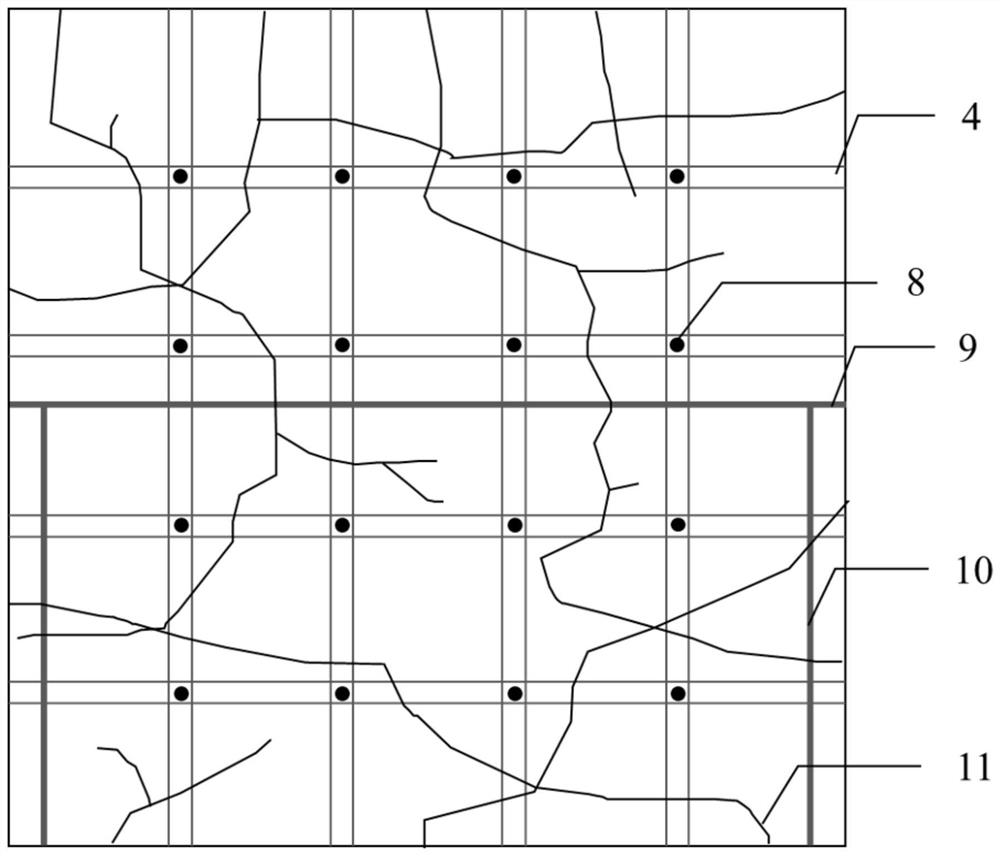

High-speed railway roadbed uneven settlement reinforcement lifting and leveling method

ActiveCN110241662APrevent proliferationLifting speed is fastRailway tracksSoil preservationEngineeringOperability

The invention relates to a high-speed railway roadbed uneven settlement reinforcement lifting and leveling method. The high-speed railway roadbed uneven settlement reinforcement lifting and leveling method comprises the following steps: S1, a reinforcement area is formed, specifically, the reinforcement area is formed in an embankment below a railway track through static pressure grouting; S2, curtain walls are formed, specifically, the curtain walls are formed on the positions, close to the slope toe, of the two sides of the embankment through static pressure grouting; and S3, lifting and leveling are conducted, specifically, an area between the reinforcement area and the curtain walls serves as an acting force pushing area, a static pressure grouting method is adopted, and by grouting the acting force pushing area, the upward grouting pressure is generated to evenly lift the embankment reinforcement area. The high-speed railway roadbed uneven settlement reinforcement lifting and leveling method has the advantages that a technology is simple, operability is high, interference is avoided, and the construction efficiency is high.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

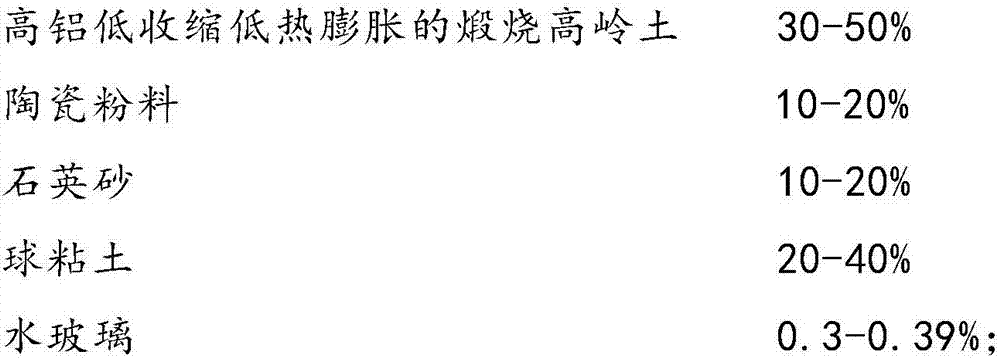

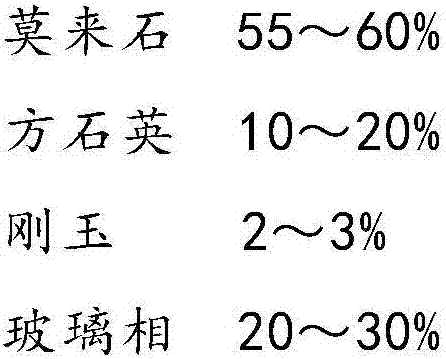

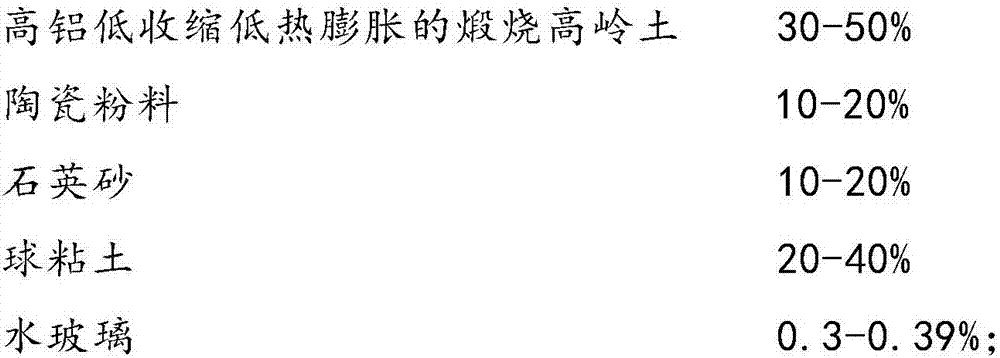

Ceramic forming slurry and high-pressure forming method

The invention relates ceramic forming slurry which comprises the following components in percentage by mass: 76%-80% of a raw material and 20%-24% of water. The raw material comprises the following components in percentage by weight: 30%-50% of high-aluminum low-shrink low-thermal-expansion calcined kaolin, 10%-20% of ceramic powder, 10%-20% of quartz sand, 20%-40% of ball clay and 0.3%-0.39% of water glass, wherein the molar ratio of the water glass is 1.5-3.5. The thickening degree of the slurry is increased from 50-80 degrees to 70-100 degrees by adding 0.3%-0.39% of water glass, and meanwhile, the viscosity of the slurry is also improved, so that the bonding property among blank bodies is greatly improved, a layering phenomenon, which is likely to happen (for example F-611), at double-sided pulp sucking parts in the prior art is substantially avoided, and the green blank rejection rate is reduced by about 3%; in addition, the permeability is improved, the grouting time is shortened, and the production efficiency is increased.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Shield tunnel reinforcement method

InactiveCN108005682AImprove reinforcementReduce in quantityUnderground chambersTunnel liningSleeve valveEngineering

The invention provides a shield tunnel reinforcement method. The method comprises the following steps that stirring piles are formed at the outer side of a shield tunnel; mortar injection holes are formed between the stirring piles and the shield tunnel, sleeve valve pipes are arranged in the mortar injection holes, and single-way valves are arranged at the upper ends of the sleeve valve pipes; gaps are formed between the mortar injection holes and the outer walls of the sleeve valve pipes and sealed by adopting accelerated cement mortar; grouting is conducted in the mortar injection holes, the grouting effect is inspected after grouting, and unqualified sections are subjected to hole patching and grouting. According to the shield tunnel reinforcement method, the reinforcement effect on the shield tunnel is good, the tunnel stratum can be prevented from rising, the stability of a subway rail is guaranteed, and then stable running of a subway is guaranteed.

Owner:GUANGZHOU METRO DESIGN & RES INST

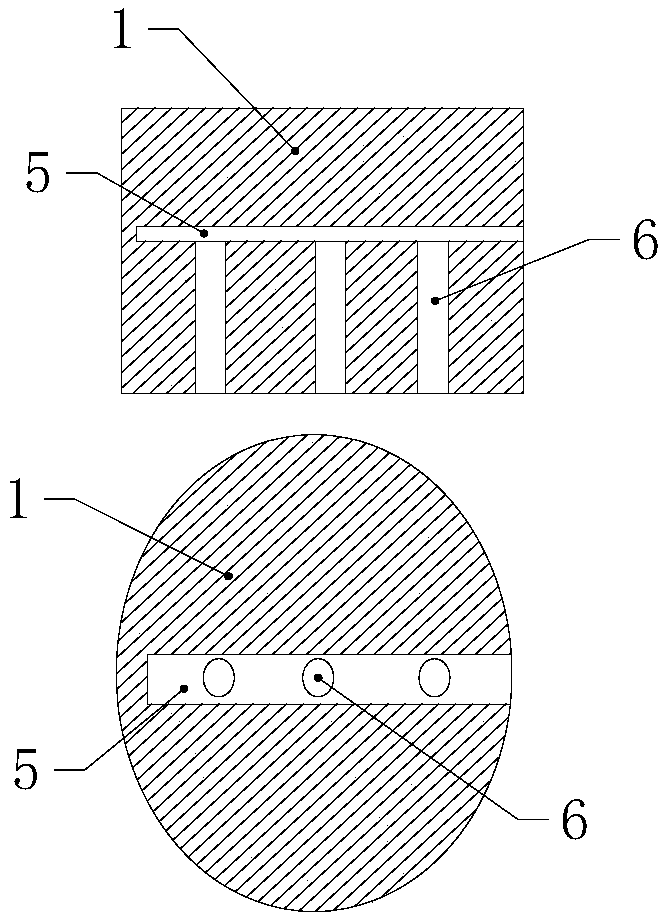

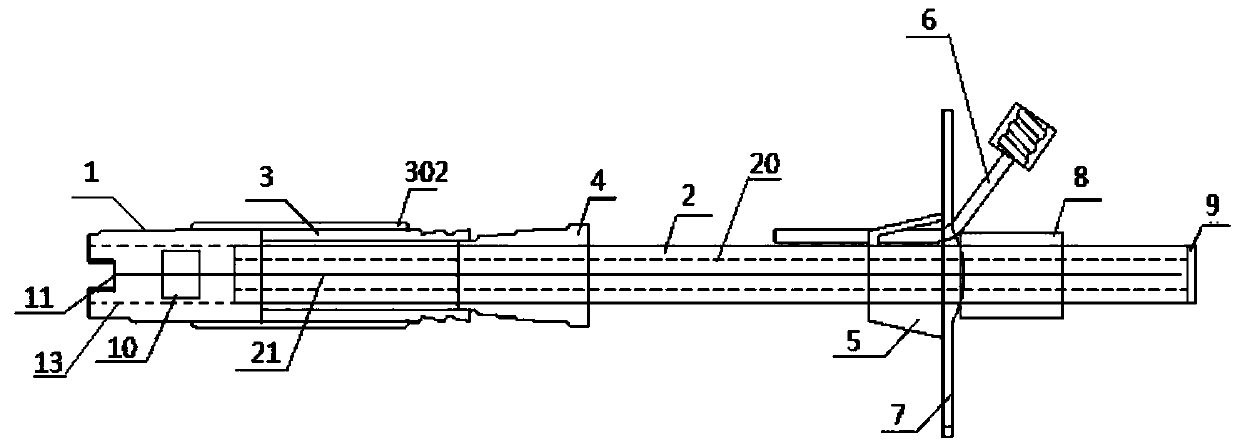

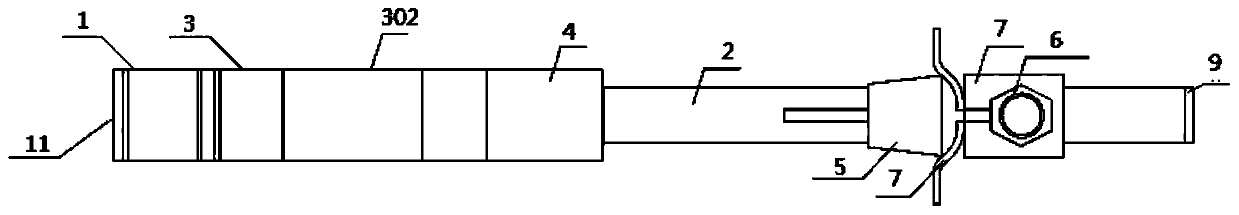

Grouting device and method suitable for single-point displacement meter in tunnel engineering

PendingCN107882568AImprove work efficiencyIncrease job securityTunnelsMechanical engineeringTube drain

The invention discloses a grouting device and method suitable for a single-point displacement meter in tunnel engineering. The grouting device is composed of a fixed and sealed base, a grouting pipe,air and water discharging pipes and a sensor device; the sensor device is fixed to the center of the fixed and sealed base and is connected with a measuring rod provided with a protection pipe; a grouting channel and an air and water discharging channel are formed in the fixed and sealed base, wherein the grouting channel is provided with the grouting pipe, and the air and water discharging channel is provided with the air and water discharging pipes; the grouting pipe and the air and water discharging pipes both extend to the two sides of the fixed and sealed base; and the grouting finish time is determined through pulp returning of the air and water discharging pipes.

Owner:SHANDONG UNIV +1

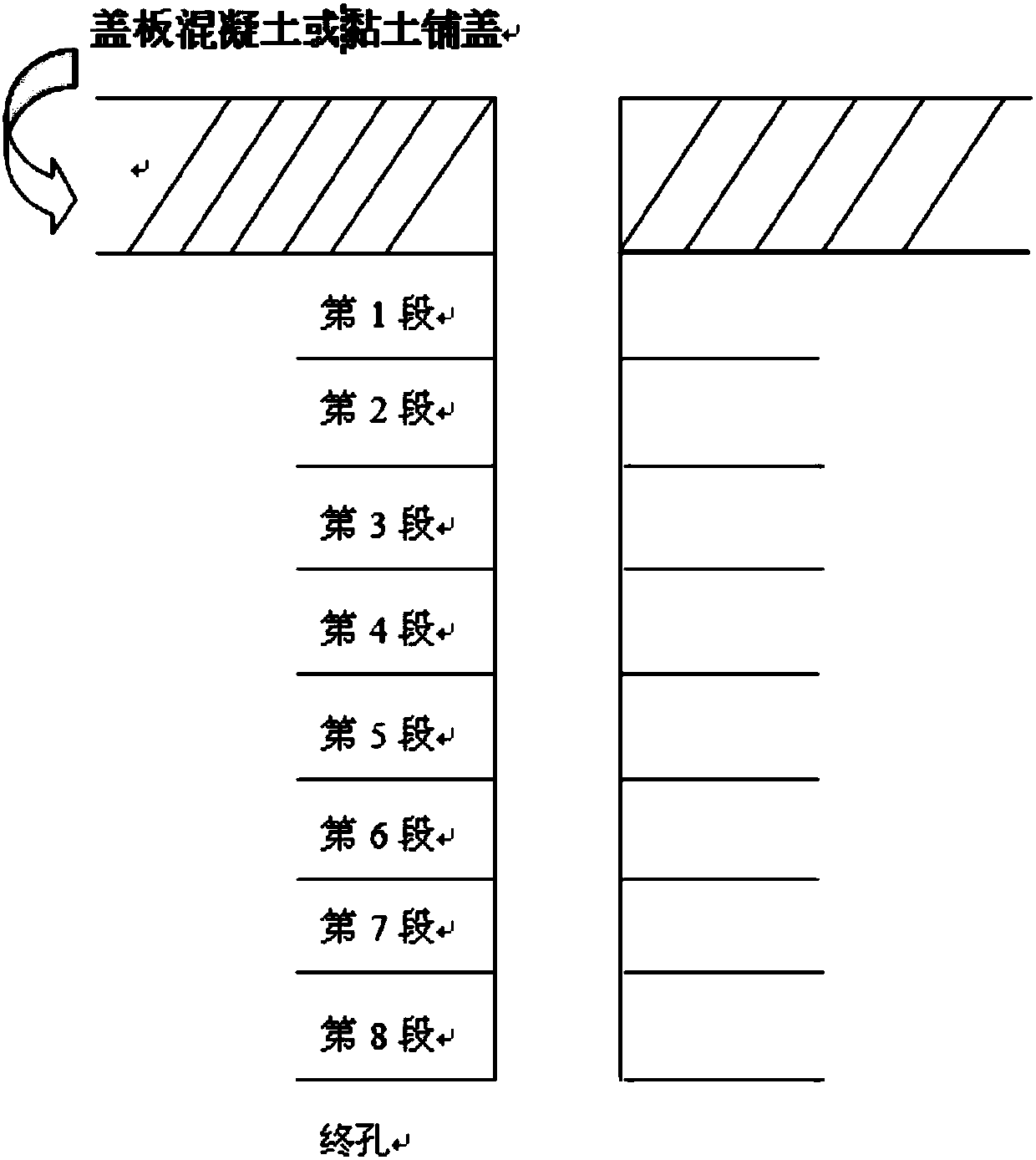

Drilling and grouting construction method for sand gravel stratum

ActiveCN107747312ASimplify the difficulty of installation and operationAvoid enteringBulkheads/pilesGroutEnvironmental geology

The invention belongs to the technical field of civil engineering, and relates to a drilling and grouting construction method for a sand gravel stratum. The drilling and grouting construction method for the sand gravel stratum comprises the following steps that firstly, hole drilling is carried out, and pipe following drilling is conducted for downward feeding of a wall protection casing pipe; secondly, a grout pipe line is downwards fed; thirdly, an orifice blocking device is installed; fourthly, according to grouting procedures, a proper water cement ratio is adopted for grouting and grout proportioning changing till grouting completion; and fifthly, grouting construction is carried out. The drilling and grouting construction method for the sand gravel stratum has the beneficial effectsthat the problems caused when a perforated pipe enters the sand gravel stratum are solved; the setting depth is controllable, and compared with an inserting and beating method, the drilling and grouting construction method is easy to conduct; the problem that in the process of pulling out the casing pipe, the sand gravel stratum collapses, and consequently the perforated pipe is blocked is prevented, and the problem that slip casting cannot be effectively conducted in the sand gravel stratum is solved; the installation and operation difficulty of a stop-grouting plug is lowered; the effect onthe grouting diffusion radius is relatively small; the process defects are overcome, and the grouting quality is reliable; and the drilling and grouting construction method is suitable for any sand gravel stratum, can be implemented without process tests and has very obvious beneficial effects for a region where the stratum is complex.

