Patents

Literature

76results about How to "Avoid drumming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement sealing and solidifying agent and construction technique thereof

InactiveCN104016714APlugging structural voidsImprove hardened wear resistanceSodium silicateMagnesium fluorosilicate

The invention relates to a construction paint, particularly a lithium-base permeable crystallization cement sealing and solidifying agent. The cement sealing and solidifying agent is composed of 15-20 parts of sodium silicate, 8-15 parts of lithium metasilicate, 3-5 parts of magnesium fluosilicate, 2-4 parts of sodium dihydrogen phosphate, 0-6 parts of water-based color paste for paint and 50-70 parts of water. The construction technique comprises the following steps: new ground: troweling the new ground, carrying out primary hardening, coating the solidifying agent, completely drying and curing, flushing the ground with clear water, naturally drying, and sanding and polishing with a sander; and old ground: sanding and cleaning the old ground, coating the solidifying agent, naturally drying, cleaning the ground, naturally drying, and sanding and polishing (or additionally coating solidifying agent, cleaning the ground, naturally drying, and sanding and polishing). By using the solidifying agent and construction technique, the strength, hardness and compactness of the concrete are greatly enhanced, and the durability and weathering resistance of the concrete are effectively improved.

Owner:HARBIN UNIV OF SCI & TECH

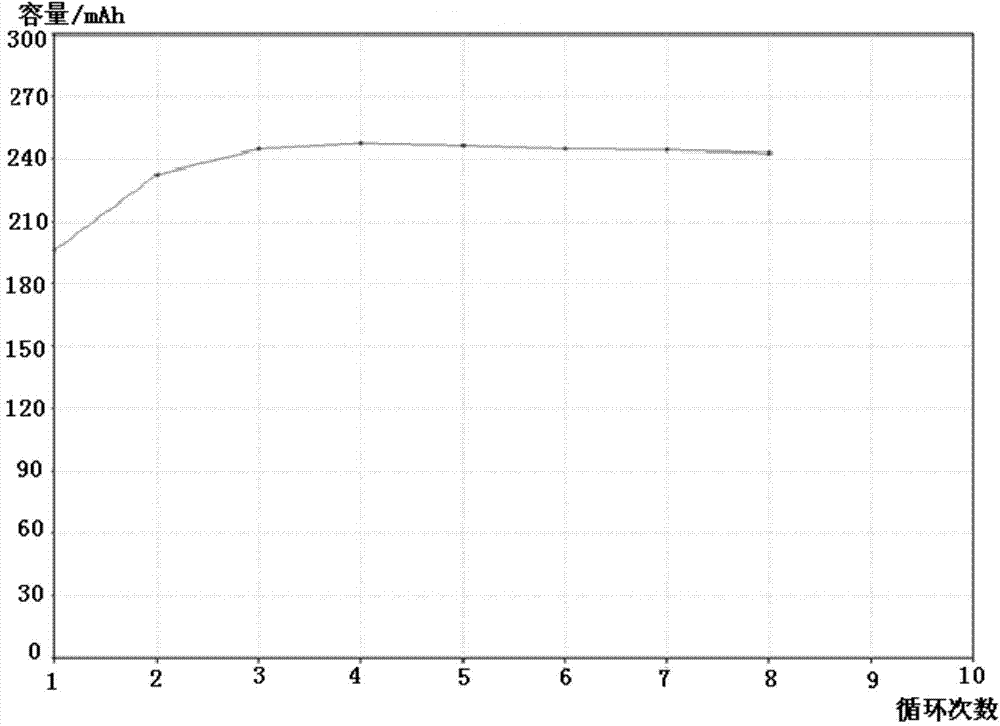

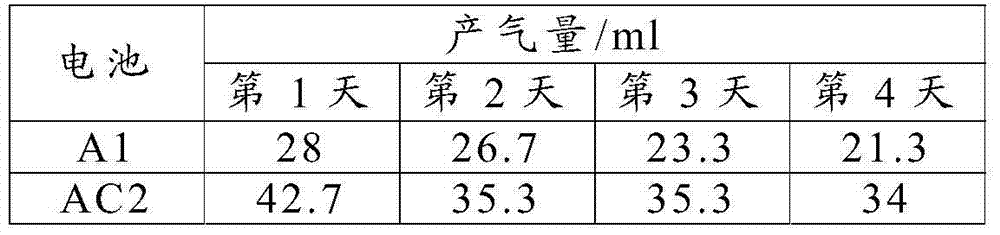

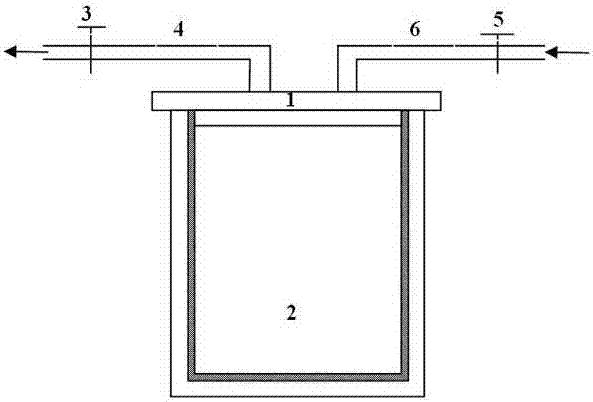

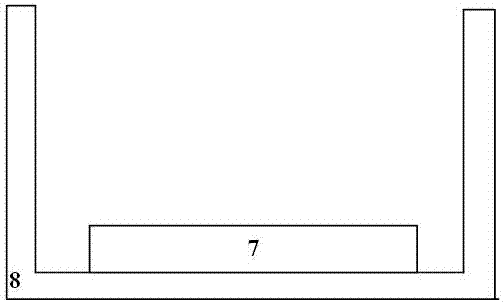

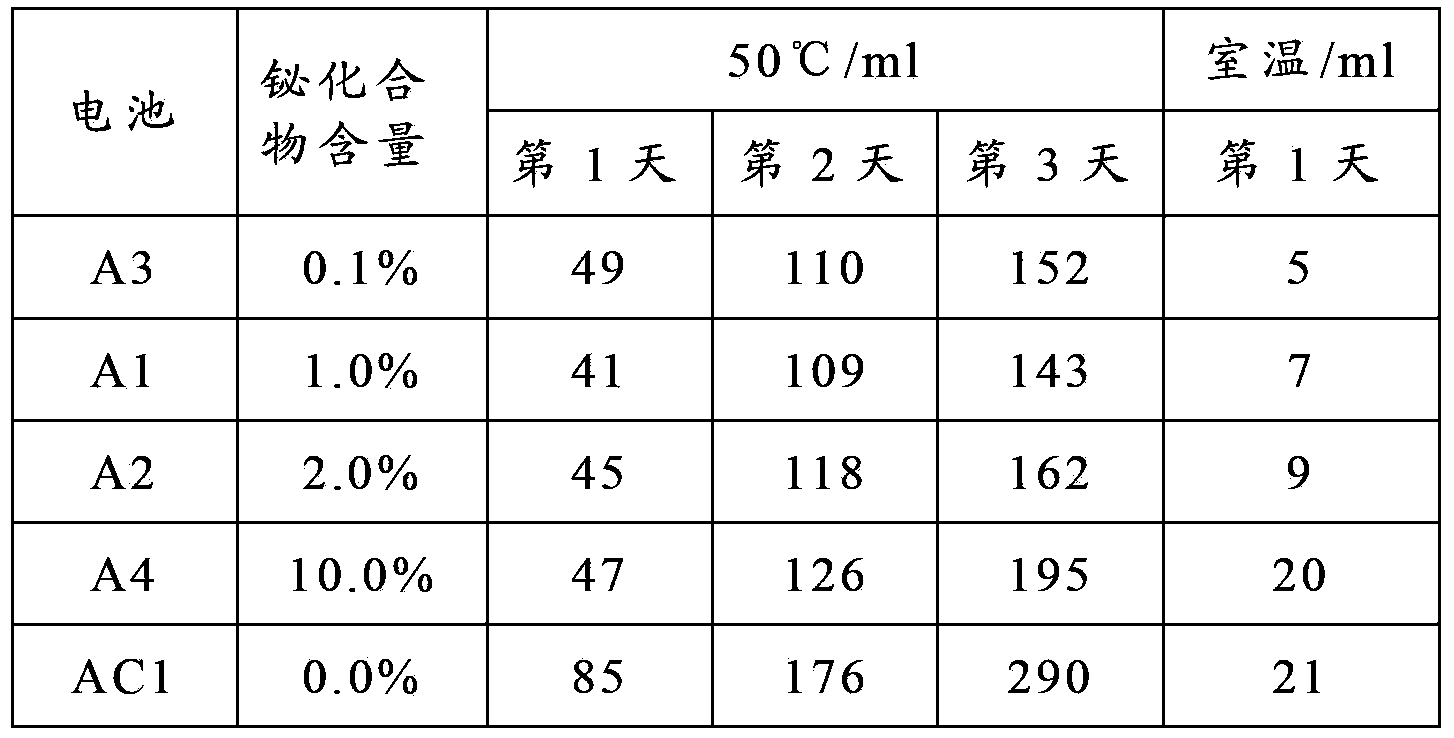

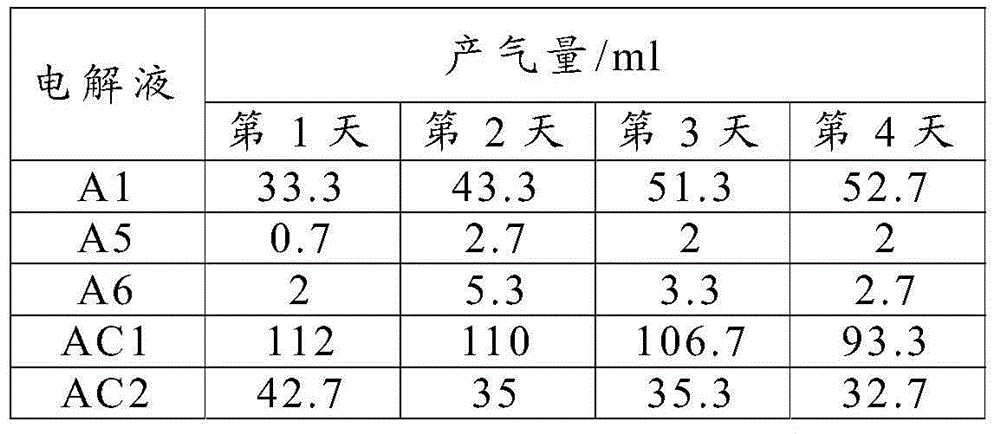

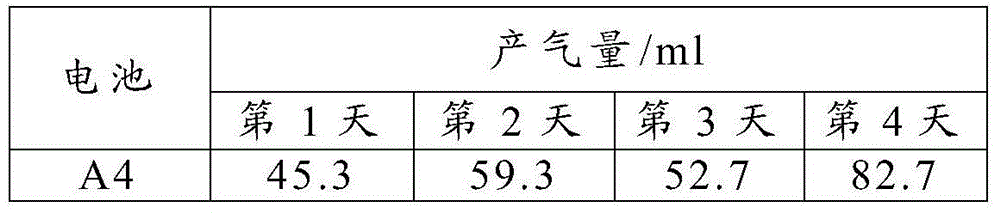

Preparation method for zinc anode, zinc anode and battery

ActiveCN104518205AReduce generationInhibitionFinal product manufactureNegative electrodesUltrasound attenuationCerium

The invention discloses a preparation method for a zinc anode. The preparation method comprises: pretreating a metal zinc, and preparing the anode from the pretreated metal zinc, wherein pretreatment comprises contacting the metal zinc with a processing liquid for modifying the metal zinc surface, and the processing liquid is one of a hydrogen peroxide solution, a permanganate solution, a trivalent ferric ion solution and a tetravalent cerium ion solution. The invention also provides the zinc anode obtained by employing the above preparation method and a battery containing the above zinc anode. By using the processing liquid for pretreating the metal zinc, the side reaction of the zinc anode is reduced, generation of a zinc anode gas is effectively inhibited, and thus cell inflation is avoided, the safety performance of the cell is improved, and cell performance attenuation is effectively inhibited.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

