Patents

Literature

78results about How to "High lifting precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

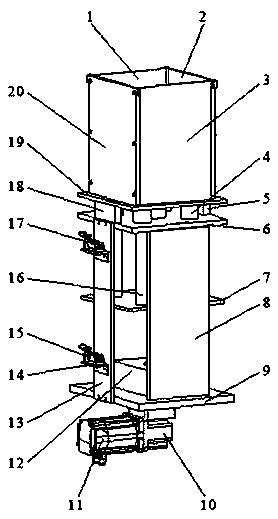

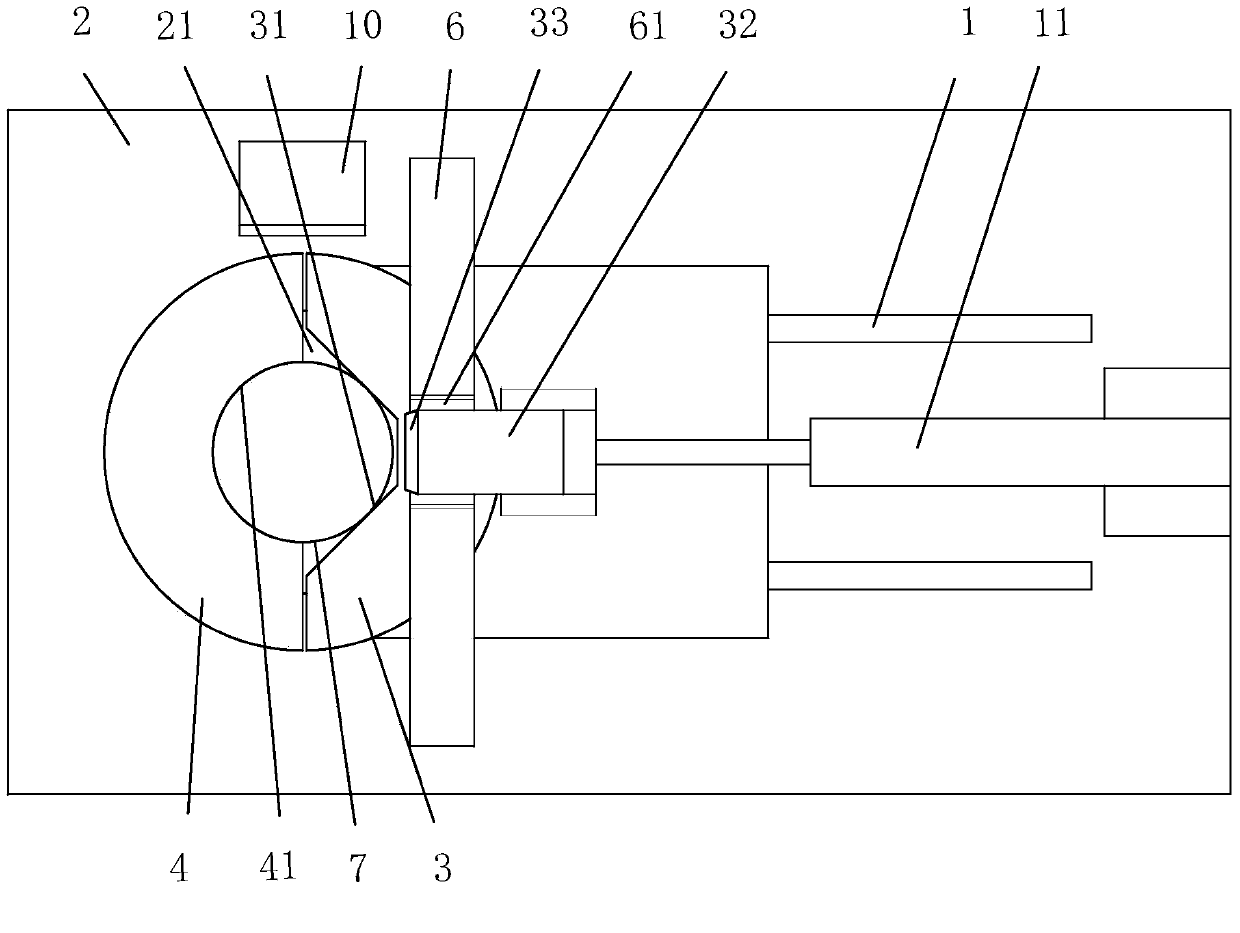

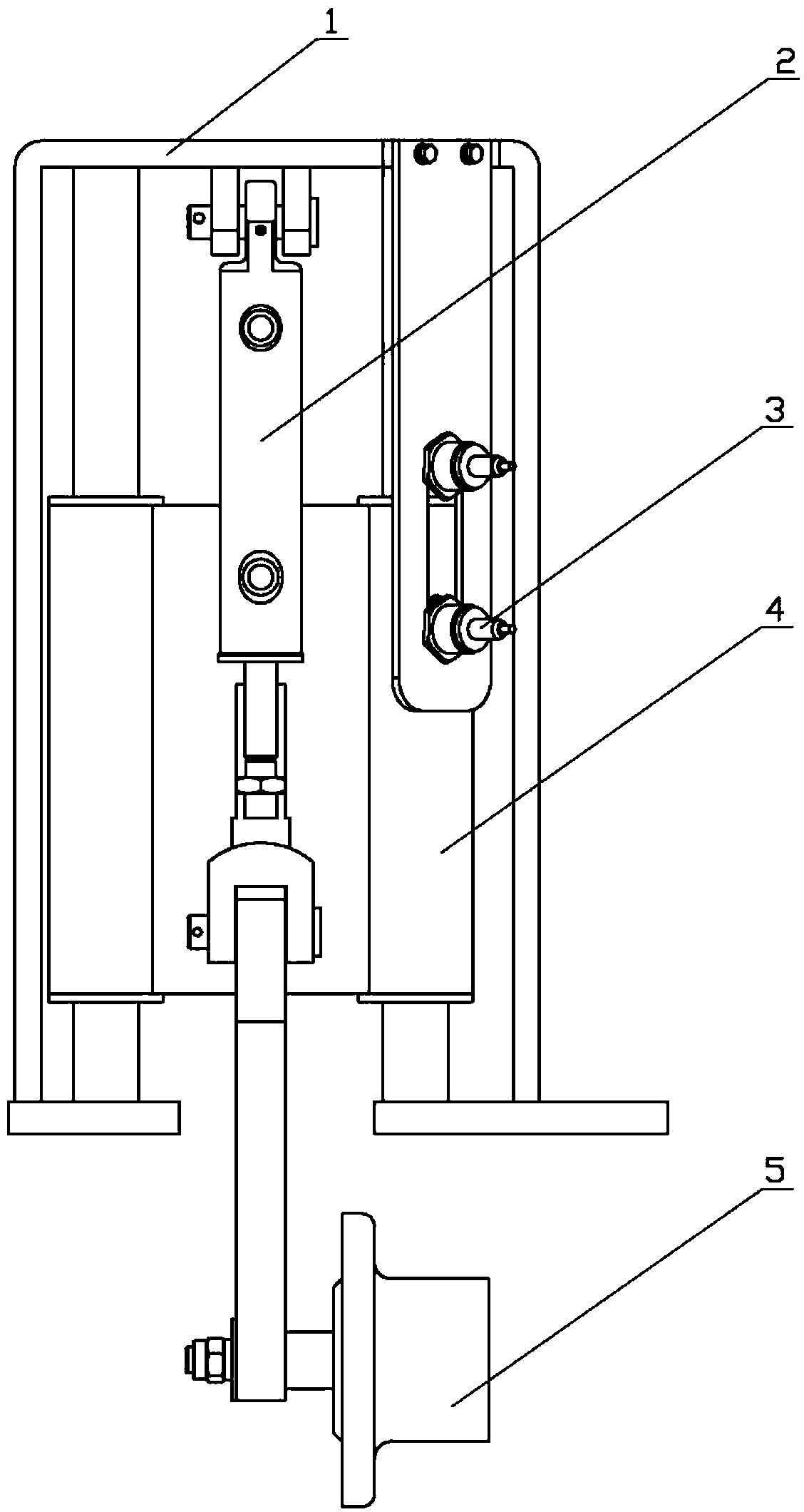

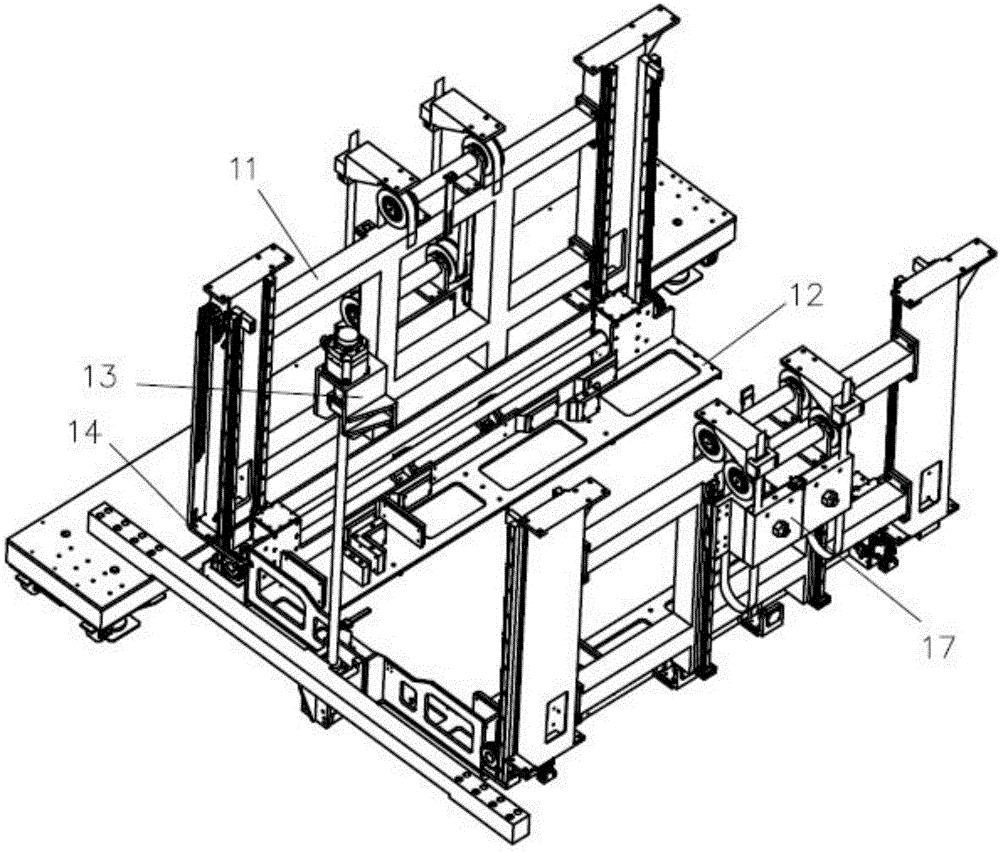

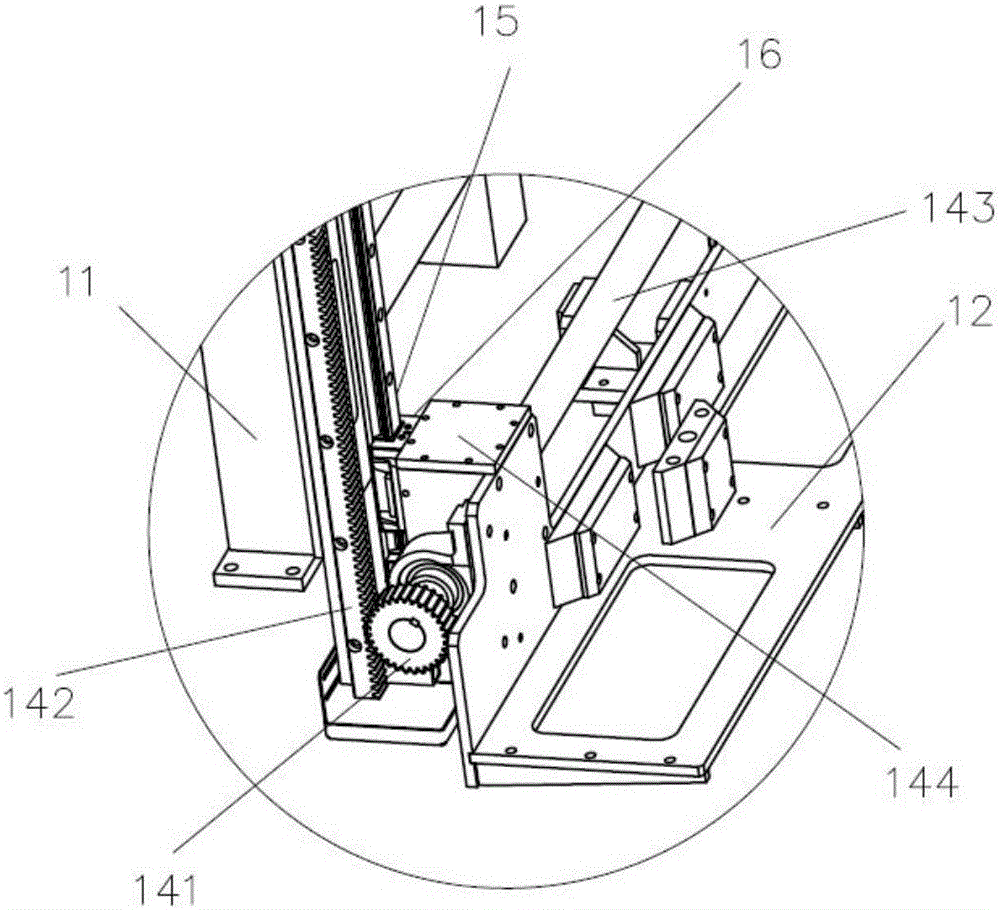

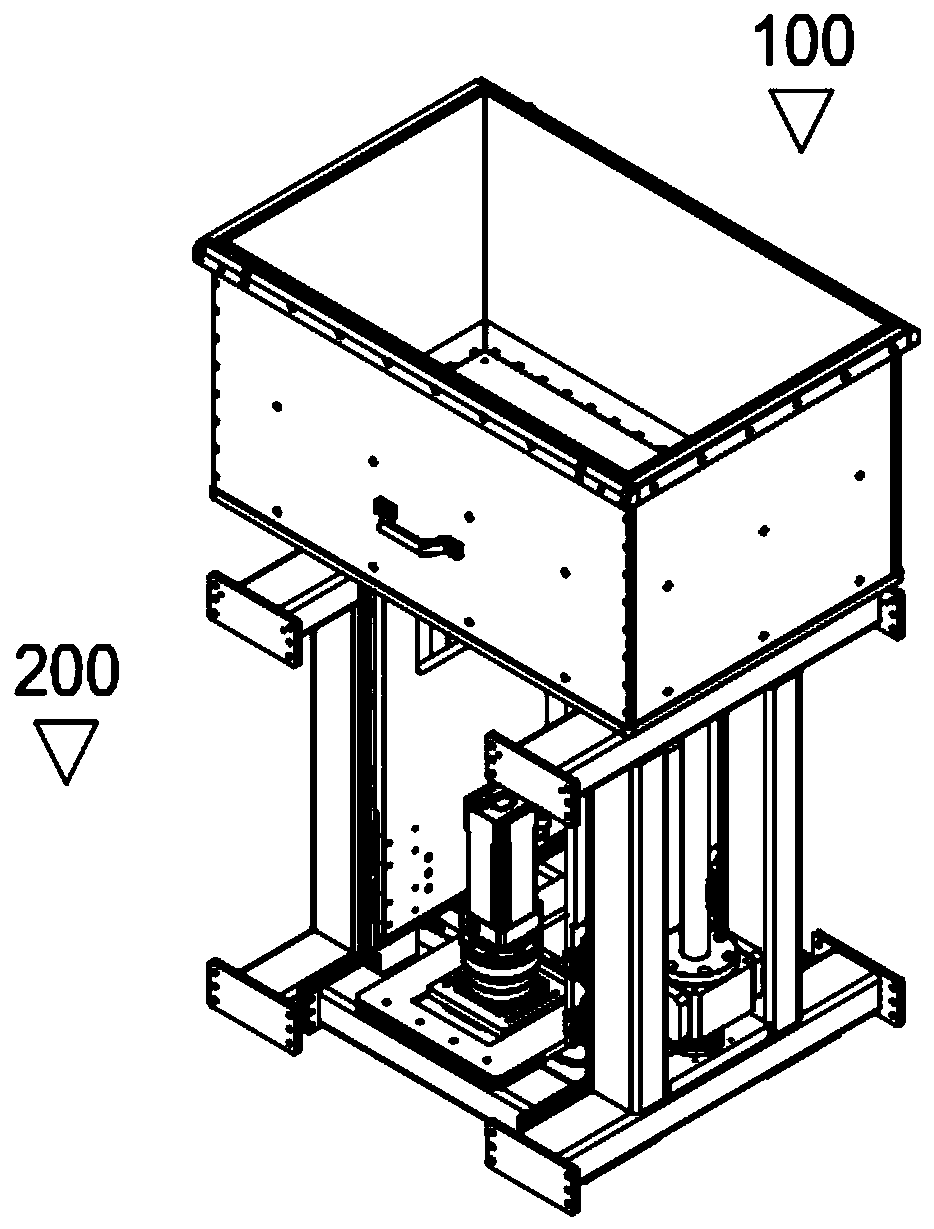

Lifting platform

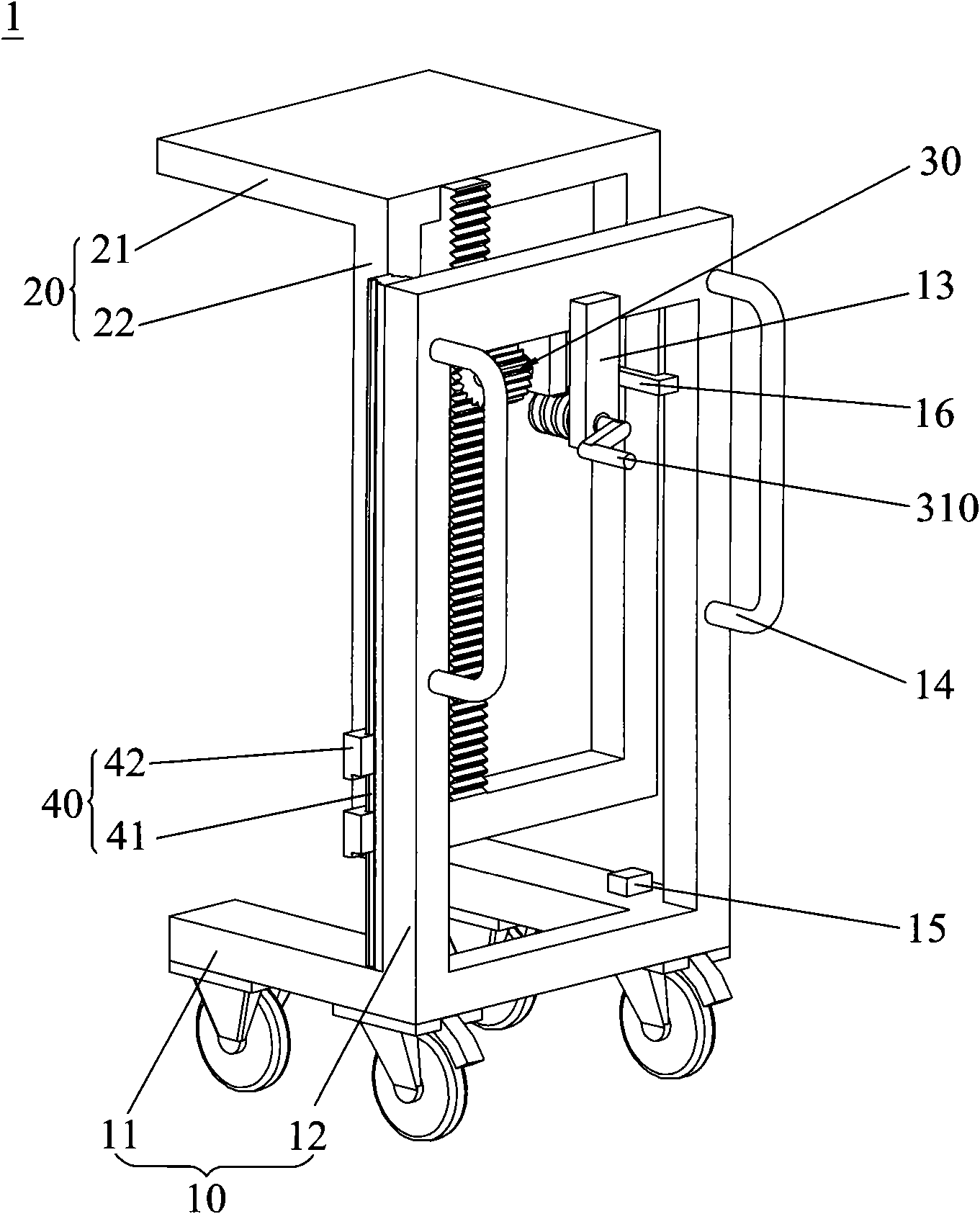

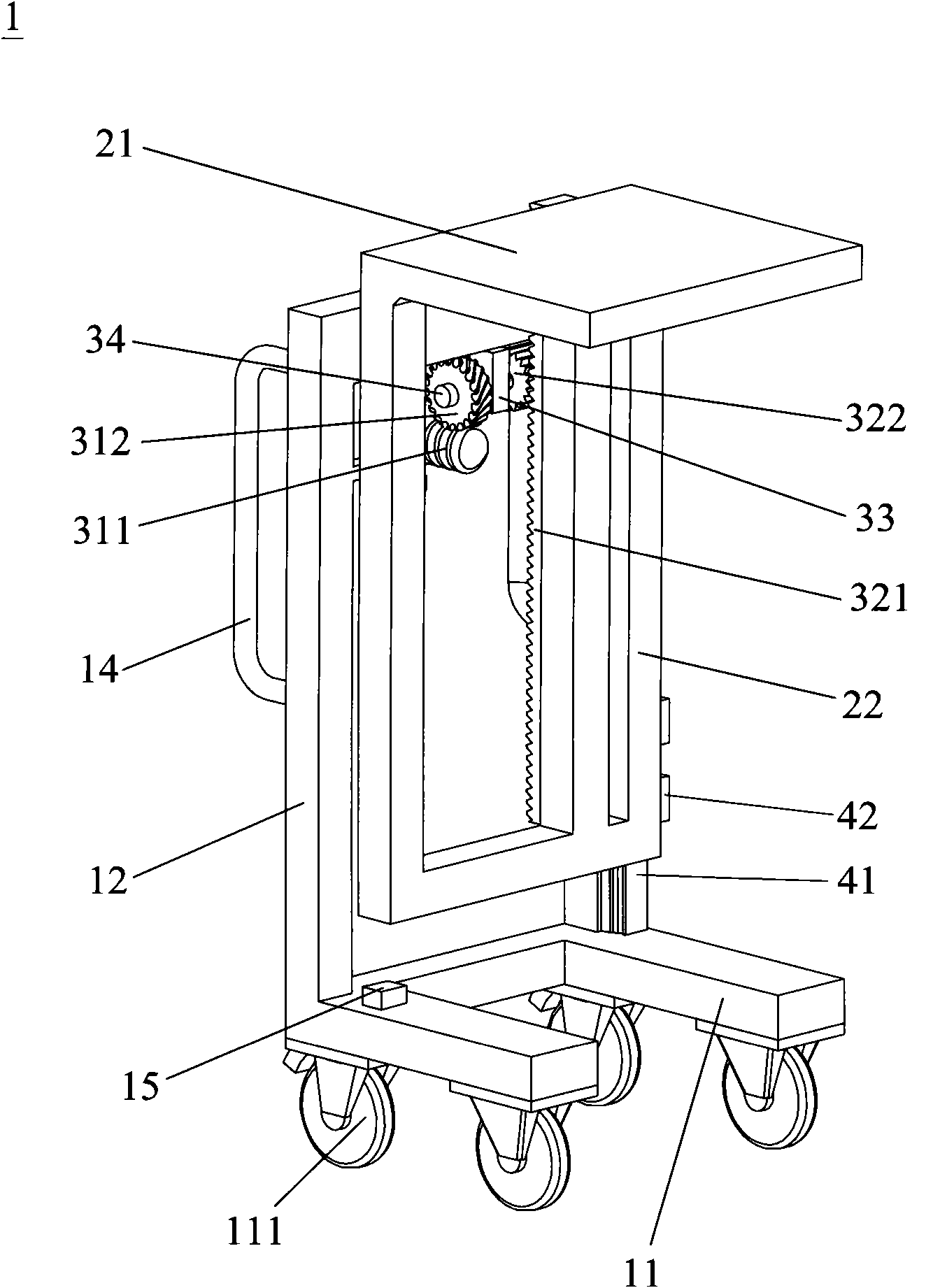

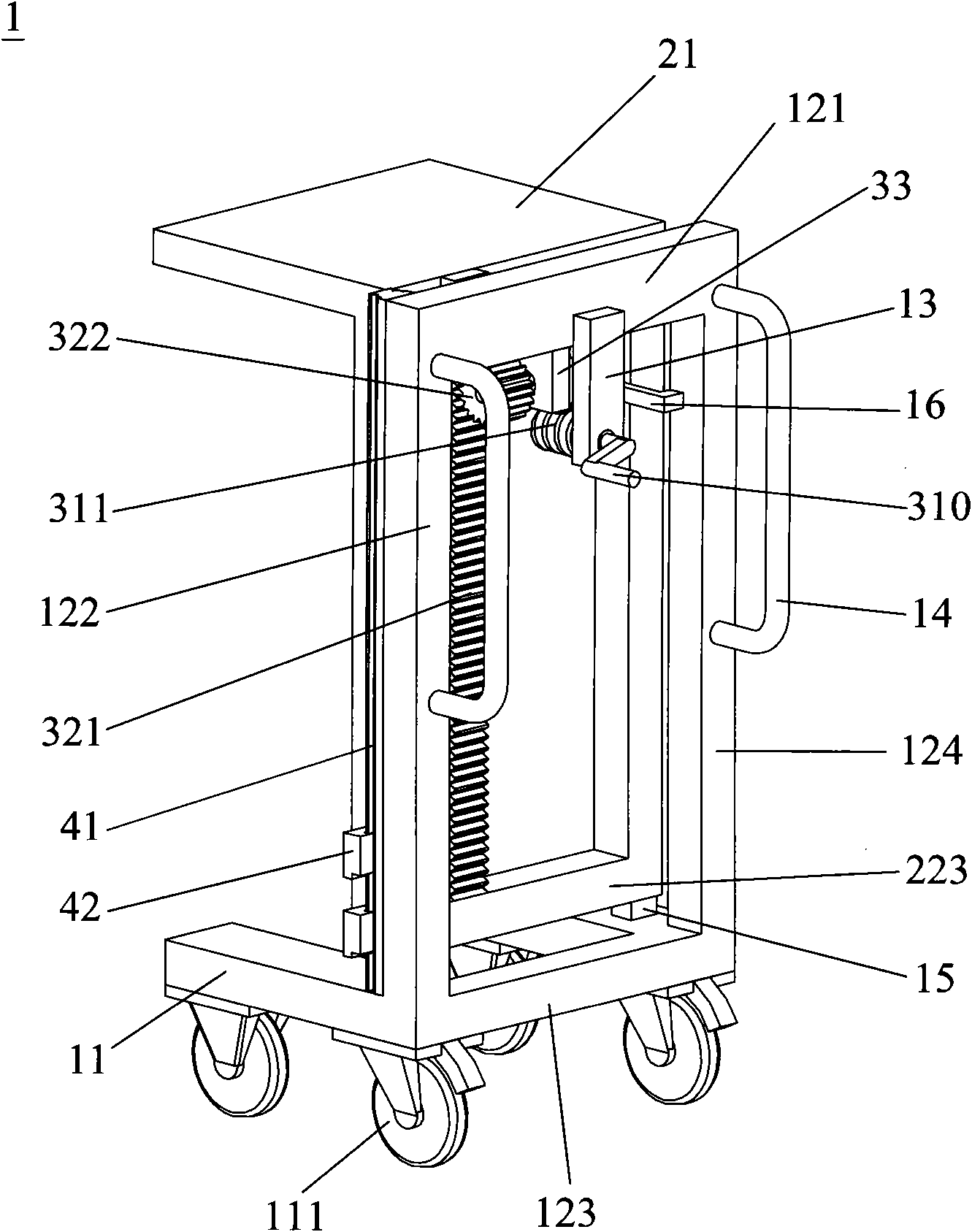

The invention discloses a lifting platform, comprising a supporting frame, a transmission mechanism, a sliding mechanism and a lifting bracket. The transmission mechanism comprises a first transmission assembly, a second transmission assembly, a fixed seat and a transmission shaft, wherein the fixed seat is arranged on the supporting frame, and the transmission shaft penetrates through the fixed seat and the two ends of the transmission shaft are respectively and fixedly connected with the first and second transmission assemblies; the first transmission assembly comprises a handle, a worm and a worm wheel, wherein the handle penetrates through the supporting frame and is pivoted with the supporting frame, the worm is fixedly connected with one end of the handle, and the worm wheel is fixedly connected with one end of the transmission shaft and is engaged with the worm; the second transmission assembly comprises a rack and a gear, wherein the rack is vertically arranged on the lifting bracket, and the gear is fixedly connected with the other end of the transmission shaft and is engaged with the rack; and the sliding mechanism comprises a guide rail and a sliding block, wherein the guide rail is arranged on the supporting frame and is parallel with the rack, and the sliding block is arranged on the lifting bracket and is clamped with the guide rail in a sliding manner. The lifting platform has the advantages of steady, safe and reliable lifting, high lifting precision, large stroke, no noise when in use, no pollution of environment, simple structure and compactness.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