Owner:SINOHYDRO BUREAU 11 CO LTD

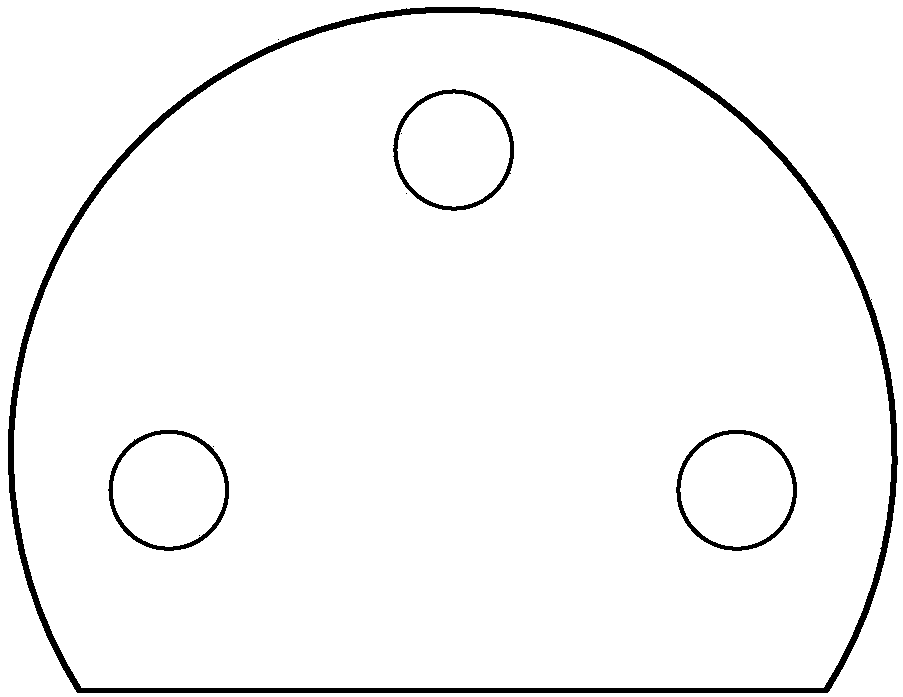

Compacting grouting method

ActiveCN108005681AConsistent structureStable structureUnderground chambersTunnel liningSleeve valveCement mortar

The invention provides a compacting grouting method. The compacting grouting method comprises the following steps of drilling grouting holes in a standard block of an annular pipe sheet, wherein the grouting holes comprise the first set of grouting holes, the second set of grouting holes and the third set of grouting holes which are symmetrically distributed from bottom to top in sequence; installing sleeve valve pipes in all the grouting holes, and installing one-way valves at the upper ends of the sleeve valve pipes; adopting rapid hardening cement mortar to seal the gaps formed by outer walls of the grouting holes and the outer walls of the sleeve valve pipes; conducting symmetric grouting on the first set of grouting holes, the second set of grouting holes and the third set of groutingholes from bottom to top in sequence; after grouting is finished, checking the grouting effect, and conducting hole patching grouting for unqualified sections; after grouting construction is finished, immediately cleaning the sleeve valve pipes, a grouting machine and an agitator. By means of the compacting grouting method, the grouting efficiency can be improved, and the stability of structuresof the two sides of a tunnel is guaranteed, so that a subway is steadily run.