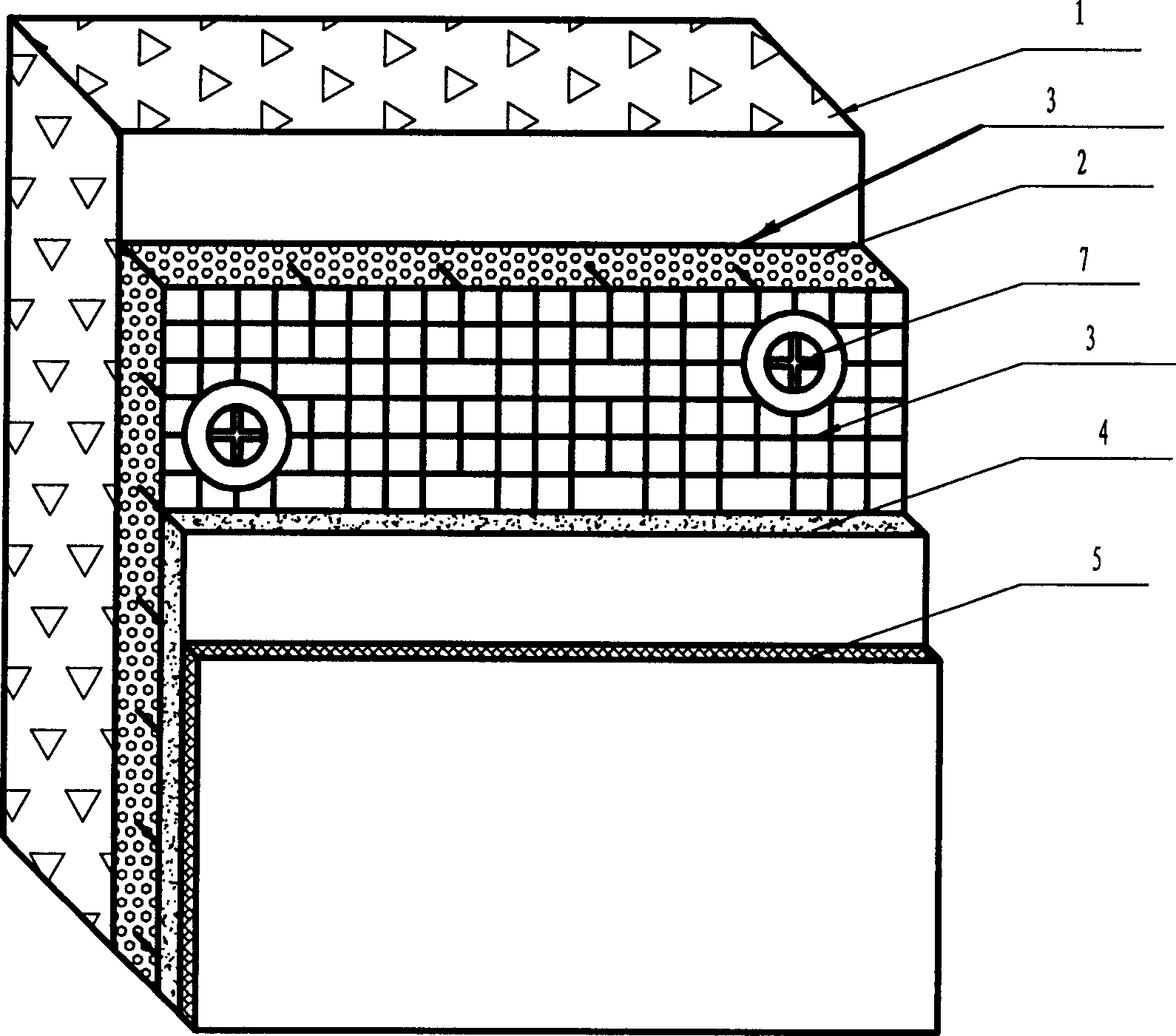

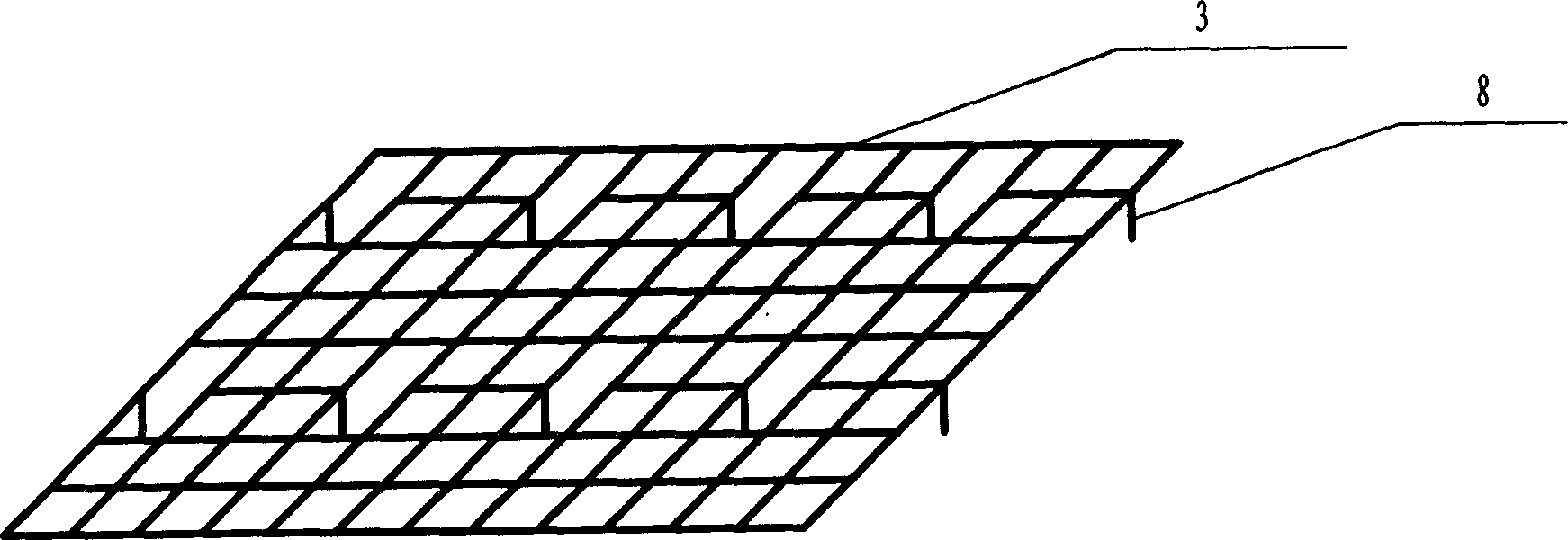

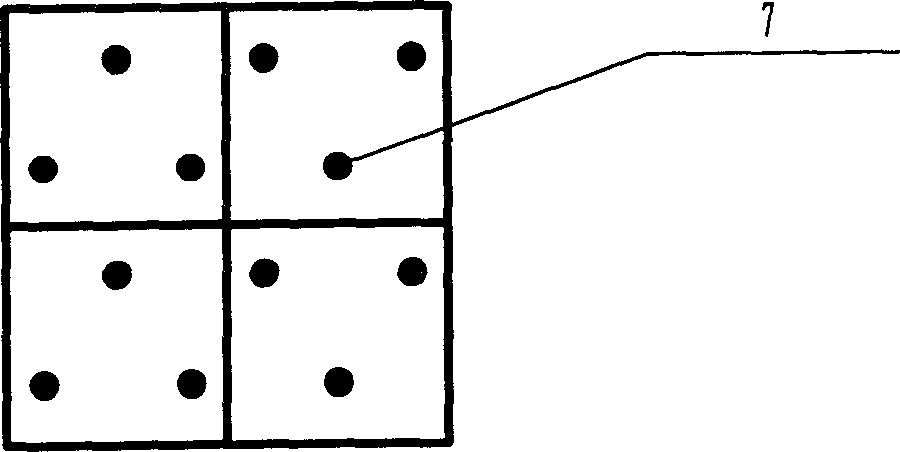

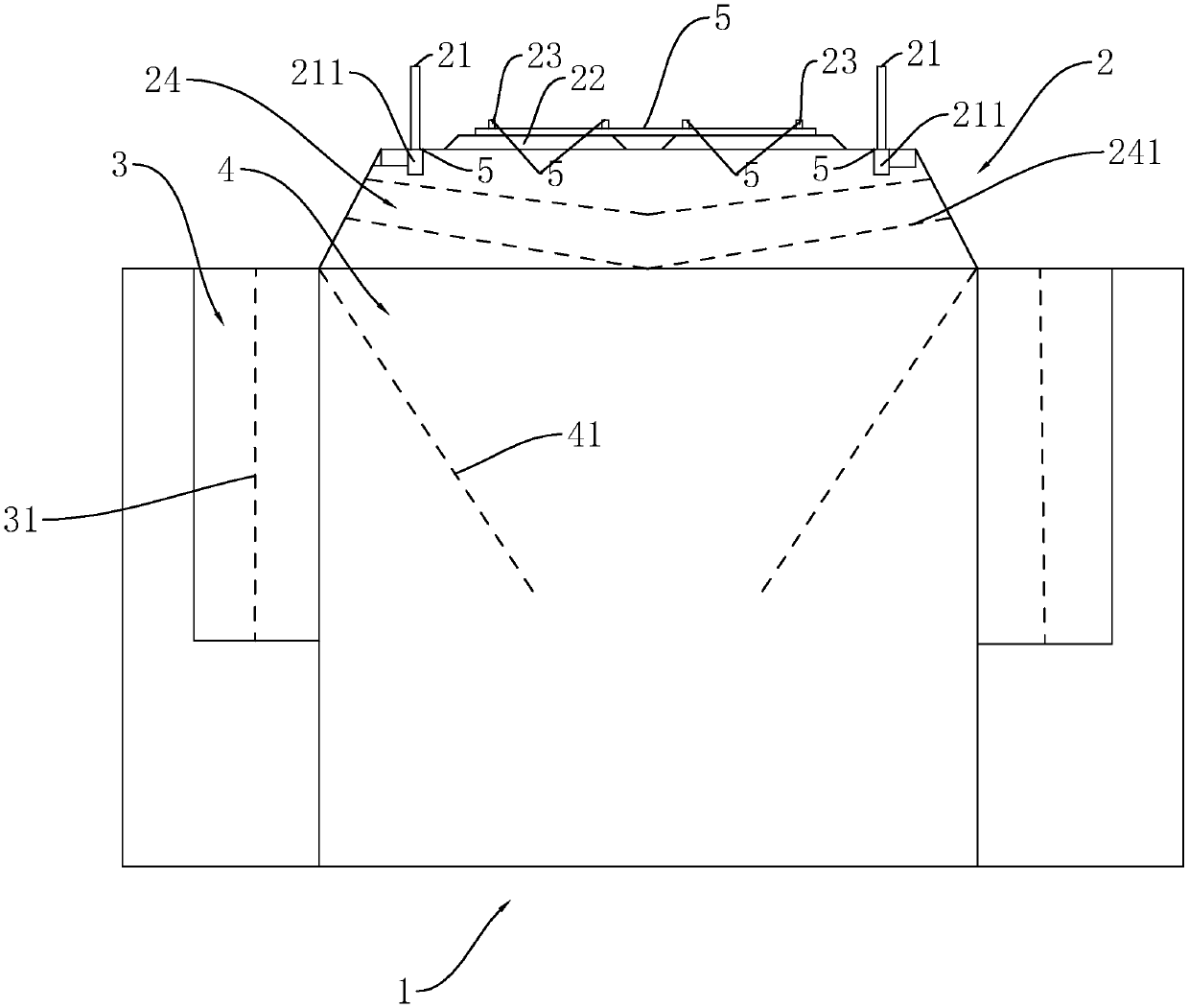

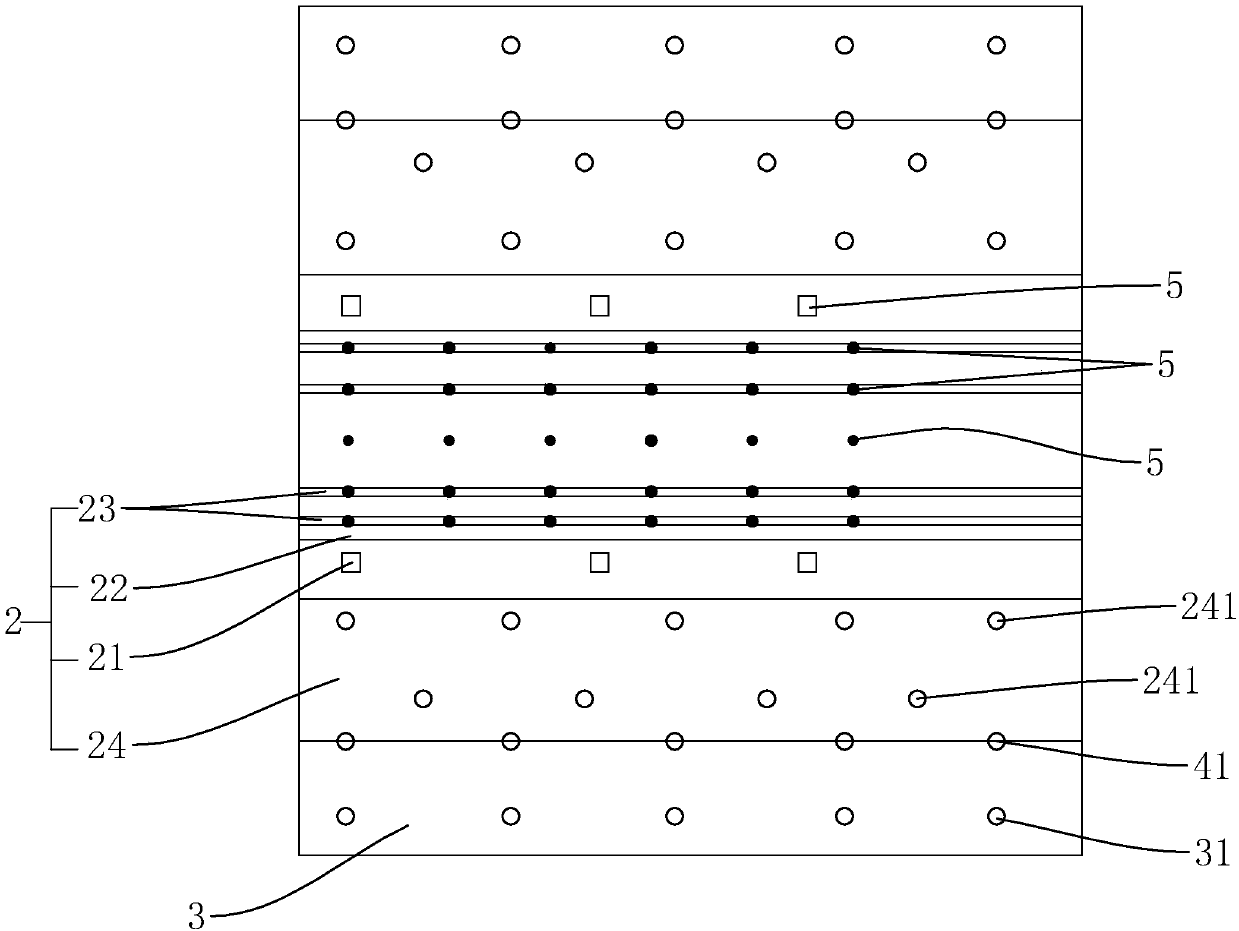

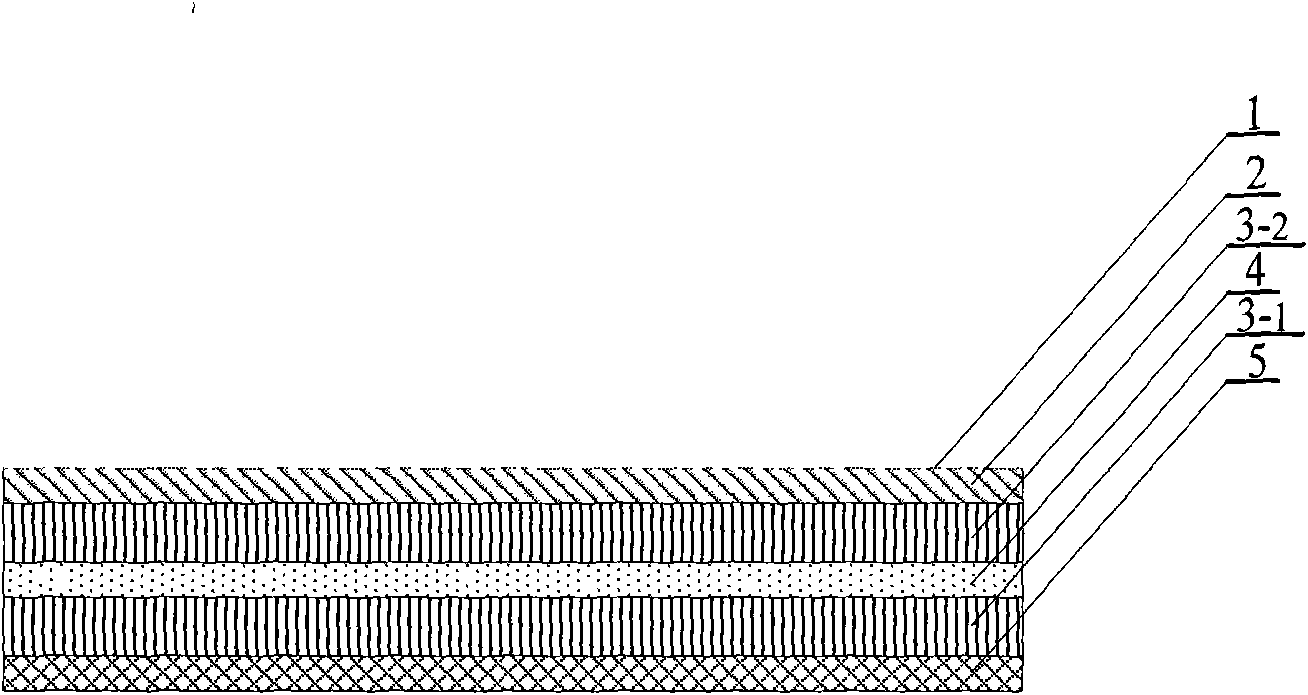

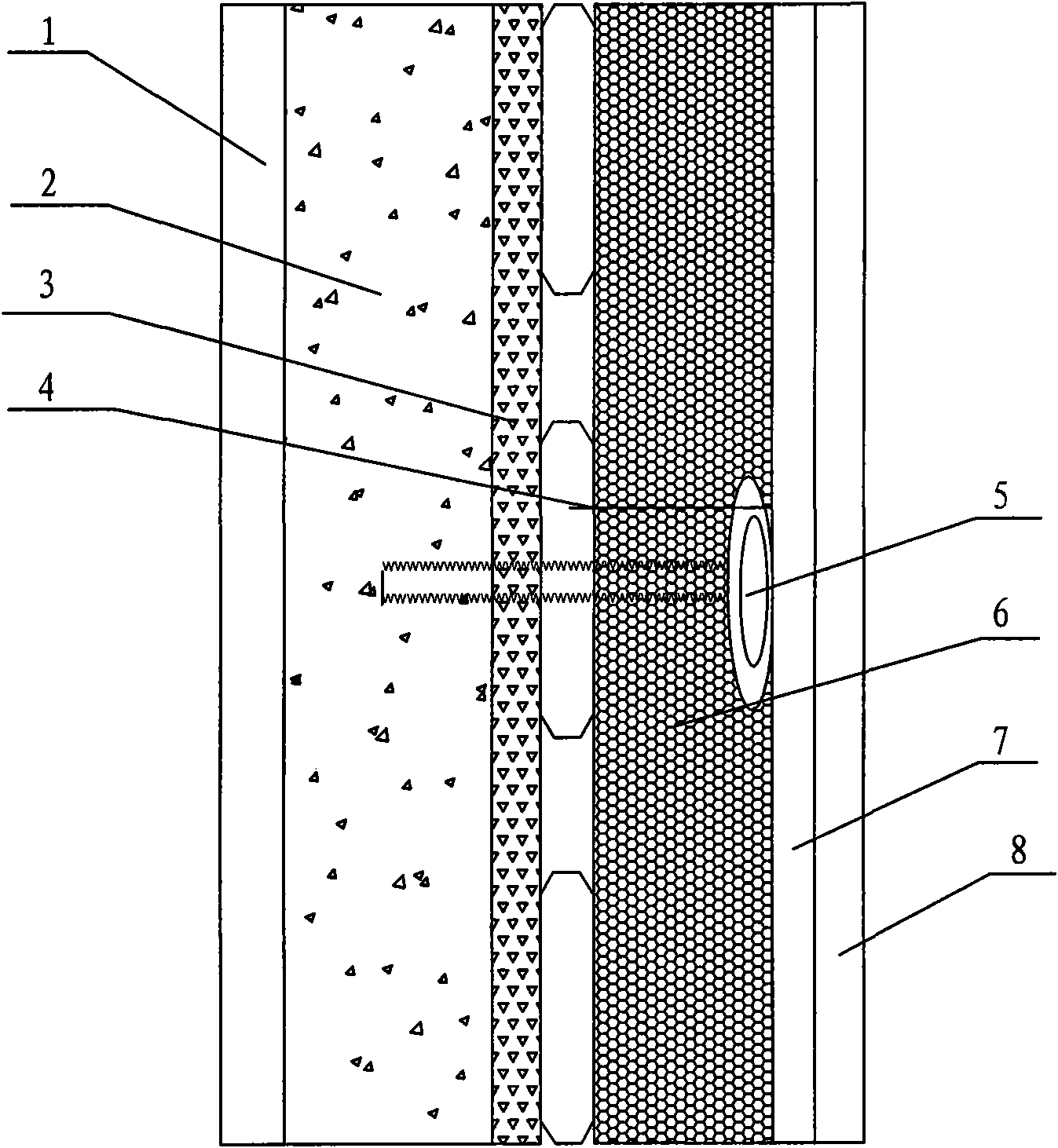

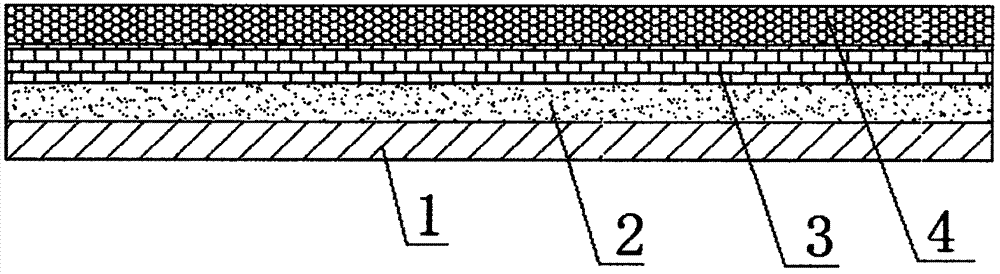

Heat-insulation wall with 3-D anchoring structure and construction technology

This invention discloses a heat preservation wall with 3-D anchorage structure including a basic layer, a heat preservation layer, a polymer anti-crack mortar layer and a decoration layer characterizing that a 3-D anchorage metal net is set between the heat preservation layer and the polymer anti-crack mortar layer and a nail-like heave plug into the heat preservation layer is set on the net and an construction technology is also disclosed.

Owner:陈海渊

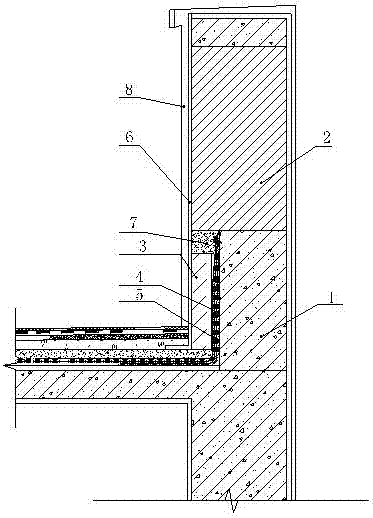

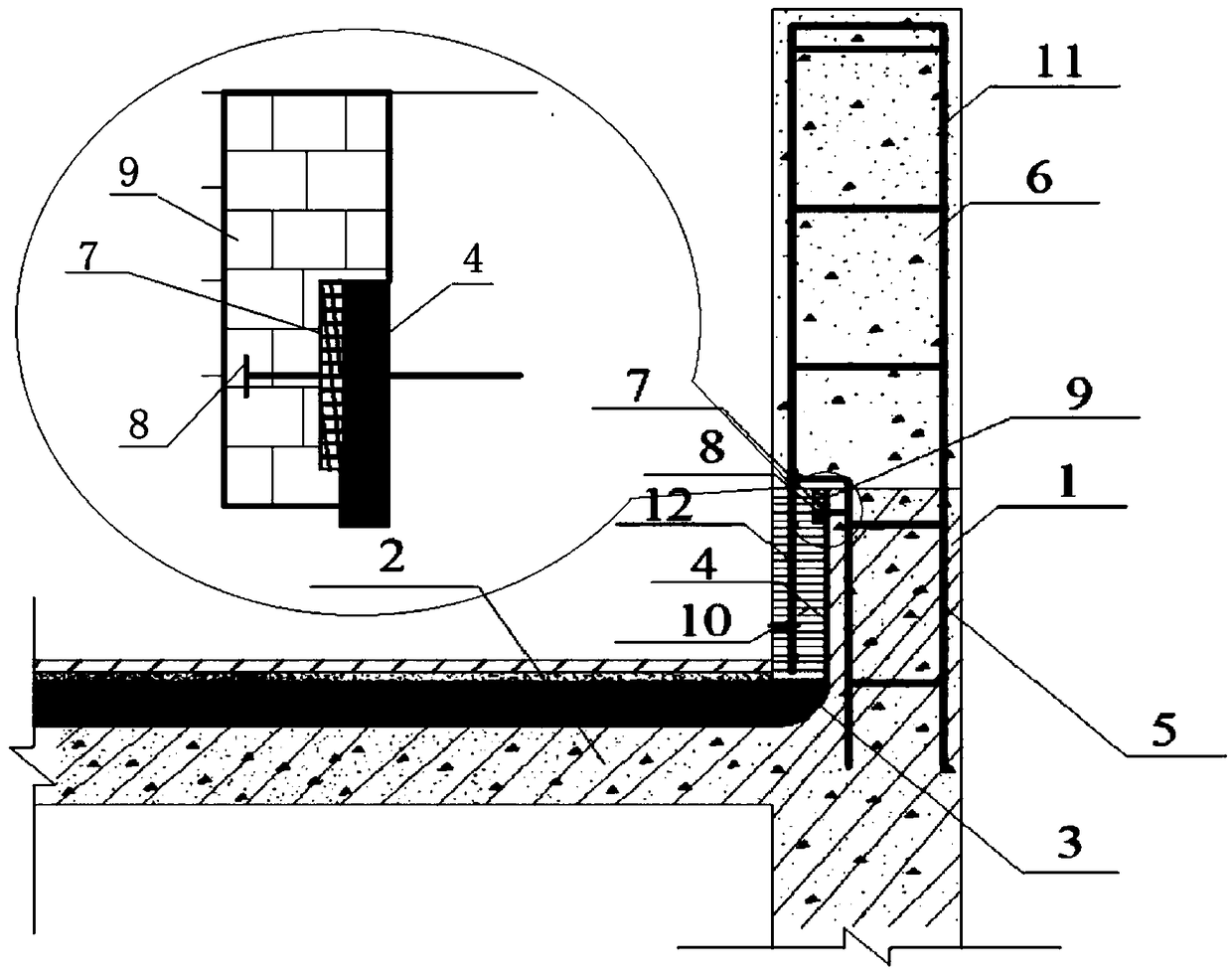

Building roof parapet wall flashing construction process

ActiveCN106906962ALow costEconomical cost, convenient operation and economicalSnow trapsBrickReinforced concrete