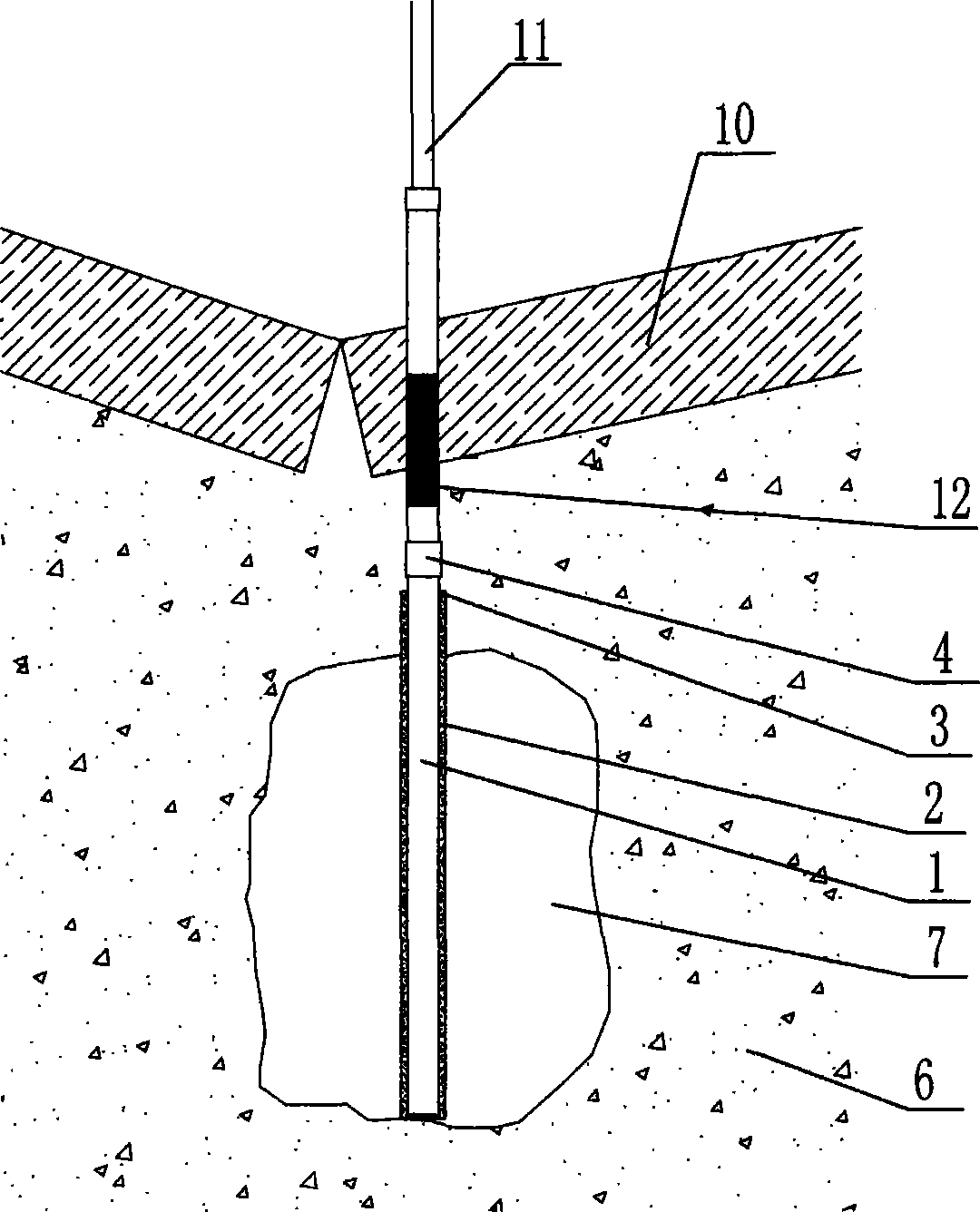

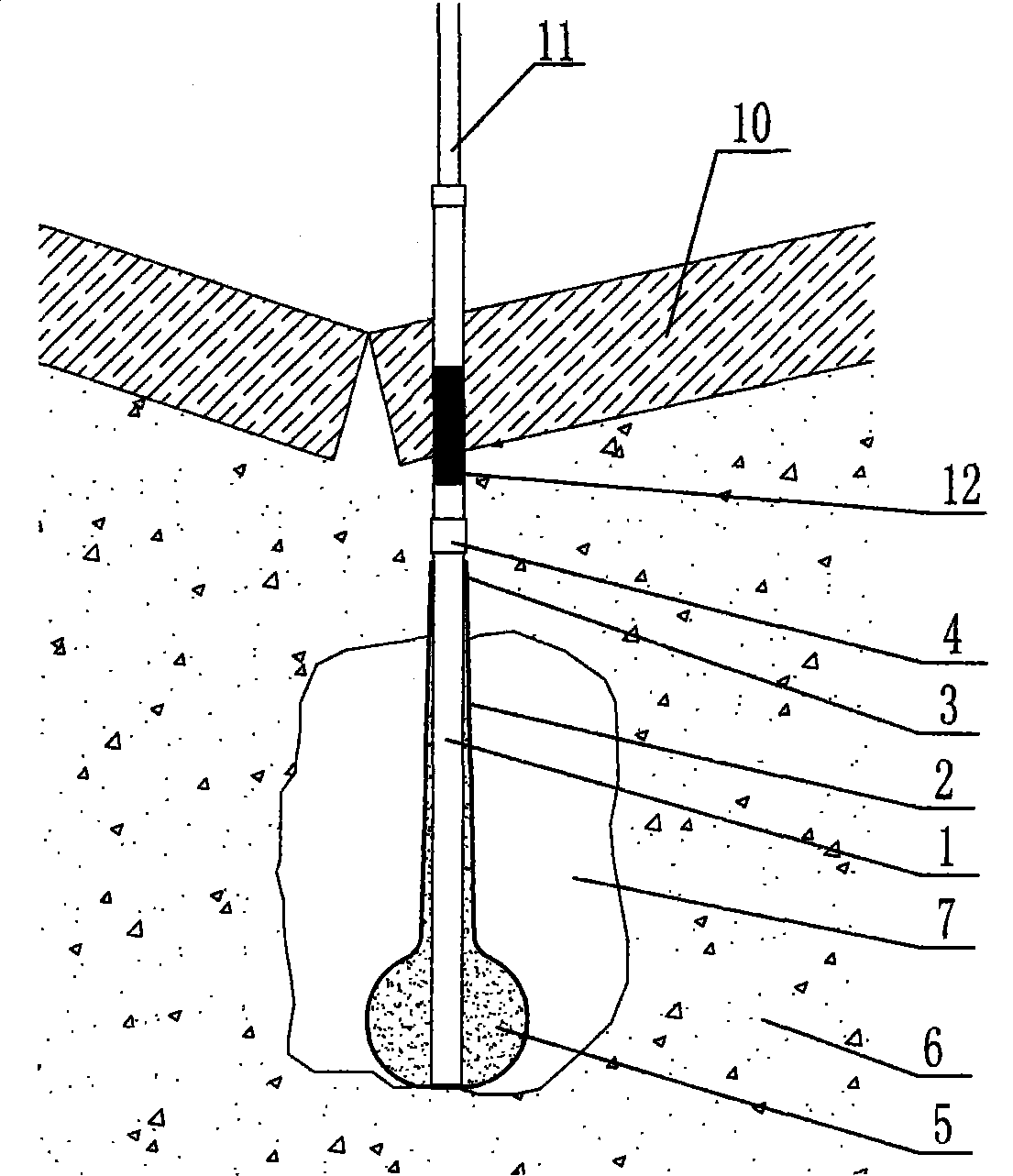

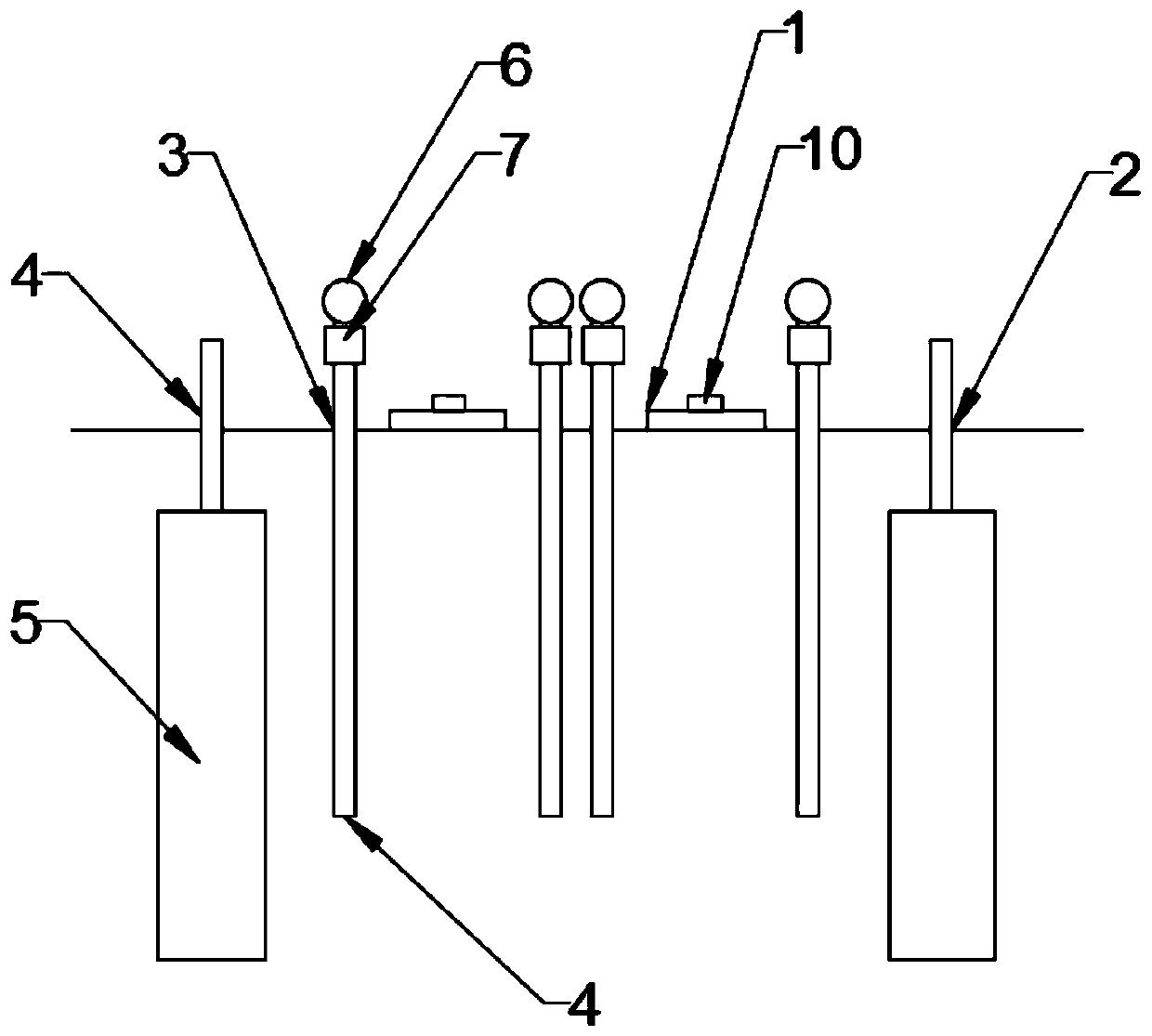

Expansive pouring device and method for governing railway roadbed sedimentation and deformation

ActiveCN104328782AIncrease profitDealing with settlement and deformation problemsRoadwaysRailway tracksSubgradeHigh pressure

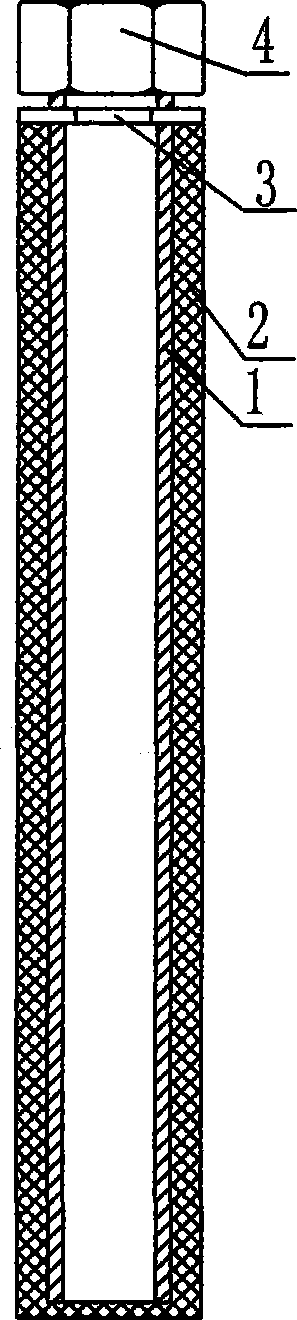

The invention relates to the field of railway roadbed maintenance, in particular to an expansive pouring device and a method for governing railway roadbed sedimentation and deformation. The expansive pouring device comprises a pouring pile core (1), a containing bag (2) and a slip casting pipe (11), wherein the slip casting pipe (11) is connected on the upper end of the pouring pile core (1) through a sleeved nut (4), the containing bag (2) sleeves the lower end of the pouring pile core (1) through a contracting sealing ring (3), and an expansive ring (12) is arranged on the contact segment of the slip casting pipe (11) and a roadbed (10). The expansive pouring device uses a frame structure supporting principle and a pile type structure principle, expansive foam, slip casting equipment and monitoring equipment are poured by matching with high pressure, the damaged roadbed can be accurately lifted, the accurate degree can realize plus-minus 1mm, the material using rate is high, the government of a large-scale cavity or an underground dark river is also effective, the damage to the roadbed structure is small, and the construction is rapid and convenient.

Owner:BEIJING RUNHIGH SCI & TECH

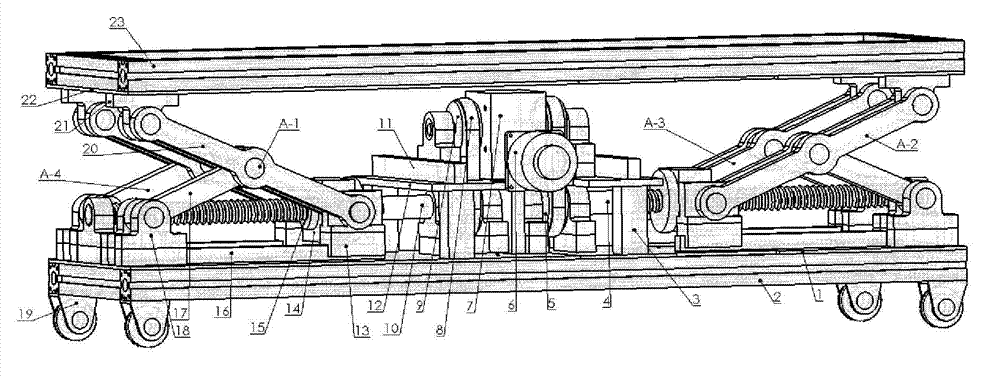

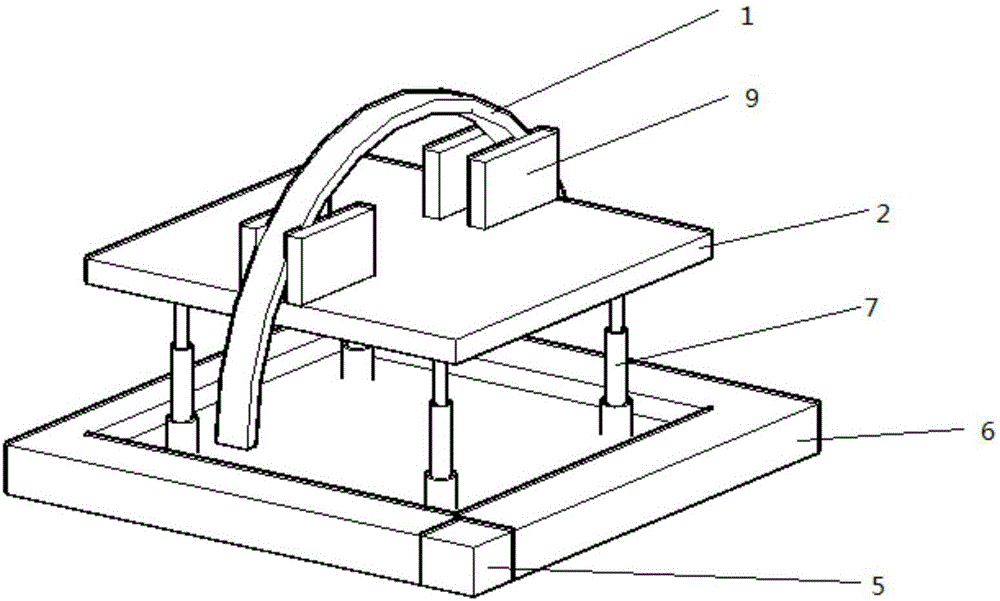

Movable type reverse self-locking lift platform

ActiveCN102774781AWith reverse self-locking functionEasy to moveLifting framesBall screwMovable type

The invention discloses a movable type reverse self-locking lift platform. The platform comprises a transmission mechanism, a lift mechanism and a platform framework. The platform framework comprises an upper platform and a lower platform; the transmission mechanism comprises a direct current motor, a turbine reducer, four sets of driving piece stand columns, a driving piece installation plate, two sets of synchronous wheel driving wheels, two sets of synchronous belts, two sets of synchronous wheel driven wheels, two sets of ball screws, two sets of ball screw slide blocks, two sets of ball screw slide block installation seats, four sets of linear guide rail slide saddles and four sets of linear guide rails; and the lift mechanism comprises four sets of lift trestle combinations. According to the movable type reverse self-locking lift platform, the turbine reducer is arranged in the transmission mechanism, so that the lift platform can be reversely self-locked, and the upper platform is guaranteed to be locked firmly; the four sets of lift trestle combinations are driven by the same motor, so that movements of the four sets of lift trestle combinations are totally identical, and stable lift of the platform can be achieved; and a position sensor is configured on the direct current motor, and accordingly, the lift height of the platform can be accurately controlled.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Construction trolley for lagging jack in tunnel and underground construction and construction method

ActiveCN106522997AAvoid shakingGuaranteed accuracyUnderground chambersTunnel liningInterference fitArchitectural engineering

The invention discloses a construction trolley for a lagging jack in tunnel and underground construction and a construction method. The construction trolley comprises a bottom support structure, a middle support structure and a top jacking structure, wherein the top jacking structure comprises a base, a lifting structure and a third support platform; the base is arranged on a horizontal guiding structure; the lifting structure is arranged on the base; the third support platform is fixed on the lifting structure; a clamping and fixing structure is arranged on the upper surface of the third support platform; the clamping and fixing structure comprises a blocking slot; the slot body width of the blocking slot is corresponding to the width of a to-be-jacked lagging jack, so that the blocking slot is in interference fit with the to-be-jacked lagging jack; and the widths of the first, second and third support platforms are gradually reduced, so that the two opposite edges of the first, second and third support platforms are all in contact with the to-be-jacked lagging jack after the to-be-jacked lagging jack is fully fixed on the construction trolley, and an acting force for fixing the lagging jack is generated.

