Precise lifting method for plant equipment foundation

A kind of equipment-based and sophisticated technology, which is applied in basic structure engineering, basic structure repair, construction, etc., can solve problems such as failure to meet the design foundation bearing capacity requirements, settlement and deformation of backfill soil layers, and incompact backfill soil layers. Controllability and accuracy, strengthening the bearing capacity of the foundation, reducing the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] The invention discloses a method for precisely raising the foundation of plant equipment, which is described below by taking strip-shaped equipment as an example. Include the following steps:

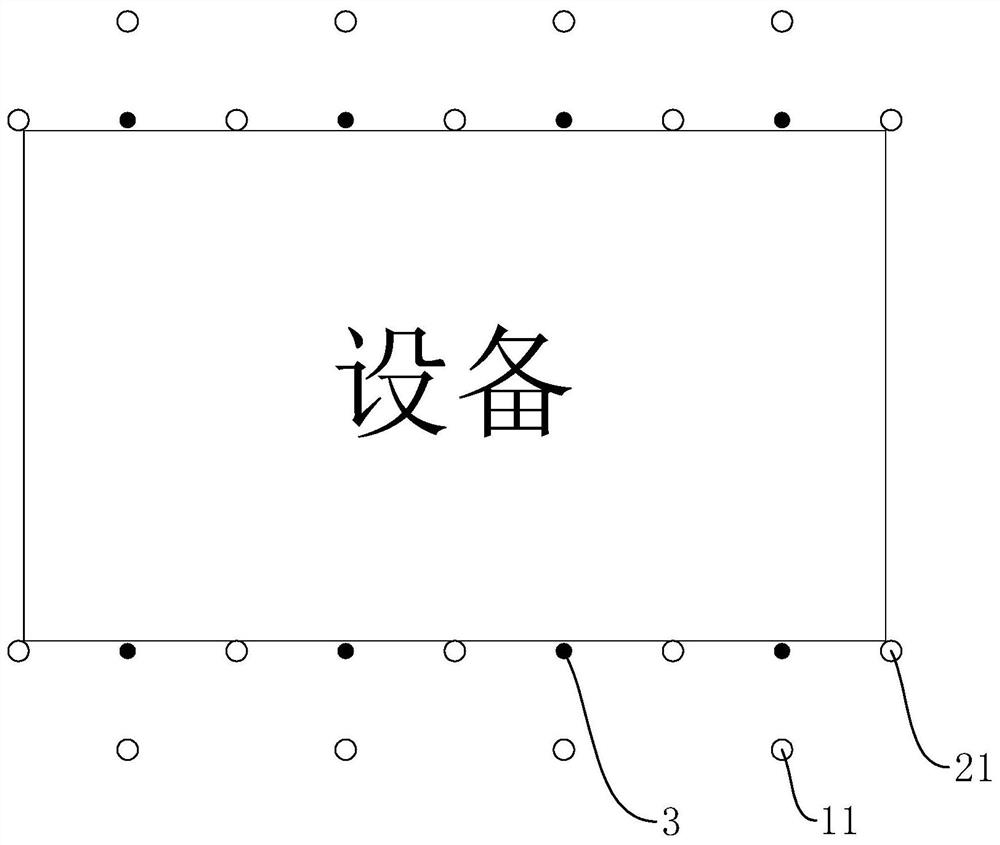