The invention relates to a flashing structure construction process, in particular to a building roof parapet wall flashing construction process. The building roof parapet wall flashing construction process comprises the following steps that step one, a flashing wall body of a reinforced concrete structure is poured on a building roof; step two, a waterproof roll is paved and pasted on the inner facades of the roof and the flashing wall body to form a waterproof layer, and the upper end of the waterproof roll is subjected to head retraction treatment; step three, a protective brick wall is laid on the outer facade of the waterproof layer through solid bricks, the inner facade of the protective brick wall is tightly attached to the waterproof roll, and the waterproof roll is tightly pressed on the flashing wall body, wherein the protective brick wall is no larger than the flashing wall body; and step four, a parapet wall is laid on the flashing wall body through solid bricks on the basis of the top of the flashing wall body, wherein the thickness of the wall body of the parapet wall is equal to the distance between the outer facade of the flashing wall body and the outer facade of the protective brick wall. A flashing structure built through the building roof parapet wall flashing construction process has the advantages of being resistant to cracking and falling-off and long in guarantee period and is convenient to construct and low in cost, and materials are convenient to obtain.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

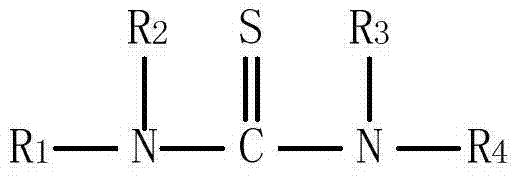

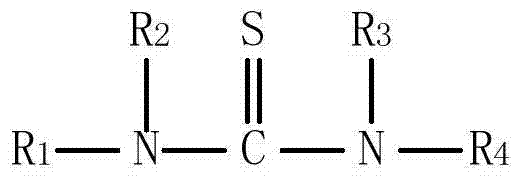

Battery

The invention discloses a battery comprising a cathode, an anode, and an electrolyte solution. According to the battery, the cathode comprises a cathode active material capable of realizing reversible deintercalation-intercalation into first metal ions; the electrolyte solution comprises a solvent capable of dissolving and ionizing electrolytes; the electrolytes comprise the first metal ions and second metal ions; in charging processes, the second metal ions are transformed into second metal via reduction, and the second metal is deposited on the anode; and in discharging processes, the second metal can be transformed into the second metal ions via reversible oxidation dissolving. The battery also comprises additives added into the electrolyte solution; and the additives comprise one or a plurality of compounds selected from Tween, tertiary amine compounds, heterocyclic quaternary ammonium salts, and thioamide. The battery is capable of inhibiting generation of gas effectively, so that battery expansion is avoided, and battery safety is improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

Fabrication method for surface electroplating coating layer of NdFeB rare-earth permanent magnet

ActiveCN107039168AIncreased vacuum handlingContains to avoidPermanent magnet manufactureVacuum pumpingMetallurgy

The invention belongs to the technical field of corrosion-prevention surface processing, and particularly relates to a fabrication method for a surface electroplating coating layer of an NdFeB rare-earth permanent magnet. The fabrication method comprises the steps of firstly, pre-processing a surface of the NdFeB rare-earth permanent magnet; secondly, performing vacuum pumping on the NdFeB rare-earth permanent magnet; and finally, electroplating by employing an ultrasonic wave electroplating groove. By the fabrication method, expansion and bubbles of a plating layer caused by a hydrogen evolution effect are prevented, the corrosion prevention performance of the surface coating layer of the NdFeB rare-earth permanent magnet is improved, an existing NdFeB electroplating corrosion-prevention technology is expected to be substituted, and thus, the fabrication method has a very wide application prospect.

Owner:凉山稀土产业技术研究院

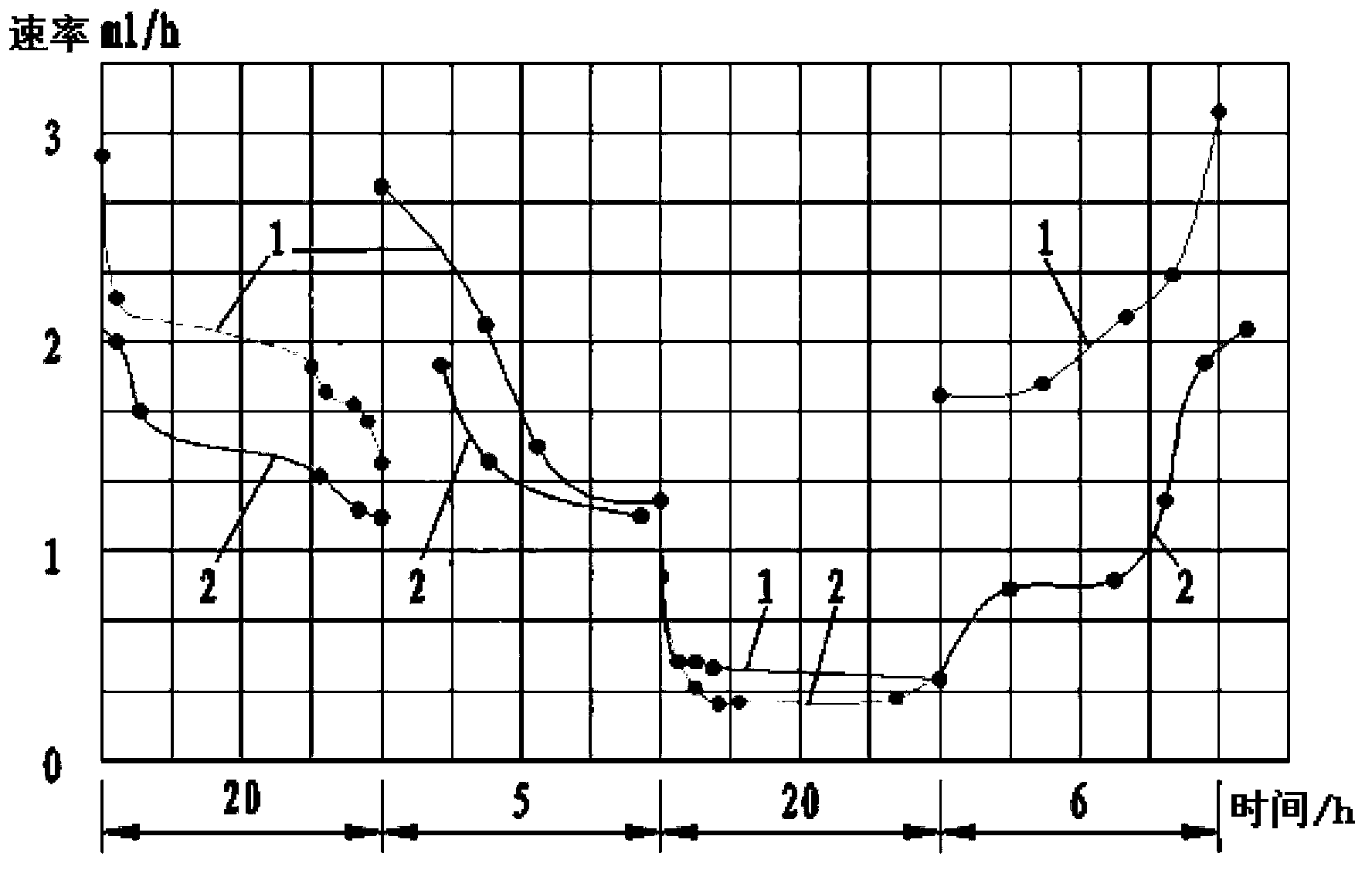

High-speed railway roadbed uneven settlement reinforcement lifting and leveling method

ActiveCN110241662APrevent proliferationLifting speed is fastRailway tracksSoil preservationEngineeringOperability

The invention relates to a high-speed railway roadbed uneven settlement reinforcement lifting and leveling method. The high-speed railway roadbed uneven settlement reinforcement lifting and leveling method comprises the following steps: S1, a reinforcement area is formed, specifically, the reinforcement area is formed in an embankment below a railway track through static pressure grouting; S2, curtain walls are formed, specifically, the curtain walls are formed on the positions, close to the slope toe, of the two sides of the embankment through static pressure grouting; and S3, lifting and leveling are conducted, specifically, an area between the reinforcement area and the curtain walls serves as an acting force pushing area, a static pressure grouting method is adopted, and by grouting the acting force pushing area, the upward grouting pressure is generated to evenly lift the embankment reinforcement area. The high-speed railway roadbed uneven settlement reinforcement lifting and leveling method has the advantages that a technology is simple, operability is high, interference is avoided, and the construction efficiency is high.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

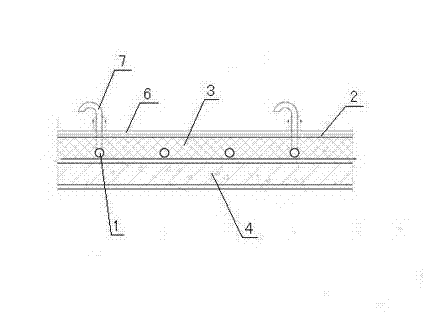

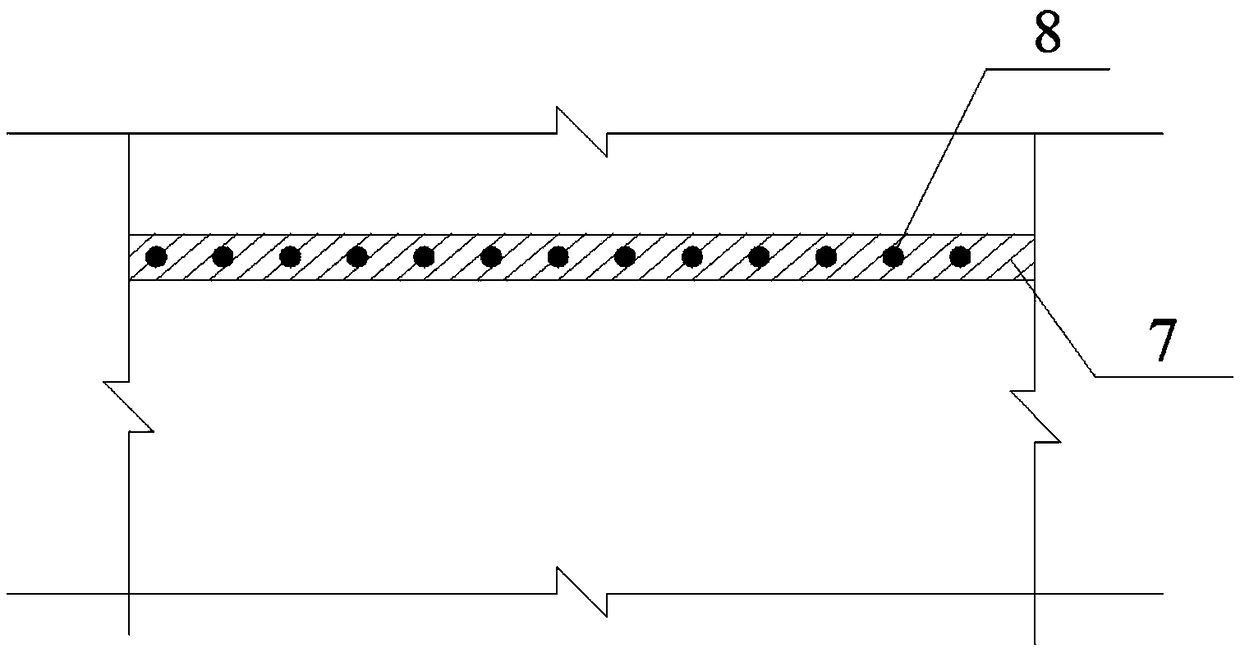

Construction method for insulating layer of roof

InactiveCN103362253AAvoid drummingAvoid crackingLighting and heating apparatusBuild-up roofsInsulation layerArchitectural engineering

The invention relates to a building construction method, in particular to a construction method for an insulating layer of a roof. According to the construction method, the insulating layer is constructed with cement expanded perlite and can be prevented from cracking. The construction method is characterized by including: paving the cement expanded perlite insulating layer on the roof, mounting an exhaust pipe in the cement expanded perlite insulating layer, paving a waterproof layer on the cement expanded perlite insulating layer, and paving a fine aggregate concrete protective layer on the waterproof layer. By the aid of the construction method, water vapor in the insulating layer can be well exhausted from the exhaust pipe, the roof can be prevented from convex and crack, and good heat insulating and water proofing effects can be achieved.

Owner:夏翠萍

Method for preparing Fe-Ni soft-magnetic material with high anti-corrosion capability

InactiveCN107785142AUniphasic goodEvenly dispersedInorganic material magnetismPermanent magnet manufactureMagnetite NanoparticlesHydrogen evolution

The invention discloses a method for preparing a Fe-Ni soft-magnetic material with high anti-corrosion capability. NiFe2O4 magnetic nanoparticles are prepared by adopting an improved sol-gel method and are good in single-phase property and relatively uniform in dispersion; the method is simple and is relatively low in cost compared with the prior art. In addition, the surface of soft magnetic alloy is electroplated with a coating, the bubbling and blistering of the plating caused by a hydrogen evolution effect are avoided, and the corrosion resistance of the soft magnetic alloy is improved.

Owner:SUZHOU NANER MATERIAL TECH CO LTD

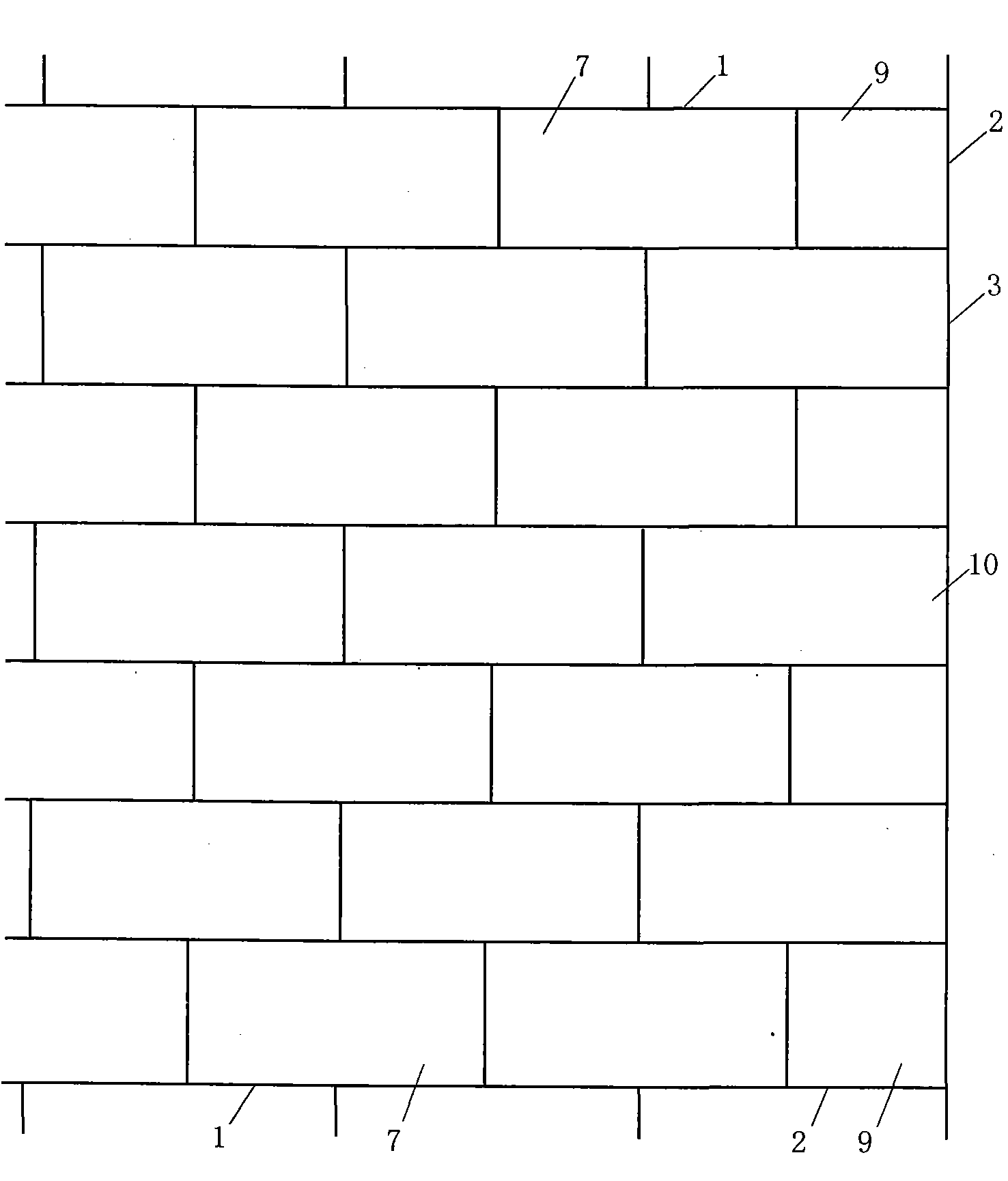

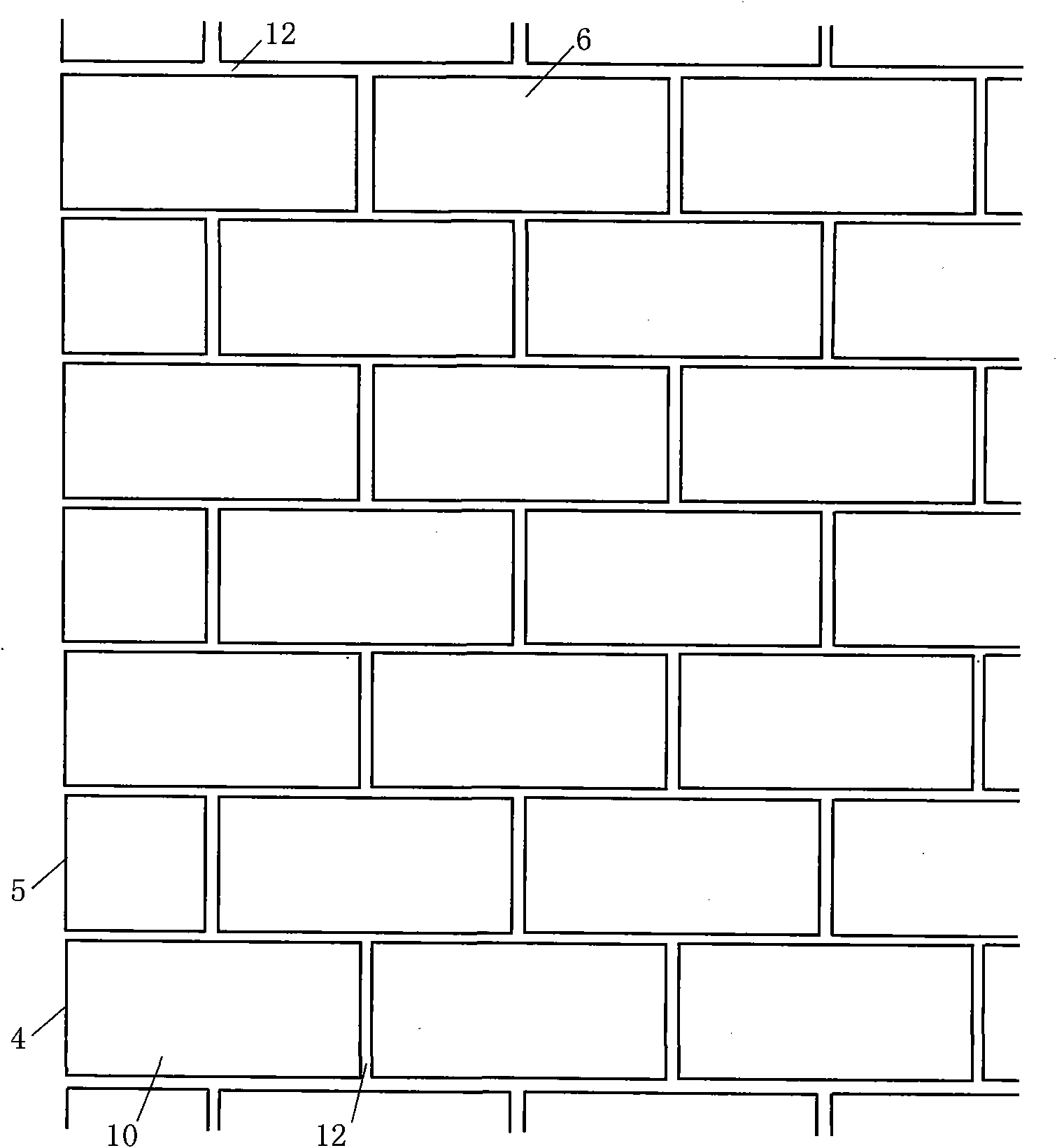

Integral load-bearing, thermal-insulation heat-preservation wall body structure

InactiveCN101851980AAvoid drummingIncreased strength andConstruction materialWallsBuilding productEngineering