Owner:GUANGZHOU METRO DESIGN & RES INST

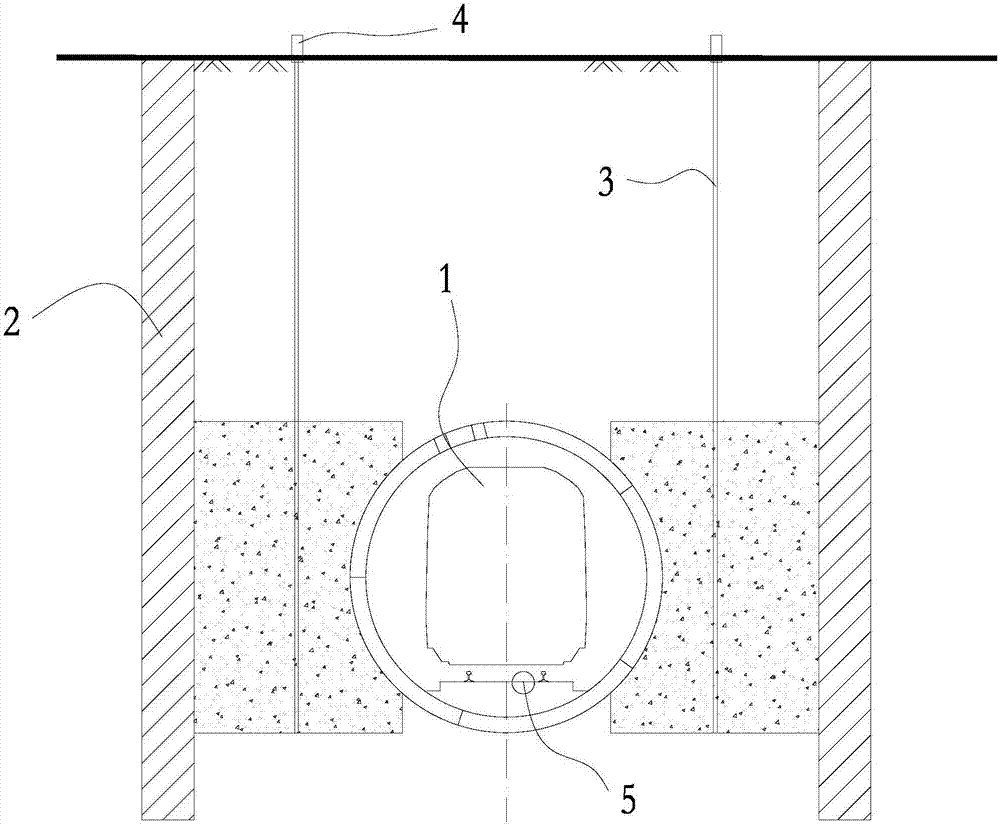

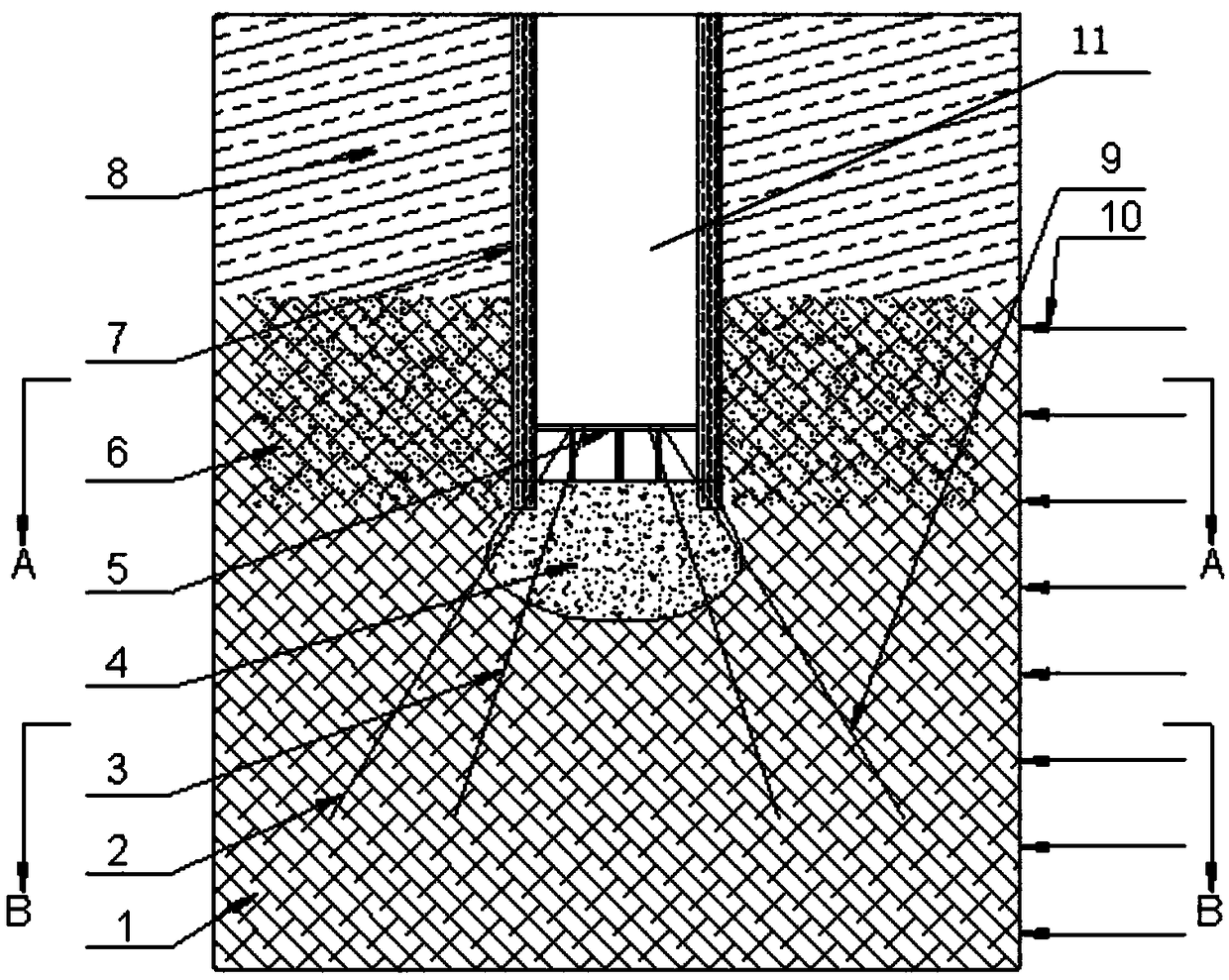

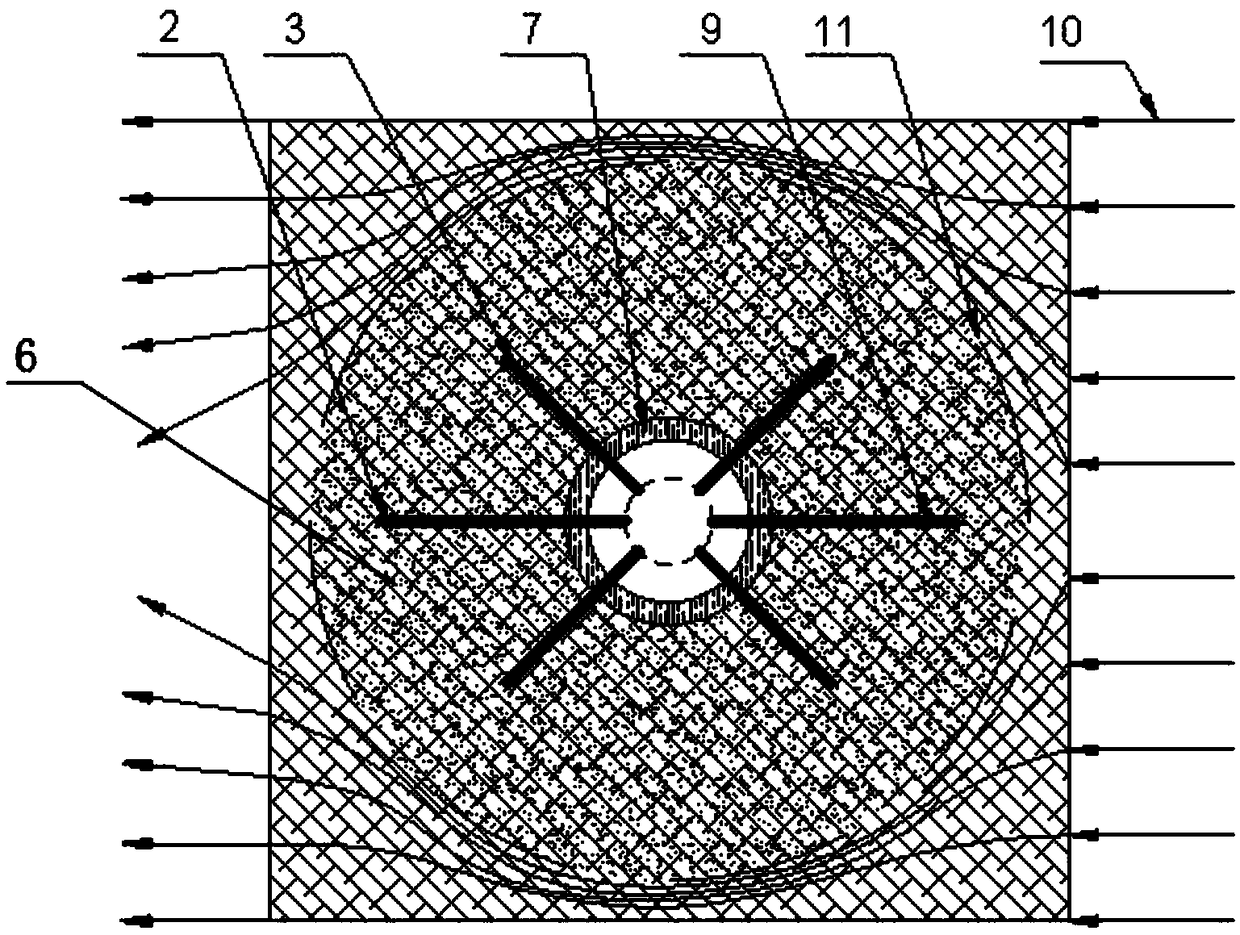

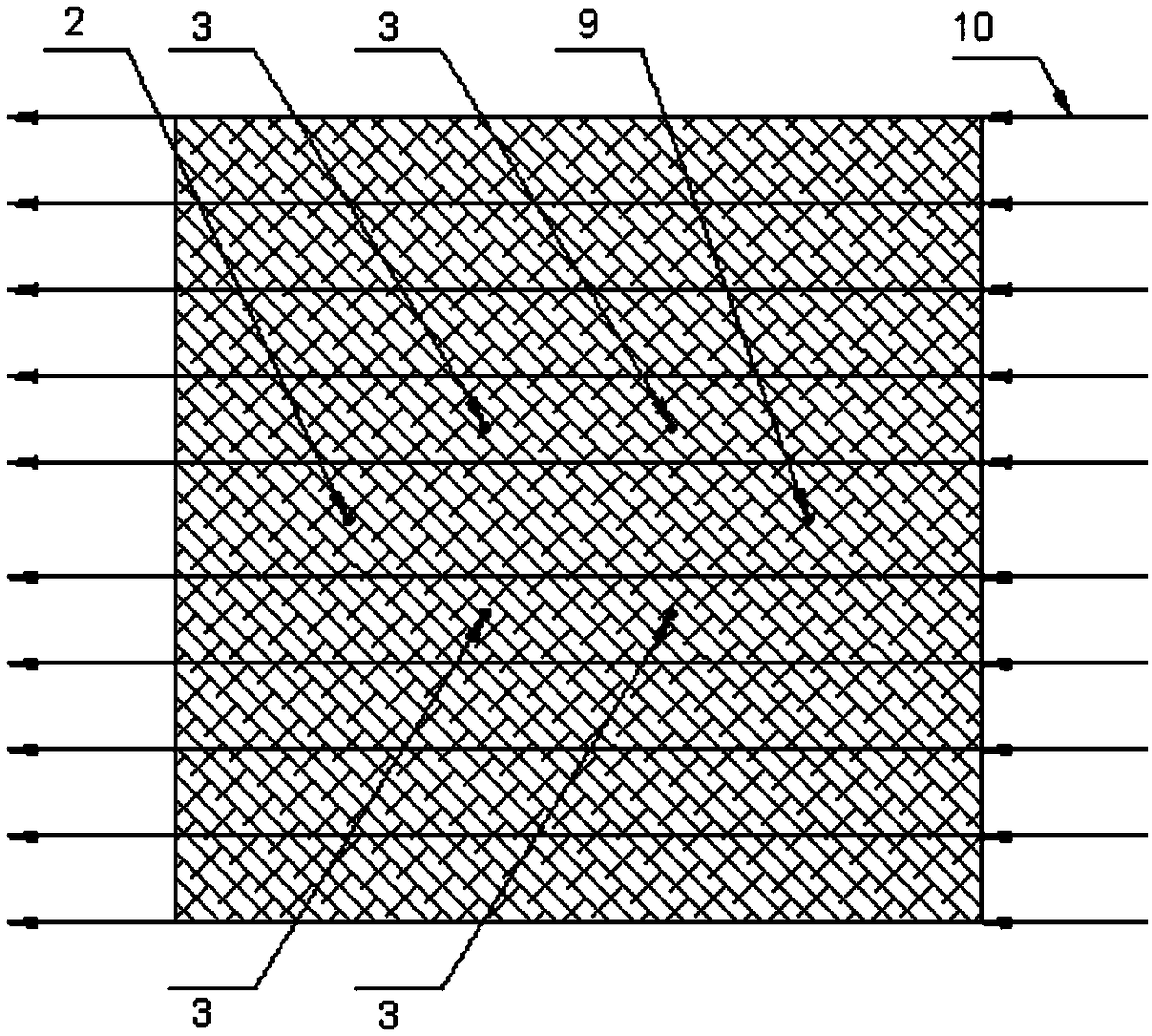

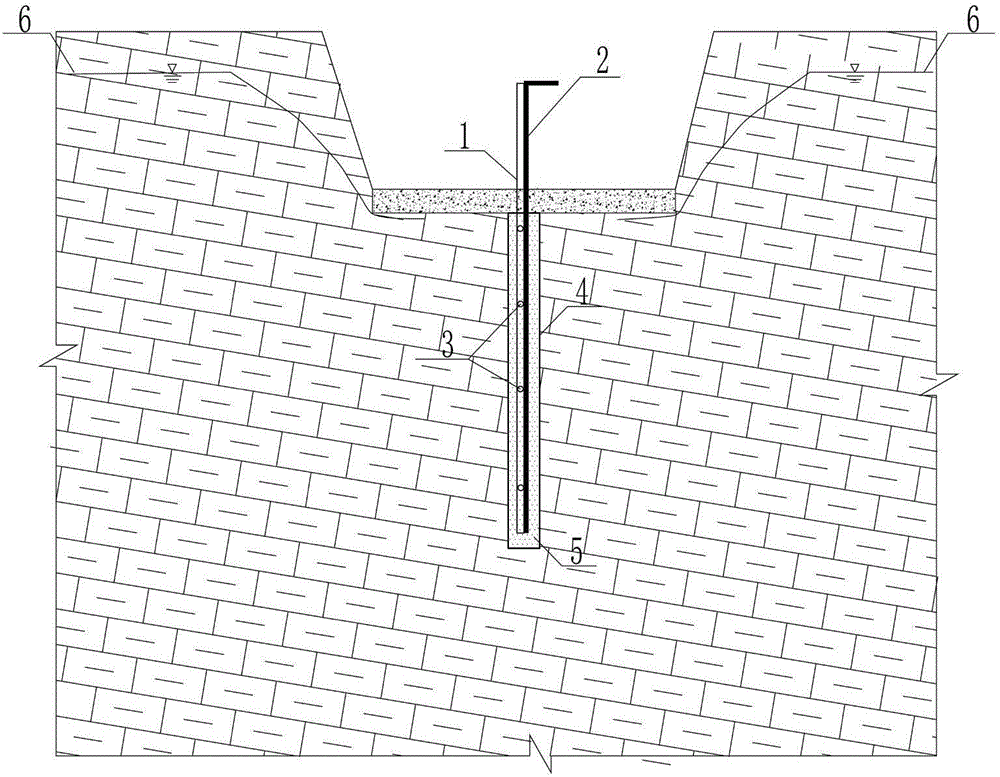

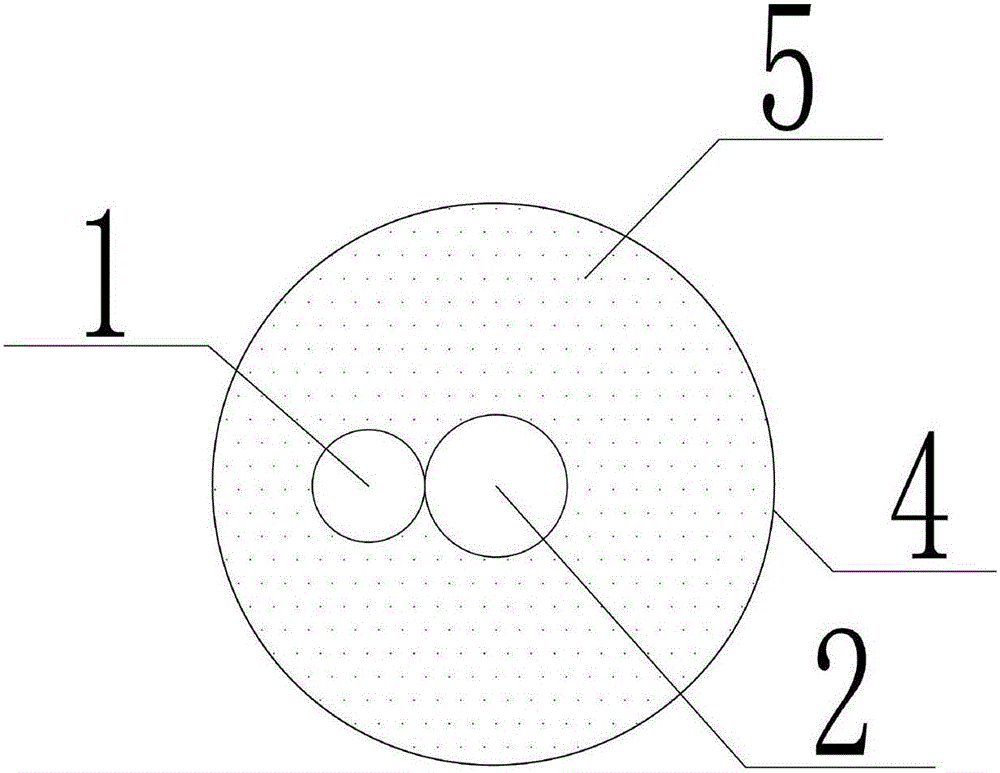

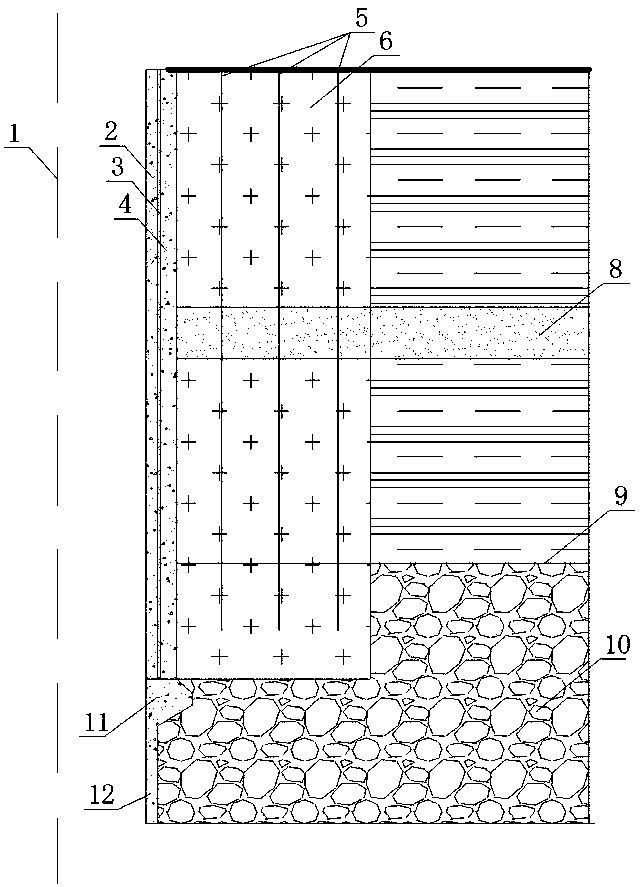

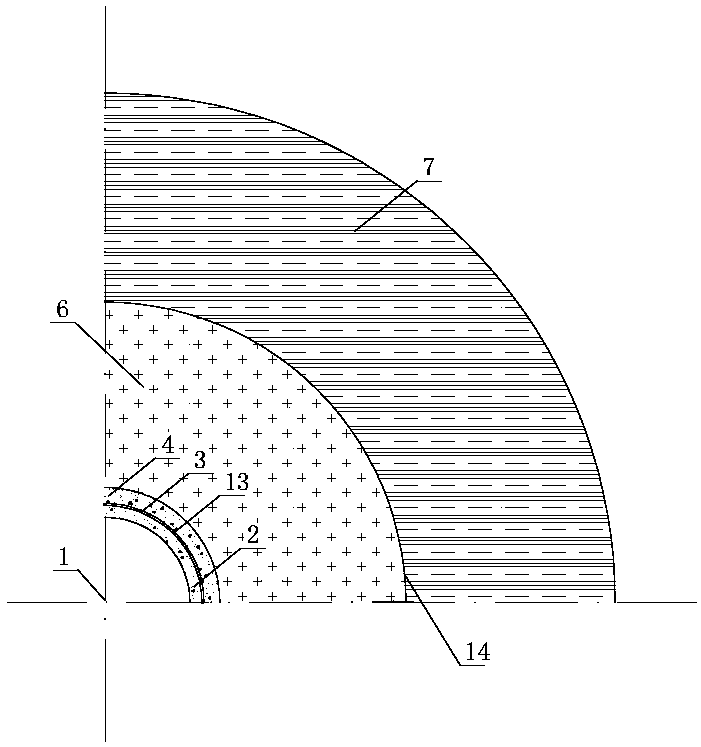

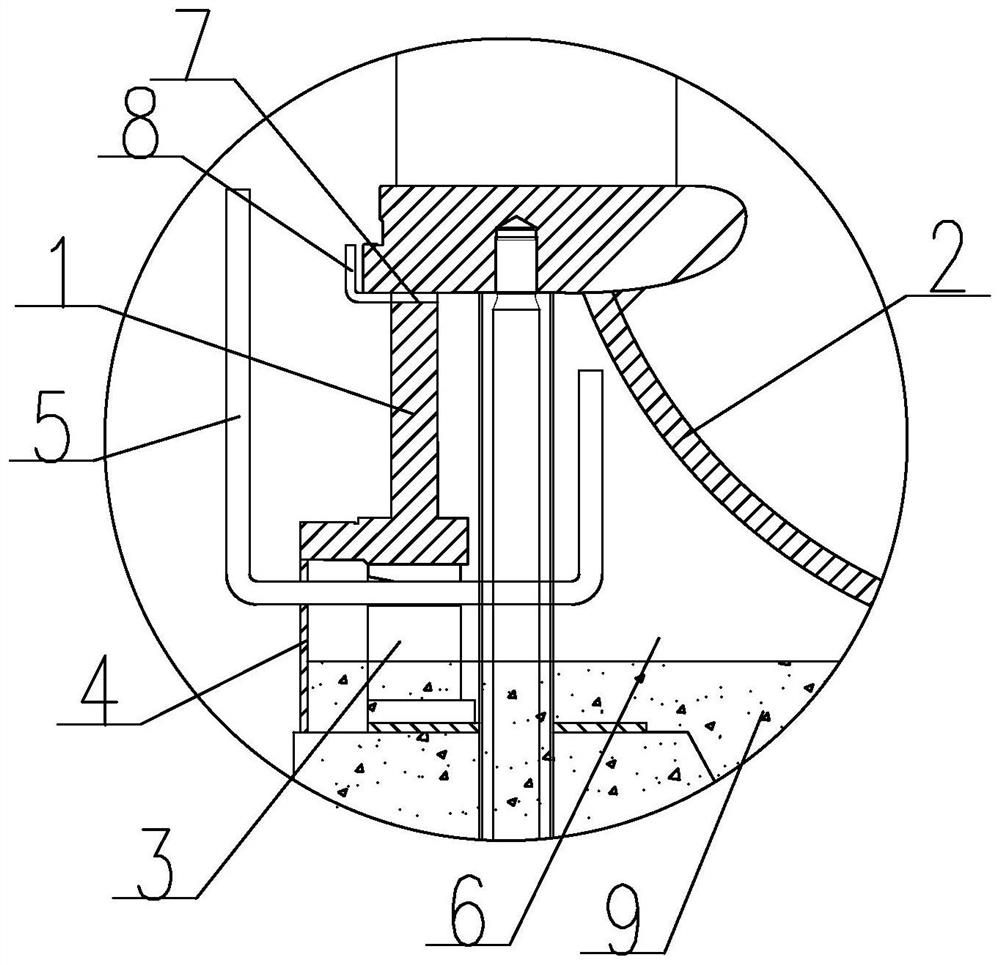

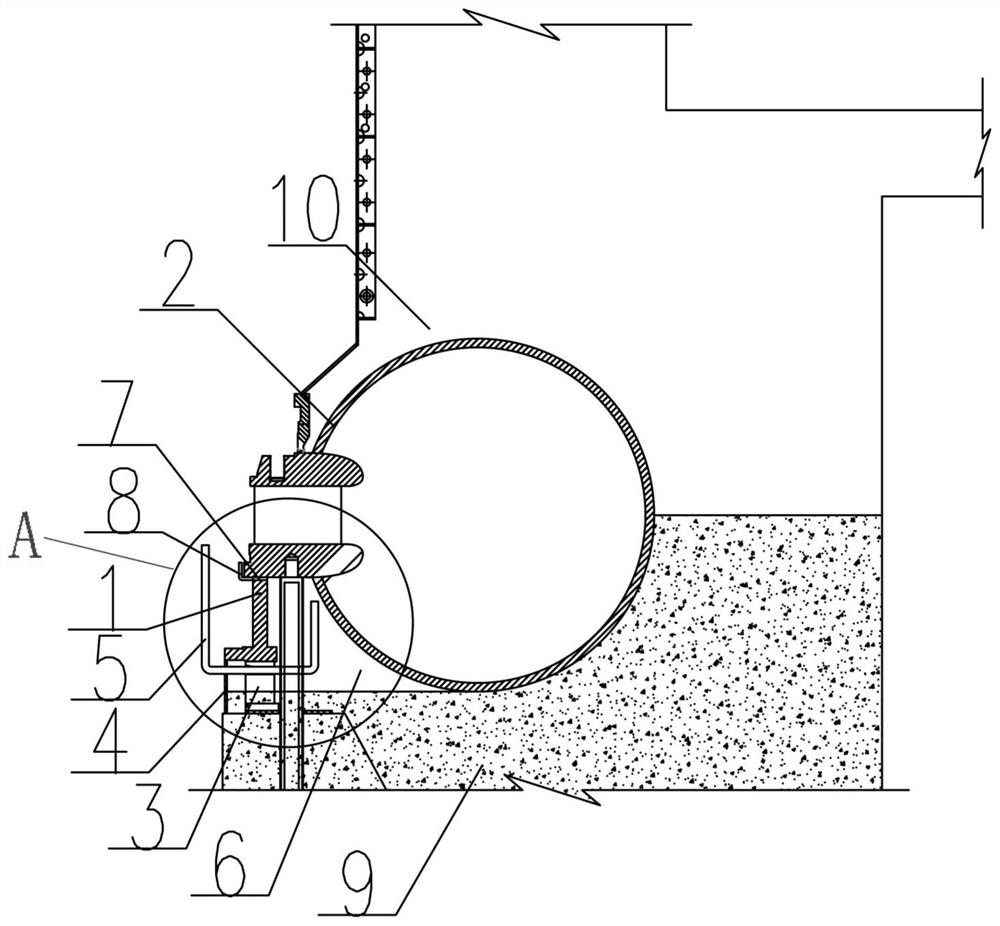

Novel method for preventing water inrush from shaft wall in shaft aquifer sinking

The invention discloses a novel method for preventing water inrush from the shaft wall in shaft aquifer sinking. A grouting pad (4) is constructed, and an operating platform (5) is mounted on the constructed grouting pad (4); a grouting hole (3), a water injection hole (2) and a water pumping hole (9) are obliquely, downwardly and outwardly drilled from the grouting pad (4) on the working platform(5), and the water pumping hole (9) is arranged at the upstream of a water flow field (10); water is injected into the water injection hole (2), water is pumped out of the water pumping hole (9), andgrout is then injected into the grouting hole (3). According to the invention, by water pumping and drainage, the water flow field and water pressure distribution of a to-be-grouted area are controlled, consequently, grout can be uniformly diffused into the grouted are, the phenomenon of grout runout is reduced, moreover, grouting pressure is moderately decreased, and furthermore, the grouting cost is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

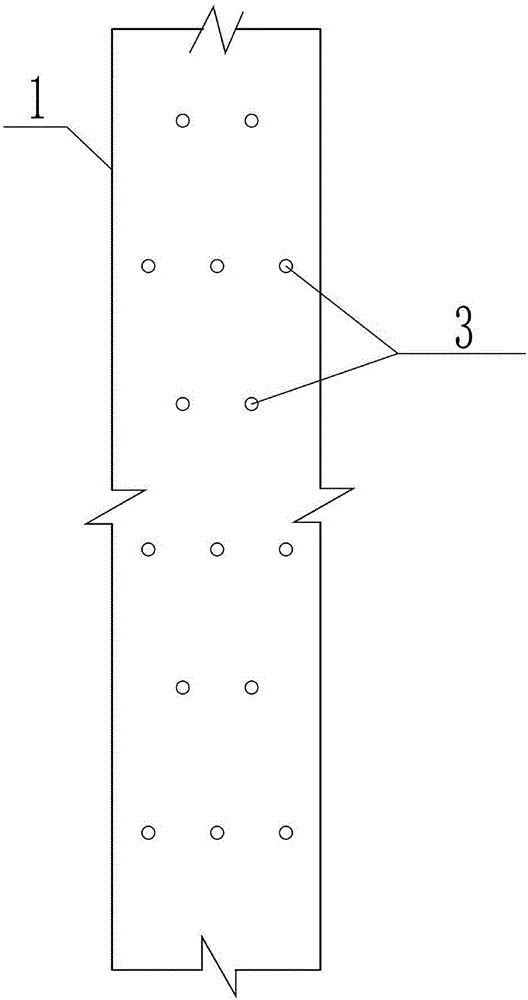

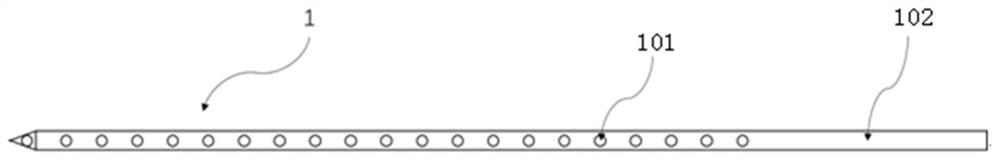

Carbonate rock area pulling-resistant anchor rod grouting and drainage device and construction method thereof