Owner:THE FIFTH PROJECT OF CHINA RAILWAY BUREAU 14 GROUP +1

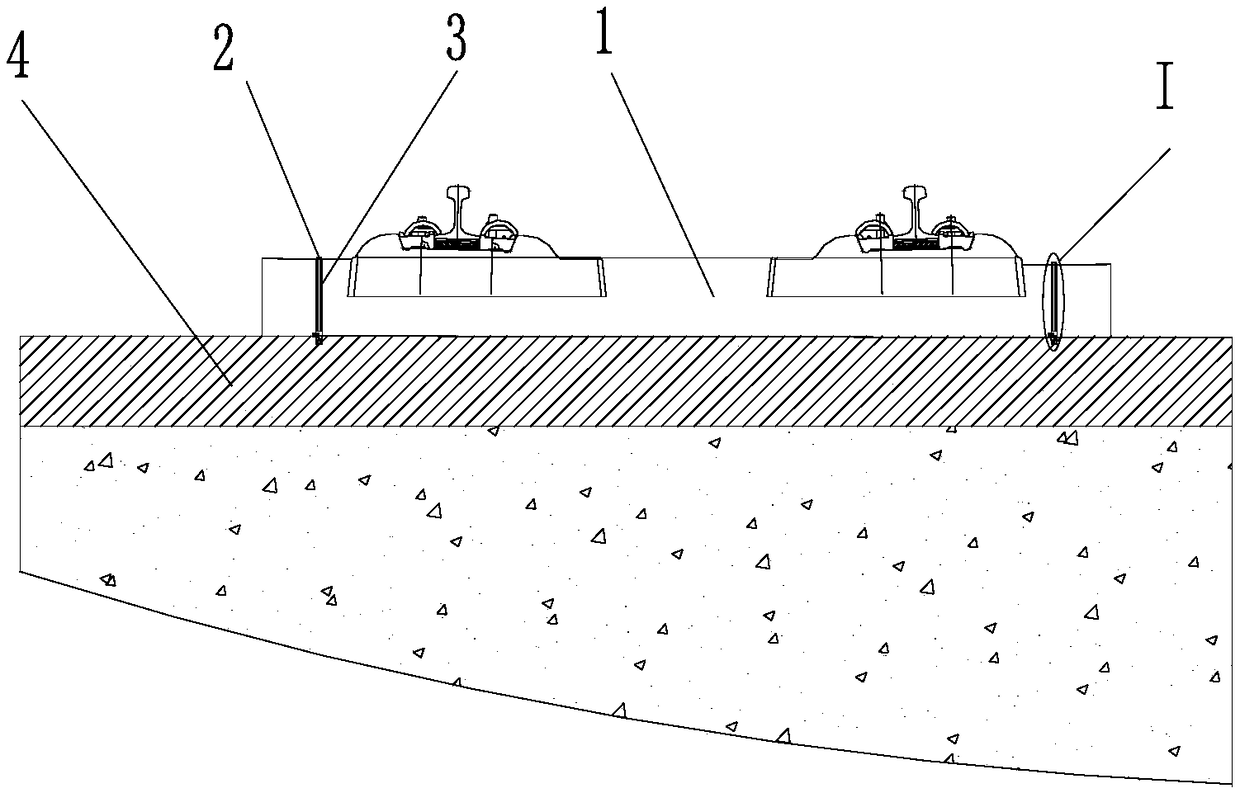

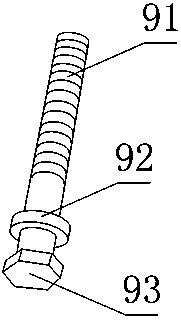

Ballastless track structure settlement lifting device and lifting method thereof

PendingCN108951322ASettle settlementSimple equipmentBallastwayRailway track constructionEngineeringControllability

The invention discloses a ballastless track structure settlement lifting device and a lifting method thereof. The device is used for lifting the ballastless track plate, and comprises screw rods embedded in two sides of the ballastless track plate and arranged at intervals along an extension direction thereof; the ballastless track plate has pre-burying holes for pre-burying the screw rods, the pre-burying holes vertically pass through the allastless track plate and extend downward to a concrete cushion layer, the screw rods are sleeved with nuts which are threadably connected with the screw rods, the outer walls of the screw rods are sleeved with sleeves, mortar columns are poured into annular gaps between the outer walls of the sleeves and the inner walls of the pre- burying holes, the mortar columns are integrated with the ballastless track plate by being cemented with the inner walls of the burying holes, and the bottoms of the mortar columns are in contact with the top end faces of the nuts. As the ballastless track structure settlement lifting device is not limit by the ballastless track structure and the operation space, the ballastless track structure settlement lifting device is easy to operate, has high lif accuracy, good controllability and high efficiency, and can effectively solve the settlement problem of ballastless track in a special section.