The invention relates to an integral load-bearing, thermal-insulation heat-preservation wall body structure, which consists of various prefabricated brick bodies, wherein various prefabricated brick bodies comprise straight bricks, left external corner bricks, right external corner bricks, left internal corner bricks and right internal corner bricks. Various brick bodies are all made of two kinds of foaming concrete with high density and low density through composite casting, the straight bricks consist of two kinds of cuboids with different densities, each corner brick consists of two cuboids with two different densities and the included angle of 90 degrees, and the boundary of two densities of the two adjacent surfaces forms a step to be used as a mortar layer during the construction. Four surfaces constructed by the cuboids with small density are all provided with semicircular lug bosses or grooves, wherein two sides are provided with the lug bosses, and the other two sides are provided with the grooves. The integral load-bearing, thermal-insulation heat-preservation wall body structure is prepared from cement, industrial residue, various aggregates, foaming agents and additives through different-density recipe adoption, mixing, stirring and foaming composite casting, and can be matched to be manufactured with in-site casting elements. The invention aims at providing an integral building structure, which is suitable for various wall body structures and has integrated dual function of one-step construction, load bearing and external wall thermal insulation and heat preservation. The invention has the characteristics of heat preservation effect and no exfoliation of external wall, no cold bridge, no blistering phenomenon, convenient construction, high efficiency and low cost, and belongs to a novel environment protection and energy saving construction product.

Owner:顾世章

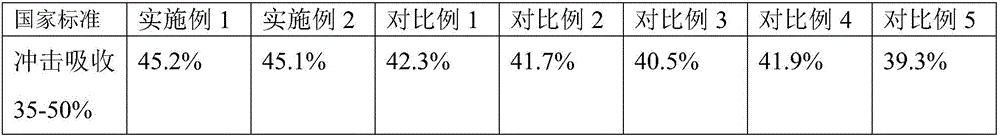

Environment-friendly track and field runway and preparation method thereof

The invention provides an environment-friendly track and field runway. The environment-friendly track and field runway is prepared from the main raw materials of 58-62% of Pvc paste resin, 35-39% of dioctyl terephthalate, 1-3% of a calcium-zinc stabilizer and 0.5-2% of azodicarbonamide. The invention further provides a preparation method of the environment-friendly track and field runway. Four substances are mainly adopted for matching, the environment-friendly track and field runway has the advantages of being good in damping effect, excellent in rebounding performance, large in adhesive force, high in spike resisting capability, good in slip resistance and wear resistance and the like and can be widely applied to pavement materials for athletic grounds, and the maintenance frequency can be reduced in application of the environment-friendly track and field runway.

Owner:河北东兴塑胶有限公司

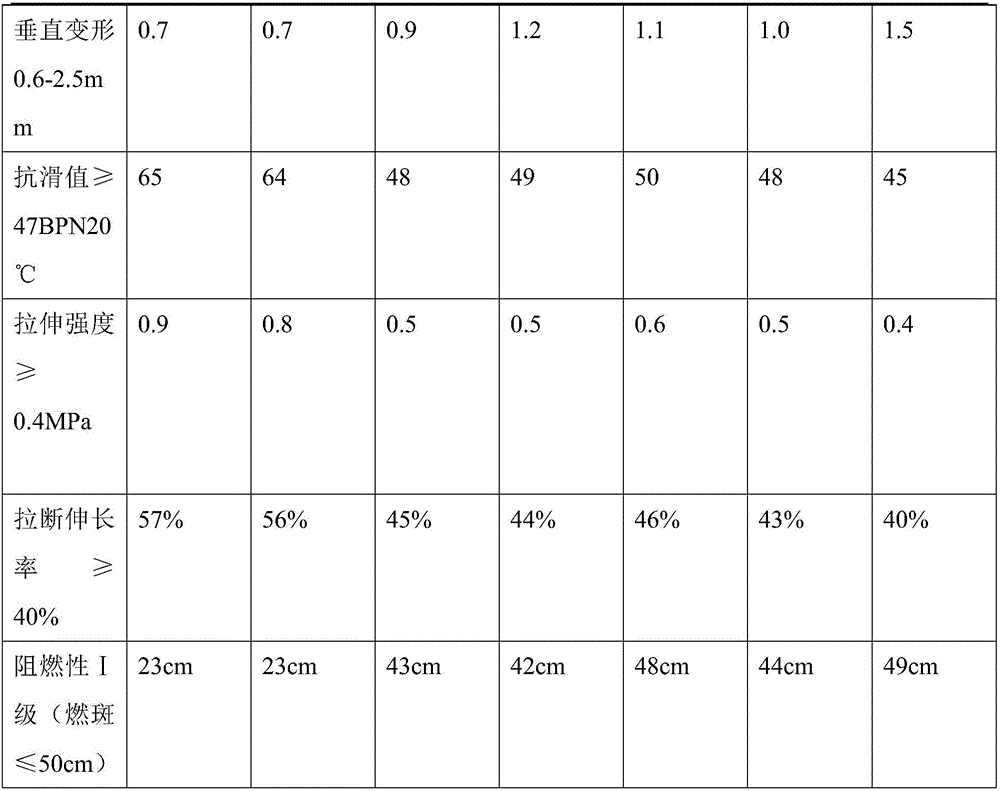

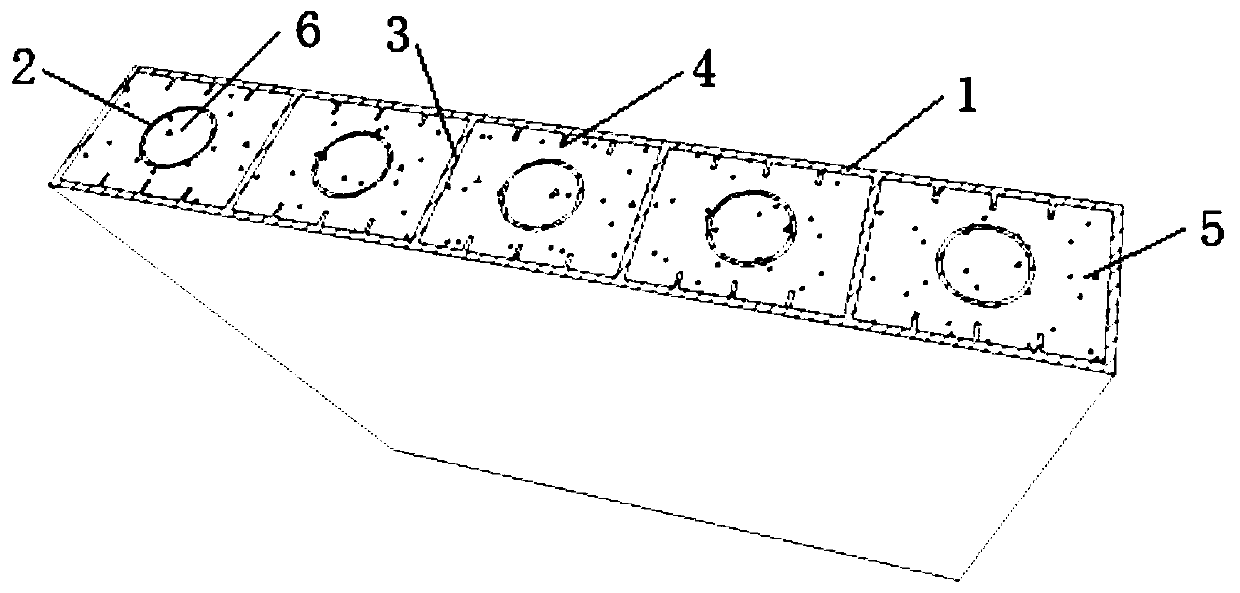

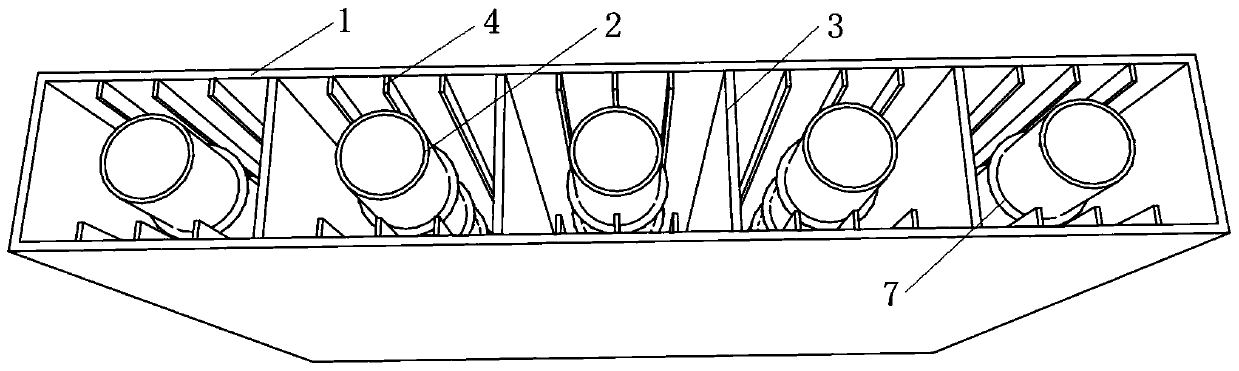

Multi-cavity steel plate build-in steel tube high-strength concrete shear wall

PendingCN111119379AGood adhesive couplingAvoid exposureWallsEarthquake resistanceClassical mechanics

The invention relates to the technical field of construction engineering, and discloses a multi-cavity steel plate build-in steel tube high-strength concrete shear wall. The shear wall comprises outerwrapping steel plates, partition plates and steel tubes. The multiple outer wrapping steel plates are connected to form a space with the closed cross section, and the partition plates are arranged inside the space at intervals, so that the space is partitioned into a plurality of cavity bodies. The steel tubes are arranged in the cavity bodies respectively. Concrete is poured into the cavity bodies and the steel tubes. The shear wall has the beneficial effects that the restraint effect of the steel plates and the steel tubes for concrete is sufficiently utilized, the bearing capacity, rigidity and ductility of the shear wall are enhanced, the good anti-seismic performance is achieved, the outer side steel plates can also be used as formworks, construction is easy and convenient, the construction period is shortened, and the shear wall is expected to be a novel shear wall system in a super high-rise building.

Owner:GUANGZHOU UNIVERSITY

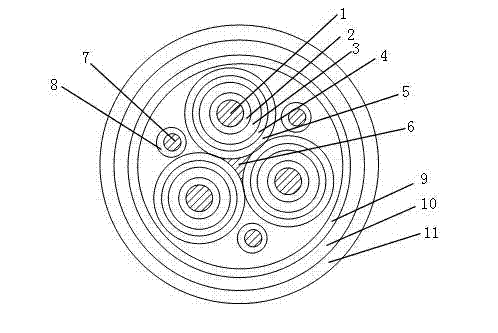

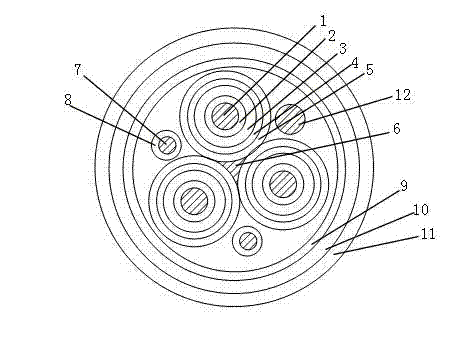

High-voltage dragging rubber-sheathed flexible cable for mine

InactiveCN103208333AHigh strengthImprove insulation performancePower cables with screens/conductive layersElectrical conductorElectric cables

The invention discloses a high-voltage dragging rubber-sheathed flexible cable for mine. The high-voltage dragging rubber jacketed flexible cable comprises a cable conductor which is formed by a plurality of power wire cores and a plurality of pilot wire cores through twisting, an inner sheath is extruded outside the cable conductor, an outer sheath is extruded at the outermost layer of the cable, and a reinforcement layer is woven between the inner sheath and the outer sheath. Each of the three power wire cores is composed of a power conductor and a semi-conductive inner shielding layer, a power wire core insulating layer, a semi-conductive outer shielding layer and a metal shielding layer which are extruded outside the monitoring conductor. By means of the high-voltage dragging rubber-sheathed flexible cable, performances of sheathes are improved, a flexible reinforcement structure is adopted, ground pilot wire cores and the reinforcement layer are added, so that not only the resistance to abrasion and corrosion and the anti-dragging tensile strength of the cable are improved, but also the safe use performance of the cable is added, and the deflection performance of the cable is not affected simultaneously.

Owner:JIANGSU ZHONGMEI CABLE

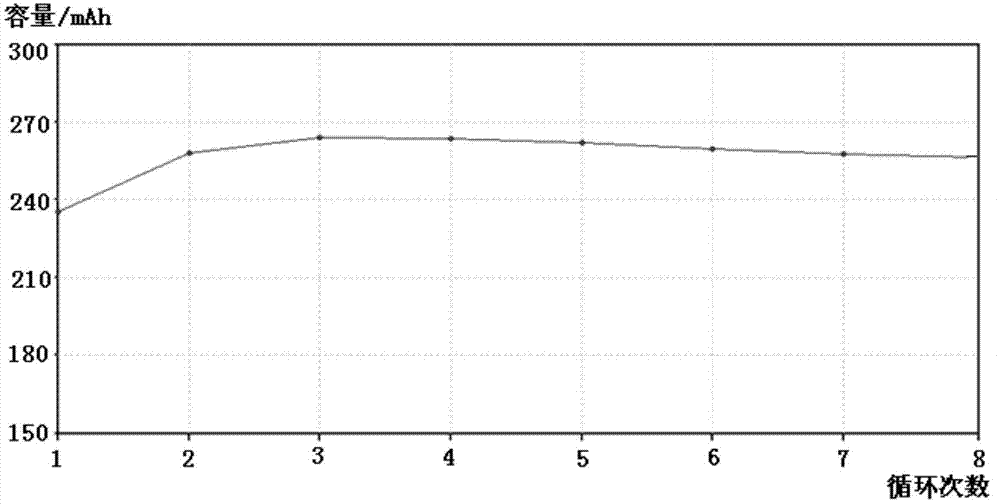

Battery

InactiveCN104282910AInhibitionAvoid drummingNon-aqueous electrolyte accumulatorsCell electrodesBismuth compoundPhysical chemistry

The invention discloses a battery. The battery comprises a positive pole, a negative pole and electrolyte and also comprises an additive, wherein the positive pole comprises a positive pole active substance, and first metal ions can be reversibly separated from or embedded into the positive pole active substance; the electrolyte comprises at least one solvent through which the electrolyte can be dissolved and ionized; the electrolyte comprises second metal ions and the first metal ions; in the charging and discharging processes, the second metal ions can be reduced and deposited on the negative pole, so as to form second metal, and the second metal can be reversibly oxidized and dissolved; the first metal ions can be reversibly separated from or embedded into the positive pole in the charging and discharging processes; and the additive is added into the negative pole and / or the electrolyte and refers to a bismuth compound. According to the battery disclosed by the invention, gases are effectively inhibited, so that the battery is prevented from swelling, and the safety performance of the battery is enhanced.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

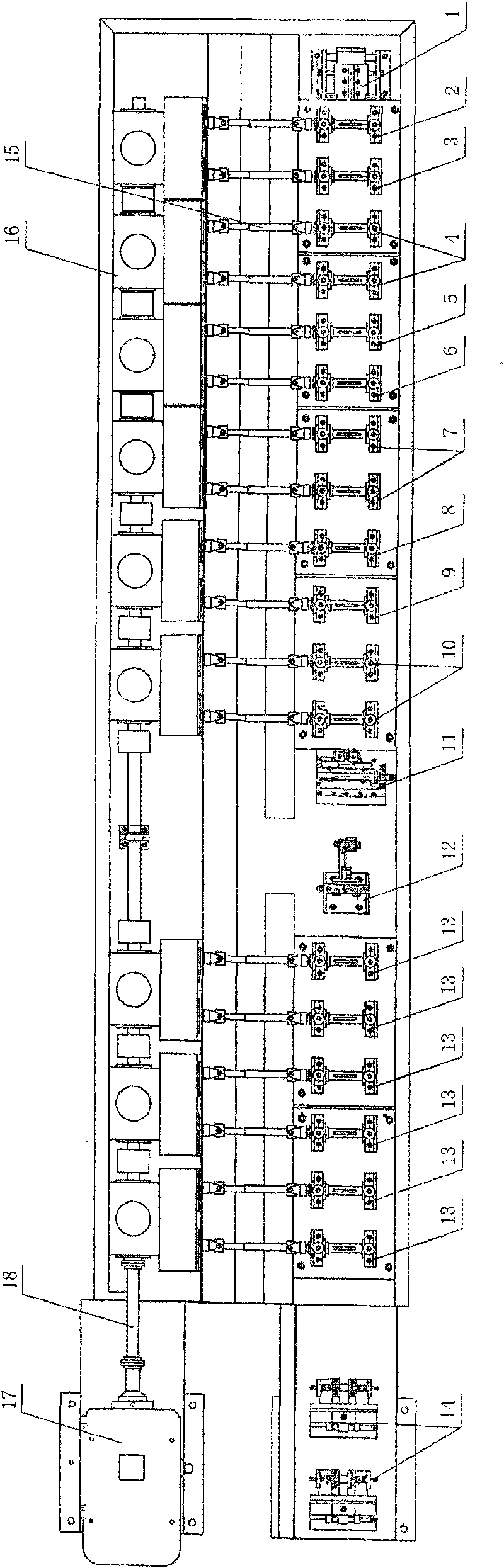

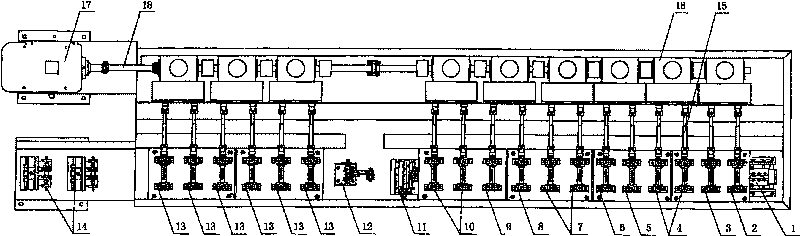

Aluminum strip forming machine

ActiveCN101733637AReduce stressReduce saw kerf burrsOther manufacturing equipments/toolsSurface finishPunching

The invention relates to an aluminum strip forming machine; a character mould (2), a press line mould (3), one or two press angle mould(s) (4), a closing in mould (5), a press arc mould (6), one or two closing in mould(s) (7), a punching mould (8), a rear closing in mould (9), one or two closed mold(s) (10) and a plurality of integral parts (13) are respectively connected with a transmission shaft (15); all the transmission shafts (15) are respectively connected with a speed changing box (16); each speed changing box (16) is connected with a main shaft (18); each main shaft (18) is connected on a motor (17); the plurality of speed changing boxes (16),the main shafts (18) and the motor (17) are sequentially arranged on a working platform in a row in parallel; and material guiders (1) are arranged in front of the character mould (2) of the working platform in parallel. The aluminum strip forming machine has the advantages of saving cost, improving the product quality and enhancing the surface finish quality of the product.