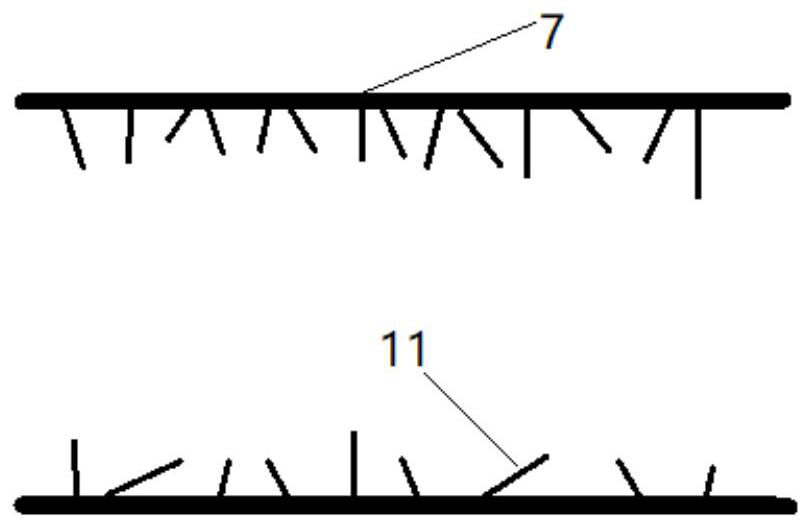

InactiveCN106555399ASolve the problem of difficult groutingGrouting pressure is smallProtective foundationBulkheads/pilesRock boltSteel tube

The invention discloses a carbonate rock area pulling-resistant anchor rod grouting and drainage device and a construction method of the carbonate rock area pulling-resistant anchor rod grouting and drainage device. The device comprises a steel pipe and an anti-floating anchor rod. The anti-floating anchor rod and the steel pipe are bound and fixed side by side and stretch into a grouting hole, and the section, stretching into the grouting hole, of the steel pipe is provided with sieve holes. The steel pipe with the sieve holes and the anti-floating anchor rod are bound, fixed and placed into the anchor rod grouting hole, and drainage and pressure relief are carried out through the sieve holes during grouting, so that grouting pressure is effectively reduced, the grouting difficulty is lowered, grouting is rapider, particularly, the secondary grouting effect is better, the problem that grouting of the anti-floating anchor rod is difficult due to the high water pressure of a carbonate rock area is effectively solved, and the carbonate rock area pulling-resistant anchor rod grouting and drainage device further has the advantages of being simple in structure, low in cost and convenient to operate.

Owner:ZHENGYE ENG & INVESTMENT INC

Landslide prevention and control method based on microbial mineralization

ActiveCN113882407AImprove coordinationGood control effectClimate change adaptationProtective foundationMicroorganismSoil science

The invention belongs to the crossing field of geotechnical engineering and microbial engineering, and particularly relates to a landslide prevention and control method based on microbial mineralization. The landslide prevention and control method comprises the steps that microbial liquid and cementing liquid are sequentially added to the surface of a soil body and the potential sliding face of the soil body, and meanwhile sand anti-slide piles and sand lattices are prepared in the soil body through the microbial liquid and the cementing liquid; and a sand drainage ditch and a sand intercepting ditch are arranged in the soil body, the microbial liquid and the cementing liquid are sequentially sprayed to the sand drainage ditch and the sand intercepting ditch, and the purpose of stabilizing the soil body is achieved. According to the landslide prevention and control method, landslide prevention and control are conducted from multiple angles, considered factors are comprehensive, the prevention and control effect is good, adopted bacteria widely exist in the soil body in the nature, and the environment coordination is good; chemical substances used in the adopted microbial liquid and the cementing liquid are non-toxic and harmless substances, and the environment friendliness is high; and used sand is originally existing substances in the nature, and influences hardly exist on the environment.

Owner:NANJING UNIV +1

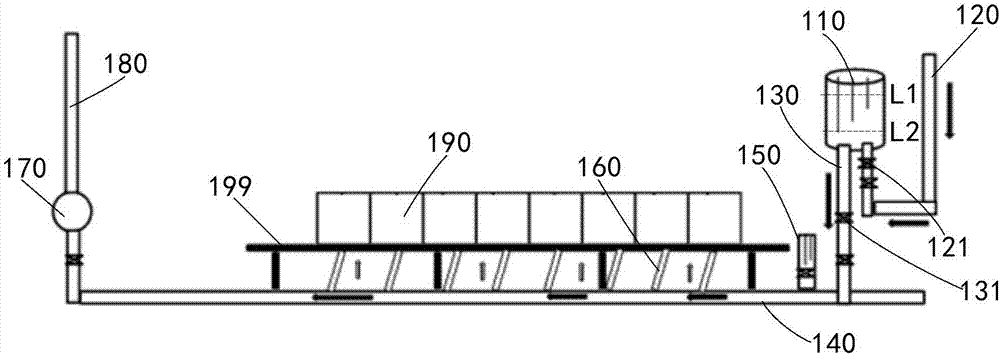

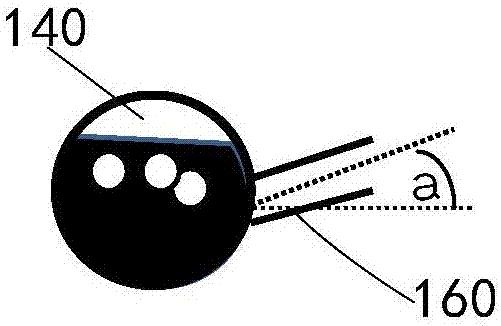

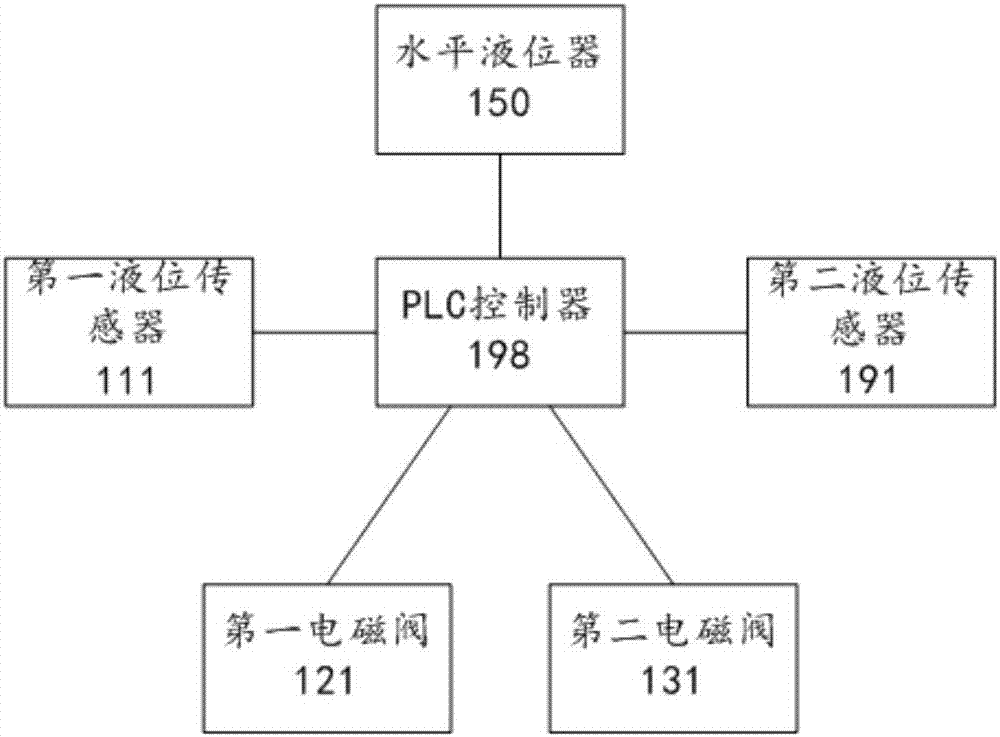

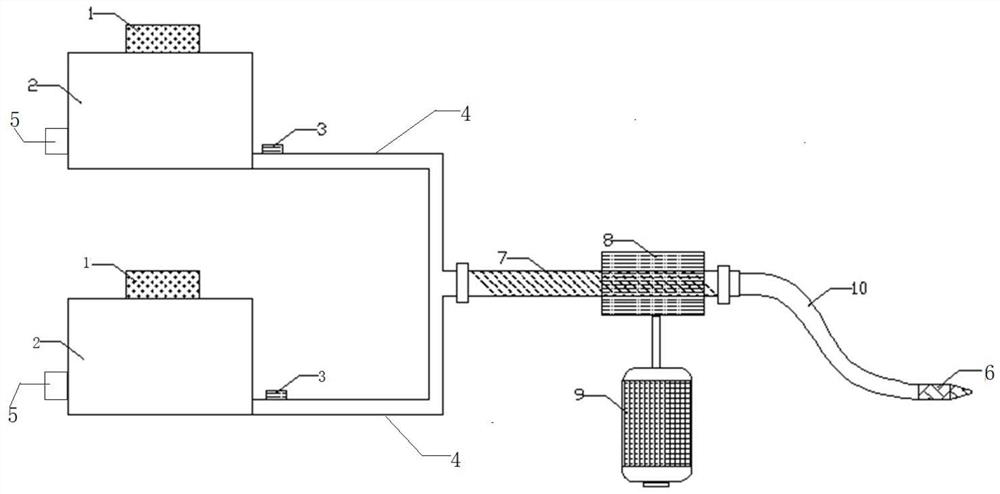

Grouting forming method for ceramic blanks

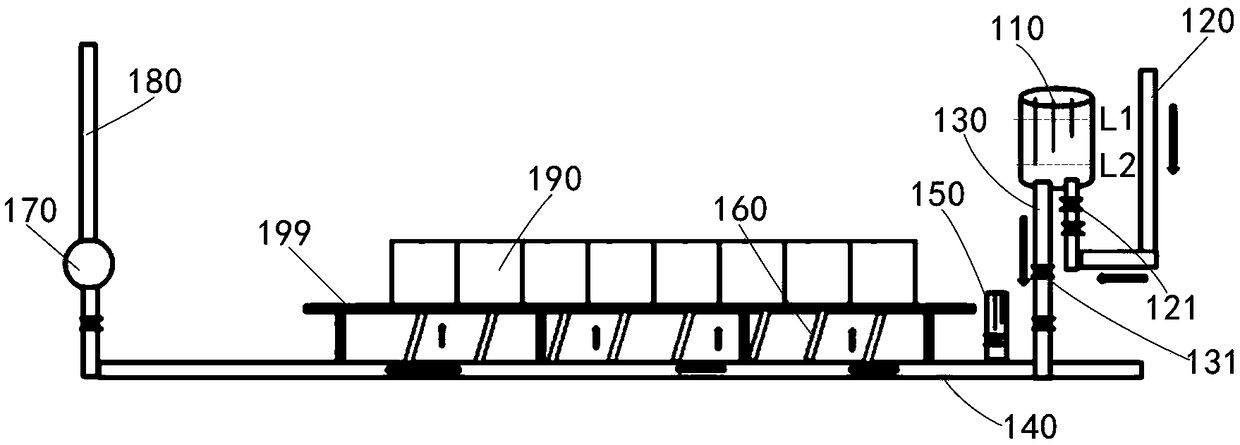

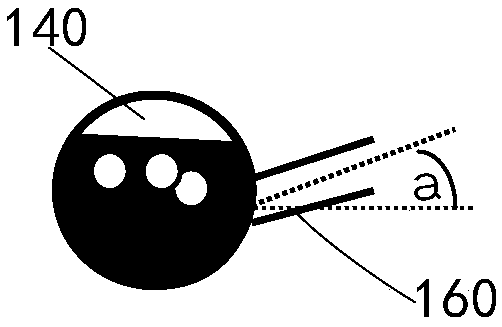

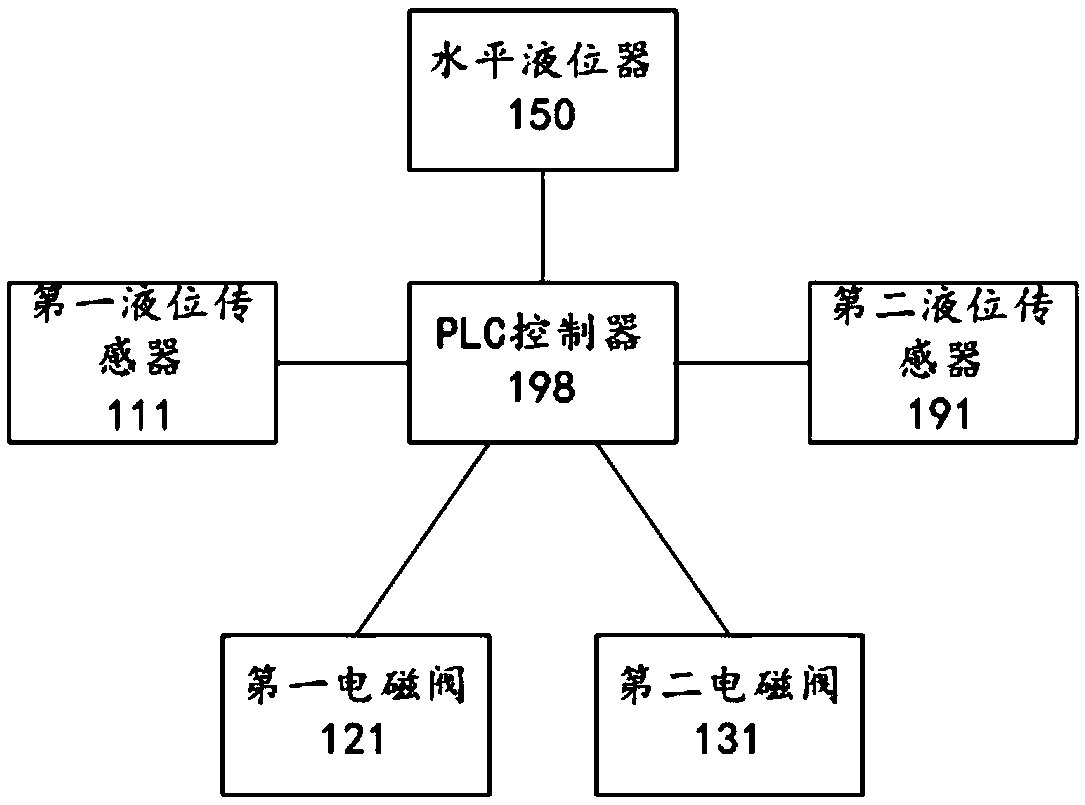

A grouting forming method for ceramic blanks comprises the steps of grouting, slurry blanking, slurry mold injection preparation and slurry mold injection forming. According to the grouting forming method for the ceramic blanks, the liquid level in a grouting barrel is controlled through a first liquid level and a second liquid level, the relatively constant grouting pressure can be kept in grouting and is small, slurry is prevented from leaking from seams of a mold, the effect that the same height (a preset liquid level) is kept when the slurry enters the mold is guaranteed through a horizontal liquid level device before slurry mold injection, it is ensured that air in a pipeline is completely exhausted, and the thickness difference between the blanks is reduced.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