Owner:中铁四院集团工程建设有限责任公司

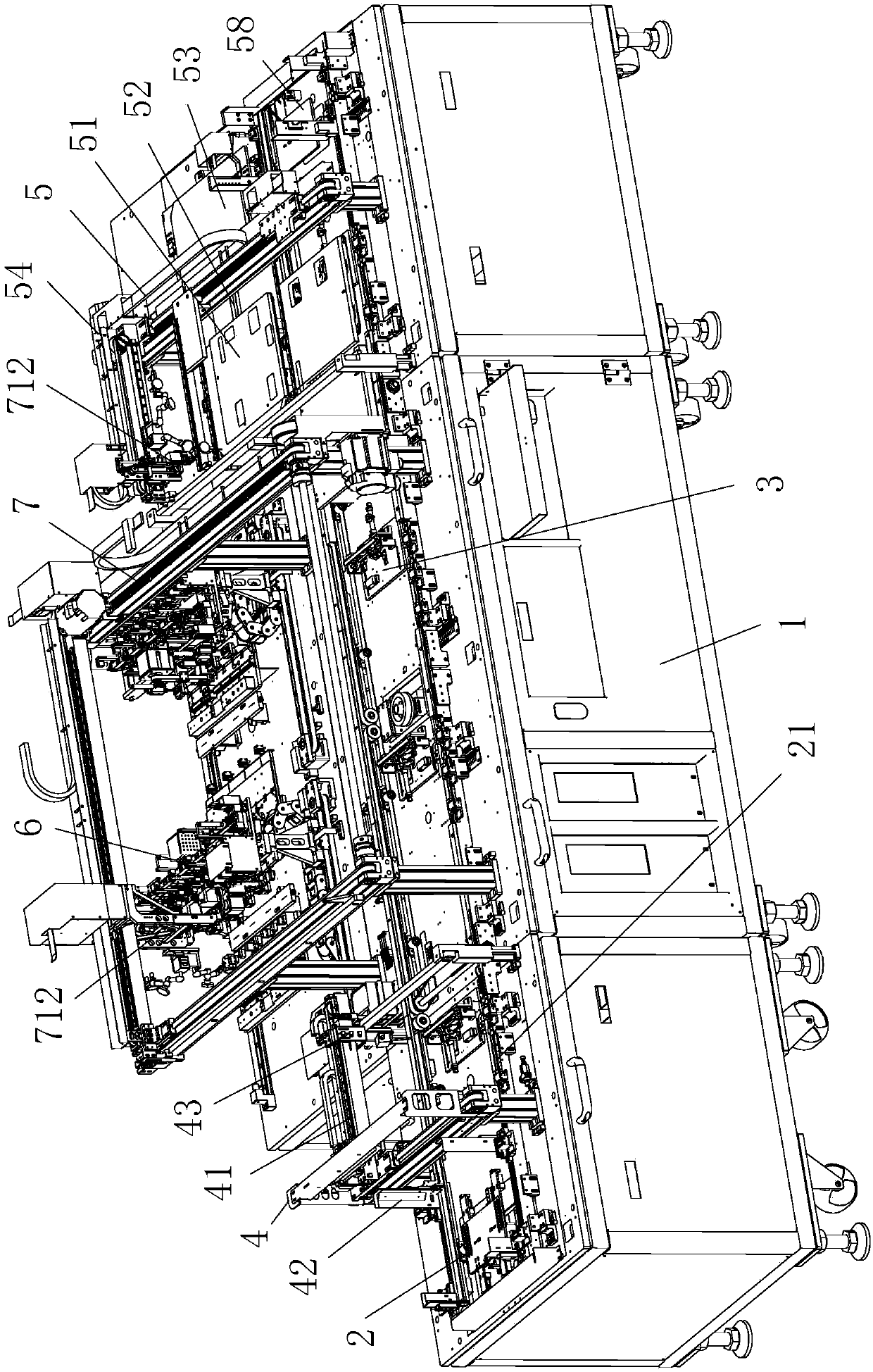

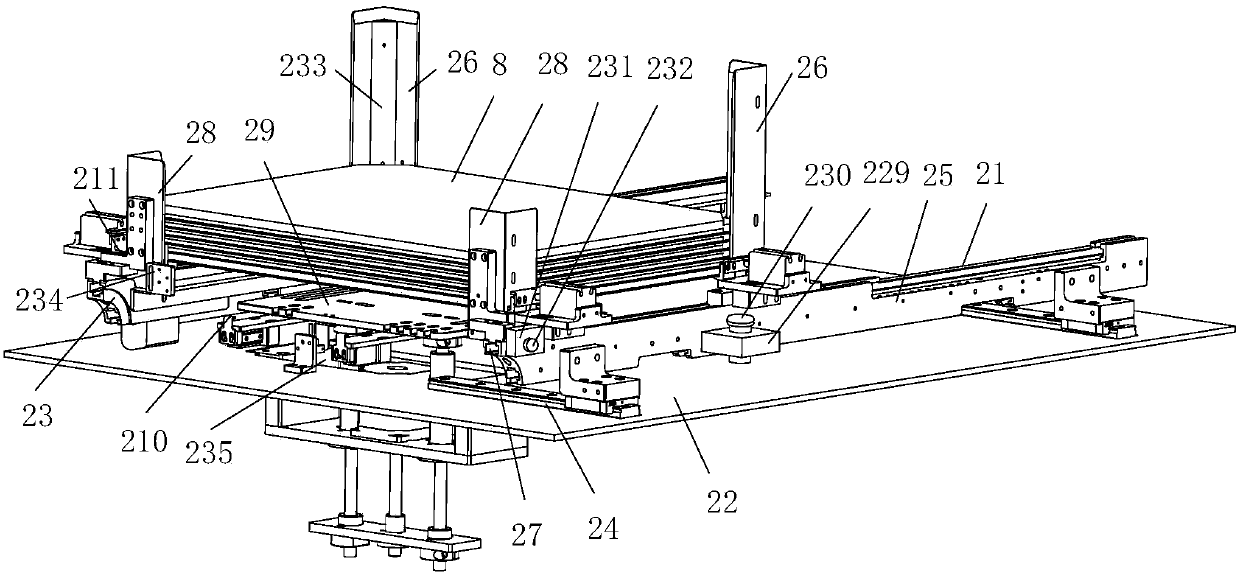

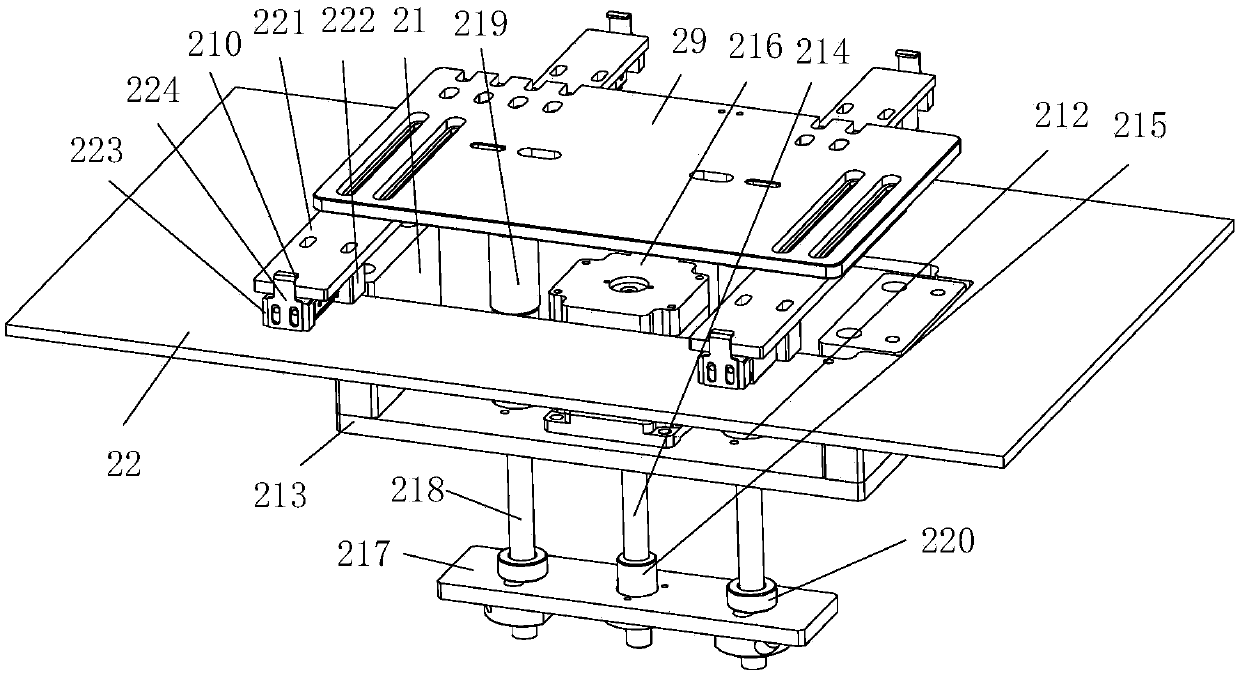

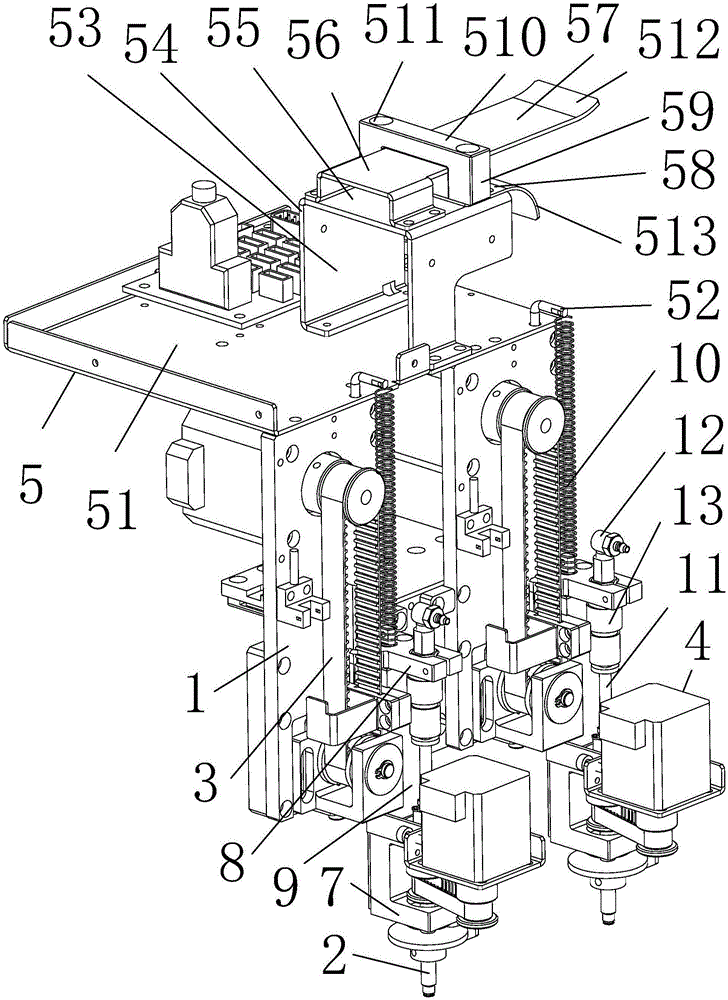

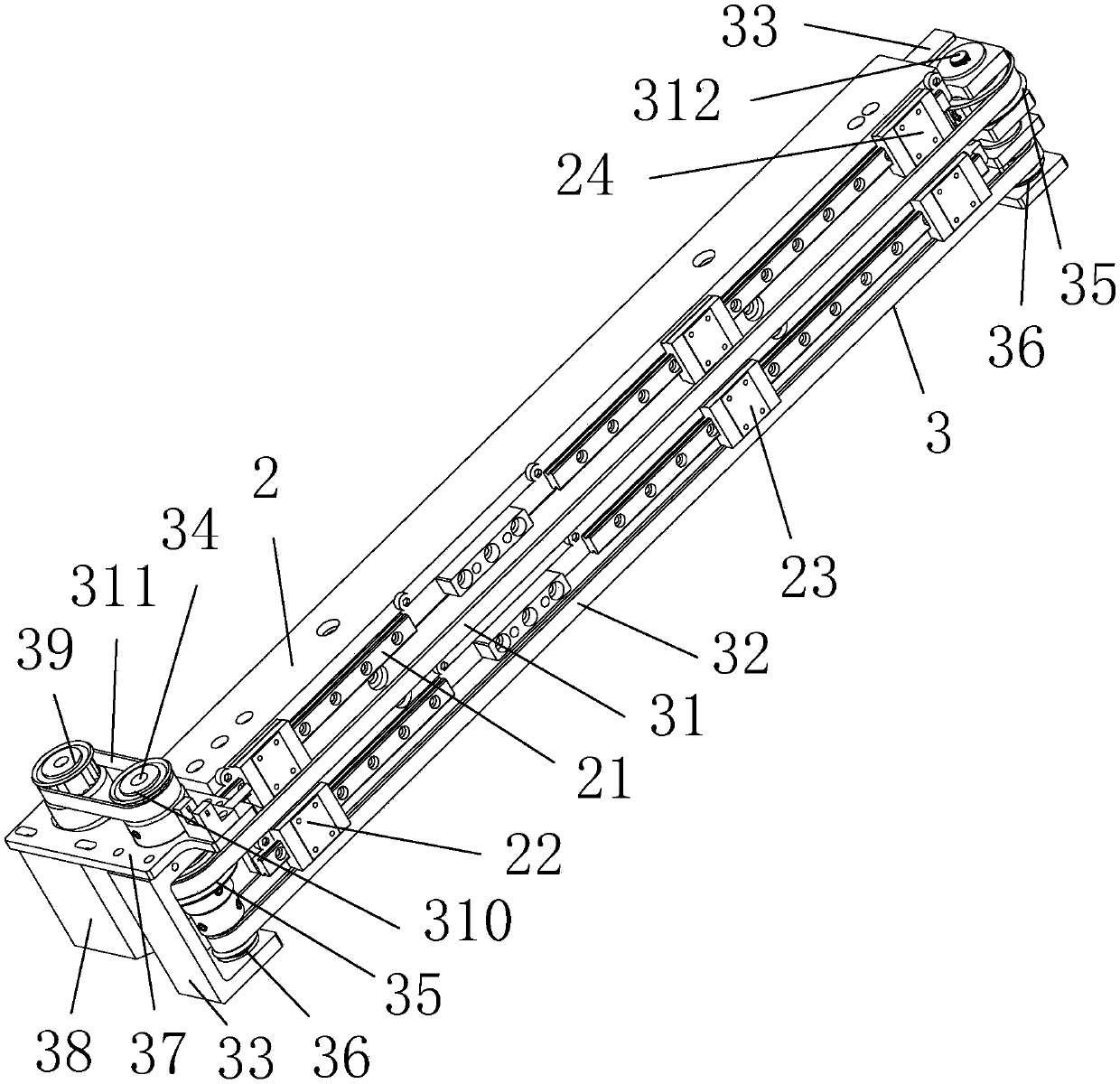

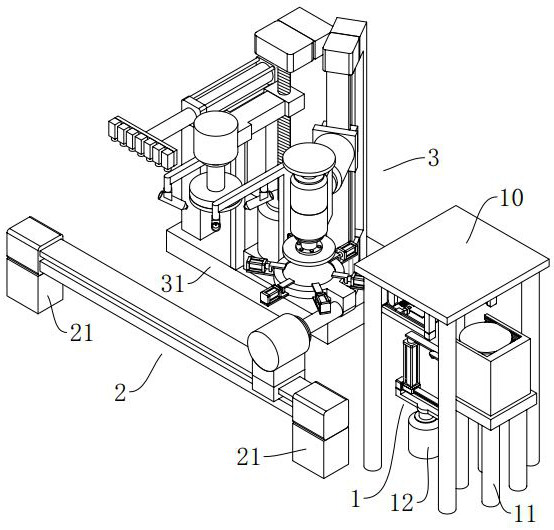

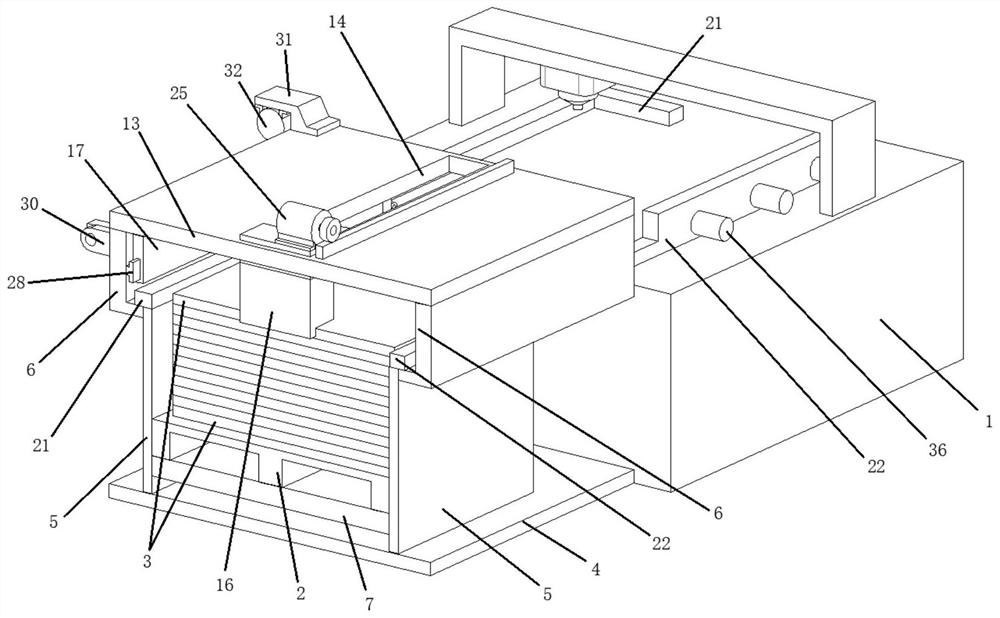

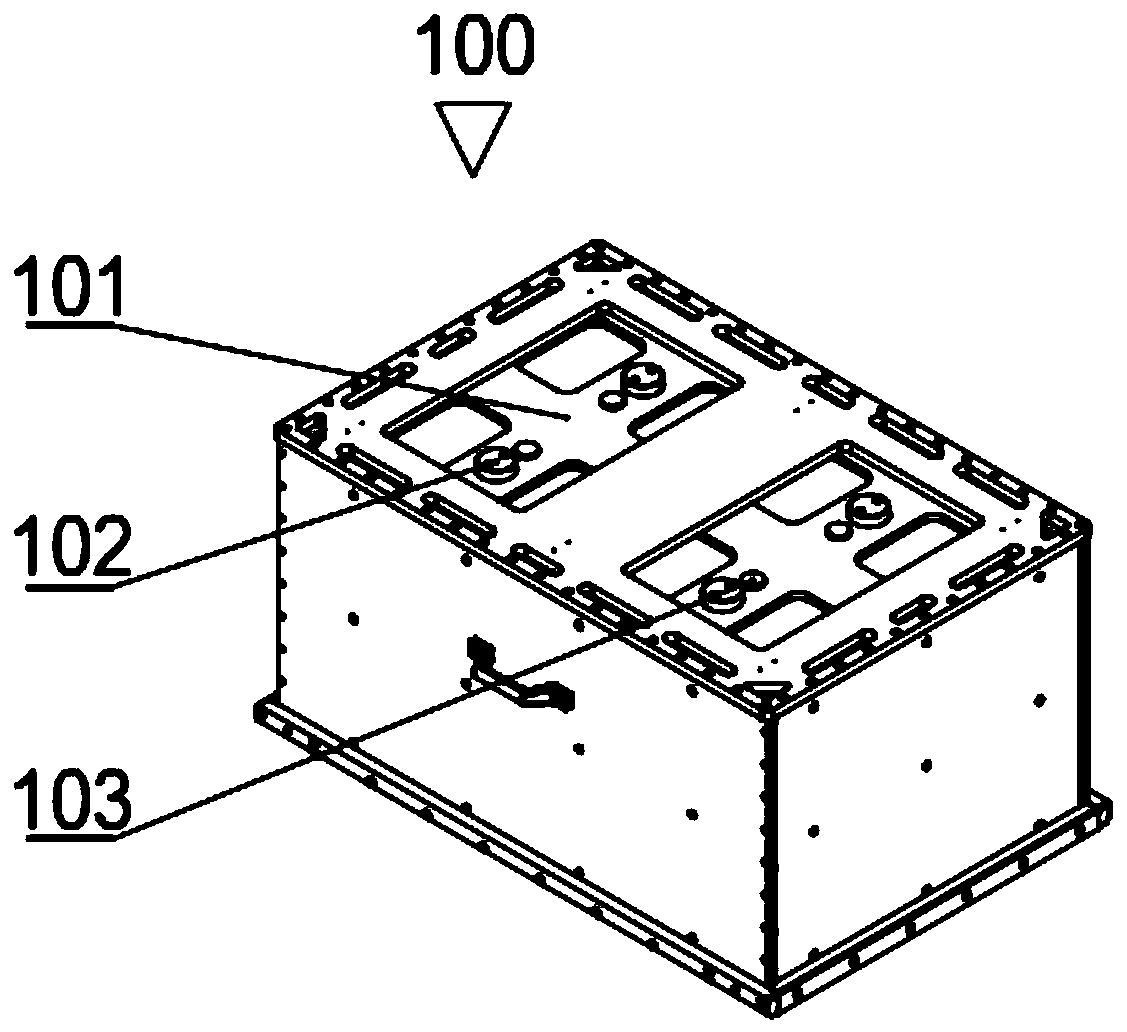

Fingerprint chip electrical performance testing device

ActiveCN108051727AHigh separation and feeding efficiencyAccurate orientationElectronic circuit testingElectricityTest efficiency

The present invention relates to a fingerprint chip electrical performance testing device. The fingerprint chip electrical performance testing device includes a testing system, a feeding system, and amaterial collection system; the feeding system includes a tray separating and conveying device, a plurality of tray positioning devices, a fingerprint chip number identification device, and a material collection system, wherein the tray separating and conveying device is provided with two tray delivering conveyor belts, the plurality of tray positioning devices are arranged between the two tray delivering conveyor belts, the fingerprint chip number identification device is provided with a machine vision system located above the first tray positioning device, the material collection system isprovided with an adsorption mechanism located above the last tray positioning device; and the test system includes two test devices and material taking devices, wherein the two test devices are arranged symmetrically outside one side of the tray separating and conveying device, and the material taking devices are located at the test devices and adsorption devices located above the other tray positioning devices. The fingerprint chip electrical performance testing device can automatically feed, transfer and convey fingerprint chips and has high test efficiency.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