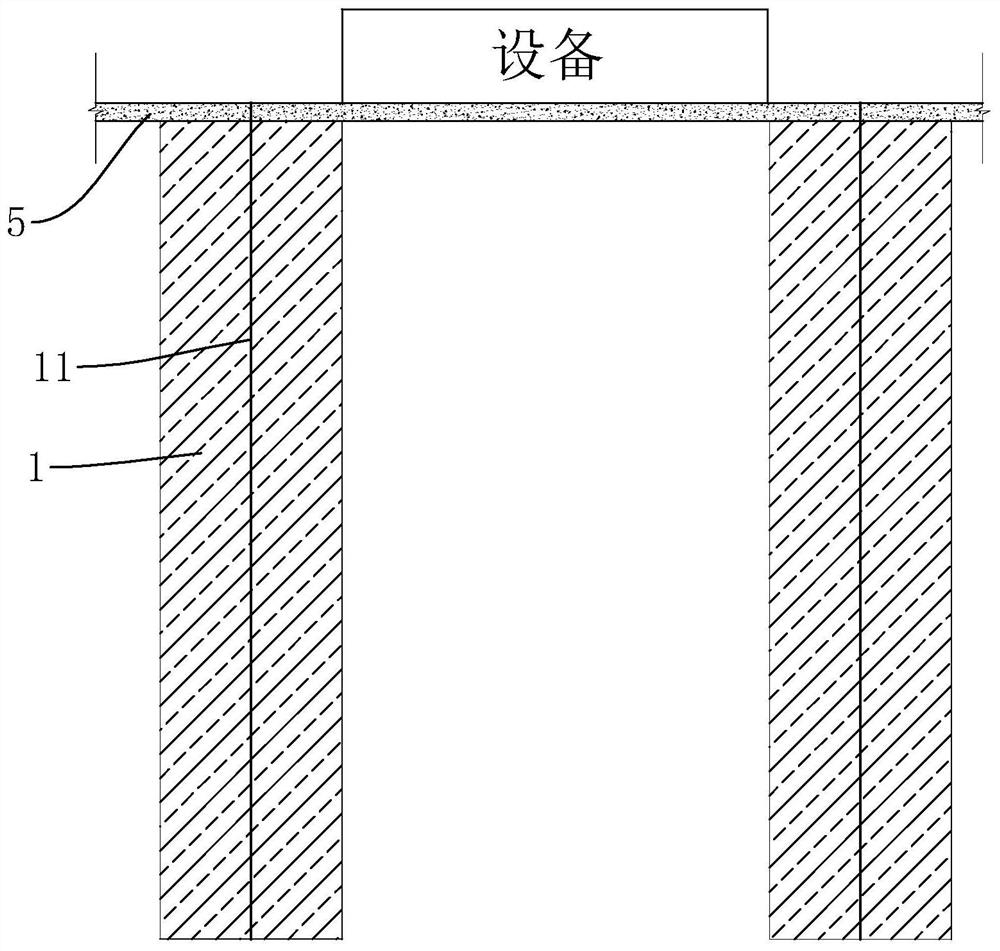

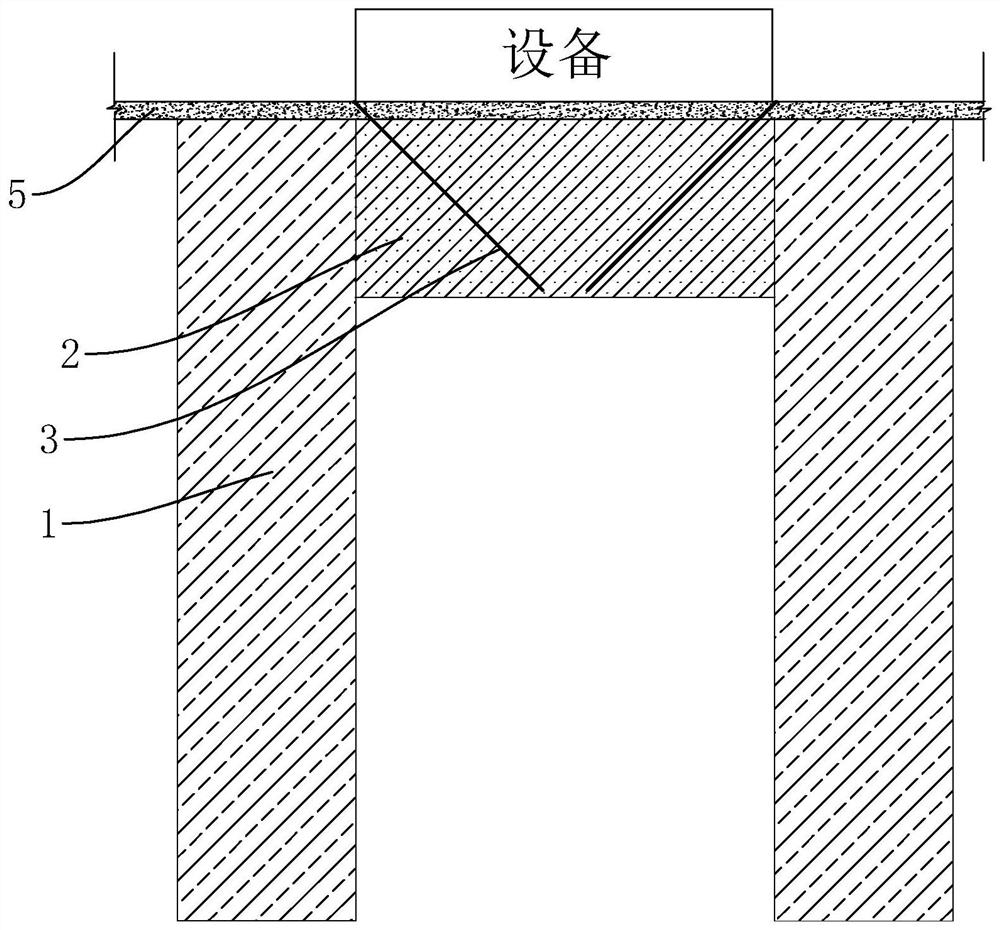

[0040] S1, forming curtain wall 1: refer to figure 1 and figure 2 Drill and inject curtain holes 11 vertically on both sides of the lifting section of the equipment. The diameter of the curtain holes 11 is 42 mm. A plurality of curtain holes 11 are evenly spaced along the length direction of the equipment. Between adjacent curtain holes 11 The spacing is 2-3m, and the curtain hole 11 is 1-2m away from the equipment. Grout is injected into the curtain hole 11. The grouting range overlaps with each other to form two parallel curtain walls 1. The height of the curtain wall 1 can be the backfill soil layer thickness of. The curtain wall 1 separates the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com