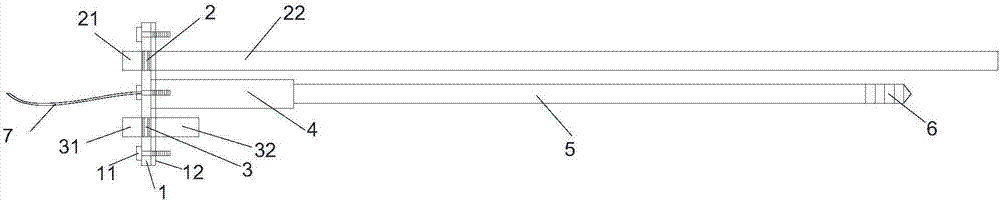

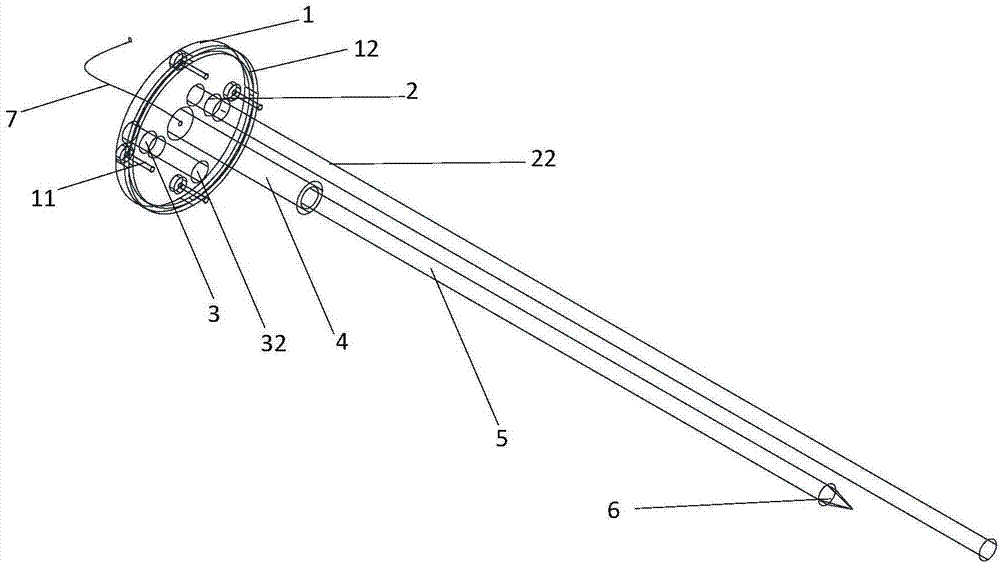

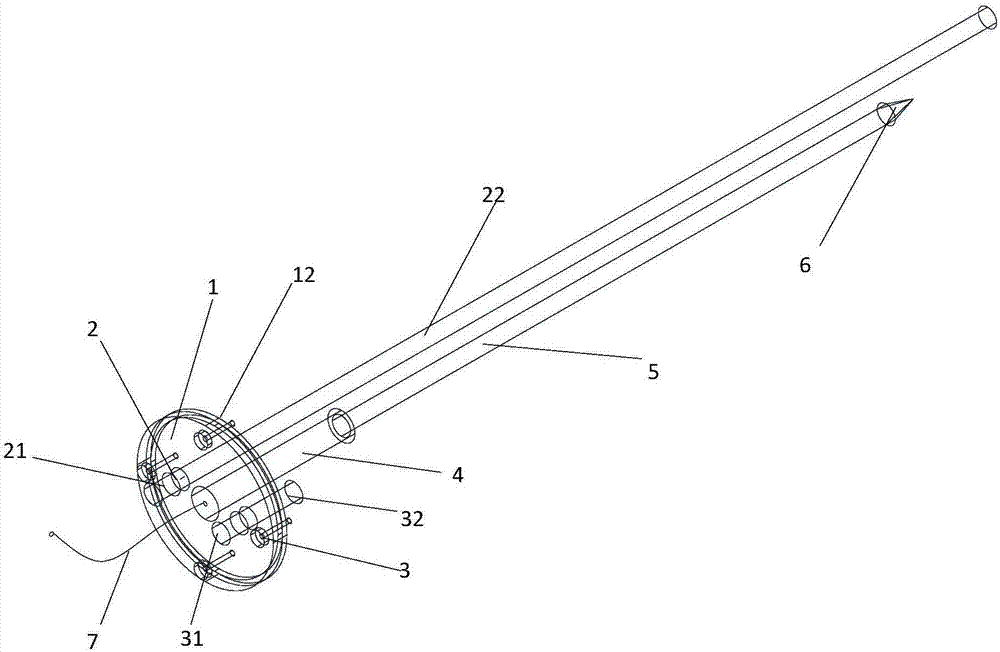

Hollow anchor rod having functions of geological detection and anchoring and exhaust and grouting method of hollow anchor rod

PendingCN110630304AFlexible opening sizeEasy to installExcavationsBulkheads/pilesEngineeringUltimate tensile strength

The invention discloses a hollow anchor rod having functions of geological detection and anchoring and an exhaust and grouting method of the hollow anchor rod. The hollow anchor rod comprises an expansion-shell anchor head, an anchor rod, an expansion shell piece, an expansion shell, a steel plug, a grouting stop plug, a grouting pipe, a cushion plate, a nut and a plug head. The exhaust and grouting method comprises the ways that (1) the hollow anchor rod having the functions of geological detection and anchoring is downwards placed in an anchor hole formed by a drill when the hollow anchor rod is used for a side wall or a part with a downwards-inclining anchor hole, the bottom of the anchor hole is jacked up by the expansion-shell anchor head, and a process of performing grouting in the anchor rod and exhausting grout and gas at the anchor hole is employed; and (2) a process of performing grouting at the anchor hole by the grouting pipe and exhausting grout and gas through the expansion-shell anchor head is employed when the hollow anchor rod is used for an arc part or a part with a downwards-inclining anchor hole having a pitching angle larger than 30 degrees. The hollow anchor rod has high anchoring function, and the strength required by tension can be instantaneously achieved; moreover, the hollow anchor rod is convenient and safe to operate, and the construction safety risk is reduced; and the anchor head is flexible in expansion size, a forecast induction chip is convenient to install, and the forecast function of measuring geological disaster is achieved.

Owner:李顺良

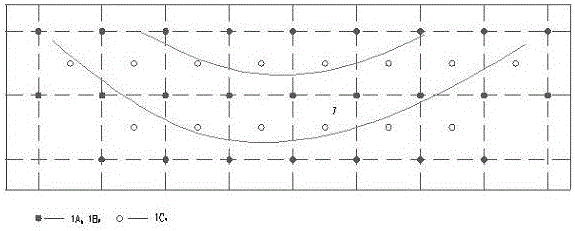

A flat hole grouting roadbed reinforcement method and structure without damaging the road surface

ActiveCN103981782BGuaranteed integrityAvoid damageRoadwaysSoil preservationCement slurryRoad surface

The invention discloses a flat hole grouting subgrade reinforcement method and structure without damaging the road surface. The steps are: A. determining the hole position of the grouting hole; B. drilling a horizontal or oblique grouting hole; The main direction is orthogonal; C, the grouting holes are drilled alternately; D, the inward grouting is drilled from the periphery of the roadbed lesion; E, the grouting flower tube is installed; F, the front end of the grouting holes arranged in a three-dimensional staggered way through the cross section of the roadbed Install the seamless grouting outer pipe; G. Inject cement slurry evenly, and the grouting pressure is determined by the test and the area; H. During the grouting process, observe the settlement, inclination, deformation and displacement of the subgrade pavement, structures and surrounding buildings. The grouting hole is formed by horizontal or oblique dry drilling of the subgrade slope in the diseased area, and the grouting flower pipe and the seamless grouting outer pipe are installed, and the grouting flower pipe and the seamless grouting outer pipe are connected by joints and screws. The method is easy to operate and the operation is simple and convenient. It does not damage the pavement structure, significantly improves the bearing capacity and stability of the subgrade structure in the diseased area, and the reinforcement effect is remarkable.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

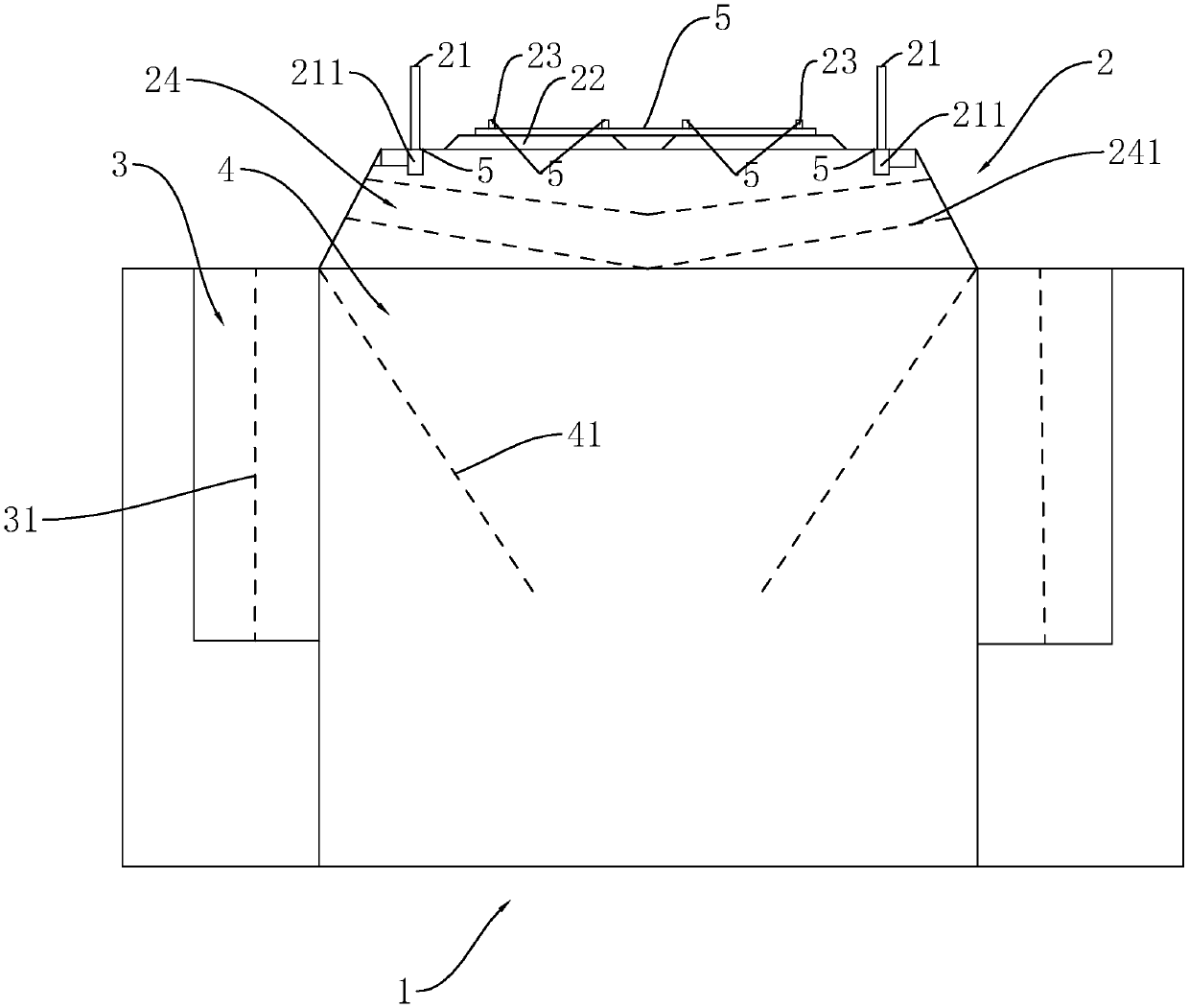

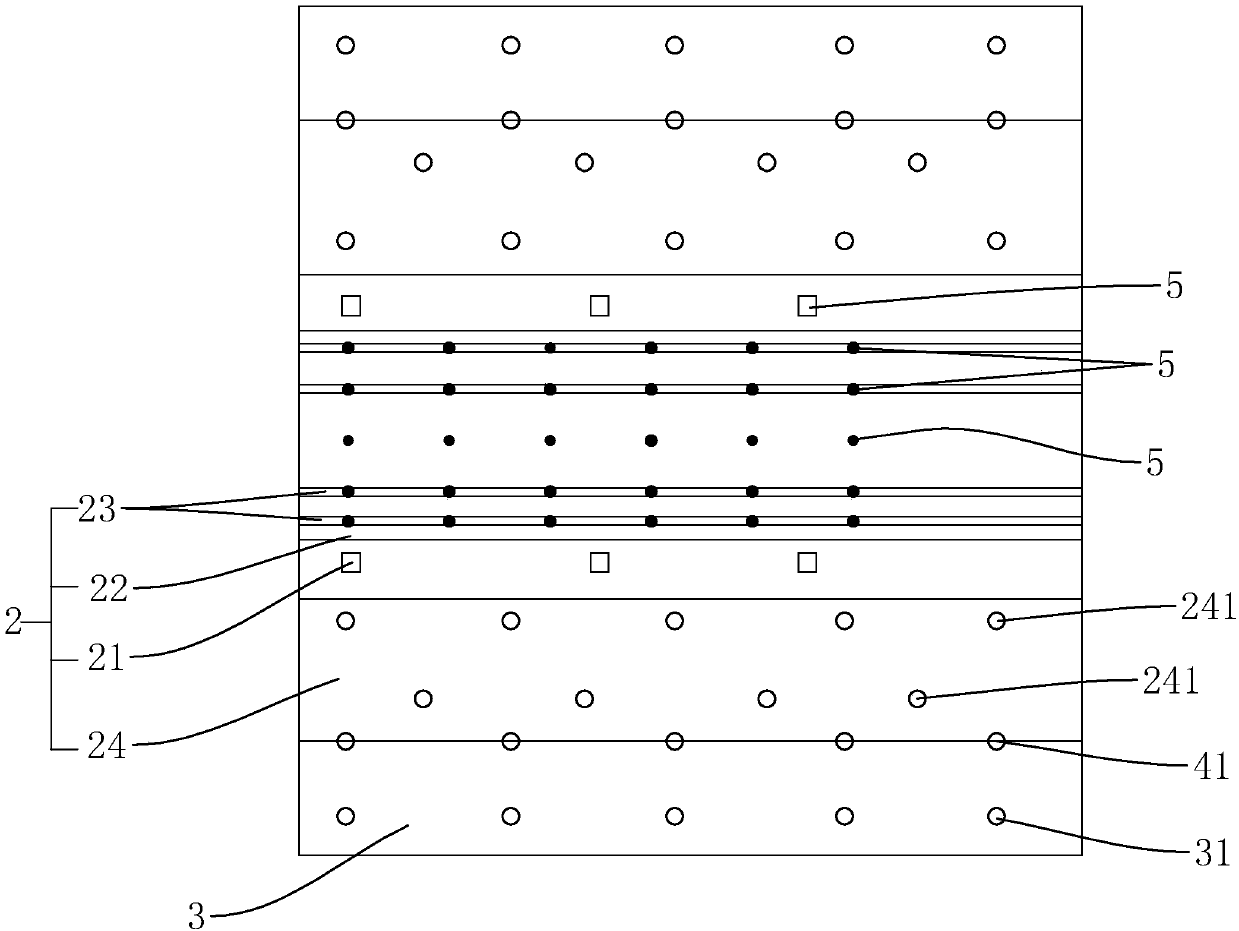

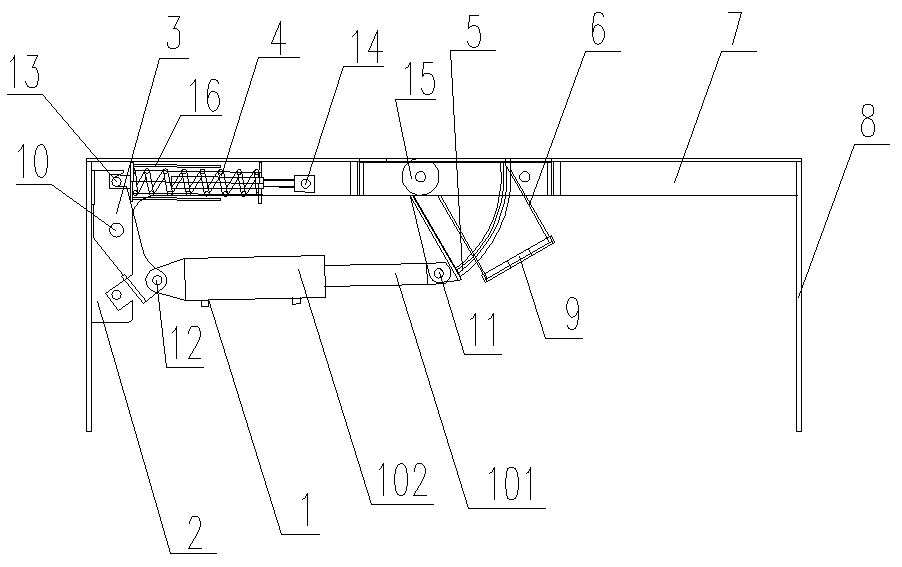

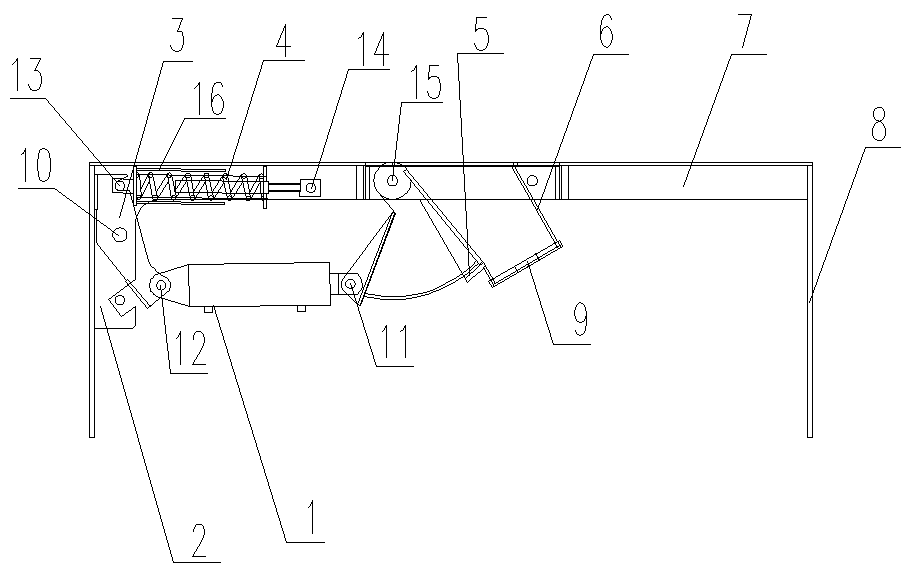

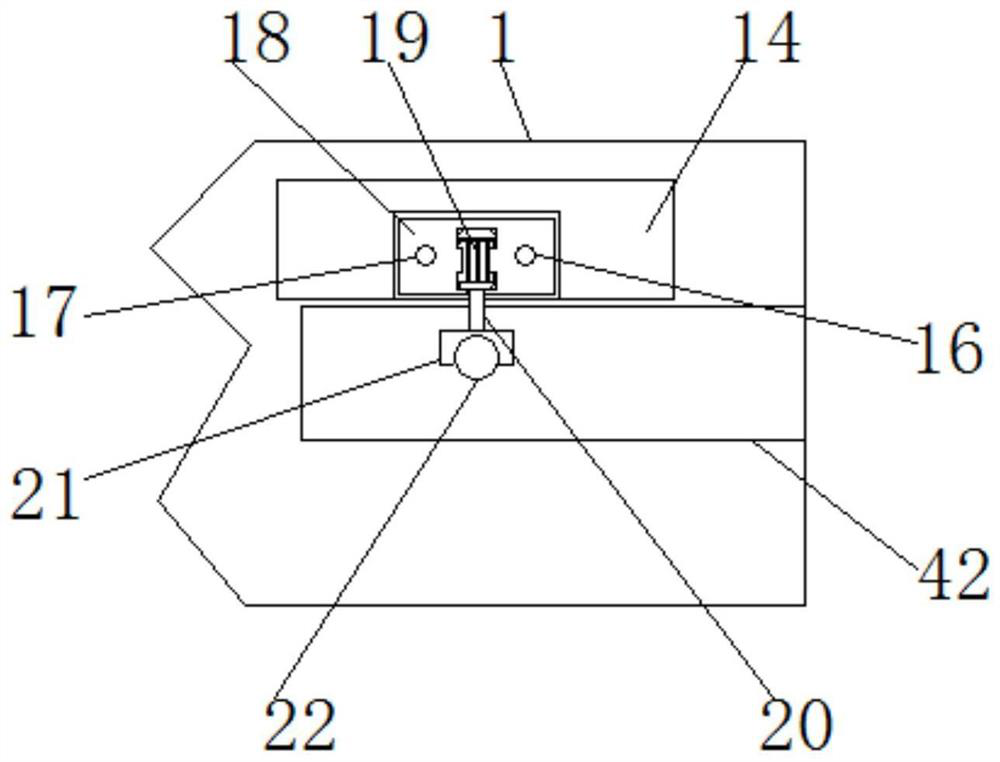

Intelligent grouting hole device for tunnel lining trolley

PendingCN108868822AHigh degree of automationImprove construction efficiencyUnderground chambersTunnel liningEngineeringSlurry