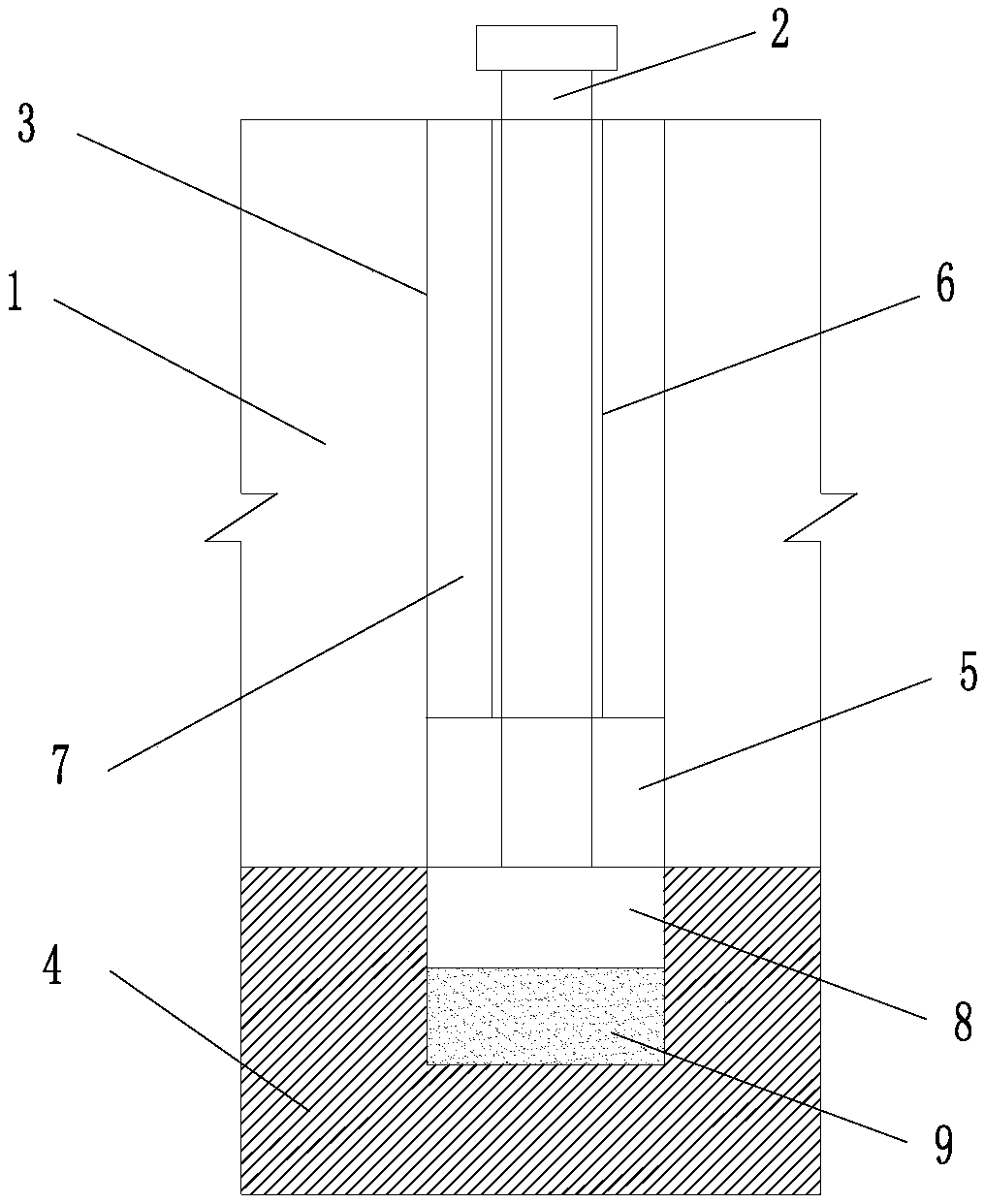

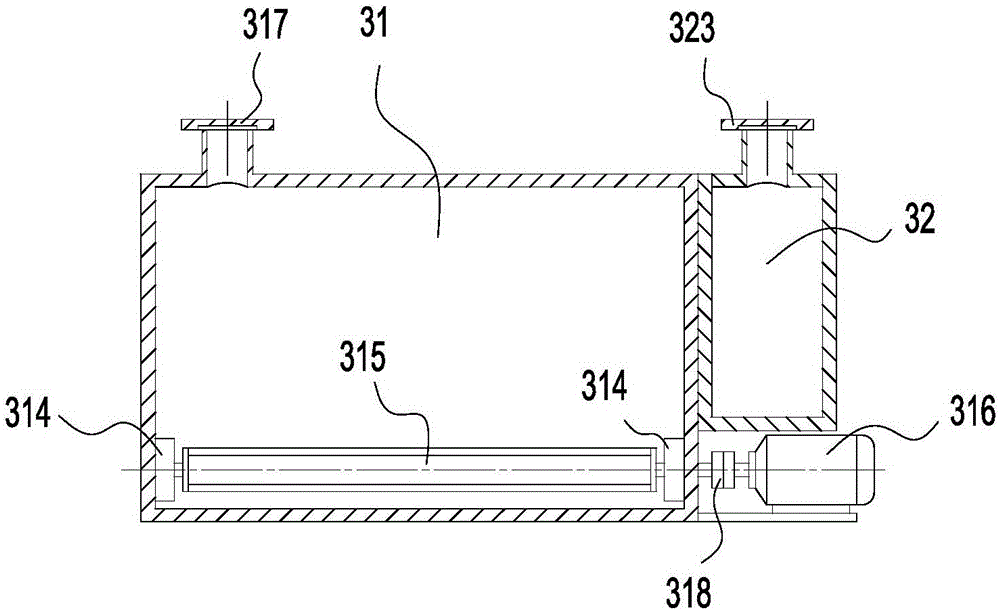

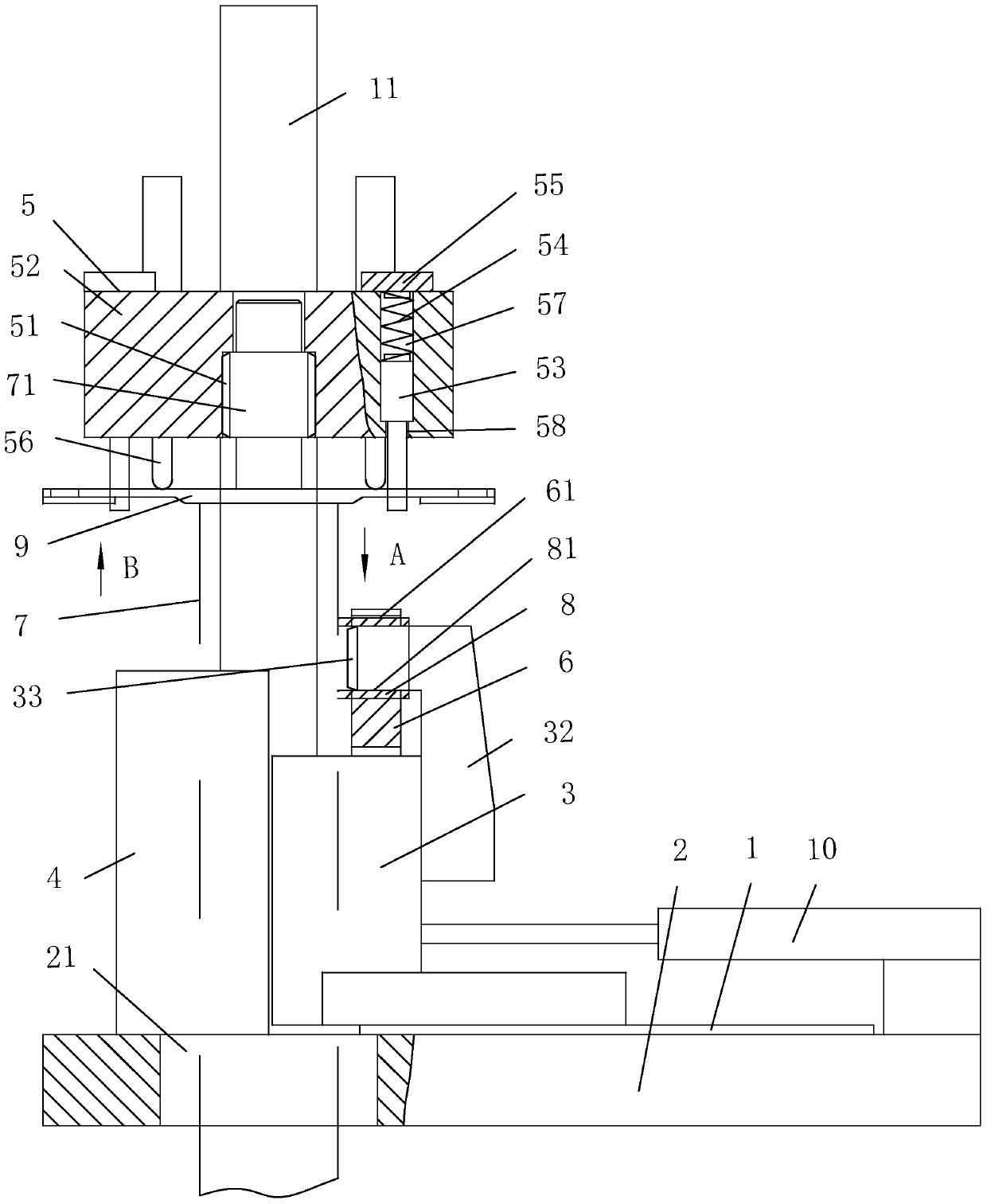

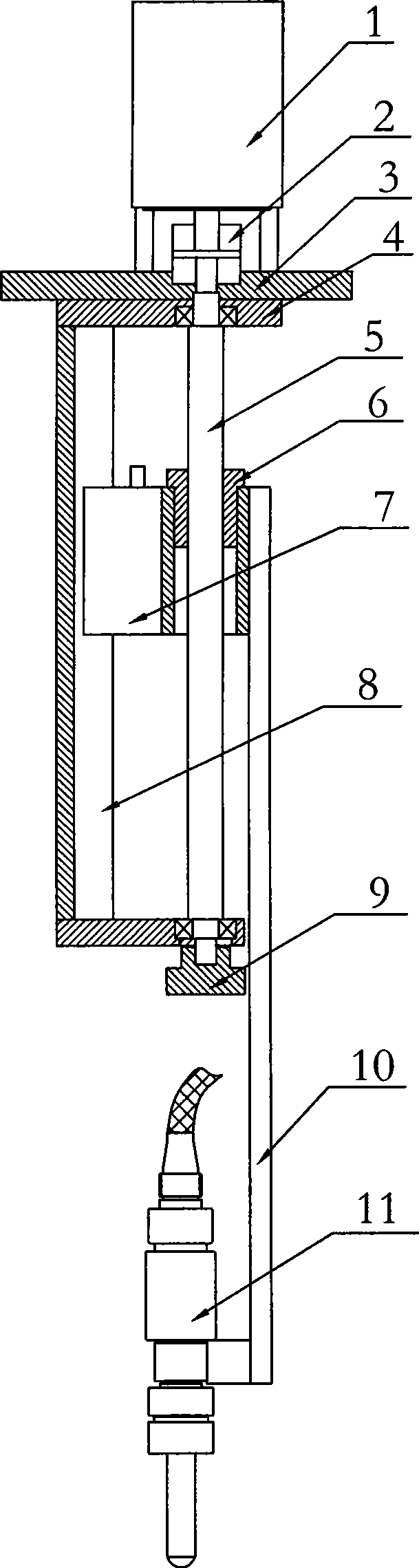

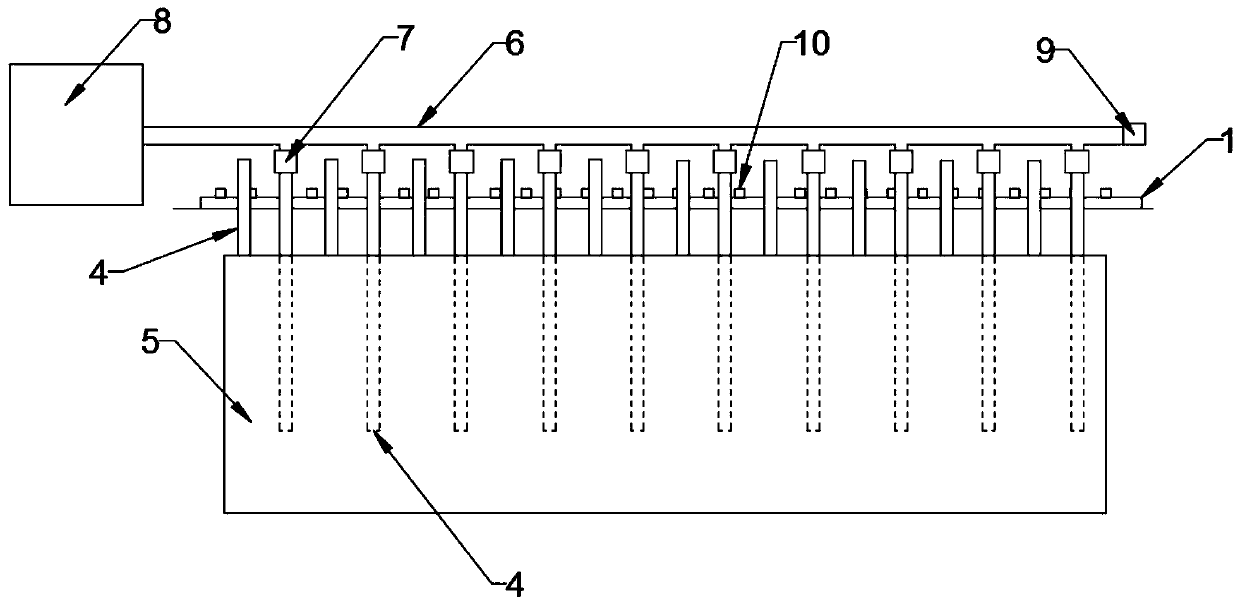

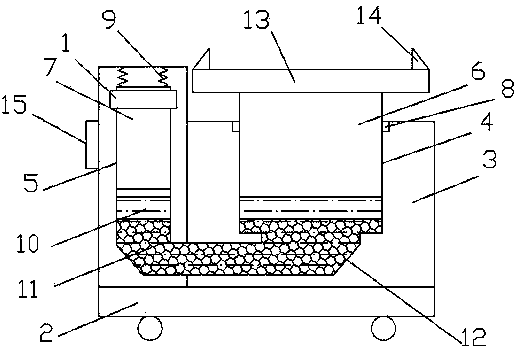

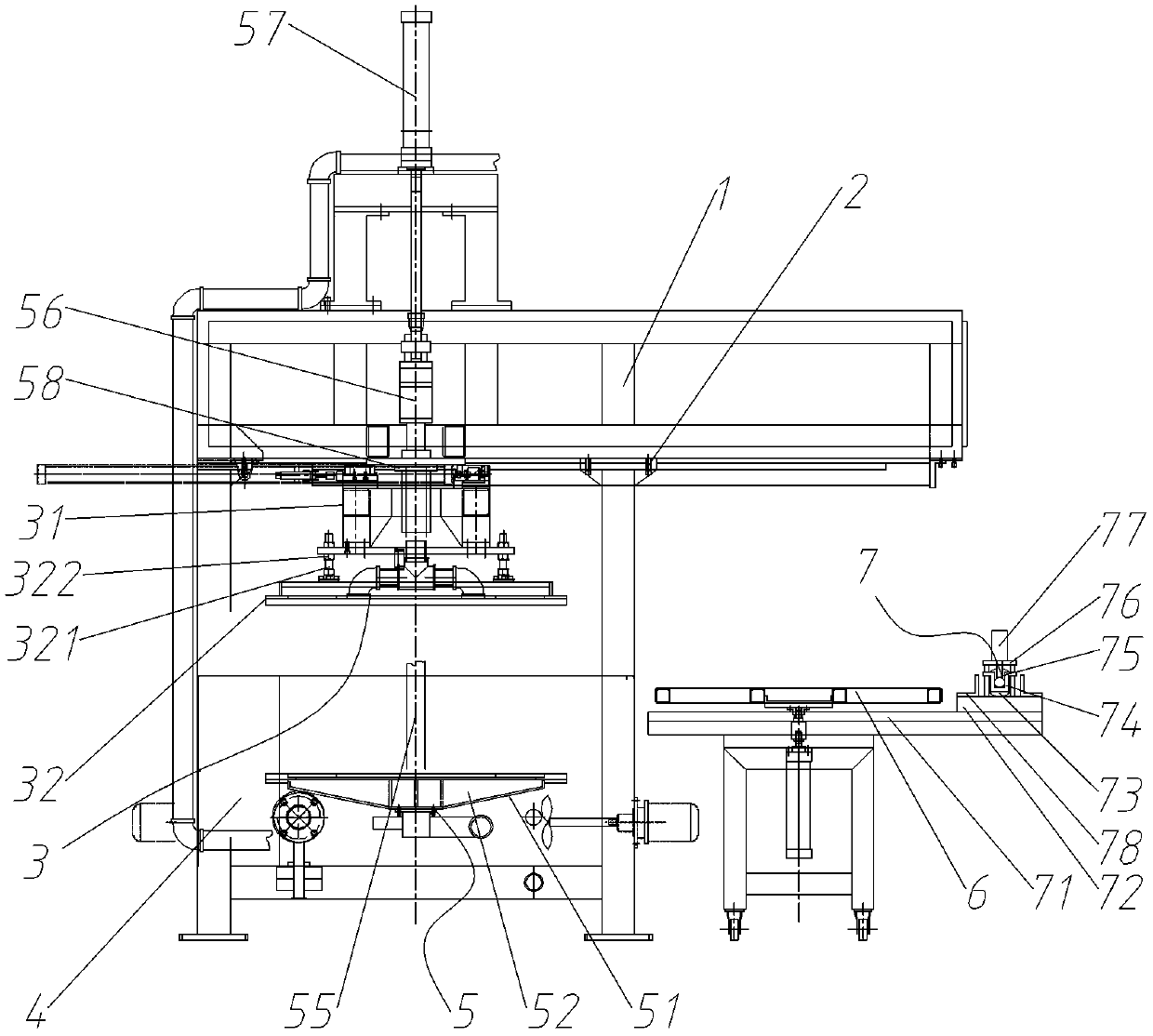

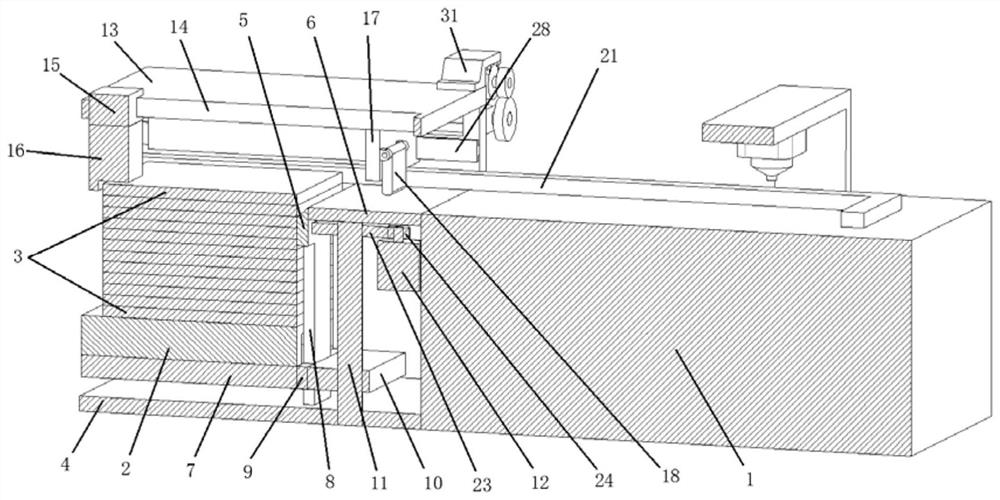

Forming cylinder system structure in SLM rapid forming equipment

InactiveCN111283198APrecise liftingEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMachined surfaceBall screw

The invention discloses a forming cylinder system structure in SLM rapid forming equipment. According to the forming cylinder system structure in the SLM rapid forming equipment, a lifting mechanism is driven by the corresponding servo motor, a ball screw nut pair is driven by a right-angle speed reducer to move, then up-down movement of a preheating system structure is achieved, and the relevantthickness of the powder laying layer is controlled. The preheating system structure heats a base plate through a cast aluminum heating plate, a thermocouple is adopted as a temperature sensor, real-time control over the temperature is achieved, heat insulation silk floss and a heat insulation plate are additionally arranged below the heating plate for relevant heat insulation, and sealing rubber strips are installed on the side edges of the base plate and the heat insulation plate to prevent machined metal powder from falling along a forming cavity. According to the forming cylinder system structure in the SLM rapid forming equipment, the lifting mechanism is used for accurately controlling the thickness of the powder laying layer, the preheating system structure is used for accurately controlling the machining temperature of the metal part, the machining environment of the whole metal part is optimized, and the machining surface quality of the metal part is controlled and improved.