Owner:宁波江花玻璃科技有限公司

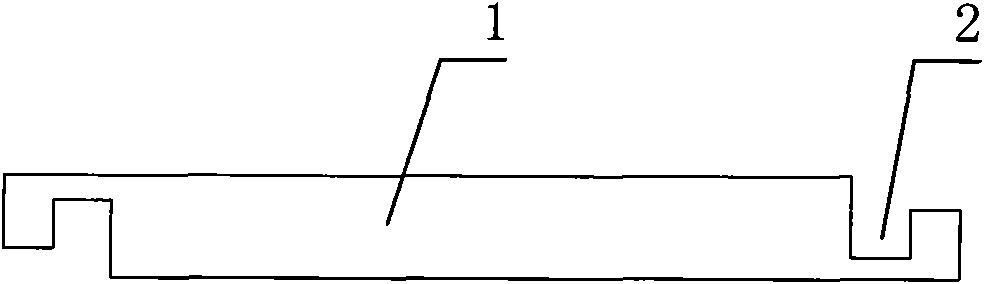

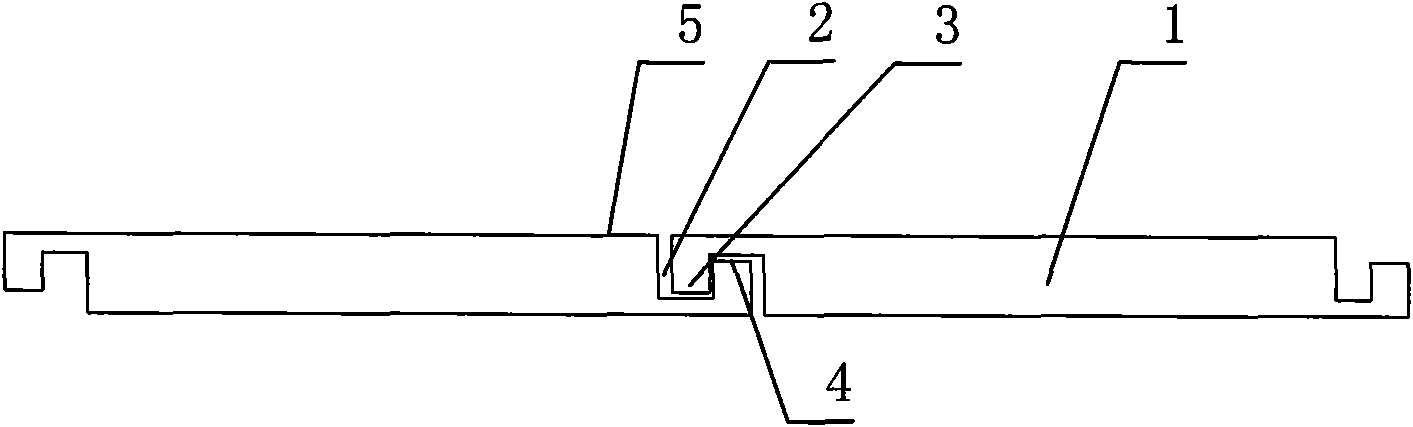

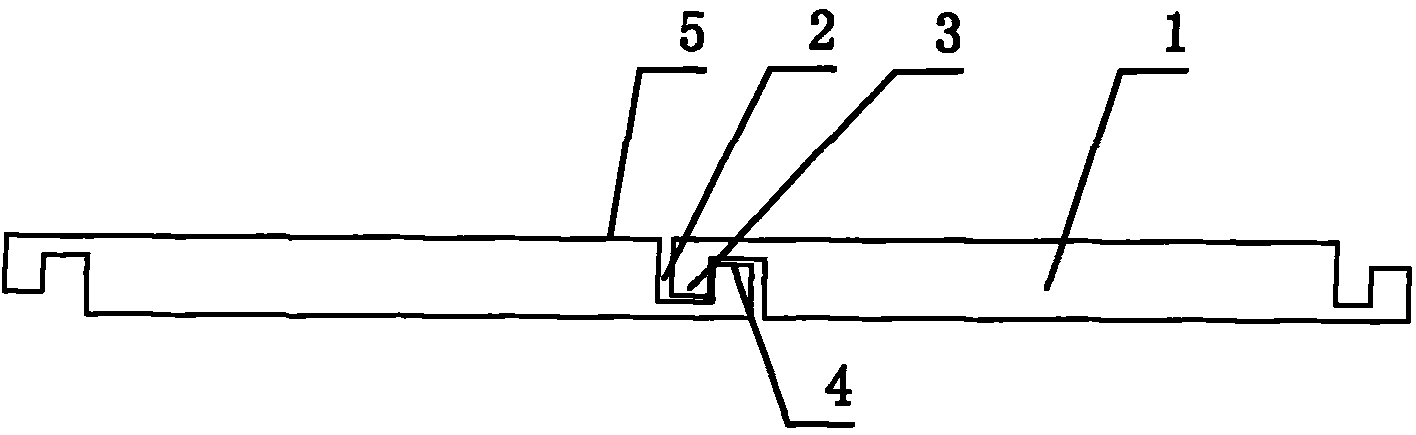

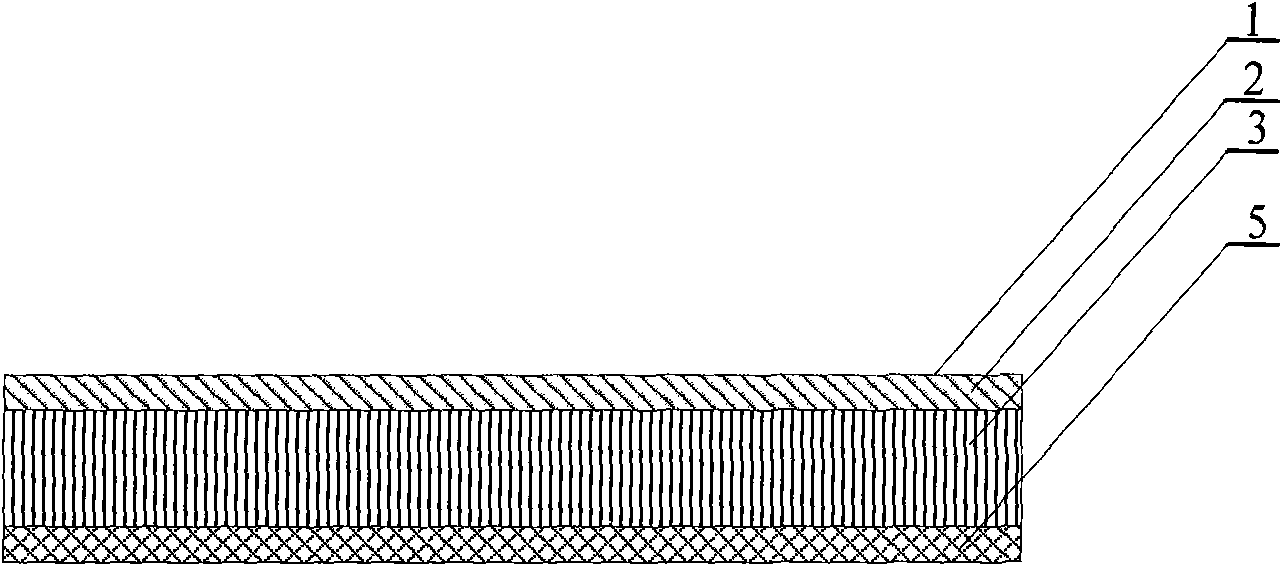

Floor block

The invention relates to a floor block and provides the floor block by aiming at the problem of no lap joint between the floor blocks in the prior art. The floor block has the innovation points that grooves are arranged at the edge of the floor block, the thickness of the floor block at the outer ends of the grooves is smaller than the thickness of the floor block at the inner ends of the grooves, and the grooves are matched with bulges arranged on the adjacent floor block for realizing the connection. The floor block in the structure does not have too high requirement on the skill of floor paving workers, the floor blocks can be paved only through the seam matching lap joint, in addition, after the floor block is paved onto the ground, when the floor block expands, the width of the grooves is greater than the thickness of the bulge blocks of the adjacent floor blocks, and the automatic contraction can be realized at the lap joint part, so the floor bulge is avoided. When the floor contraction occurs, the floor block receives the tension of the lap joint part during the contraction, so the attractive appearance influence on the ground caused by the excessive contraction of the floor block is avoided. The floor block has the advantages that the structure is simple, and greater cost does not need to be taken during the manufacture, so the floor block is favorable for popularization and application.

Owner:王晶晶

Waterproof roll with multilayer structure

ActiveCN101581137AStop erosionExtended service lifeCovering/liningsRoof covering using flexible materialsToxic gasBituminous waterproofing

The invention relates to a waterproof roll with multilayer structure, comprising a plastic substrate, asphalt or modified asphalt layers and a color nano fluorine-silicon-acrylate layer and a faying surface plastic side membrane; wherein, the first layer of the asphalt or modified asphalt layers and the color nano fluorine-silicon-acrylate layer are coated in sequence on the upper surface of the plastic substrate, and the faying surface plastic side membrane is compounded on the upper surface of the asphalt layer or the modified asphalt layer on the two sides of the color nano fluorine-silicon-acrylate layer; wherein, the thickness of the asphalt layer or the modified asphalt layer is 0.3-6.0mm; the thickness of the color nano fluorine-silicon-acrylate layer is 0.1-1.0mm. The waterproof roll with multilayer structure of the invention has colors on the surface, can prevent the erosion of strong solar ultraviolet and other harmful gases in the air, suppress the volatilization of the toxic gas in the asphalt under high temperature, improve the environment and be wholesome to the society. The waterproof roll can improve the service life of the asphalt or modified asphalt waterproof rolls, and can be taken as an environmental protection product with double functions of waterproofing and decorating and beautifying the environment.

Owner:KESHUN WATERPROOF TECH CO LTD

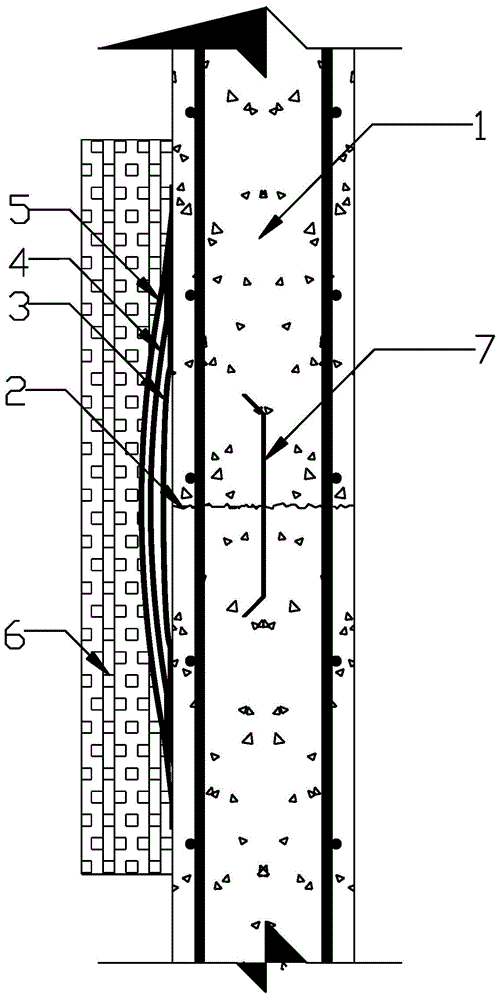

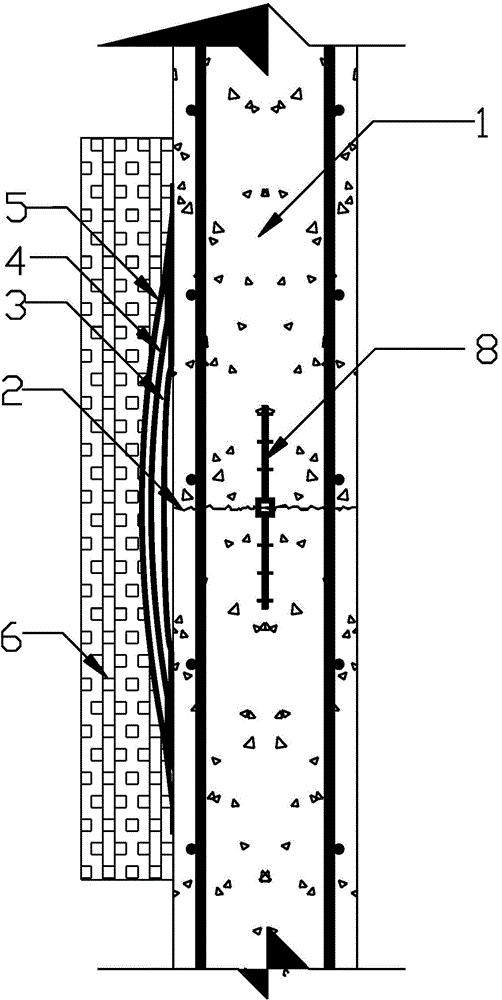

Concrete wall construction joint waterproof treatment method

ActiveCN104153397AEffective protectionPrevent leakageArtificial islandsUnderwater structuresEngineeringProtection layer

The invention relates to a concrete wall construction joint waterproof treatment method which comprises the steps of (1) cleaning a wall, (2) laying a first layer of waterproof coiled material, (3) laying a second layer of waterproof coiled material, (4) laying a third layer of waterproof coiled material and (5) attaching an outer protective layer. Compared with the prior art, the method has the advantages that a mode of stacking multiple layers of coiled materials is adopted, so that wall construction joints with a waterproof requirement are effectively protected, and an underwater leakage phenomenon caused by failure of waterproof measures is avoided; the waterproof coiled materials are not attached to a basic layer within a range and properly reserve expansion amount, so that the ability of a waterproof layer adapting to basic layer deformation is improved, and the waterproof coiled materials are prevented from being bumpy and cracking; the protective layer is additionally disposed outside the coiled materials, so that construction portions are protected from underground water or erosion of corrosive matter; the method is easy and convenient to operate, and people only need to operate according to conventional construction methods.