The invention provides an intelligent grouting hole device for a tunnel lining trolley. The device comprises a cross beam and stand columns, wherein the cross beam is horizontally arranged, and the stand columns are arranged at the two ends of the cross beam and are vertically connected with the cross beam; a grouting pipe is fixedly arranged on the cross beam, the upper part of the grouting pipeis open, and the lower part of the grouting pipe is closed; a slurry outlet is formed in the lower part of the grouting pipe, and a fixed lug plate is arranged on one of the two stand columns; a movable lug plate is hinged to the fixed lug plate through a first pin shaft, a spring and a hydraulic oil cylinder are arranged between the movable lug plate and the grouting pipe, and a baffle is arranged between the hydraulic oil cylinder and the grouting pipe; one end of the baffle is hinged to the end of a piston rod of the hydraulic oil cylinder through a second pin shaft, the other end of the baffle penetrates through the grouting pipe, and the piston rod of the hydraulic oil cylinder drives the baffle to move, so that the baffle blocks or does not block the slurry outlet; a cylinder body ofthe hydraulic oil cylinder is hinged to the movable lug plate through a third pin shaft, one end of the spring is hinged to the movable lug plate through a fourth pin shaft, and the other end of thespring is hinged to the cross beam through a fifth pin shaft.

Owner:PINGDINGSHAN COAL MINE MACHINERY EQUIP CO LTD

Preparation of a geopolymer grouting material and its method for static pressure grouting

ActiveCN106587782BReduce labor intensityLow viscosityCement productionRoads maintainenceSodium BentoniteSlag

The invention provides a method for preparing a geopolymer grouting material and a method for applying the geopolymer grouting material to static pressure grouting. Raw materials for preparing the geopolymer grouting material include steel slag, mineral slag, sodium silicate, silica fume, calcium bentonite, softened water and a composite alkali activator. The method for preparing the geopolymer grouting material comprises the steps that 1, a component A is prepared; 2, a component B is prepared; 3, a component C is prepared; and 4, the geopolymer grouting material is prepared. The method for static pressure grouting comprises the steps of 1, survey; 2, assessment; 3, pit sounding; 4, hollowing general survey; 5, deflection value check; 6, comprehensive evaluation; 7, measurement and hole arrangement; 8, drilling; 9, grouting; 10, check; 11, grouting hole sealing; and 12, recheck to complete static pressure grouting. The methods have the advantages of environmental friendliness, low viscosity, high elasticity modulus, high cohesiveness, low cost, high efficiency and high durability.

Owner:JIANGSU ZHUODIAN DRILLING & TUNNELING TECH CO LTD

Settling, reinforcing and lifting method of independent foundations of existing building

PendingCN110258677AReduce the impactImprove stabilityFoundation engineeringBuilding constructionSettling

The invention discloses a settling, reinforcing and lifting method of independent foundations of an existing building, and belongs to the technical field of building foundation reinforcing and lifting. The settling, reinforcing and lifting method comprises the following steps: S1, settlement survey is conducted, specifically, all the independent foundations are subjected to settlement survey according to datum elevation points set on site, settlement data are recorded, the differential settlement is calculated, and a unified elevation line is set; S2, the foundations are stabilized, specifically, soil bodies at the bottoms of the independent foundations are subjected to grouting reinforcement treatment, and a stable area is formed; and S3, the foundations are lifted, specifically, soil bodies, close to the independent foundations, on the upper part of the stable area are grouted so as to lift the independent foundations to the unified elevation line. The settling, reinforcing and lifting method has the characteristics of high stability, high precision, easy construction and low cost.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

