High-speed railway roadbed uneven settlement reinforcement lifting and leveling method

A high-speed railway, uniform technology, applied in the direction of roads, infrastructure engineering, soil protection, etc., can solve the problems of slowing down the lifting and leveling speed, reducing construction efficiency, reducing grouting pressure, etc., to slow down the lifting speed, reduce the Construction efficiency and the effect of accelerating the lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

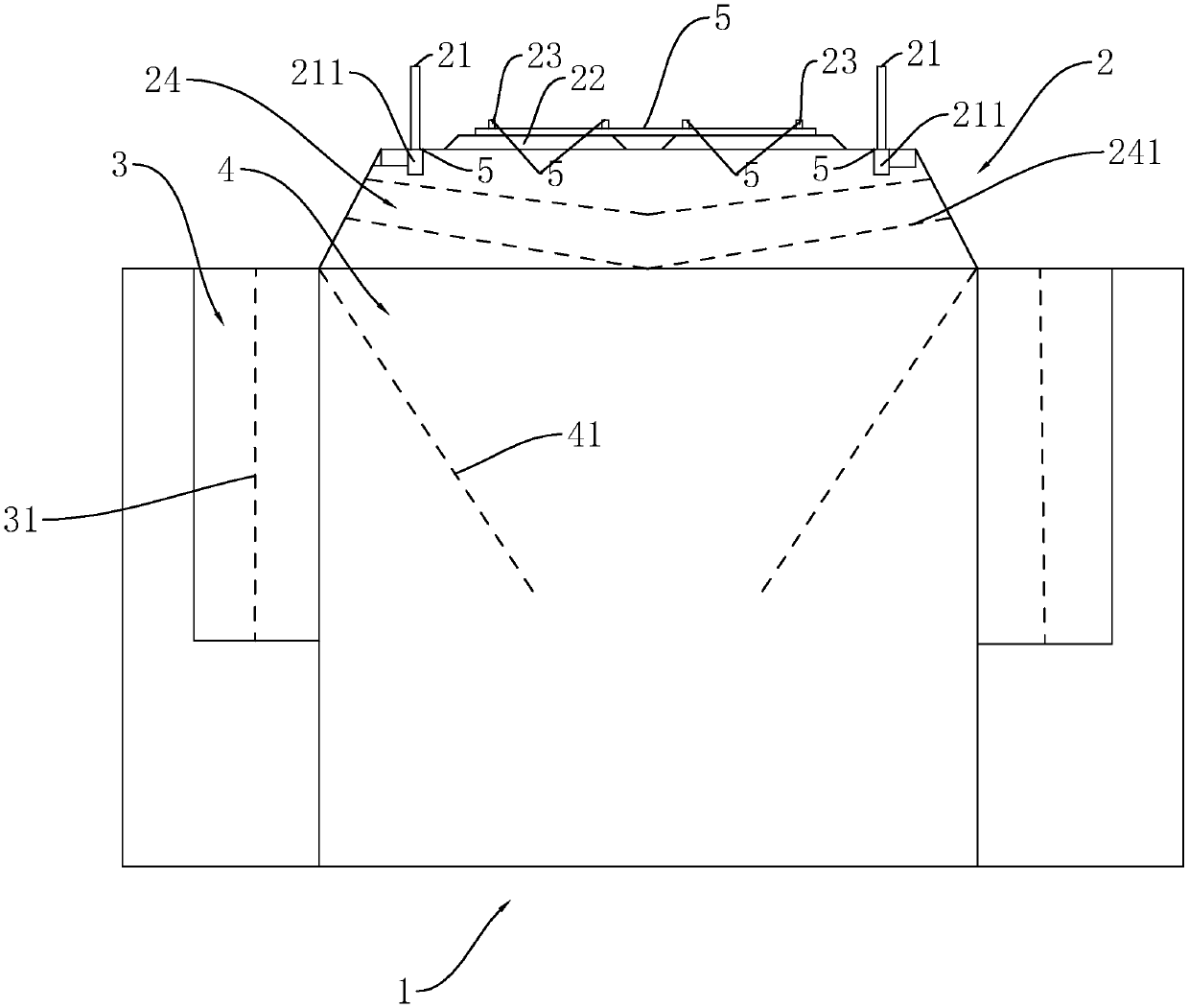

[0040] refer to figure 1 , is a high-speed railway subgrade uneven settlement reinforcement lifting leveling method disclosed by the present invention, comprising the following steps:

[0041] S1 forms a reinforcement zone:

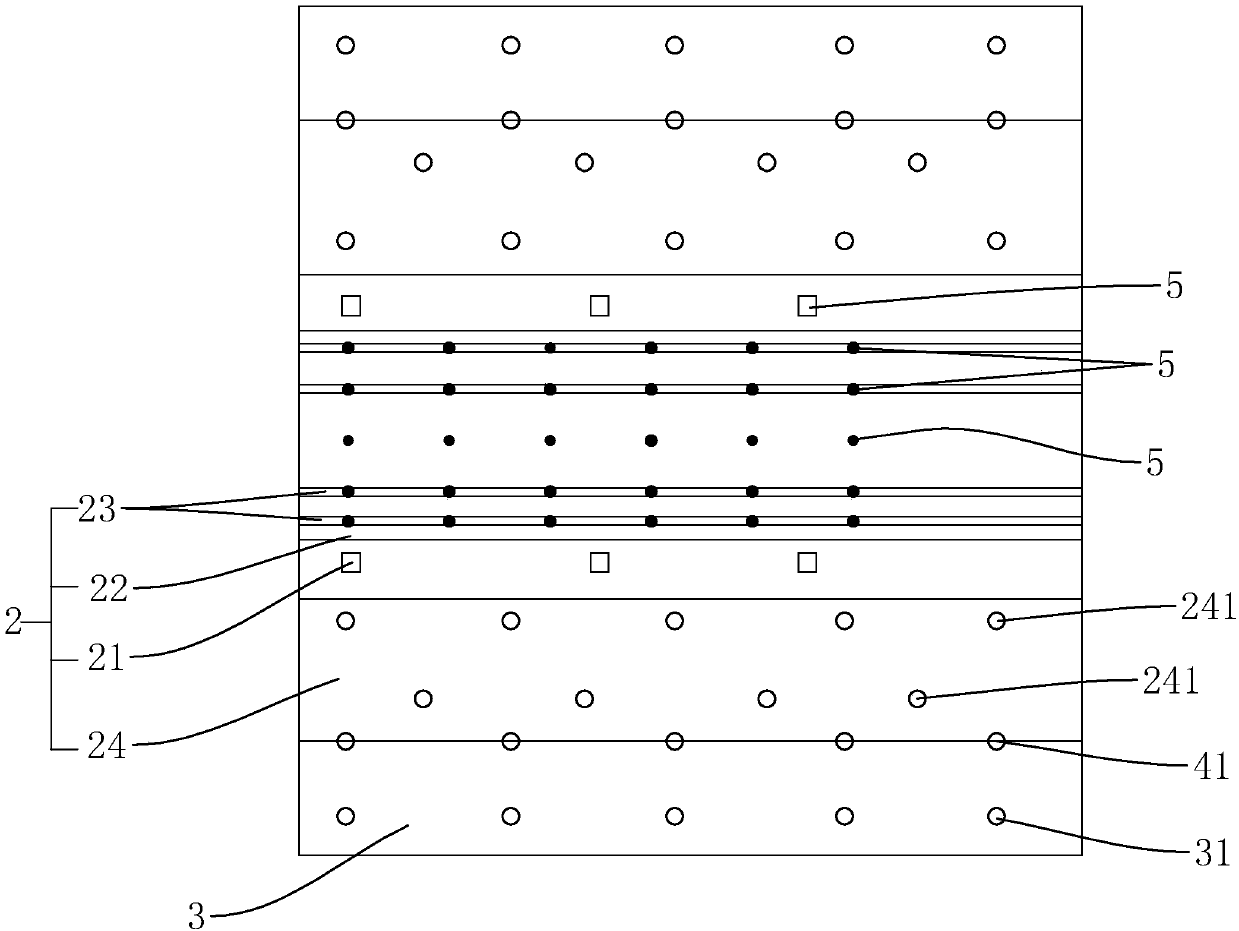

[0042] refer to figure 1 , the reinforcement area formed by static pressure grouting inside the embankment under the railway track to improve the overall compactness and strength of the weak embankment fill layer. combine figure 2 , during static pressure grouting, arrange multiple rows of grouting holes in the reinforcement area on the slope of the embankment, which can be set horizontally or at a downward angle of 10°-30°, using plum blossom-shaped holes with a hole spacing of 2.5m-3.5m, Hole-jumping method is used for construction, and grouting steel pipe permeation grouting reinforcement technology is used for grouting, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com