Owner:CHINA THIRD METALLURGICAL GRP

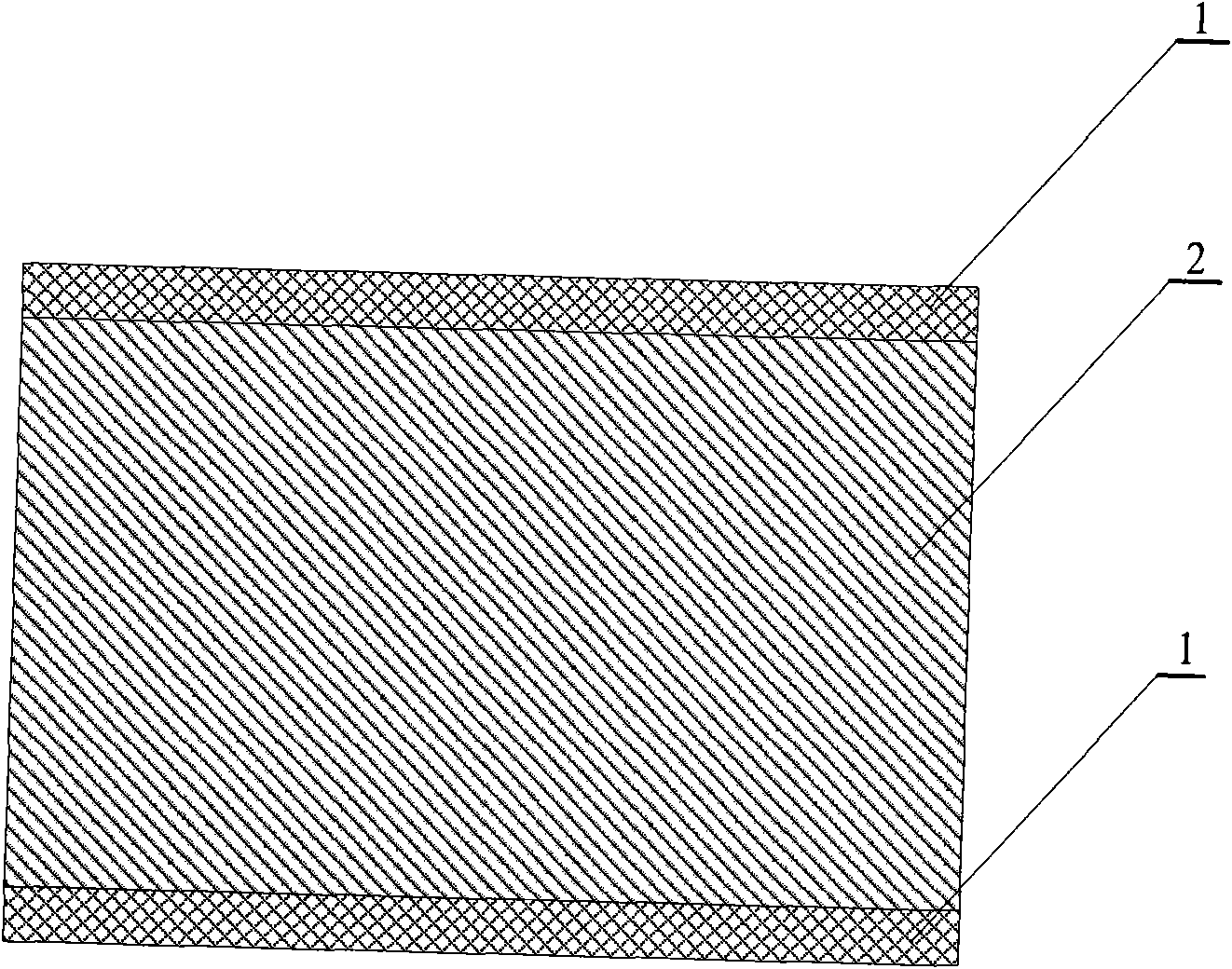

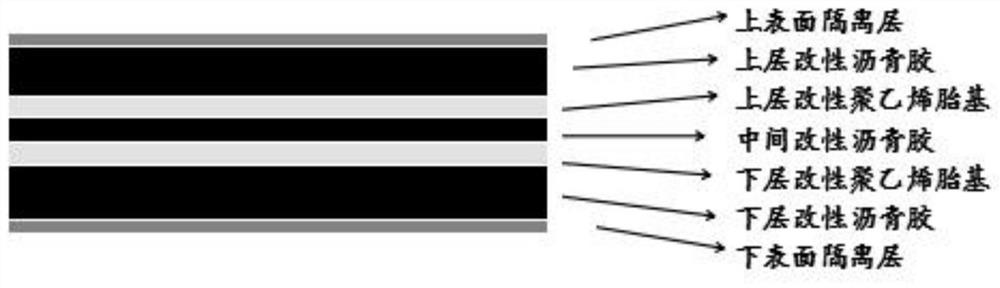

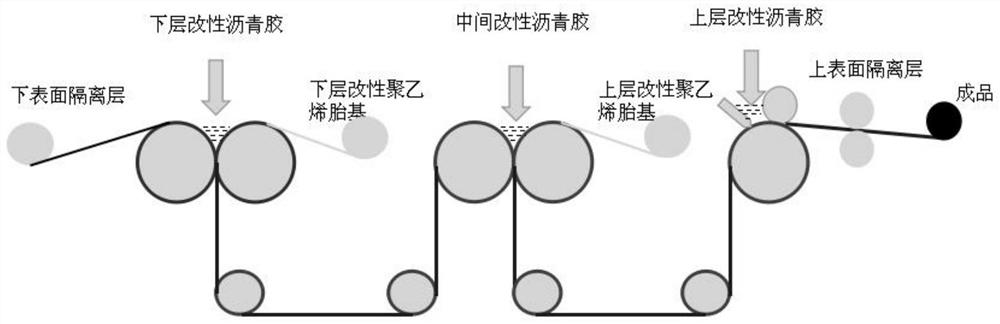

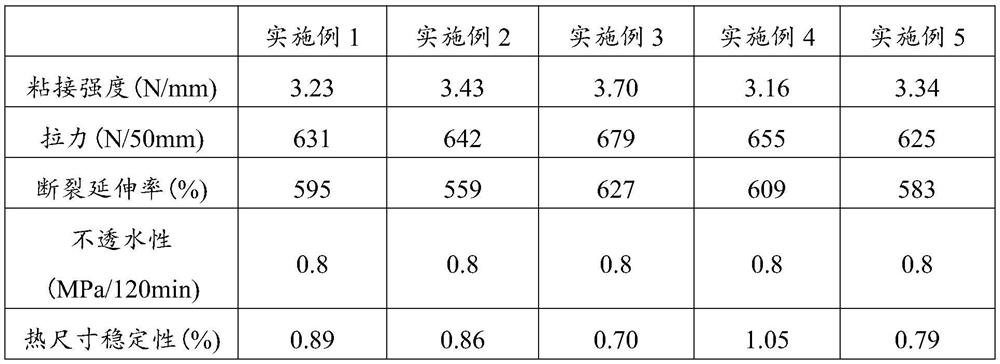

Double-base waterproof roll and preparation method thereof

InactiveCN111635710AHigh tensile strengthHigh elongationNon-macromolecular adhesive additivesBituminous material adhesivesAsphalt masticStructural engineering

The invention relates to the technical field of building materials, in particular to a double-base waterproof roll and a preparation method thereof. The structure of the double-base waterproof roll sequentially comprises an upper surface isolation layer, upper modified asphalt mastic, an upper modified polyethylene base, middle modified asphalt mastic, a lower modified polyethylene base, lower modified asphalt mastic and a lower surface isolation layer from top to bottom. The double-base waterproof roll is high in strength and elongation, the contradiction between the strength and the elongation of a traditional material is solved, the water impermeability is good, the thermal stability is excellent, and the waterproof effect of the roll is well guaranteed, no regenerated substance is added, the product quality is greatly improved, and the service life of the product is prolonged.

Owner:甘肃大禹防水科技发展有限公司

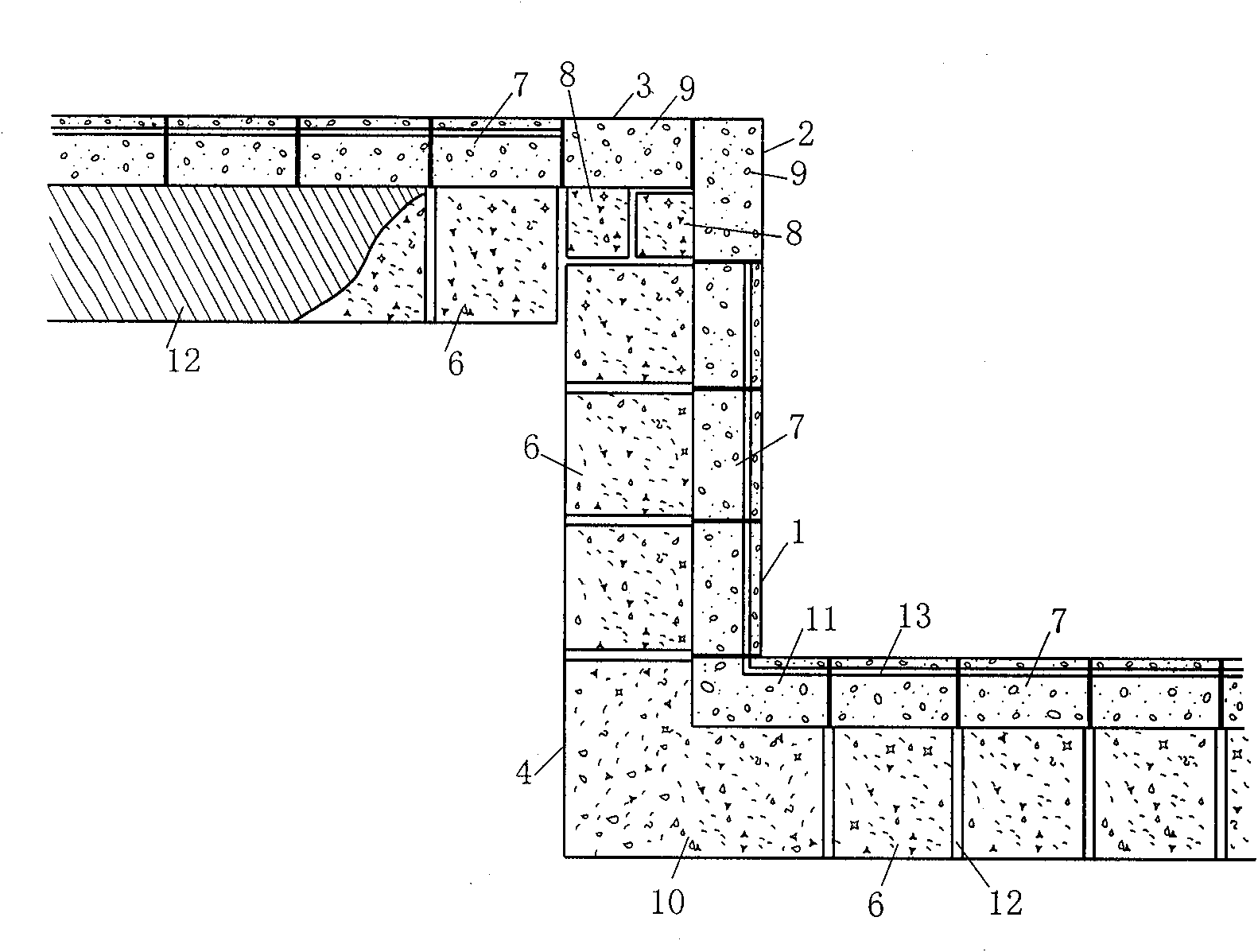

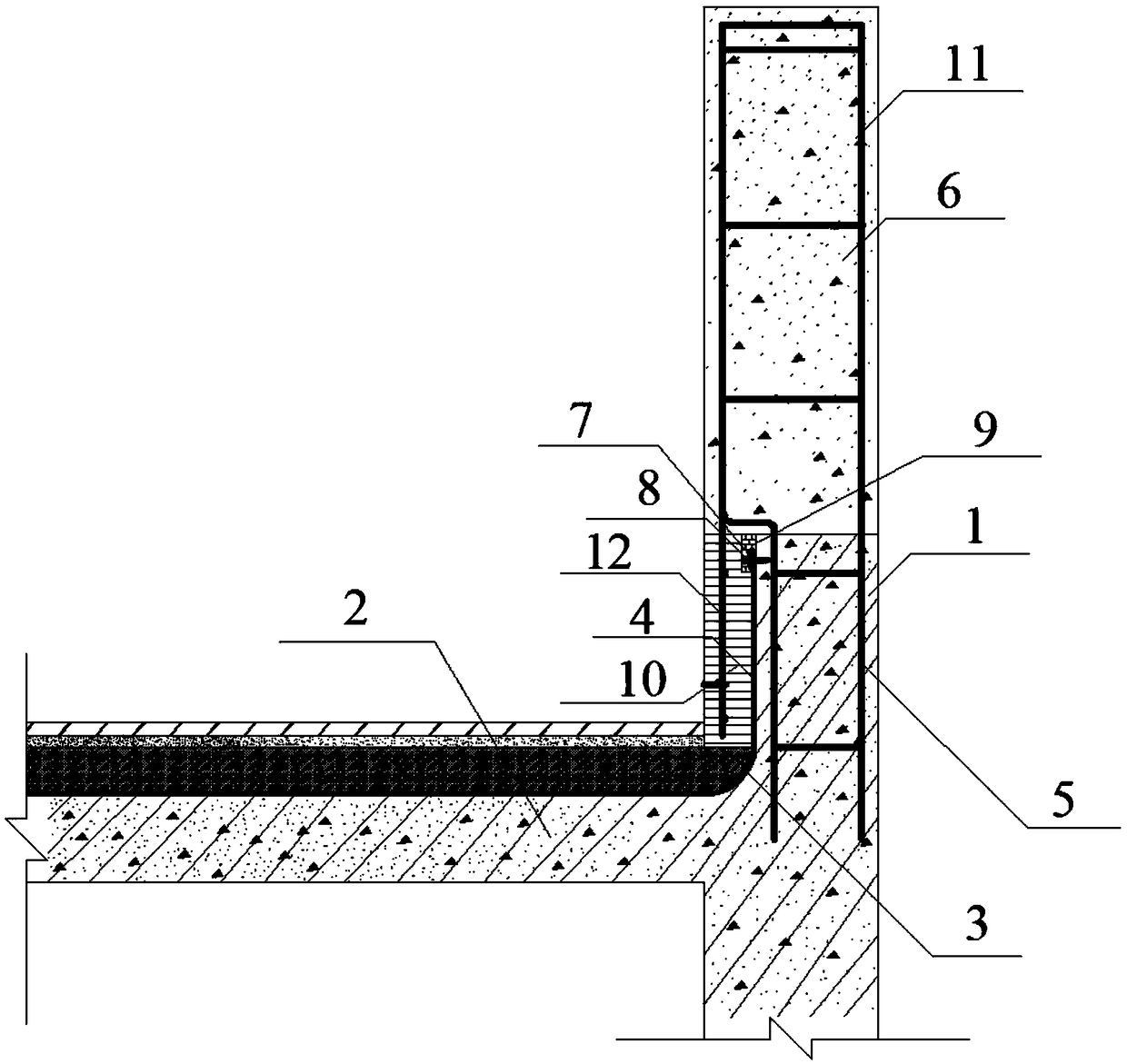

Flashing structure of building roof parapet and construction method

PendingCN109281443AAvoid crackingAvoid drummingSnow trapsReinforced concreteArchitectural engineering

The invention relates to a building roof parapet. The building roof parapet comprises a flashing wall body integrated with a building roof structural layer and a waterproof protective layer of a reinforced concrete structure poured on the outer side of a parapet body, wherein on the top surface of the flashing wall body, the parapet body and the flashing wall body are connected through an internally arranged rebar structure, the thickness of the parapet body is larger than that of the flashing wall body, and the bottom of the side, away from the flashing wall body, of the parapet body is takenas a base and extends downwards out of the vertical waterproof protective layer; and waterproof coiled materials are paved on the building roof structural layer and the inner elevation of the flashing wall body, the waterproof coiled materials are pressed on the flashing wall body through metal battens and steel nails, and gaps between the top edge of the waterproof coiled materials and the innerelevation of the flashing wall body are filled with sealants. According to the building roof parapet, the tensile property of the waterproof protective layer and the integral property of the waterproof protective layer and the parapet are enhanced, and the situation that the protective effect is lost caused by cracking and falling off due to insufficient bonding force between the waterproof protective layer and the waterproof coiled material is avoided.

Owner:WUHAN CONSTR ENG

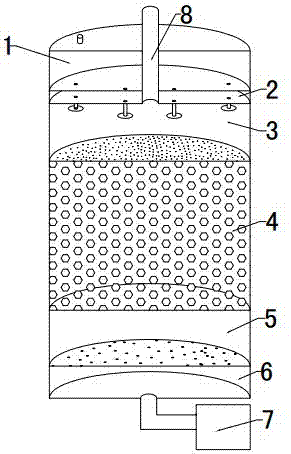

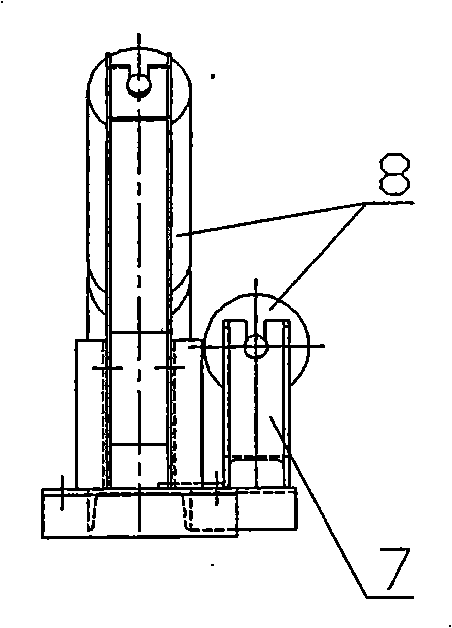

Small process for generating gas through light hydrocarbon gas generating

InactiveCN107327868AThe production ofAvoid taking awayLiquid fuel feeder/distributionLiquid fuel pretreatmentAir blowerPorous ceramics

The invention discloses a small process for generating gas through light hydrocarbon gas generating, and belongs to the technical field of gas generating equipment. The process is characterized in that a light hydrocarbon raw material chamber (1), a control chamber (2), a spray chamber (3), a porous ceramic material chamber (4), a flow stabilizing chamber (5) and a rectifying chamber (6) are sequentially arranged in a tank body from top to bottom, wherein the height of the porous ceramic material chamber (4) is 45cm-55cm; the bottom opening of the rectifying chamber (6) is connected with a hot air blower (7); and an upward gas output pipe (8) is arranged at the spray chamber (3). Liquid light hydrocarbon raw materials are added to the light hydrocarbon raw material chamber (1), the hot air blower (7) is started to supplying air 8s-15s after the oil injection of a nozzle, and the hot air and the liquid light hydrocarbon are volatilized and gasified to produce mixed air gas. The independent and small light hydrocarbon gas generating equipment and the gas generating process can be used independently by a family with stable gas quality.

Owner:SHANDONG UNIV OF TECH

External-wall external-insulation energy-saving system

InactiveCN101550748AHigh bonding strengthImprove securityCovering/liningsSolid waste managementAdhesive cementPolymer modified

The invention discloses an external-wall external-insulation energy-saving system which comprises an internal plastering layer, a wall-surface treating mortar layer, a bonding layer, an insulation layer, a plastering adhesive cement protective layer and a finishing layer that are arranged in sequence from inside to outside, wherein the bonding layer adopts polymer modification bonding agent which contains the following components based on the weight percent: 45-48 of inorganic plural gel material, 45-48 of quartz sand, 5-8 of pure acrylic resin emulsion and 1-2 of auxiliary agents. The invention is suitable for basic-level wall surfaces of various climatic environments and buildings and has the advantages of energy saving, water resistance, moisture resistance, fire prevention, crack resistance and strong protectiveness and durability.

Owner:SHANGHAI HANCAI INDAL

Solid wood composite floor installation and laying auxiliary device for decoration construction and laying method

ActiveCN111236597AGuaranteed installation qualityAvoid problems that damage the surface of your parquetBuilding material handlingSolid woodStructural engineering

The invention relates to the technical field of decoration construction, and discloses a solid wood composite floor installation and laying auxiliary device for decoration construction and a laying method. The solid wood composite floor installation and laying auxiliary device for decoration construction comprises a casing, the top of the casing is provided with a holding mechanism, two sides of the interior of the casing are provided with floor beating mechanisms, two sides of the inner top wall of the casing are fixedly connected with noise attenuating mechanisms, and the bottom of the casing is fixedly connected with a bottom plate. According to the solid wood composite floor installation and laying auxiliary device for decoration construction and the laying method, the strength of beating a solid wood composite floor can be adjusted through the floor beating mechanisms, the strength of each time of beating is constant, the installation quality of the solid wood composite floor is guaranteed, and the problem that the surface of the solid wood composite floor is liable to be accidentally damaged during beating is avoided; and besides, the two floor beating mechanisms are placed at the joint of two solid wood composite floor blocks to beat the side edges of the two solid wood composite floor blocks, it can be ensured that the joint of the two solid wood composite floor blocksis uniformly stressed, the phenomenon of bulging or edge warping is avoided, and the working efficiency of installation is improved.