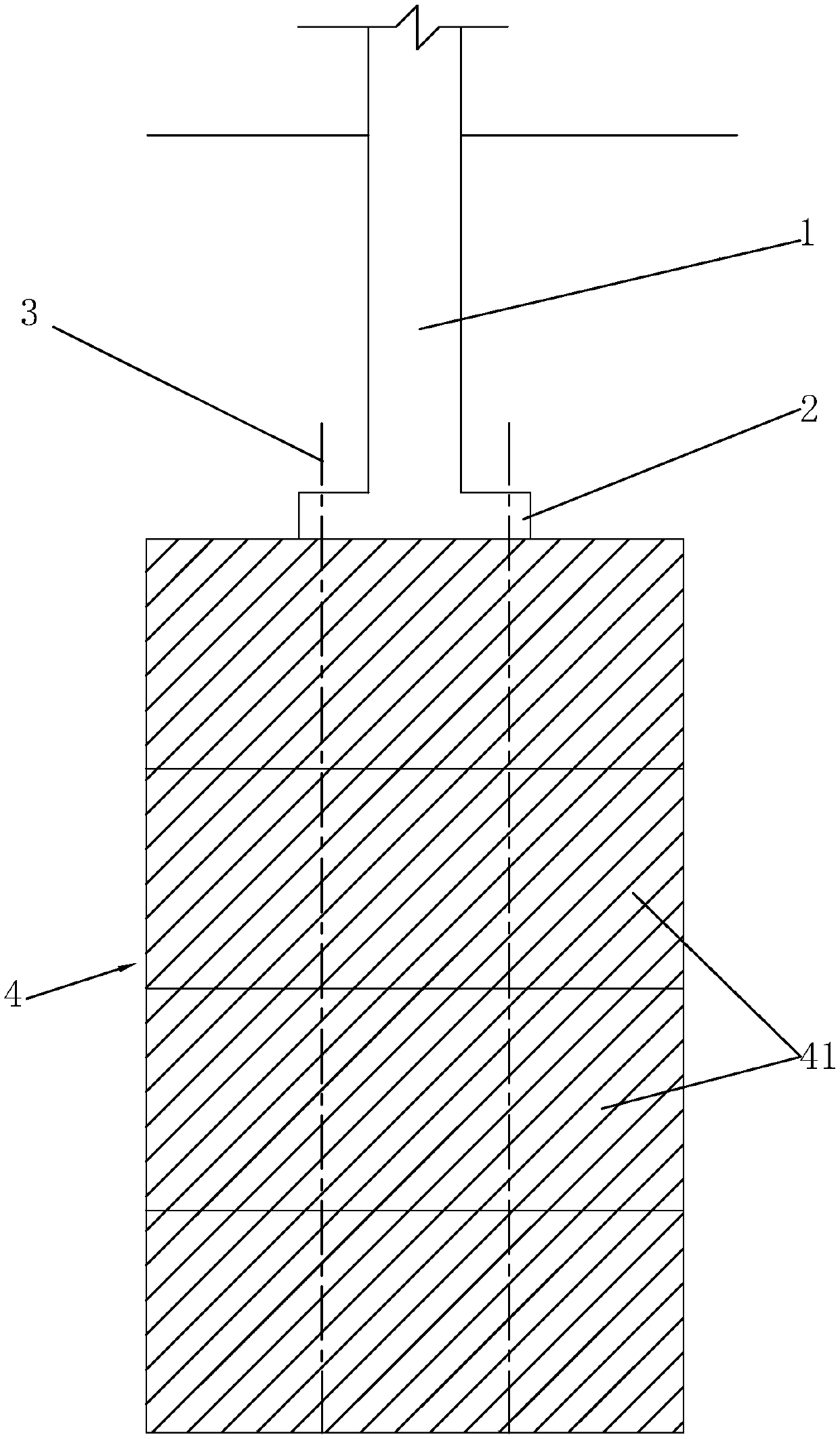

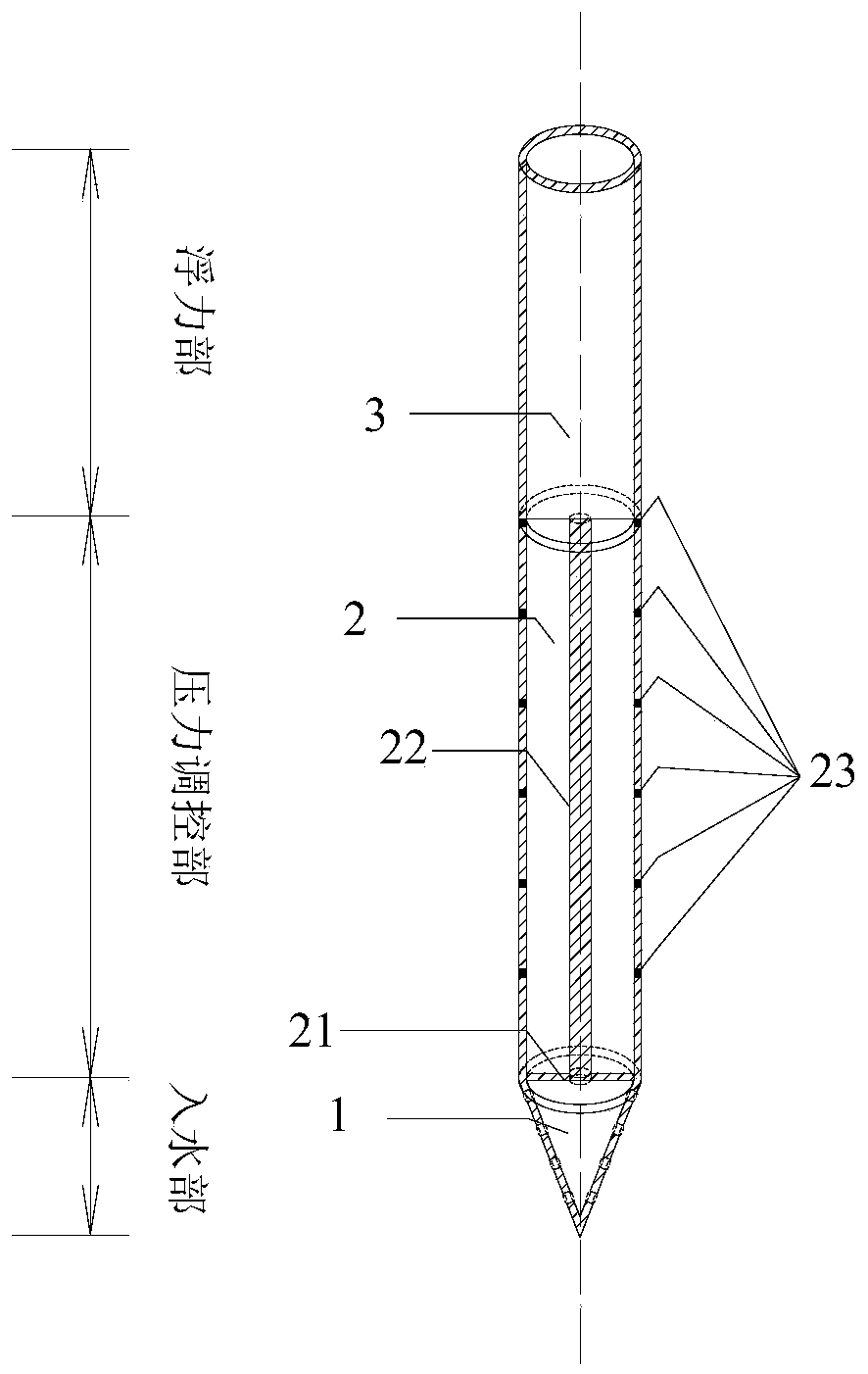

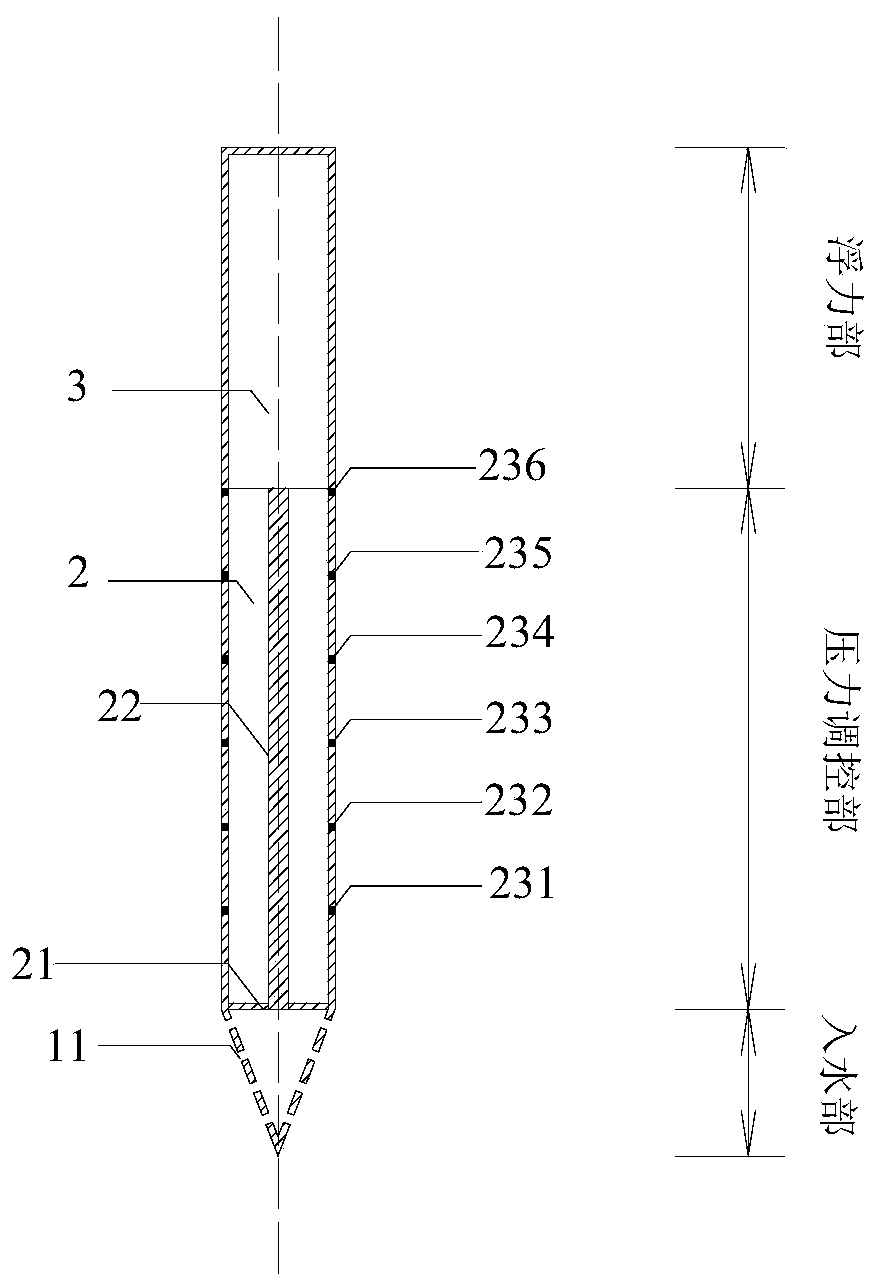

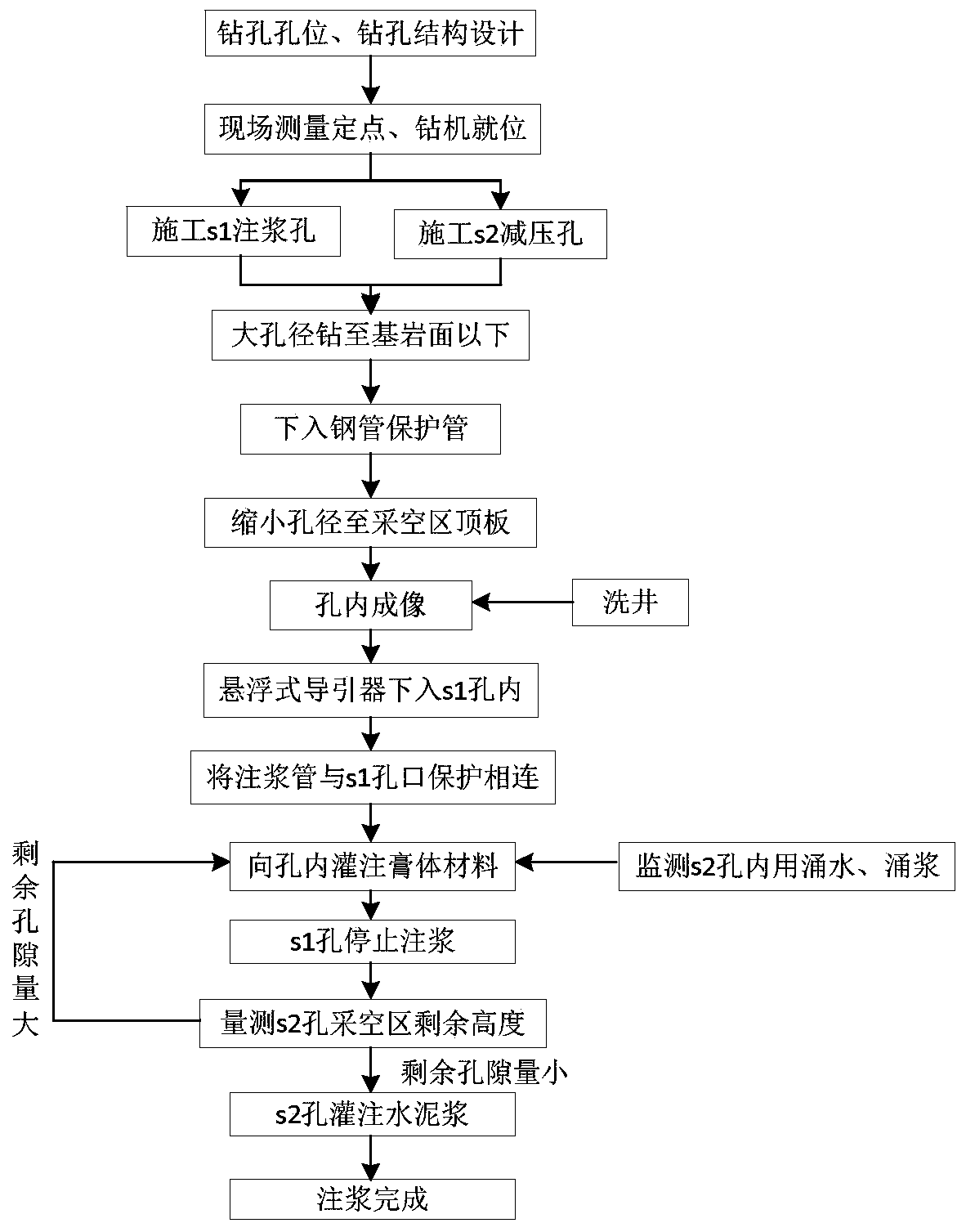

Suspension type guiding device and construction method for paste filling of underwater goaf

PendingCN110425004ASolve filling problemsSolve the problem of injecting into large volume confined spacesMaterial fill-upMarine engineeringSlide plate

The invention discloses a suspension type guiding device for paste filling of an underwater goaf. The suspension type guiding device for paste filling of the underwater goaf comprises a water enteringportion, a pressure adjusting and controlling portion and a buoyancy portion which are connected in sequence; the water entering portion is provided with at least one water entering hole; the pressure adjusting and controlling portion is provided with a pressure cavity; a pressure bearing slide plate is arranged between the pressure cavity and the water entering hole, and slides in the pressure cavity; the side wall of the pressure cavity is provided with multi-stage pressure non-return valve in an arrayed manner in the direction from the water entering portion to the buoyancy portion; and the set pressure of the multi-stage pressure non-return valves is sequentially increased in the direction from the water entering portion to thee buoyancy portion. The invention further provides a construction method for paste filling of an underwater large-volume goaf. The suspension type guiding device and construction method for paste filling of the underwater goaf have the beneficial effects that the paste filling and transporting problem of an underwater large-volume space is solved, and the grout liquid segregation problem caused by the fact that grout liquid is conveyed in a vertical non-pressure pipeline is solved.

Owner:徐州中矿岩土技术股份有限公司

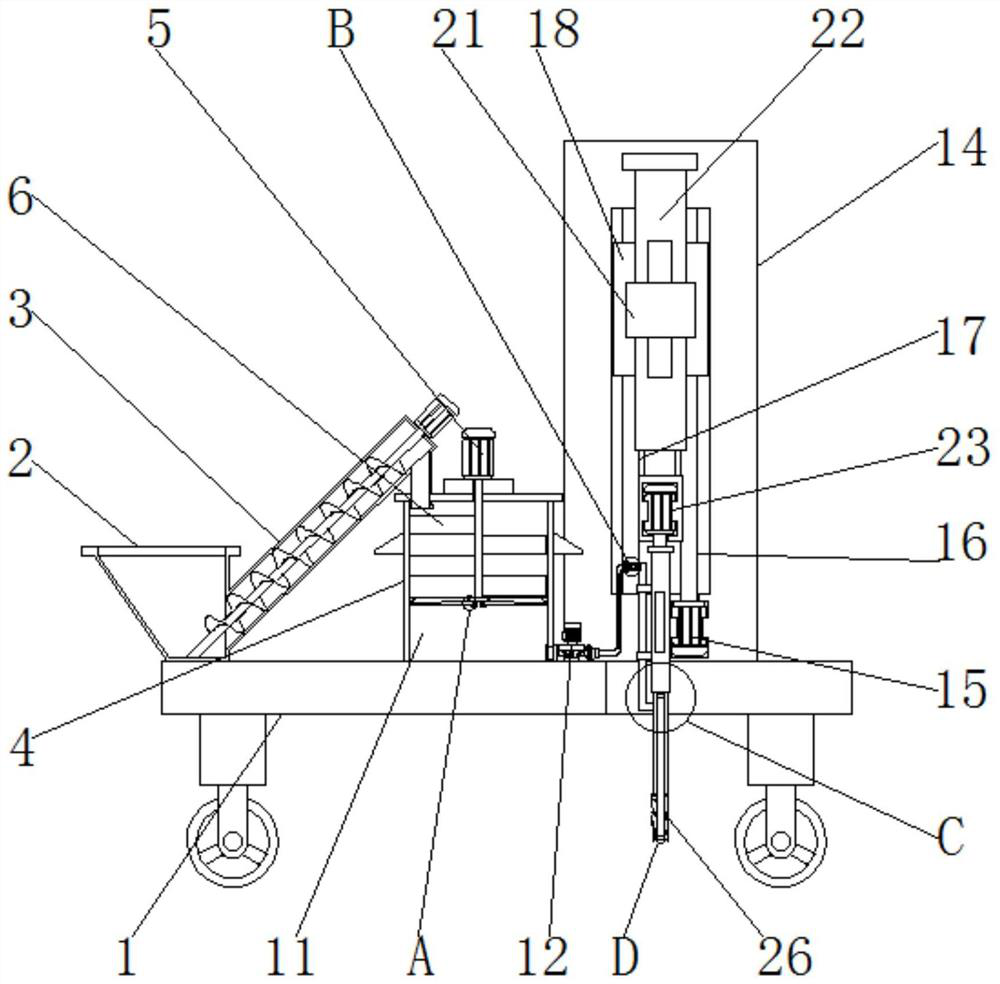

Roadbed underground grouting reinforcement device for road construction

InactiveCN112627167AOrientation is easy to adjustEasy to disassembleRoadwaysSoil preservationElectric machineryStructural engineering

The invention discloses a roadbed underground grouting reinforcement device for road construction. The roadbed underground grouting reinforcement device comprises a workbench and an adjusting groove, wherein a feeding hopper is fixed on one side of the workbench; one side of a stirrer is connected with stirring blades; grouting grooves are formed in a grouting rod and a drill bit; and the adjusting groove close to a first hydraulic rod is formed in one side of the workbench. The roadbed underground grouting reinforcement device for road construction is provided with a sliding block and a rotating block, when the drilling angle needs to be adjusted, a third motor is started, the third motor drives a second rotating shaft to rotate, the second rotating shaft rotates to drive the first hydraulic rod to rotate, the first hydraulic rod rotates to drive the grouting rod to rotate in the adjusting groove, so that the orientation of the drill bit at one end of the grouting rod is changed, then a second motor is started, the second motor drives a threaded rod to rotate, the threaded rod rotates to drive the sliding block to move along a guide rod, the sliding block moves to enable the drill bit to gradually get close to the position needing to be drilled for positioning, and the orientation of the drill bit can be conveniently adjusted.

Owner:杨鹏

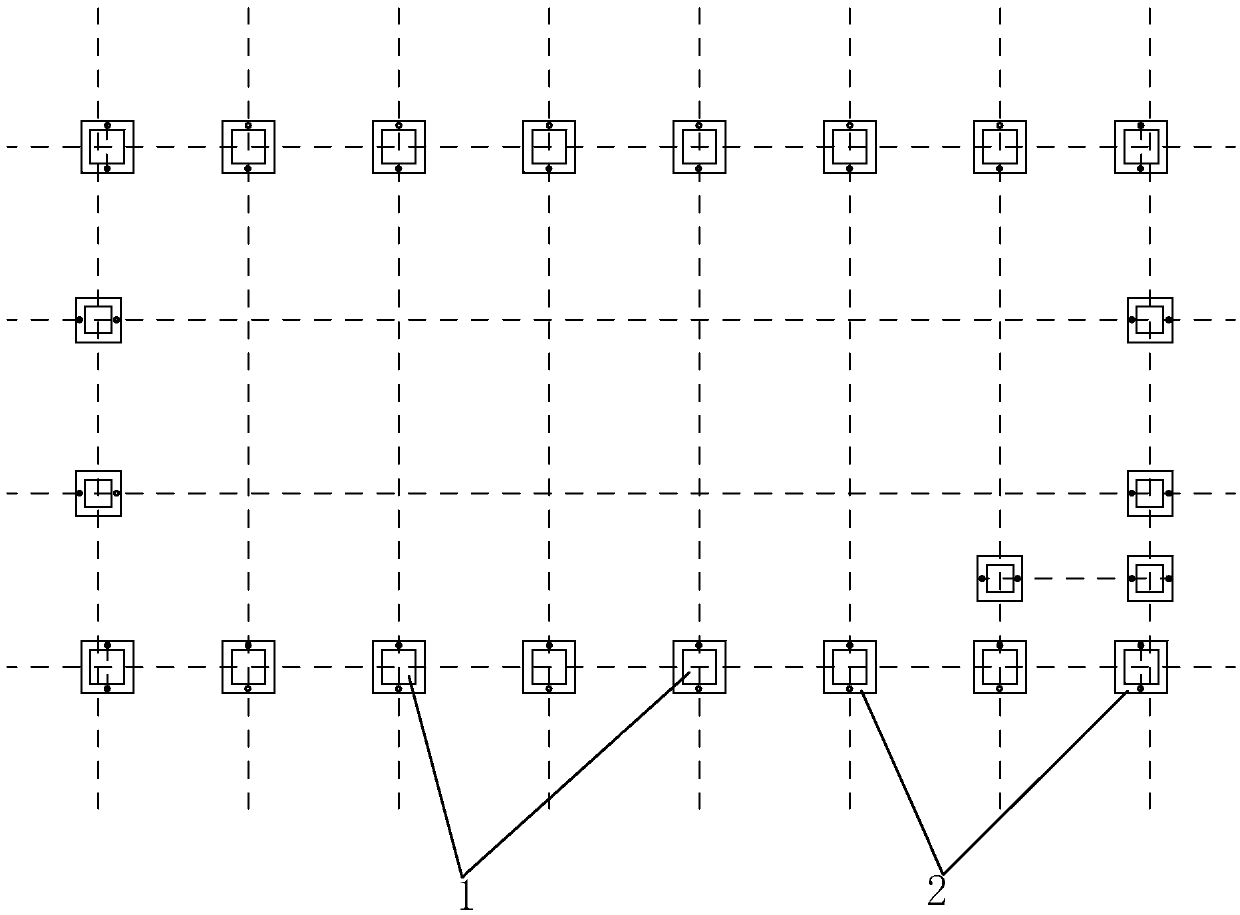

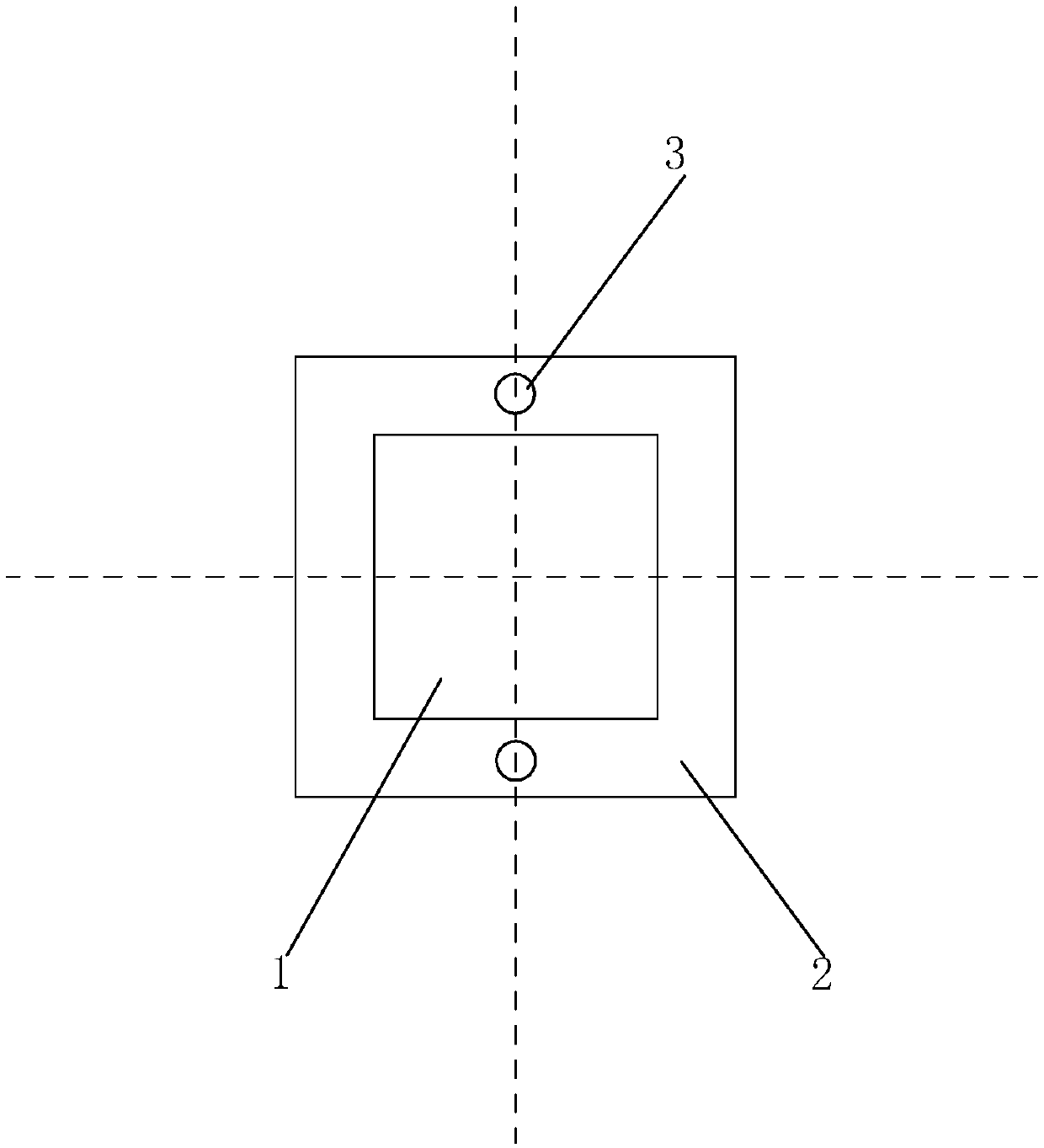

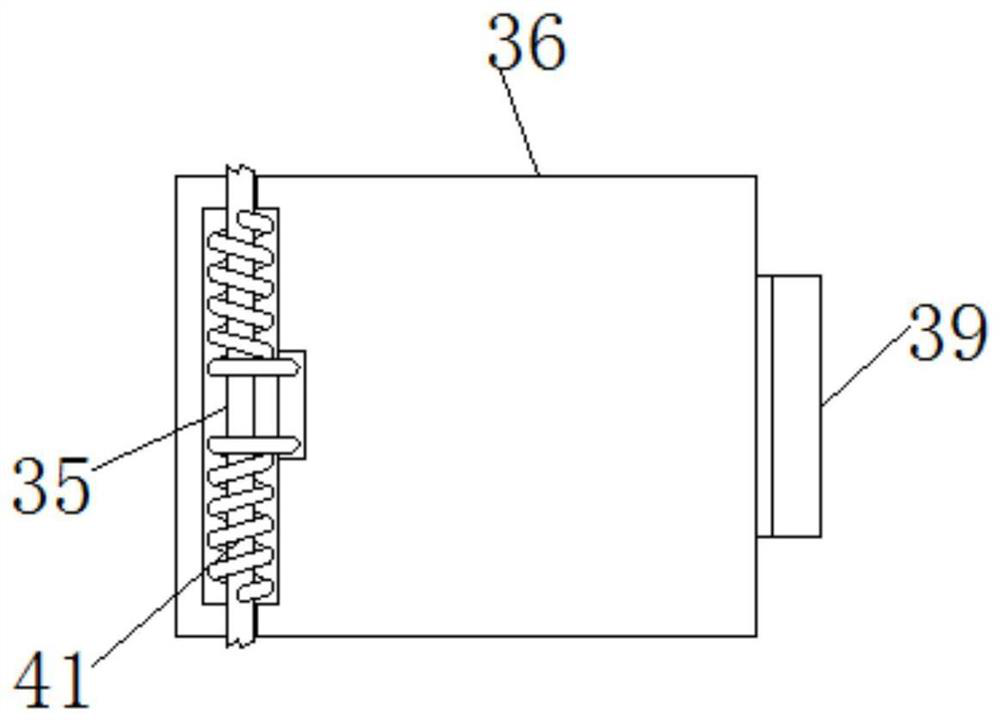

Pulse type grouting machine and double-liquid grouting construction method

PendingCN111719561AIncreased underwater dispersion resistanceImprove mobilityBallastwayFoundation engineeringRailway tunnelEngineering