Owner:HANGZHOU DIANZI UNIV

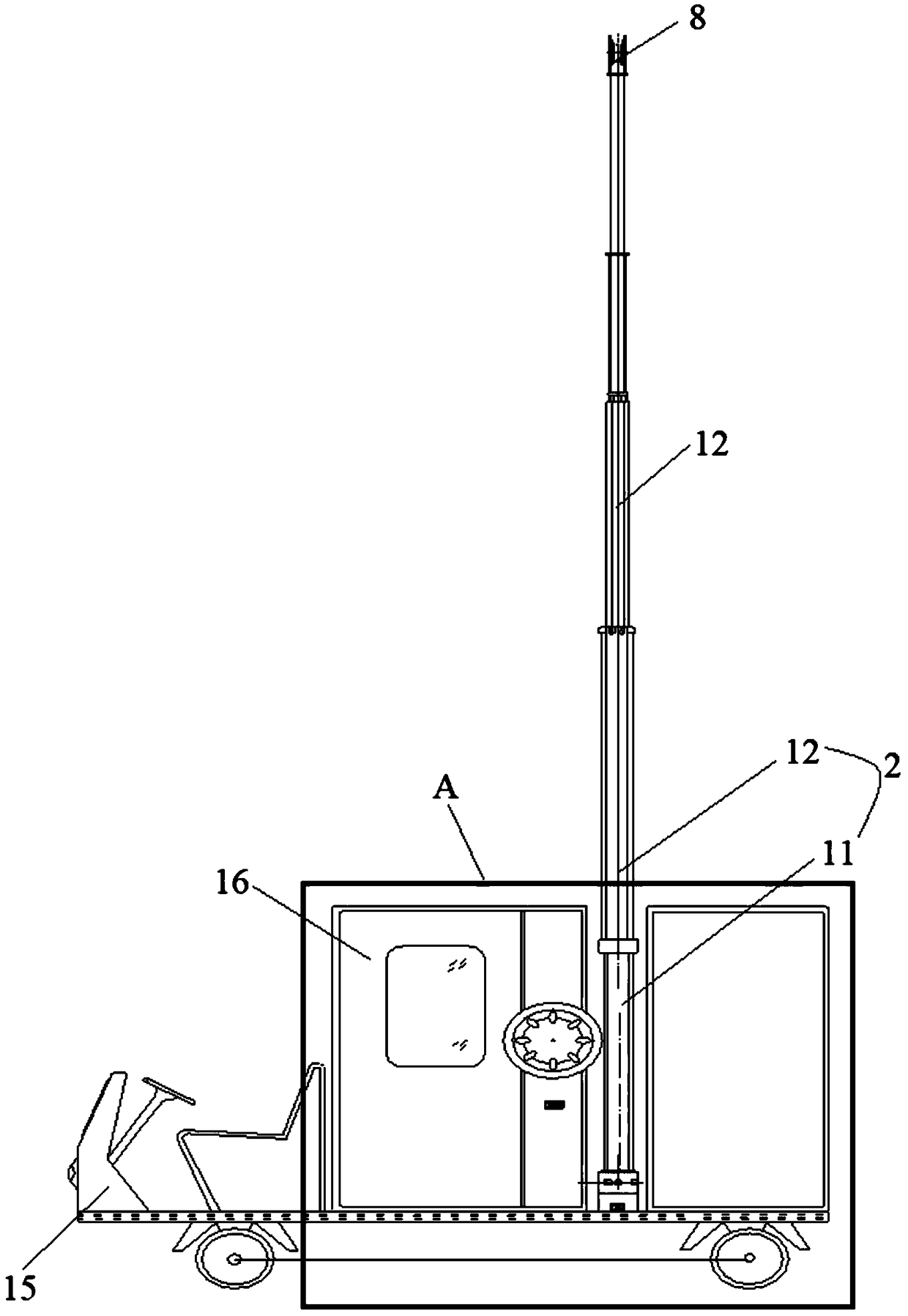

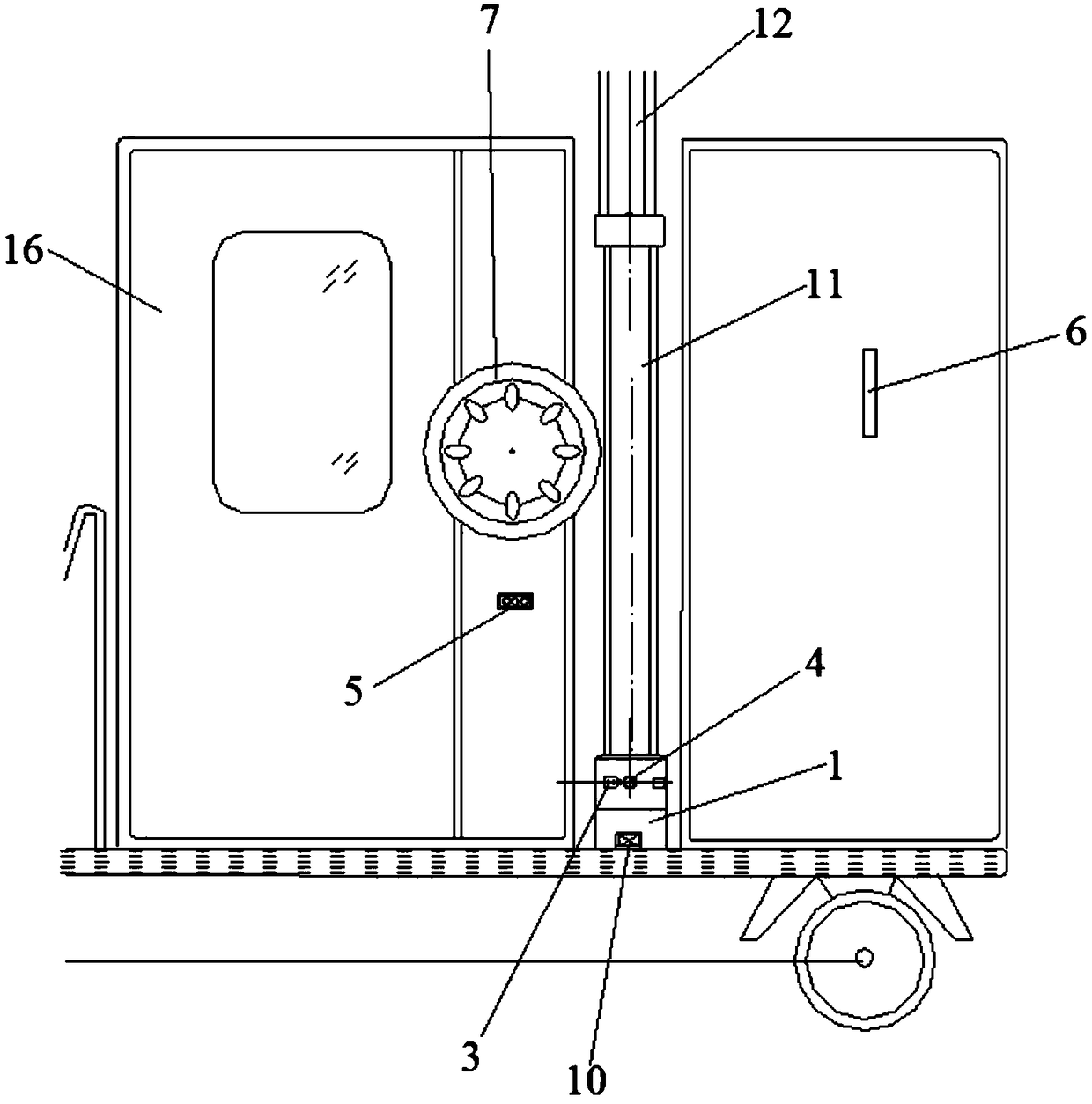

White paint spraying machine, with high lifting efficiency, for trunk

InactiveCN106583083AImprove lifting efficiencyHigh lifting precisionLiquid spraying apparatusPlant protectionLeft halfEngineering

The invention discloses a white paint spraying machine, with high lifting efficiency, for a trunk. The white paint spraying machine comprises a motor vehicle. A working arm is arranged at the front part of the motor vehicle. A spraying barrel assembly is arranged at the front end of the working arm, and comprises a left half barrel and a right half barrel, which can be opened or closed. When the left half barrel and the right half barrel are closed, the trunk is clamped between the left half barrel and the right half barrel to be sprayed with paint. A lifting mechanism is arranged between the working arm and the front part of the motor vehicle, and comprises an outer lifting cylinder, an inner lifting cylinder and a lifting cylinder. One of the outer lifting cylinder and the inner lifting cylinder is connected with the front part of the motor vehicle, and the other one is connected with the working arm. The lifting cylinder drives the outer lifting cylinder and the inner lifting cylinder to relatively move in the vertical direction. The white paint spraying machine has the advantage that the efficiency is higher when the working arm ascends or descends.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