Owner:BEIJING JISHUN CONSTR ENG CO LTD

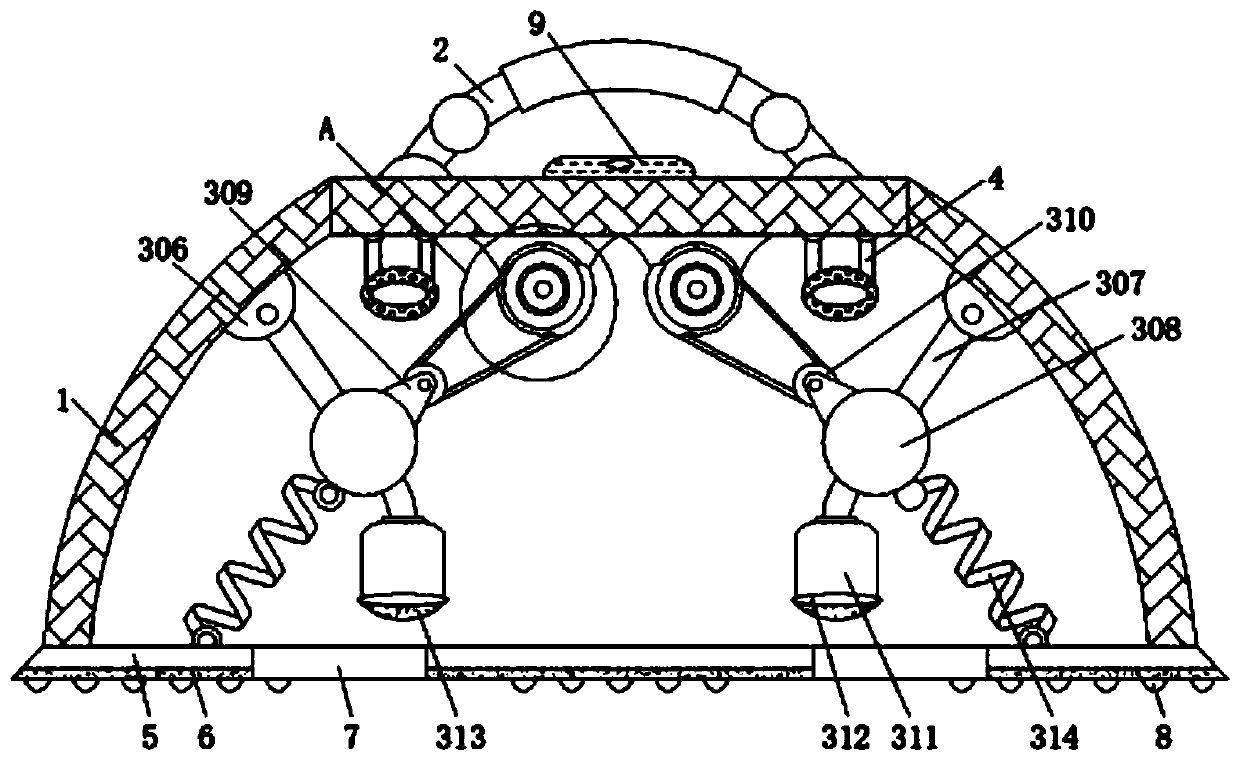

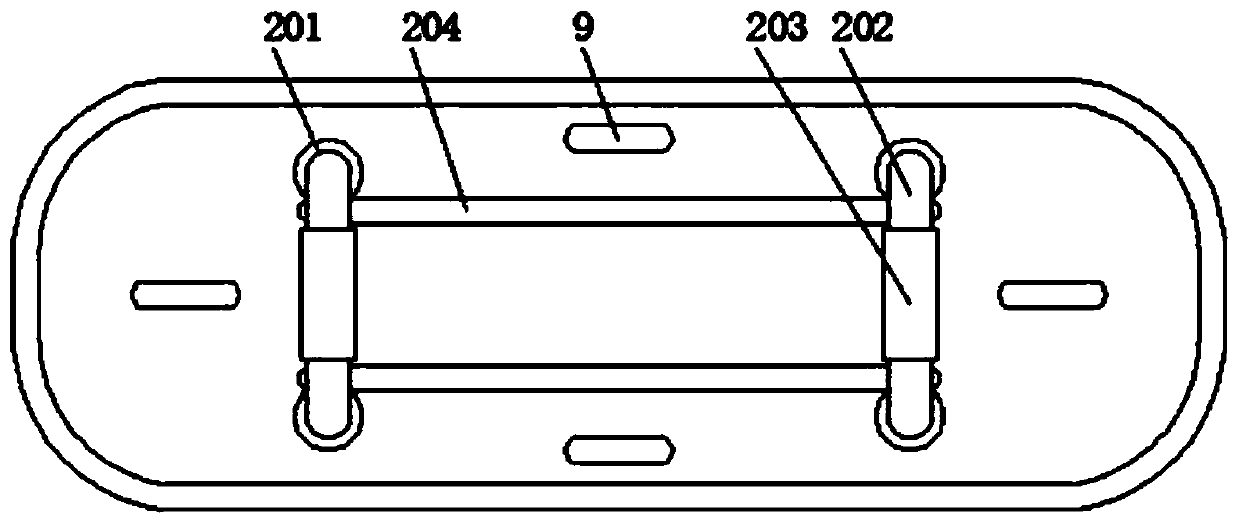

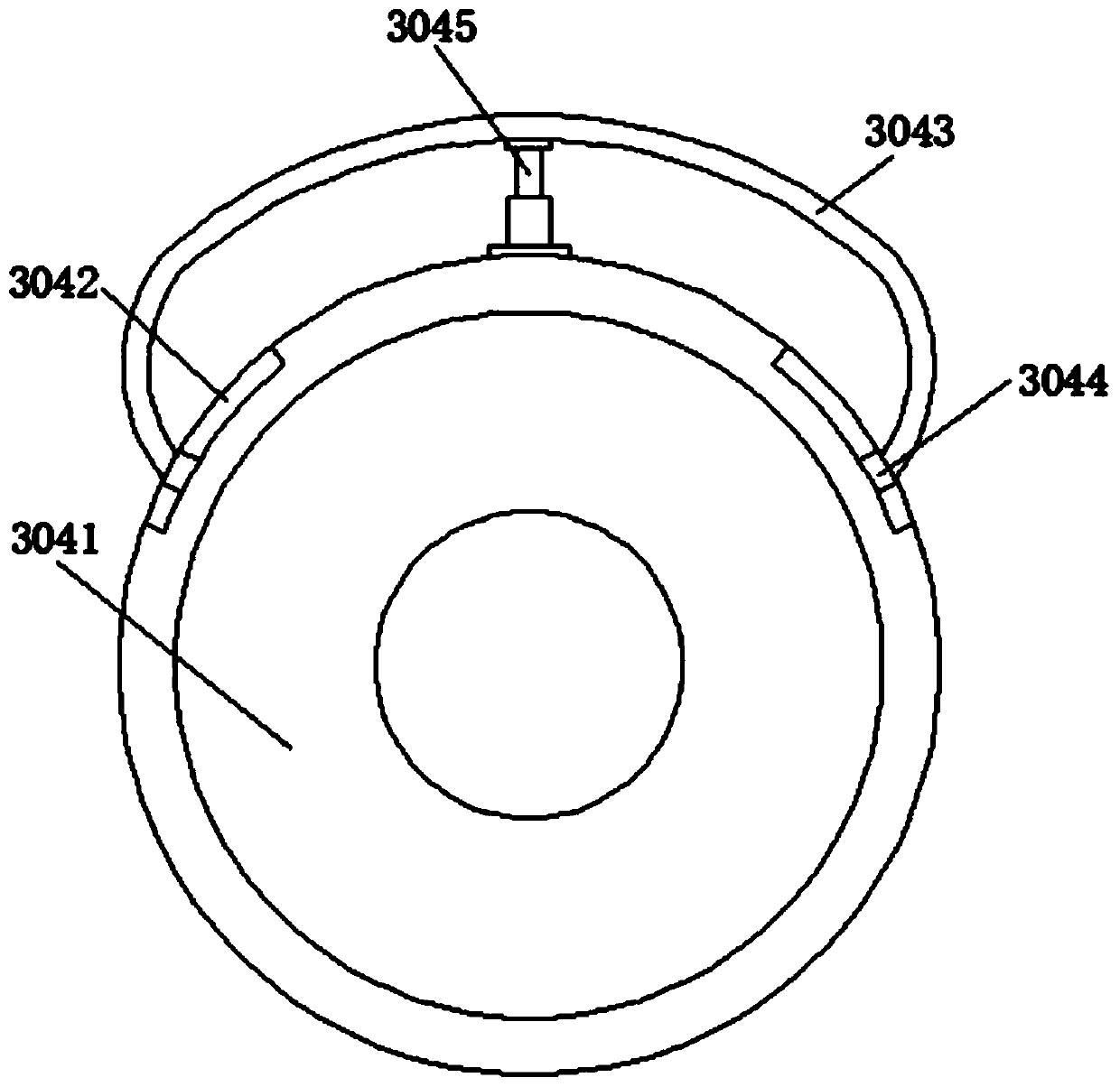

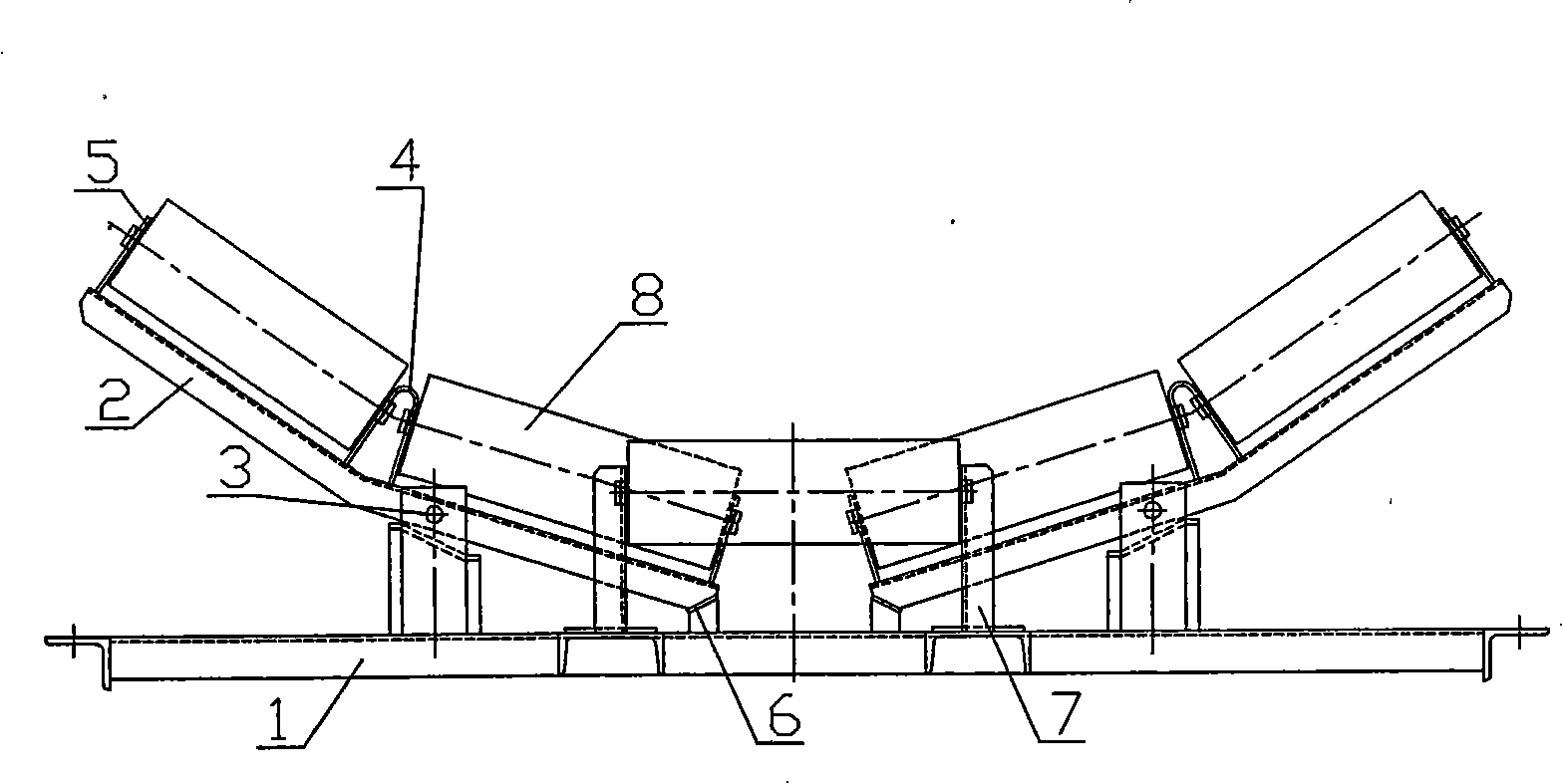

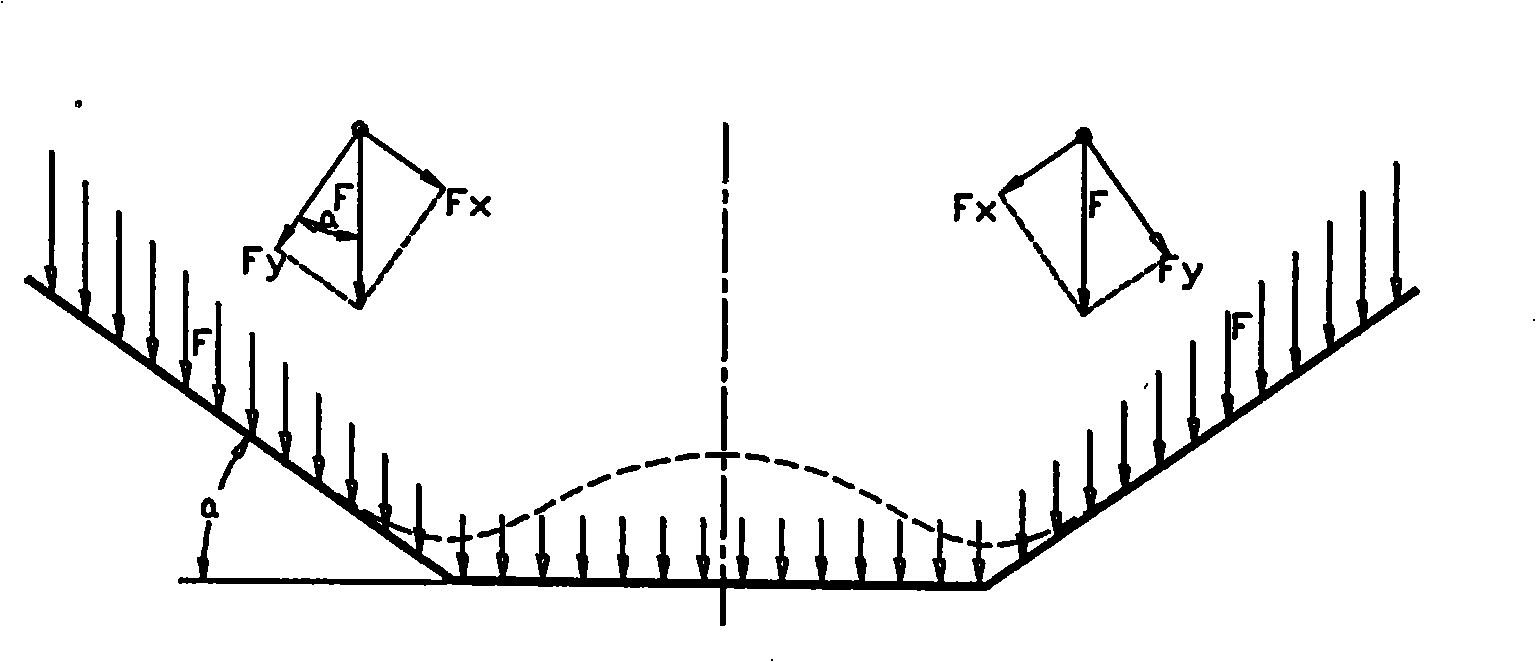

Conveyor belt self-adapting adjusting apparatus of belt conveyor

InactiveCN101301959AStrong adaptive adjustment abilityPrevent belt from drumming or lateral bucklingConveyorsRollersEngineeringConveyor belt

Owner:TIANJIN CHENGKE MECHANICAL & ELECTRICAL TRANSMISSION TECH

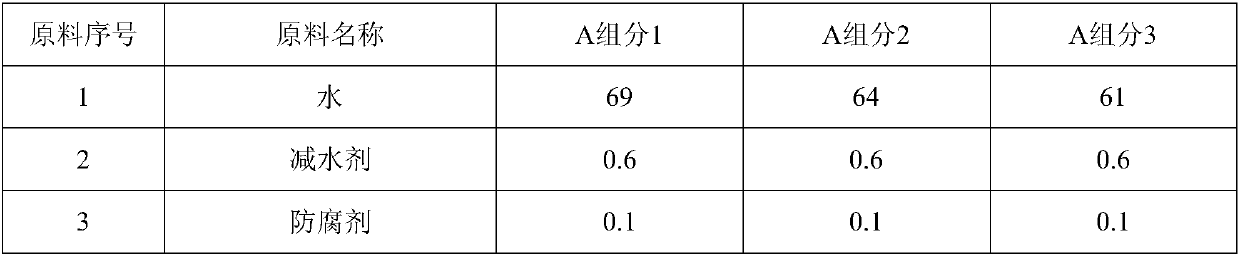

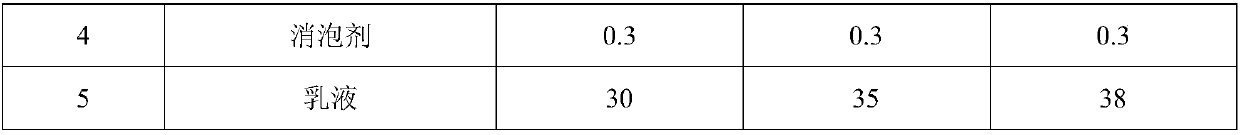

Flexible waterproof mortar, preparation method and applications thereof

The invention discloses a flexible waterproof mortar, a preparation method and applications thereof, wherein the flexible waterproof mortar is formed by compounding a component A and a component B according to a mass ratio of 1:2-4, the component A comprises water, a water reducing agent, a preservative, a defoaming agent and an emulsion according to a mass ratio of 50-80:0.3-0.8:0.1-0.2:0.1-0.3:20-50, and the component B comprises cement, a filler, cellulose ether, a thixotropic lubricant and a water repellent according to a mass ratio of 20-40:60-80:0.1-0.4:0.5-1:0.1-0.3. According to the present invention, the preparation method is simple and easy to perform; the obtained product has advantages of good flexibility, good water resistance, moderate viscosity, excellent thixotropy and excellent water retention property, wherein the surface is delicate and compact and does not produce cracking, water seepage, blistering and local projection after the construction of the flexible waterproof mortar, such that the construction performance and the decoration effect of the flexible waterproof mortar are improved.

Owner:BEIJING YUEZHU XINTIAN ENERGY SAVING TECH

Self-adhesion type ethylene propylene diene monomer waterproof roll

PendingCN107459942AImprove aging resistanceGood adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWater leakageEthylene-propylene-diene-monomer

The invention discloses a self-adhesion type ethylene propylene diene monomer waterproof roll. The self-adhesion type ethylene propylene diene monomer waterproof roll comprises a silicone oil paper layer, a butyl adhesive layer, an EPDM layer and a PE film which are arranged from bottom to top in turn; the butyl adhesive layer comprises the following components in parts by weight: 40-60 parts of butyl rubber (1751), 30-50 parts of polyisobutene (1200), 5-10 parts of C5 resin, 10-20 parts of chlorinated paraffin and 100-200 parts of talcum powder; the EPDM layer comprises the following components in parts by weight: 40-60 parts of EPDM (3092), 50-60 parts of carbon black (N550), 10-20 parts of softening agent, 5-10 parts of vulcanizing agent and 10-20 parts of talcum powder. According to the structure arrangement of the device, the butyl adhesive material is used as an adhesive layer, so that the phenomena of high adhesion and water leakage under low temperature can be effectively solved; the adhesive layer can be coated on the EPDM roll in advance, so that the trouble of on-site adhesive coating required in the construction process can be avoided; and the release paper of the roll can be directly torn off and the roll can be directly paved in the construction process.

Owner:杨志武

Preparation method of iron-based soft magnet with anticorrosive coating layer

InactiveCN107799259AImprove performanceImprove anti-corrosion performanceInductances/transformers/magnets manufactureMagnetic materialsSoft magnetAlloy

The invention discloses a preparation method of an iron-based soft magnet with an anticorrosive coating layer. Multiple elements of Ni, Cr, Cu, Al, P and C which can improve the comprehensive performance of Fe-based amorphous soft magnet alloy are adopted to prepare and obtain an iron-based soft magnet substrate; and the surface of the soft magnet alloy is electroplated with the coating layer, sothat bulging and bubble forming caused by a hydrogen evolution effect can be avoided, and the anticorrosive performance of the soft magnet alloy is improved.