The invention provides a pulse type grouting machine and a double-liquid grouting construction method. The quincuncial pile type is adopted to arrange grouting holes; grouting is carried out on one point of a central area; grouting is dense without a dead angle, the grouting effect is excellent, the grouting pressure is low, and the grouting efficiency is high; and a cabin is unlikely to be blocked on the condition that the condensation rate of mixed slurry is higher. High and low pressure peak load shifting grouting of the pulse type grouting machine is used to realize premixing; secondary mixing in a mixing pipe and third-time in-depth mixing of a vibrator are realized; the grouting speed is controllable; and on the condition that the slurry is excellent in underwater dispersity resistance and high in cohesiveness, the mixing efficiency and the uniform degree are improved. A A-component single fluid and a B-component signal fluid are designed; the single fluid components can work fora long time; when the double fluid is mixed, the underwater dispersity resistance is high, the condensation and hardening rate is high, and the underwater rapid repairing demand of a railway tunnel foundation disengaging area is met; double-liquid grouting does not affect construction due to pipe blocking caused by excessively high condensation rate. The proportion of the component A and the component B can be controlled to adjust the working time of the mixed slurry.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Ceramic body grouting molding method

A grouting forming method for ceramic blanks comprises the steps of grouting, slurry blanking, slurry mold injection preparation and slurry mold injection forming. According to the grouting forming method for the ceramic blanks, the liquid level in a grouting barrel is controlled through a first liquid level and a second liquid level, the relatively constant grouting pressure can be kept in grouting and is small, slurry is prevented from leaking from seams of a mold, the effect that the same height (a preset liquid level) is kept when the slurry enters the mold is guaranteed through a horizontal liquid level device before slurry mold injection, it is ensured that air in a pipeline is completely exhausted, and the thickness difference between the blanks is reduced.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Shallow surface ecological water protection method based on the hysteresis effect of the key layer of mining space

The invention discloses a shallow surface ecological water protection method based on the stagnation effect of key layers in mining space, utilizes the development and closure of hard rock layers (key layers) to separate layers and has a certain delay time, and according to the theory of key layers and the mechanical strength of rock layers, finds out-of-surface layers One or more key layers that are nearest and have a certain development delay time, drill holes in the key layer in advance, and set up a monitoring system in the hole; when the separation layer develops below the key layer, the monitoring system automatically recognizes and starts The grouting pump performs rapid grouting, and fills the separation space with grout before the key layer is broken and bent to block the upwardly conductive mining space, so as to prevent the mining from damaging the shallow rock formation and shallow surface water, and at the same time increase the The strength of the rock mass structure forms a "protective circle" for the shallow surface rock formation, prevents the loss of shallow surface water and surface subsidence, and protects the surface ecological water level, which is beneficial to the ecological protection of the ecologically fragile areas in the west.

Owner:NORTH CHINA INST OF SCI & TECH

A method for drilling and grouting construction in sand and gravel formation

The invention belongs to the technical field of civil engineering, and relates to a method for drilling and grouting construction in sand and gravel formations, comprising: (1) drilling and following pipes to drill into a wall casing; (2) running into a grouting pipe; 3) Install the orifice blocker; (4) According to the grouting procedure, adopt the appropriate water-cement ratio to start grouting and change the grout until the grouting is completed; (5) Grouting construction. The invention has the beneficial effects of solving the problem that the flower tube enters the gravel formation. The embedding depth is controllable, which is easier than the plugging method; it prevents the sand and gravel strata from collapsing during the process of pulling out the casing, which causes the flower tube to be blocked, and solves the problem that the sand and gravel stratum cannot be effectively grouted; simplifies the grout stopper It is difficult to install and operate; it has little effect on the grouting diffusion radius; it overcomes the process defects and the grouting quality is reliable; it is suitable for any sand and gravel stratum and can be implemented without process tests, especially in areas with complex strata.

Owner:SINOHYDRO BUREAU 11 CO LTD

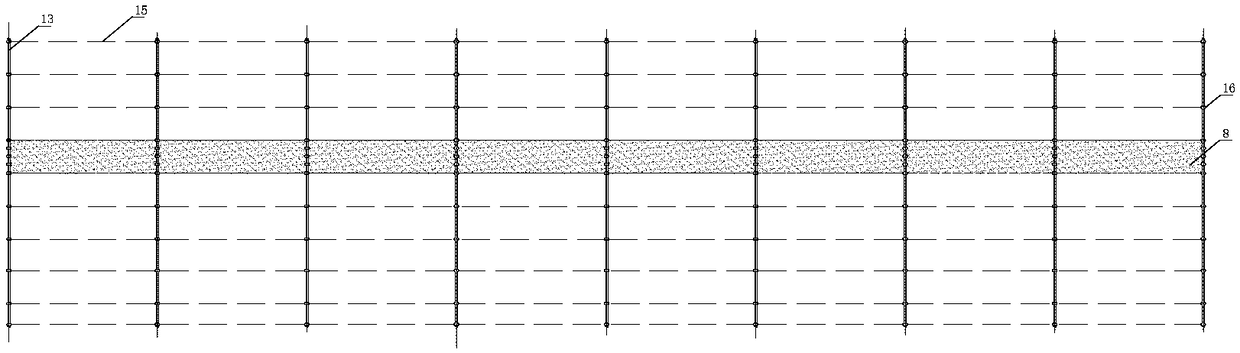

Construction method of interwall grouting waterproofing and strengthening shaft wall structure under the protection of frozen wall

ActiveCN106837340BGive full play to the water sealing effectImprove grouting effectShaft liningStress conditionsEngineering

The invention provides a construction method for an inter-wall grouting water-resisting and reinforcing well wall structure under protection of a freezing wall, and belongs to construction methods for inter-wall grouting water-resisting and reinforcing well wall structures. The construction method for the inter-wall grouting water-resisting and reinforcing well wall structure under protection of the freezing wall comprises the steps that the grouting opportunity under the protection of the freezing wall is selected actively; a grouting pipe is embedded between an inner wall and an outer wall while the inner well wall is constructed; after construction of the inner well wall is completed and before the freezing wall is melted, grouting is conducted between the inner well wall and the outer well wall from the ground under the protection of the freezing wall; and the space between the inner well wall and the outer well wall is blocked actively, so that the grouting protection effect is improved, the water sealing effect of the outer well wall is sufficiently improved, and the combined bearing effect of the inner well wall and the outer well wall is brought into play. The construction method for the inter-wall grouting water-resisting and reinforcing well wall structure under protection of the freezing wall has the advantages that the grouting pressure is low, and compact grouting is achieved; the airtightness of the outer well wall can be greatly improved after grouting, water pressure does not directly act on the inner well wall after the freezing wall is melted, and thus the stress condition of the inner well wall and the outer well wall is greatly improved; and construction is easy and convenient, the cost performance is high, the water sealing effect is remarkable, and the construction period is shortened.

Owner:CHINA UNIV OF MINING & TECH +1

Advanced grouting reinforcement method for red sandstone tunnel

PendingCN114135294ASmall viscosity coefficientReduce disturbanceUnderground chambersTunnel liningMicroorganismStructural engineering

The invention aims to provide an advanced grouting reinforcement method for a red sandstone tunnel to solve the problem that surrounding rocks are easy to soften due to disturbance during excavation of the red sandstone tunnel. The technology of inducing calcium carbonate precipitation through microorganisms is utilized, and microorganism cement grout is injected through an advanced guide pipe for tunnel advanced grouting reinforcement, so that argillization of red sandstone in the excavation process is prevented, the construction progress is accelerated, and the construction risk is reduced.

Owner:CHONGQING UNIV

Water turbine volute internal corner backfill grouting auxiliary structure and backfill grouting method

PendingCN114411736AOptimize layoutEasy groutingWater-power plantsHydro energy generationWater turbineRebar

The invention discloses a water turbine volute internal corner backfill grouting auxiliary structure and a backfill grouting method. The inner side of a seat ring is fully used as a construction space, arrangement of grouting pipelines is optimized, the arrangement work of the grouting pipelines is reduced, the grouting difficulty is reduced, and meanwhile the influence on other equipment pipelines, steel bars and concrete pouring construction is reduced. The structure comprises temporary supporting seats, inner side formworks and grouting pipes, the multiple temporary supporting seats and the multiple inner side formworks are arranged below a seat ring in a surrounding mode, and the inner side formworks are vertically arranged on the inner sides of the temporary supporting seats; the grouting pipe sequentially penetrates through the inner side formwork and the gap between the adjacent temporary supporting seats from the inner side of the seat ring and extends to the internal corner part of the volute. The method comprises the steps that the inner side formwork is installed on the inner side of the temporary supporting base; a hole is formed in the inner side formwork to install a grouting pipe; an exhaust pipe is upwards connected to the seat ring exhaust hole; backfill grouting is conducted on the volute internal corner part 6 through a grouting pipe; and cutting off the exposed parts of the grouting pipeline and the exhaust pipe.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

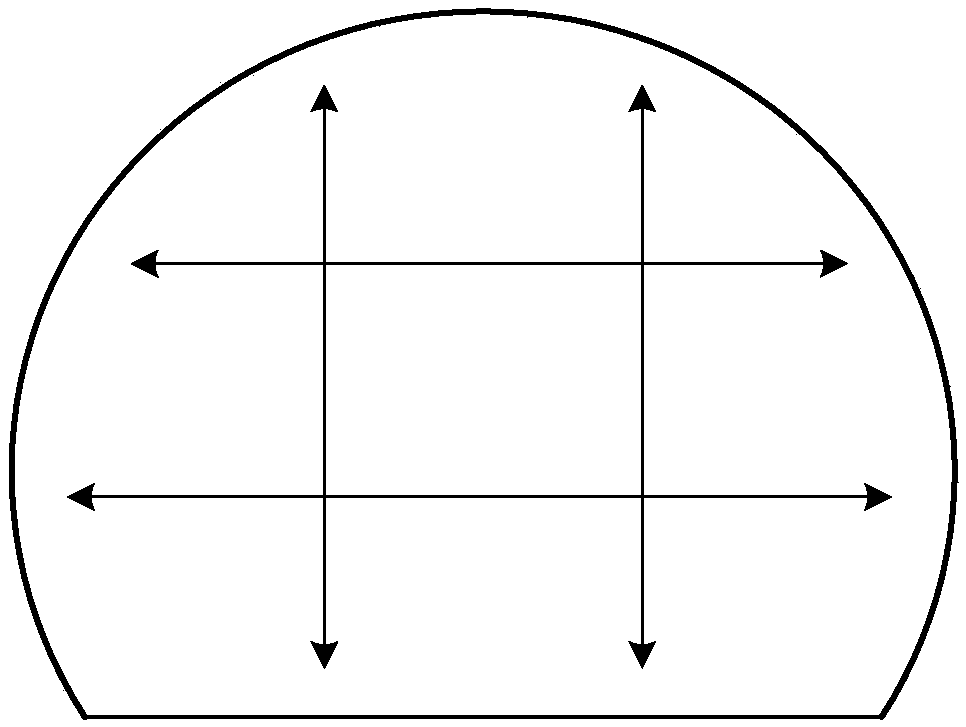

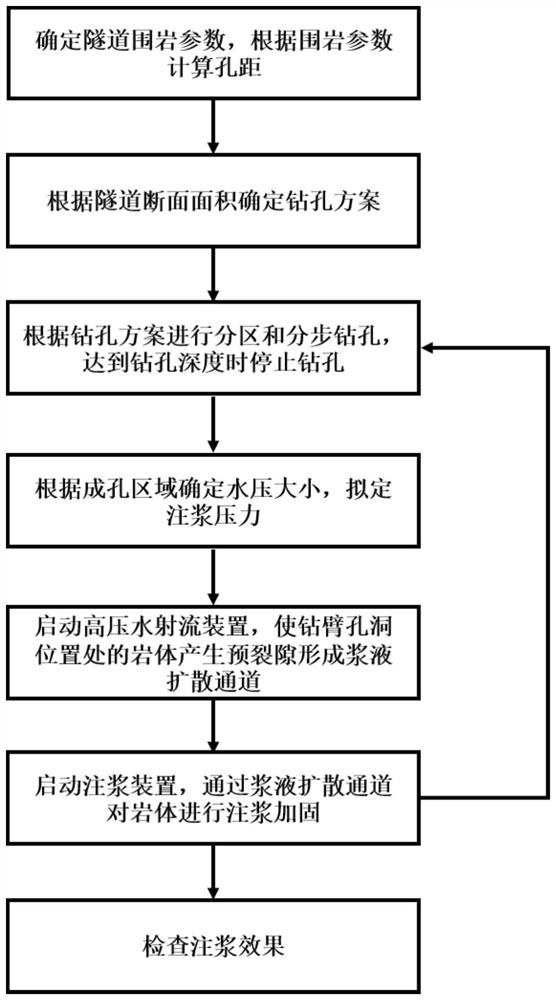

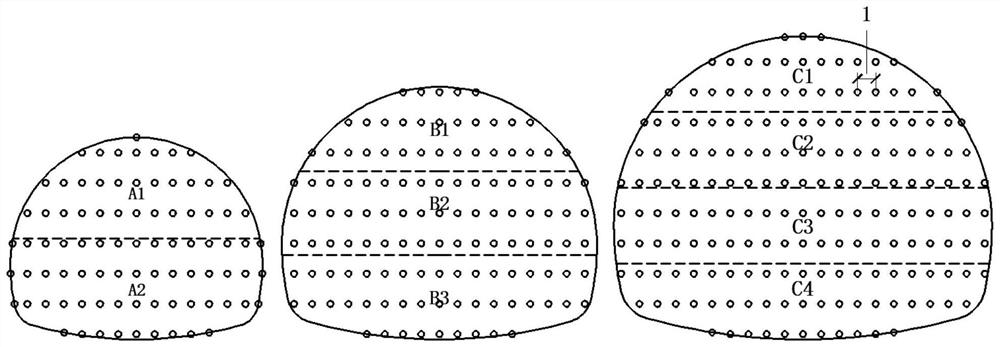

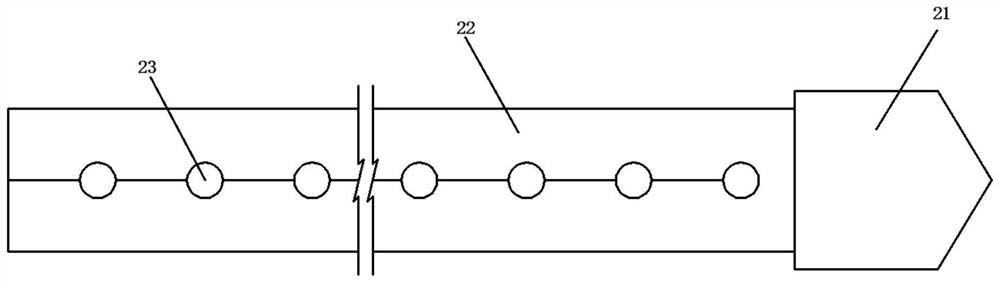

Rapid pre-reinforcement grouting method for excavation of tunnel face of deeply-buried high-pressure water-rich tunnel

PendingCN113137250AGrouting pressure is smallShorten working hoursUnderground chambersTunnel liningDrill holeWater jet

The invention provides a rapid pre-reinforcement grouting method for excavation of the tunnel face of a deeply-buried high-pressure water-rich tunnel. The rapid pre-reinforcement grouting method for excavation of the tunnel face of the deeply-buried high-pressure water-rich tunnel comprises the following steps that tunnel surrounding rock parameters are determined, and a hole distance is calculated according to the surrounding rock parameters; a drilling scheme is determined according to the section area of the tunnel; drilling is conducted in different areas and steps according to the drilling scheme, and drilling is stopped when the drilling depth is reached; a high-pressure water jet device is started, rock mass within the drilling length range is cut through drilling arm hole high-pressure water, and a pre-fracture is generated to form a slurry diffusion channel; a grouting device is started, rapid initial setting grout is pressed into the rock mass, and rapid diffusion of the grout to the excavation face is achieved through the pressure difference between the rock mass and the excavation face of the tunnel; and the grouting effect is checked, and whether the grout is reinjected or not is judged according to the tunnel face surrounding rock water seepage condition. According to the rapid pre-reinforcement grouting method for excavation of the tunnel face of the deeply-buried high-pressure water-rich tunnel, on-site dynamic regulation and control can be achieved, the pressure difference between fracture water and the excavation face is fully utilized, the number of drilled holes is reasonably optimized, the time consumption is shortened, grouting materials are saved, the disaster occurrence frequency is effectively reduced, and it is ensured that the high-pressure water-rich tunnel safely communicate.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com