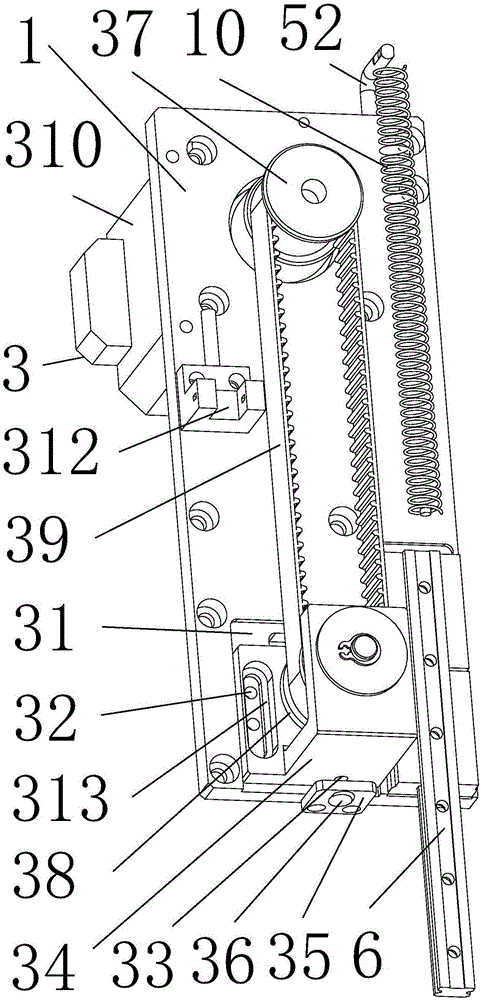

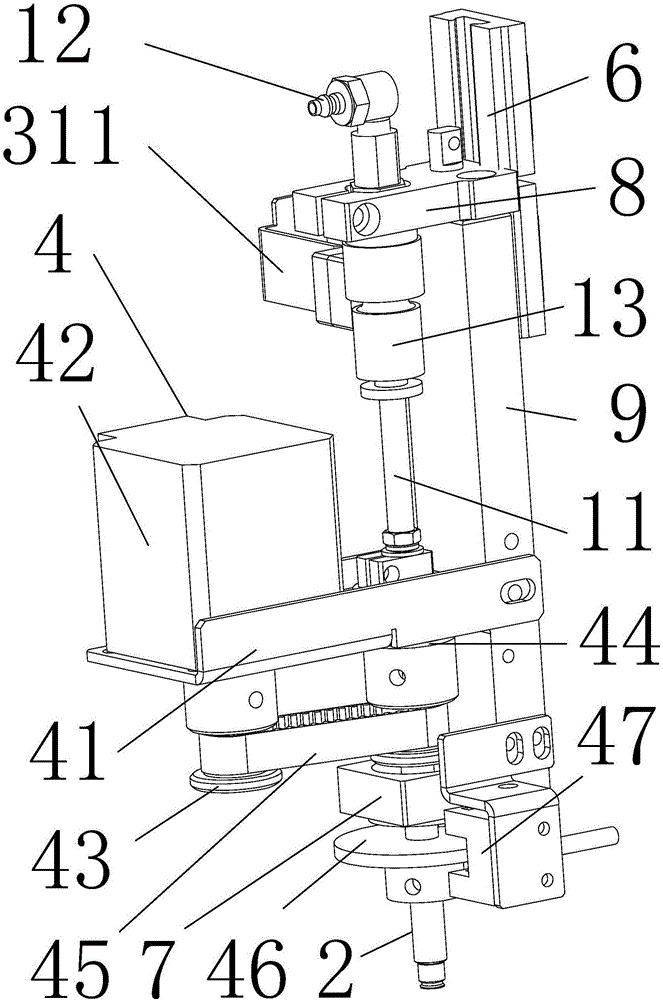

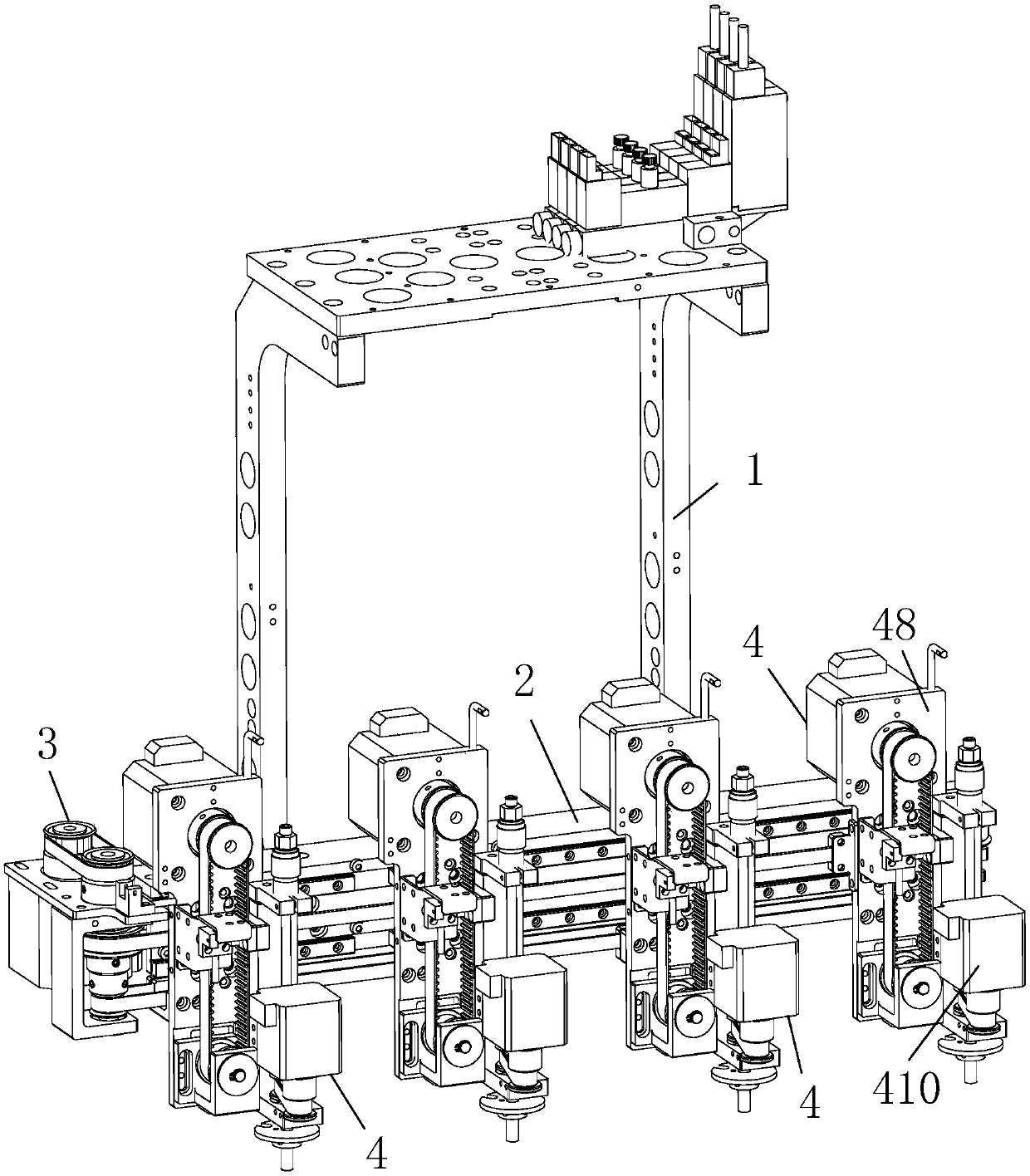

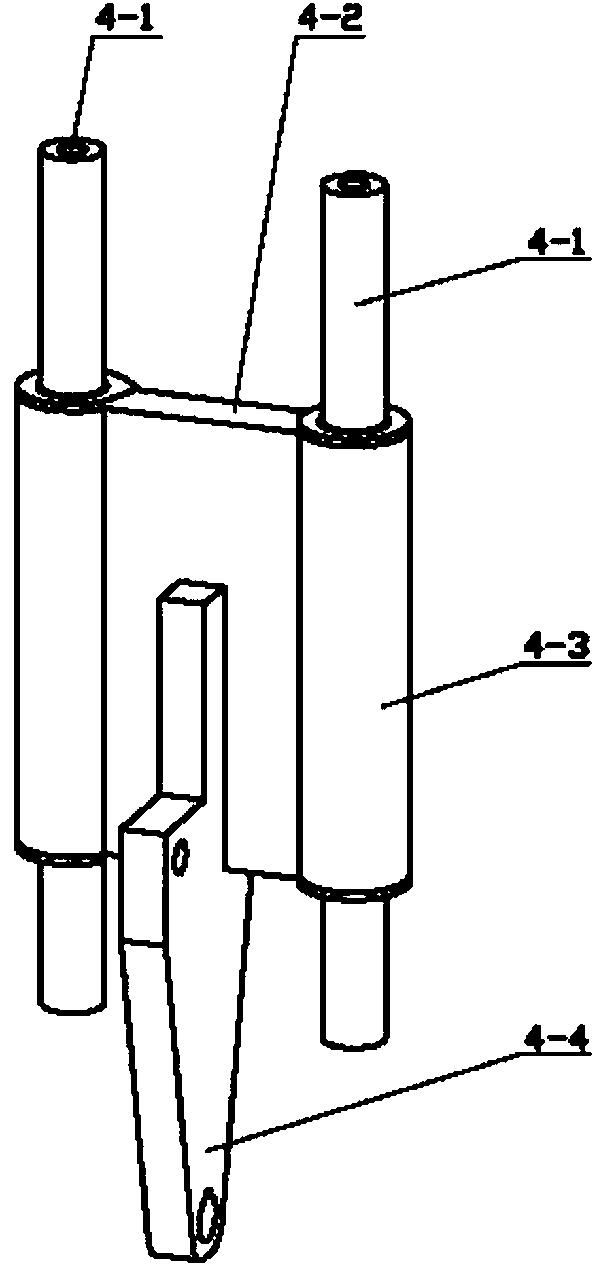

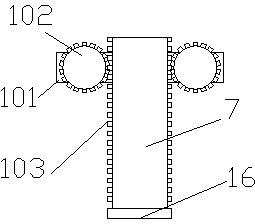

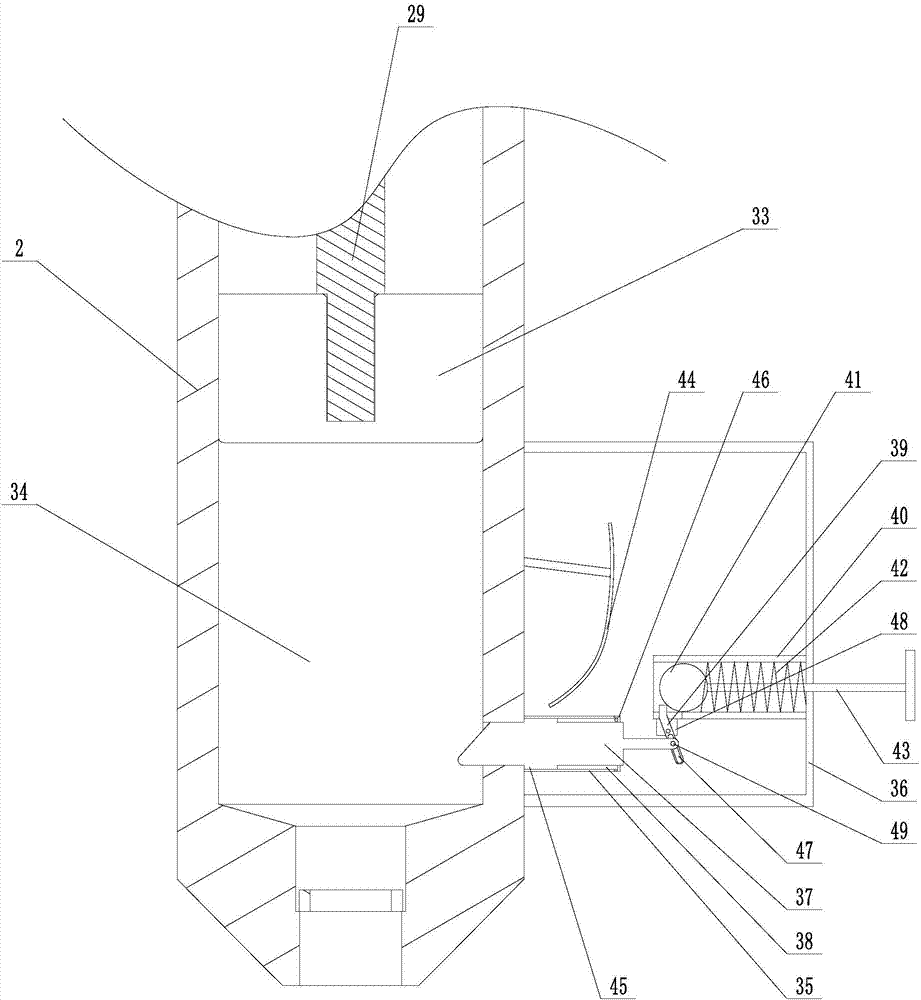

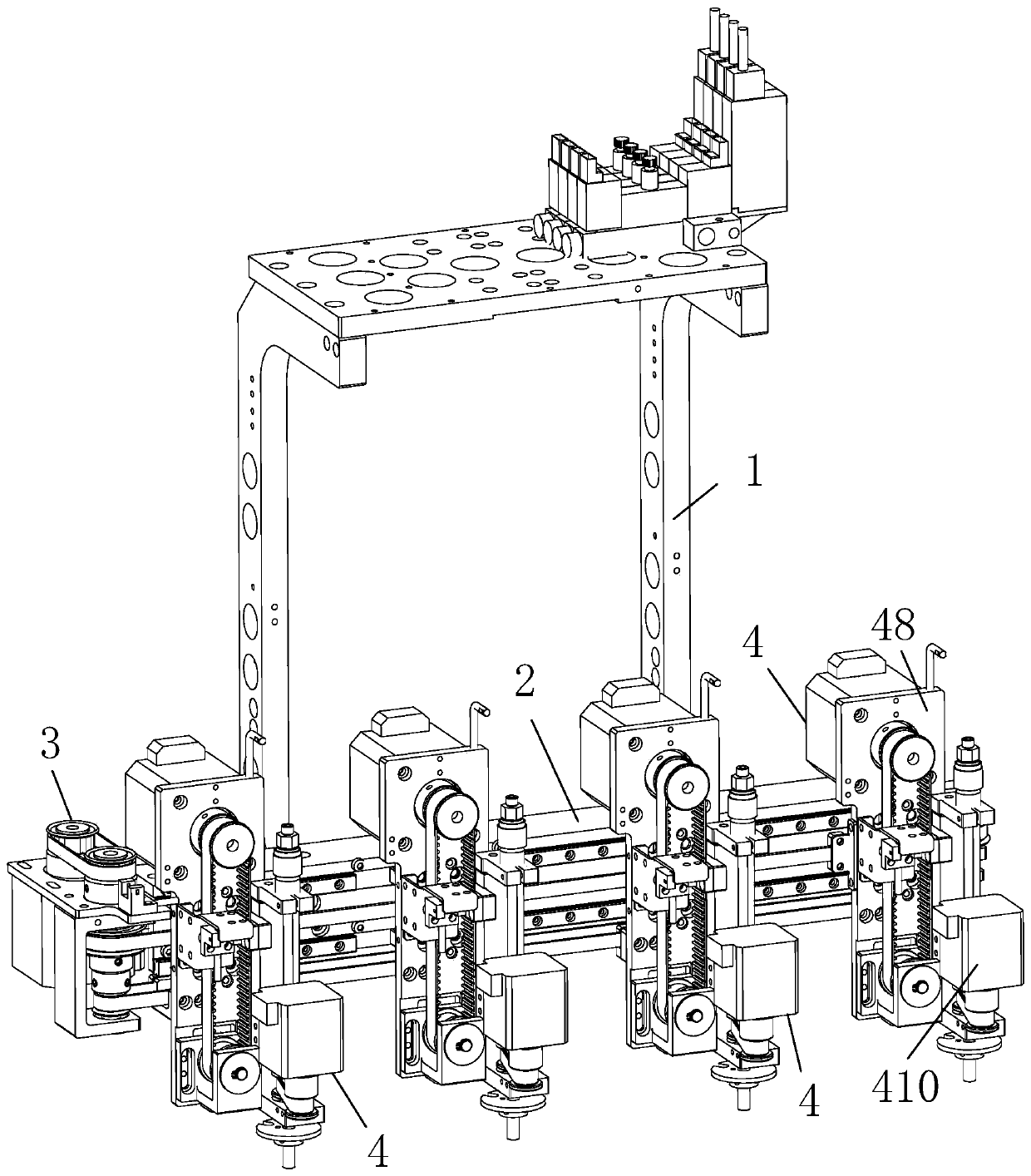

Multifunctional suction nozzle device of integrated circuit

ActiveCN107180779AClosely arrangedSimple structureSemiconductor/solid-state device manufacturingConveyor partsEngineeringIntegrated circuit

The invention relates to the field of sorting of the integrated circuits. The objective of the invention is to provide a multi-functional suction nozzle device of an integrated circuit. The suction nozzle device comprises a vertical plate, at least one suction nozzle mechanism, a pipe arrangement assembly with a cross plate connected with the upper end of the vertical plate. Each suction nozzle mechanism comprises a vacuum suction nozzle, a vertical straight line guide rail connected with the vertical plate, an evaluating seat, a pull spring, an elevating driving mechanism, a vertical vacuum pipe and a rotation driving mechanism. A connection ear and a fixed ear arranged above the connection ear are arranged on each elevating seat which is connected with a slide block of the corresponding vertical straight line guide rail. The lower ends of the vertical vacuum pipes are connected with the vacuum suction nozzles and the vertical vacuum pipes are pivoted to connection blocks. A pull rod connected with one end of each pull spring is arranged on the cross plate. The other end of each pull spring is connected with the corresponding elevating seat. According to the invention, the suction nozzle device has various functions; suction nozzles will not collide with other assemblies on a machine bench when a motor is cut off, so the safety is quite high; and through the pipe arrangement assembly, pipelines are arranged tidily and compactly and free from damage.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

Angle position test tool of clock spring installation board and ignition switch installation frame

InactiveCN103851989AReduce detection errorSimple structureAngles/taper measurementsSoftware engineeringIgnition switch

