Heat-insulation wall with 3-D anchoring structure and construction technology

A technology for thermal insulation walls and anchoring structures, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of complex thermal insulation wall structure, many construction steps, poor performance, etc., to increase product added value, simple construction technology, The effect of reducing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following structural drawings and embodiments further illustrate the present invention.

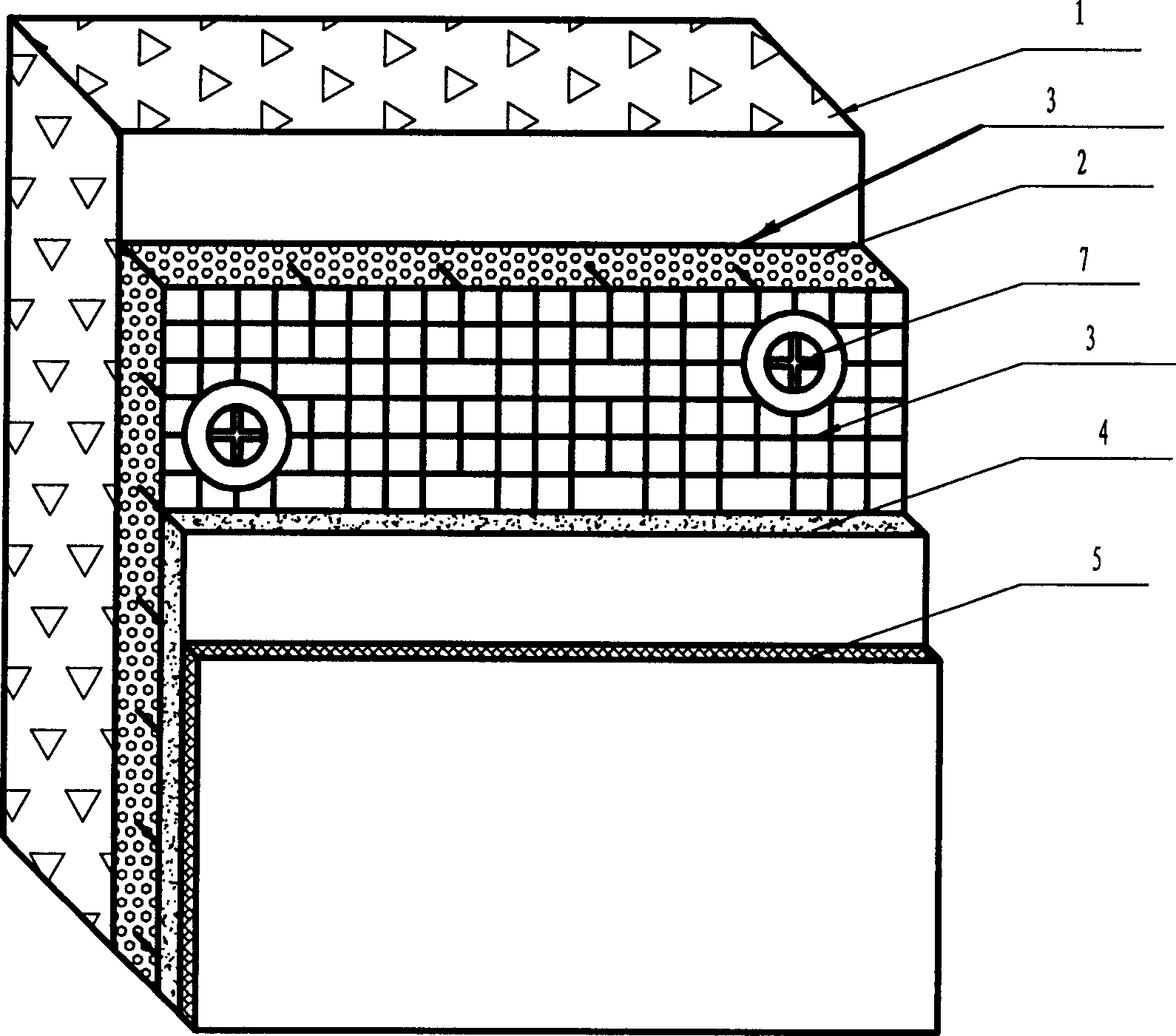

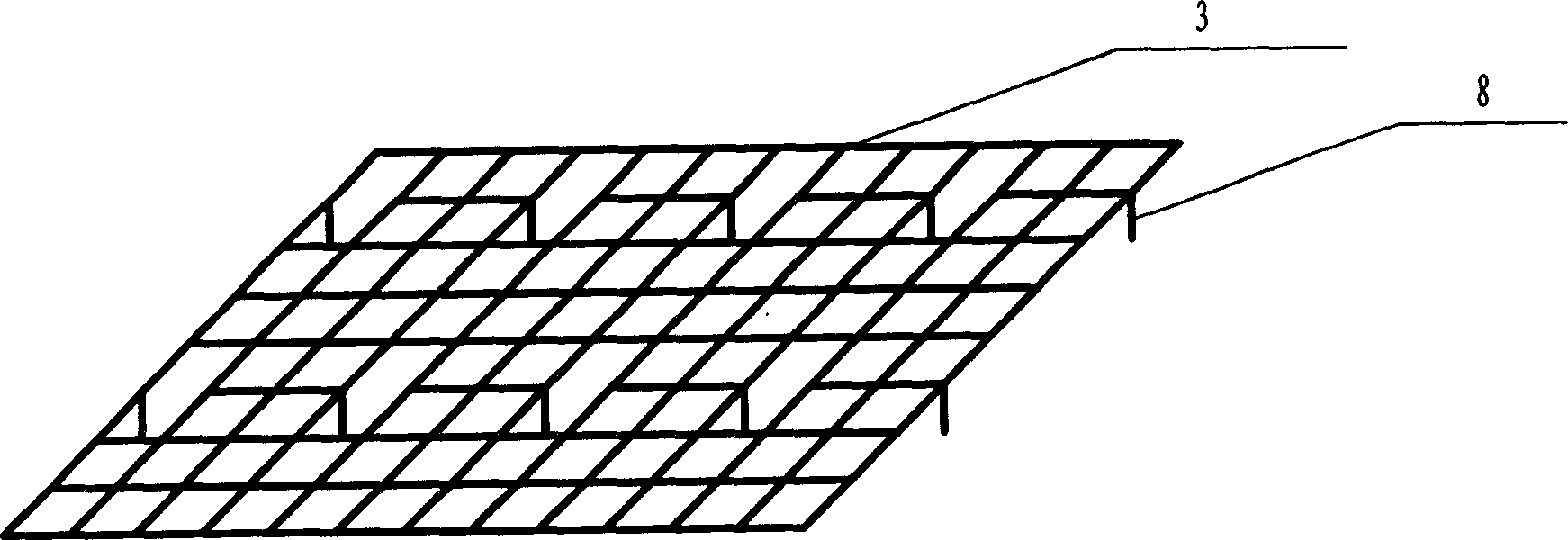

[0033] Such as Figure 1~3 shown.

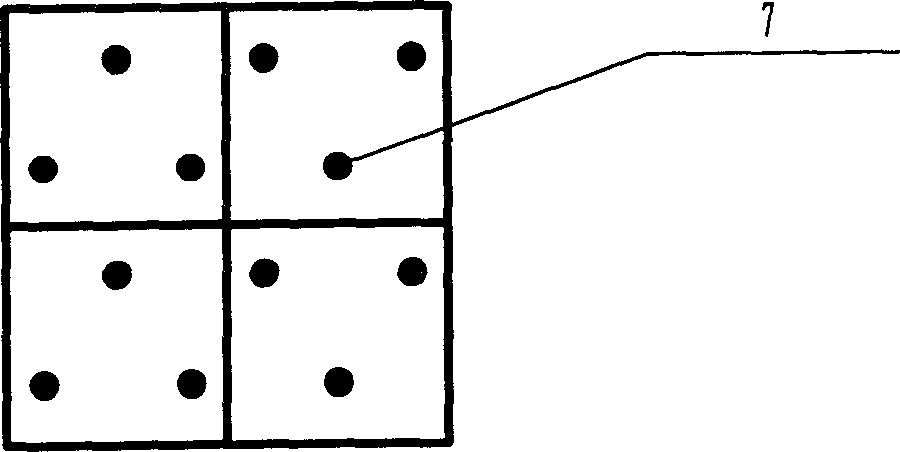

[0034] A thermal insulation wall with a three-dimensional anchoring structure, comprising a base layer 1, a thermal insulation layer 2, a polymer anti-seepage and anti-cracking mortar layer 4 and a finish layer 5 (which can be a conventional decorative layer such as paint or tiles), wherein the base layer 1 can be concrete blocks, clay porous bricks, clay bricks, aerated concrete or reinforced concrete; when the thermal insulation layer 2 is a polystyrene insulation board, the polystyrene insulation board passes through a polymer binder 6 (commercially available conventional The polymer binder) is connected to the base layer 1, and when the thermal insulation layer 2 is a thermal insulation mortar layer, it can be directly connected to the base layer 1. The polymer anti-seepage and anti-cracking mortar layer 4 is covered on the thermal insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com