Owner:SUZHOU NANER MATERIAL TECH CO LTD

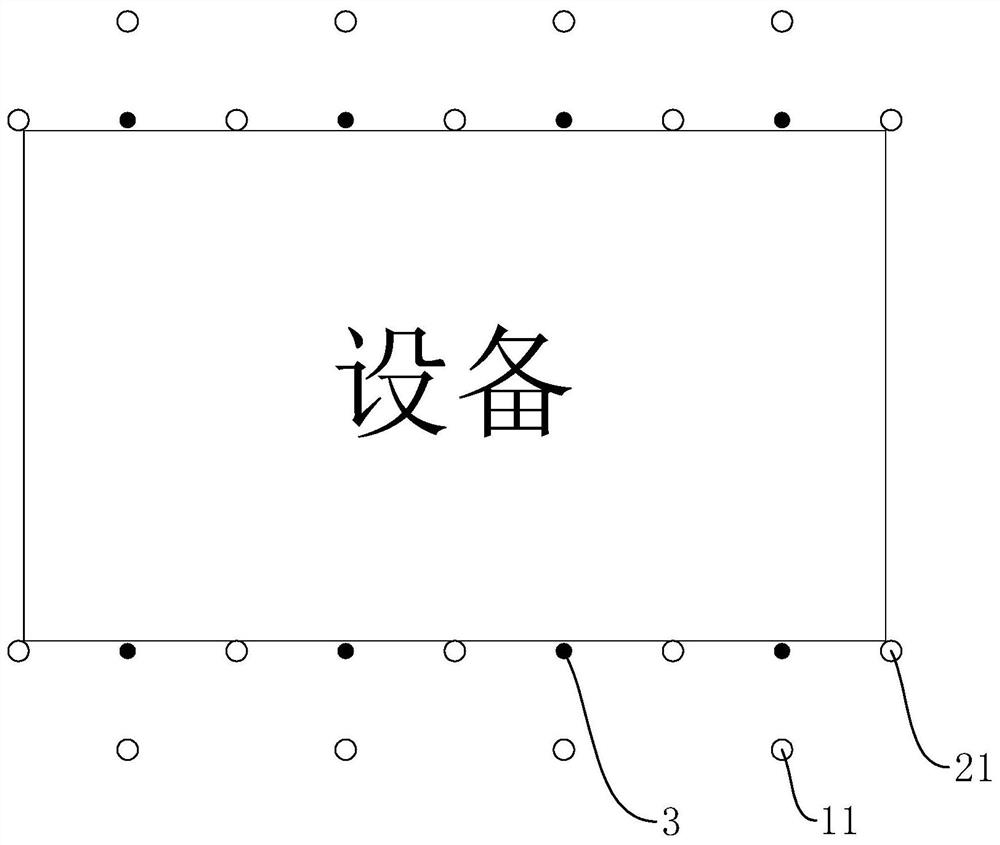

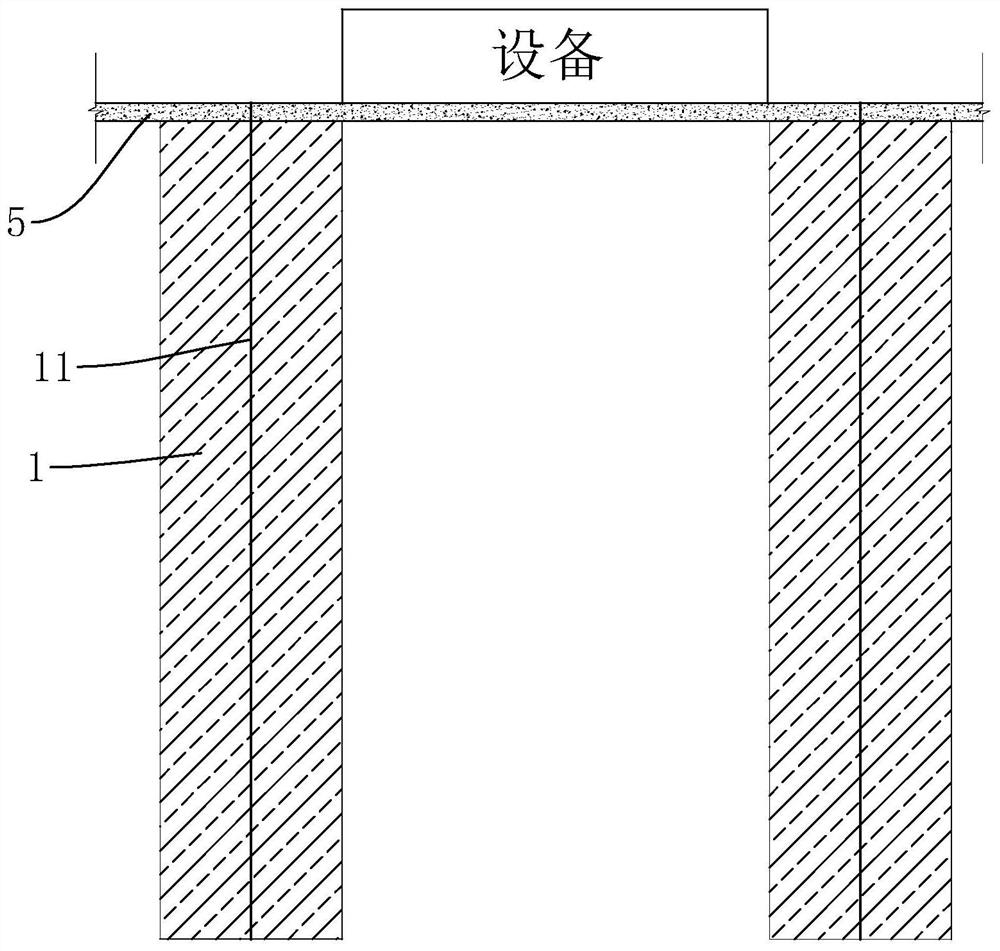

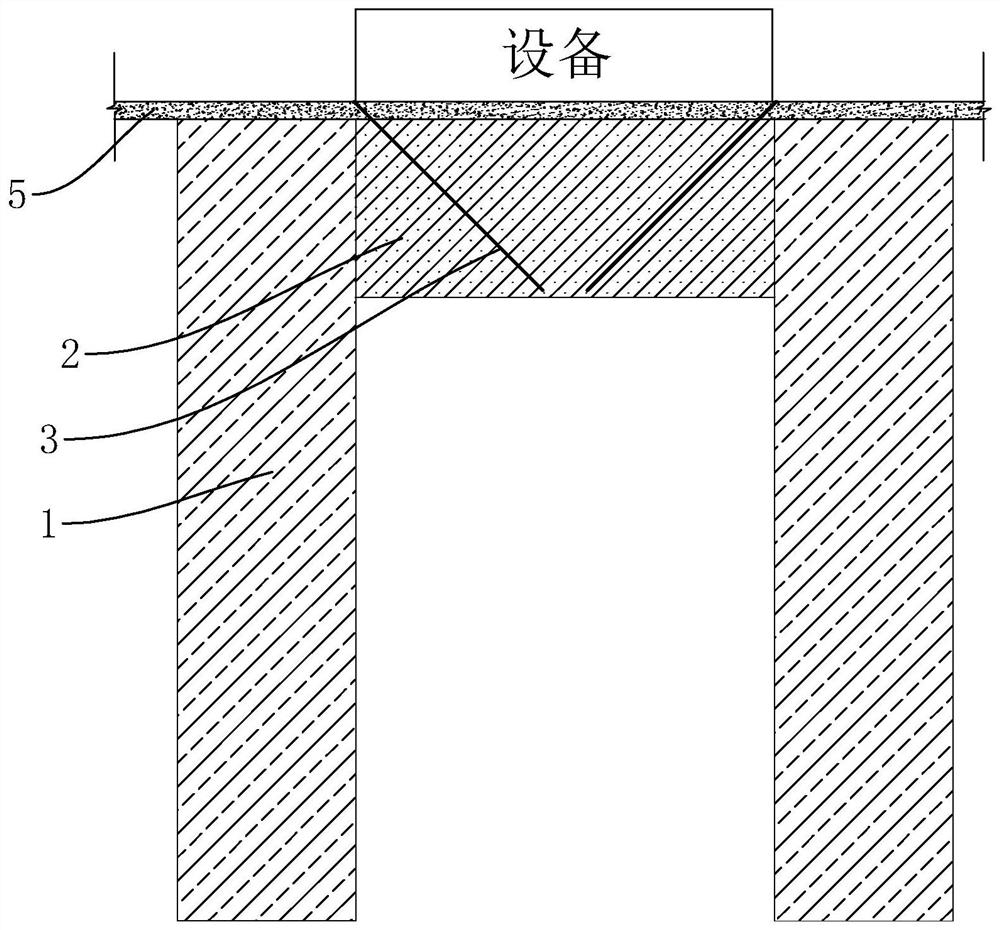

Precise lifting method for plant equipment foundation

ActiveCN112343078AReduce disturbanceImprove integrityFoundation repairSoil preservationArchitectural engineeringPressure grouting

The invention relates to a precise lifting method for a plant equipment foundation. The precise lifting method comprises the following steps that S1, curtain walls are formed, specifically, holes arevertically and downwards drilled in two sides, needing to be lifted, of the equipment to form curtain holes, and the curtain holes are grouted to form two curtain walls which are parallel to each other; S2, a reinforcing body is formed, specifically, obliquely-downward grouting holes are formed in the outer contour lines of the equipment in the length direction of the curtain walls, grouting is conducted in the grouting holes, grouting is conducted between the two curtain walls at the bottom of the equipment foundation bottom plate to form the reinforcing body attached to the lower surface ofthe bottom plate, and the reinforcing body and the two curtain walls are combined to form an n-shaped structure; and S3, lifting is conducted, specifically, the grouting hole serves as the lifting hole, a hole is obliquely drilled downwards until the hole is drilled to the position below the reinforcing body and located between the two curtain walls, pressure grouting is conducted on the bottom ofthe lifting hole to fill and reinforce the surrounding backfill layer, pressure grouting continues, retreating type grouting is adopted, and the equipment is lifted to the set lifting height. The precise lifting method has the advantages of being small in surrounding disturbance, controllable in lifting height and high in lifting precision.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

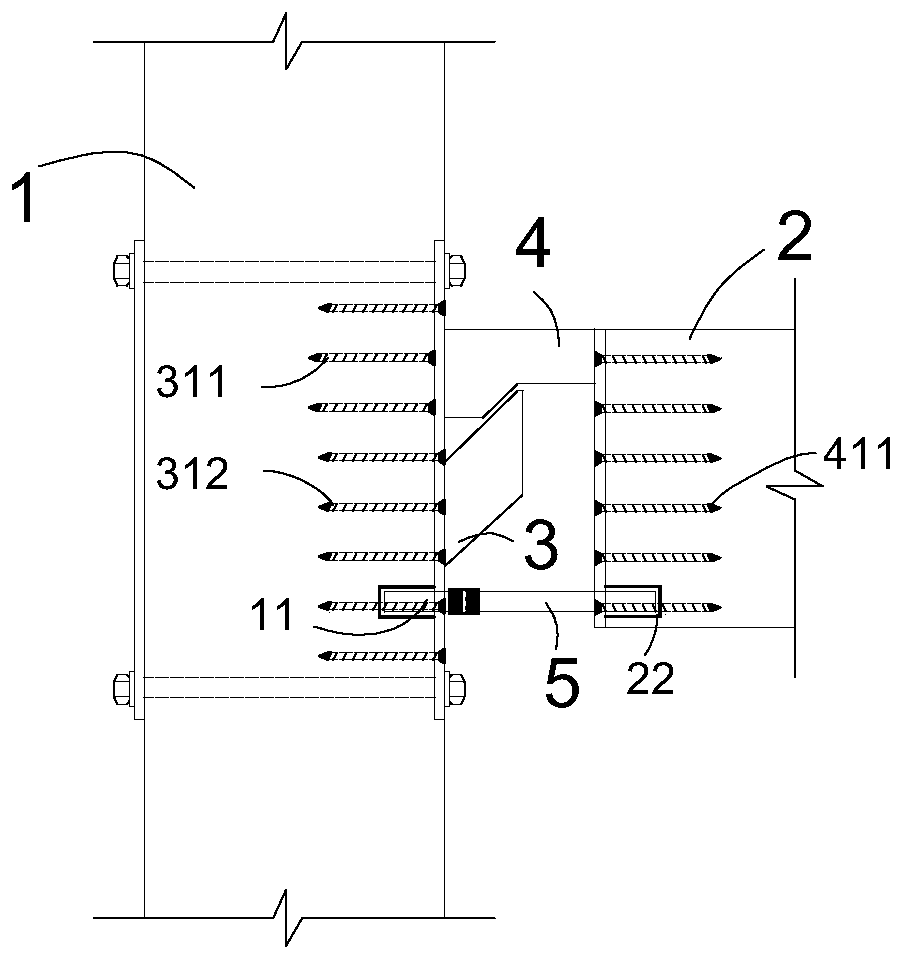

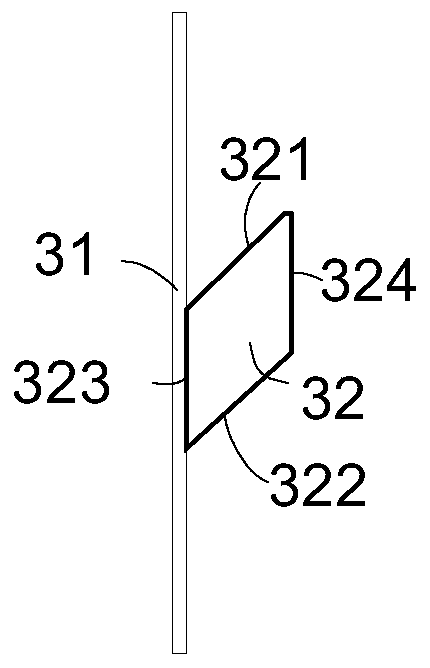

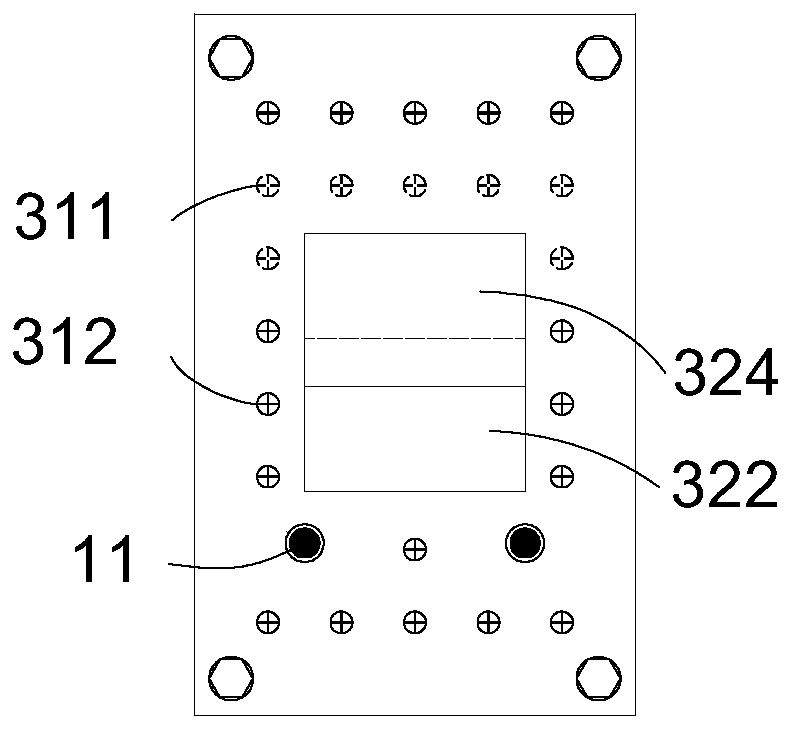

Self-positioning mounting steel wood energy dissipation combined joint

ActiveCN109838132AImprove energy consumptionEasy to replaceProtective buildings/sheltersShock proofingSelf positioningBeam column

The invention discloses a self-positioning mounting steel wood energy dissipation combined joint. The self-positioning mounting steel wood energy dissipation combined joint comprises vertical columns,horizontal beams, oblique bracket supports, steel wedge hangs and energy dissipation rods, the steel oblique bracket supports are composed of side steel plates and bracket supports, the steel obliquebracket supports are solidified to the side surfaces of the vertical wood columns through the side steel plates, the steel wedge hangs are composed of end steel plates and sphenocephalys, the steel wedge hangs are fixed to the end parts of the horizontal beams through the end steel plates, the energy dissipation rods are parallel to the beams and located on the lower parts, one ends of the energydissipation rods are solidified with the wood columns, and the other ends of the energy dissipation rods are solidified with the end parts of the horizontal beams. According to the self-positioning mounting steel wood energy dissipation combined joint, beam column mounting self-positioning can be driven by wood beam bearing, under the action of earthquake, the mounted energy dissipation rods canform hysteretic energy dissipation capacity through pull pressing depending on connection construction in the joint rotation process, replacement of the energy dissipation rods after earthquake is further facilitated, and rapid repair of the joint is realized.

Owner:SOUTHEAST UNIV

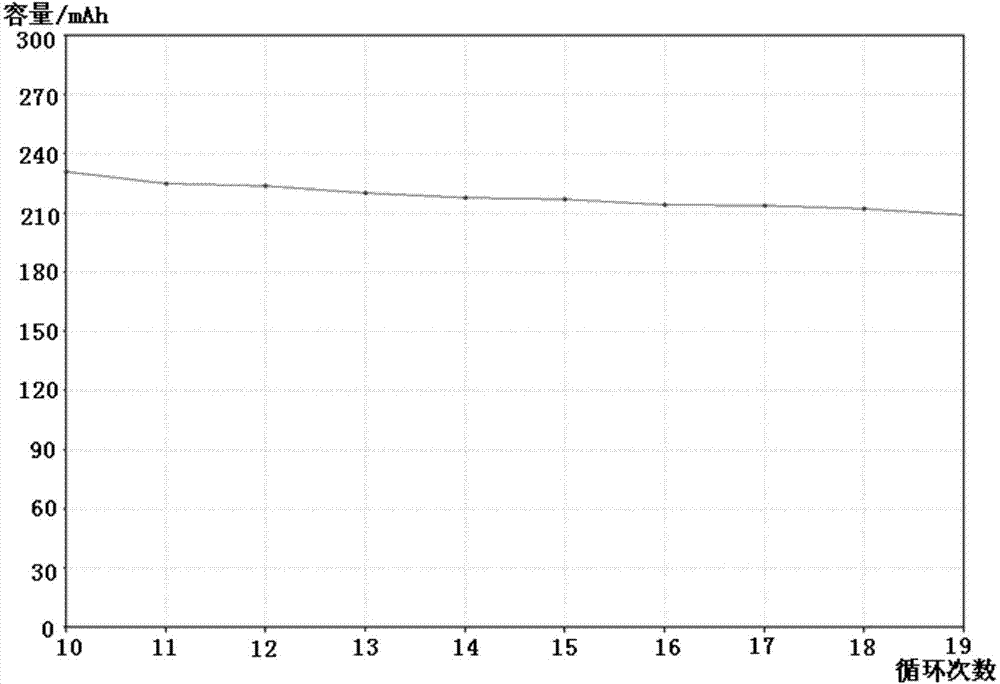

Battery and electrolytic solution thereof

InactiveCN104681846ASuppressed gasAvoid battery swellingFinal product manufactureSecondary cells manufactureSolventIon

The invention discloses an electrolytic solution and a battery. The electrolytic solution comprises a solvent which is used for dissolving electrolyte and ionizing the electrolyte; the electrolyte comprises first metal ions and second metal ions; the first metal ions can reversibly escape from or be embedded in the positive electrode of the battery in the charge and discharge processes; the second metal ions are reduced and deposited at the negative electrode to form second metal in the charge process; the second metal is oxidized and dissolved into second metal ions in the discharge process; the electrolytic solution also comprises an additive, wherein the additive comprises an oxyacid root ion compound of boron. The battery comprises the positive electrode, the negative electrode and the electrolytic solution provided by the invention; the positive electrode comprises a positive electrode active substance through which the first metal ions can reversibly escape and embedded. According to the invention, generation of a gas is effectively inhibited, thus bulging of the battery is avoided, and the safety performance of the battery is reinforced.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com