The invention relates to the field of automobile part detection devices, and provides an angle position test tool of a clock spring installation board 9 and an ignition switch installation frame 8. The angle position test tool of the clock spring installation board and the ignition switch installation frame comprises a bottom board, a right clamping block, a right clamping block drive device, a left clamping block, a lifting device, a spline section and installation hole detection assembly, a locating groove and a locating block, wherein the right clamping block is connected with the bottom board through a slide way and is provided with a right clamping groove and a square hole locating head; the left clamping block is provided with a left clamping groove and is fixedly connected with the bottom board; the spline section and installation hole detection assembly is connected with the lifting device; the locating groove is matched with the ignition switch installation frame in width; the locating block is fixedly connected with the bottom board. The angle position test tool of the clock spring installation board and the ignition switch installation frame is small in detection error and high in detection efficiency.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

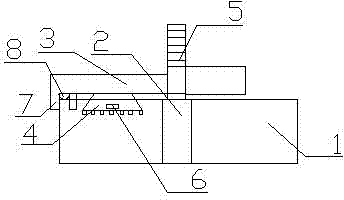

Induction type automatic bale plucker

InactiveCN104514043AHigh lifting precisionLow costFibre breaking machinesFibre breaking by beater armsBall bearingArchitectural engineering

The invention relates to a bale plucker, and specifically relates to an induction type bale plucker. The bale plucker comprises a base, a spindle, a rotating arm, and a tong; the spindle is installed in the middle of the base; the top end of the spindle is fixedly connected with the rotating arm; the bottom end of the rotating arm is fixed with the tong; the rotating arm is fixedly connected with the spindle via a self-locking lead screw lifter; a lateral end of the tong is fixed with a photoelectric inductor; the bottom end of the rotating arm is fixed with a concave groove; a ball bearing is installed inside the concave groove; a lateral edge of the base is encircled inside the concave groove and sticks to the ball bearing; the bale plucker is able to adjust the height of the tong by inducing the plucked amount; the lifting precision is higher; the cost is saved; and the effect is increased.

Owner:JIANGSU KANGYUAN TEXTILE

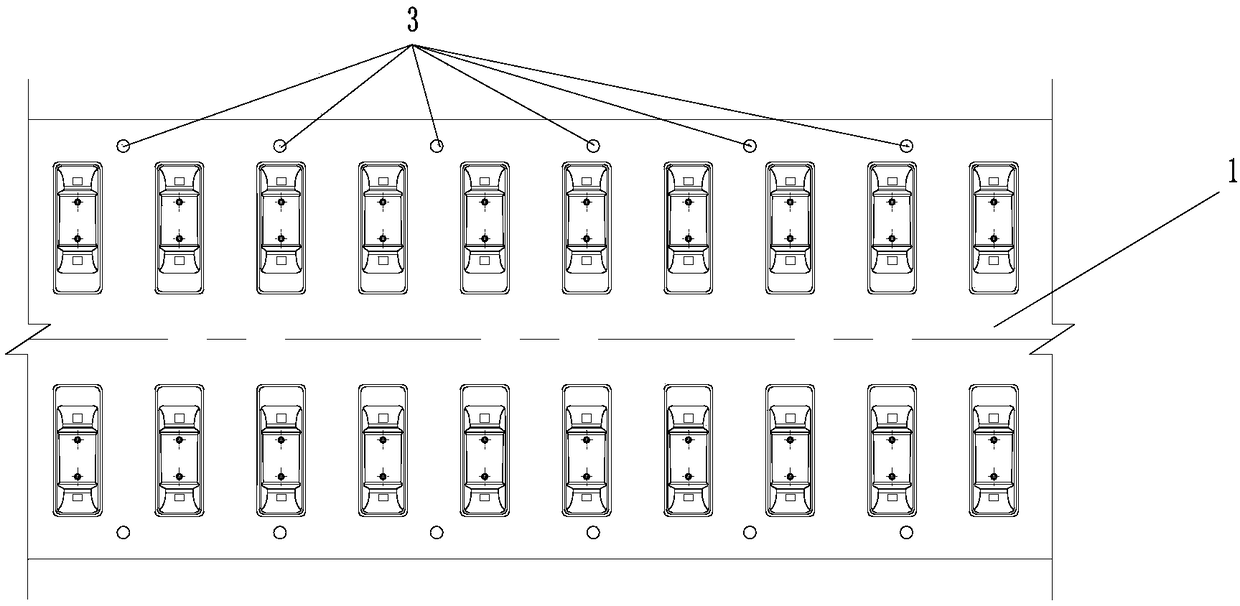

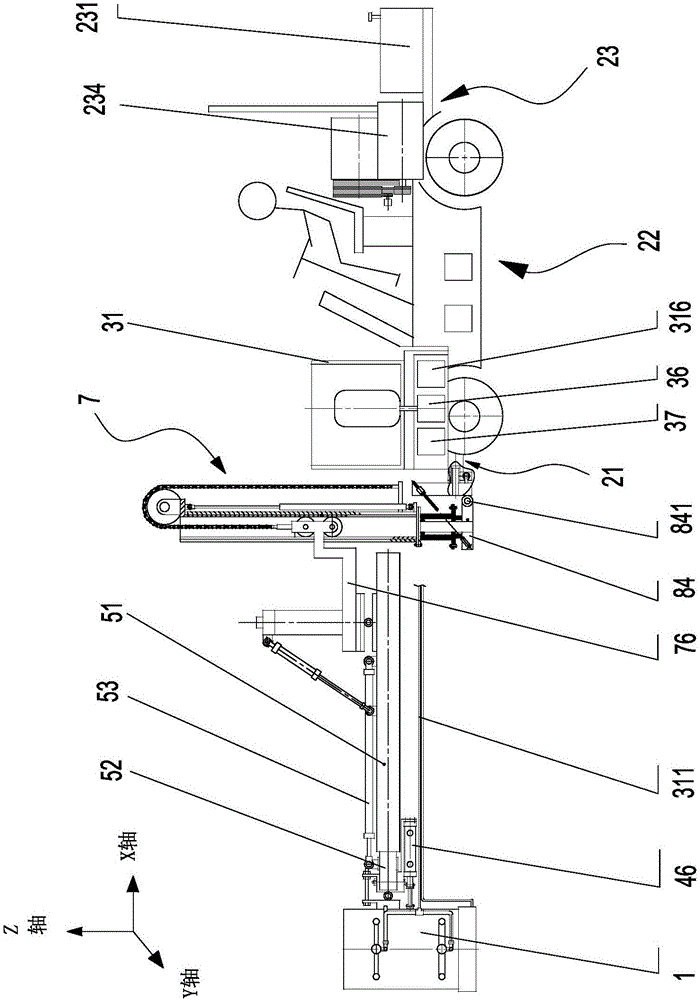

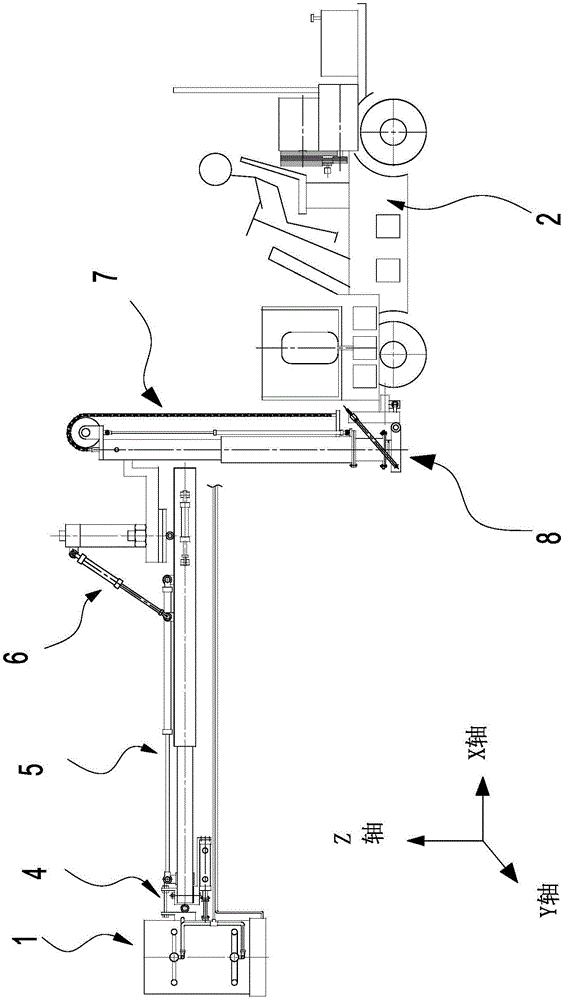

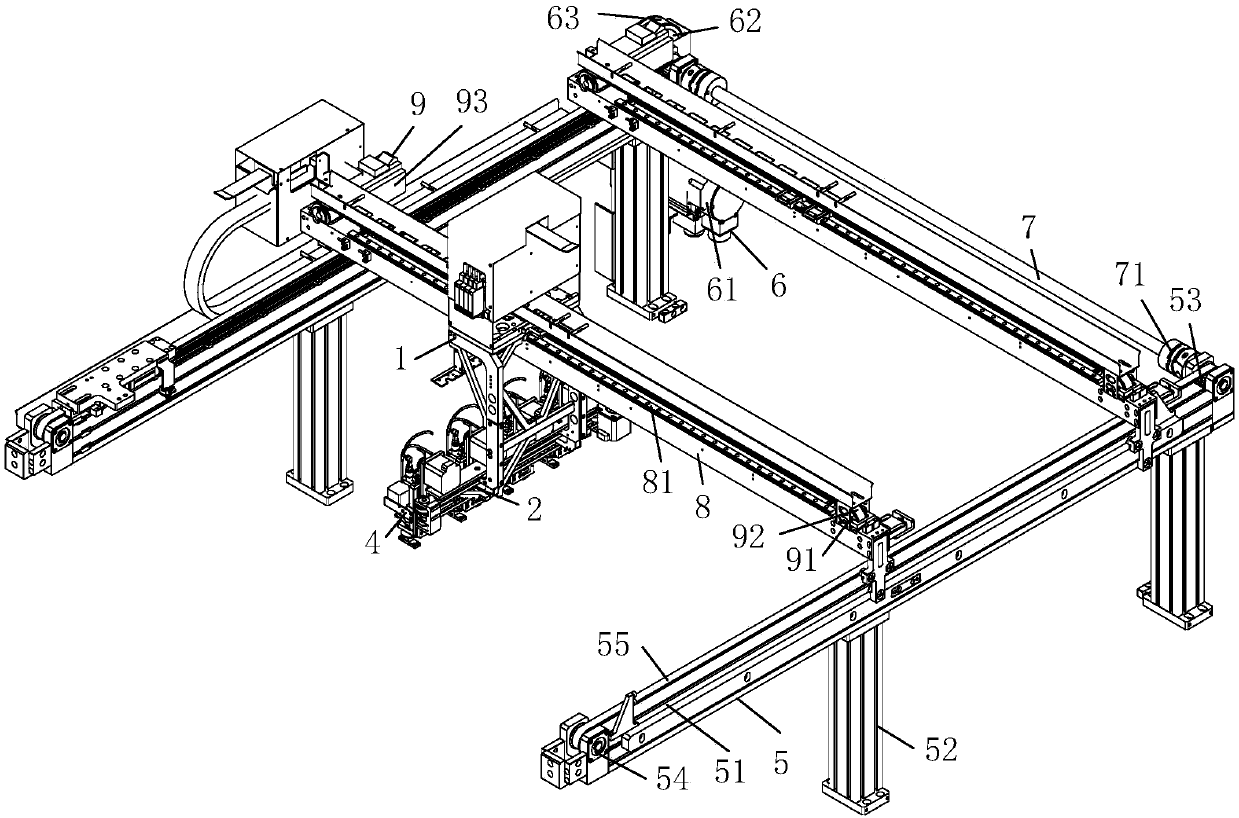

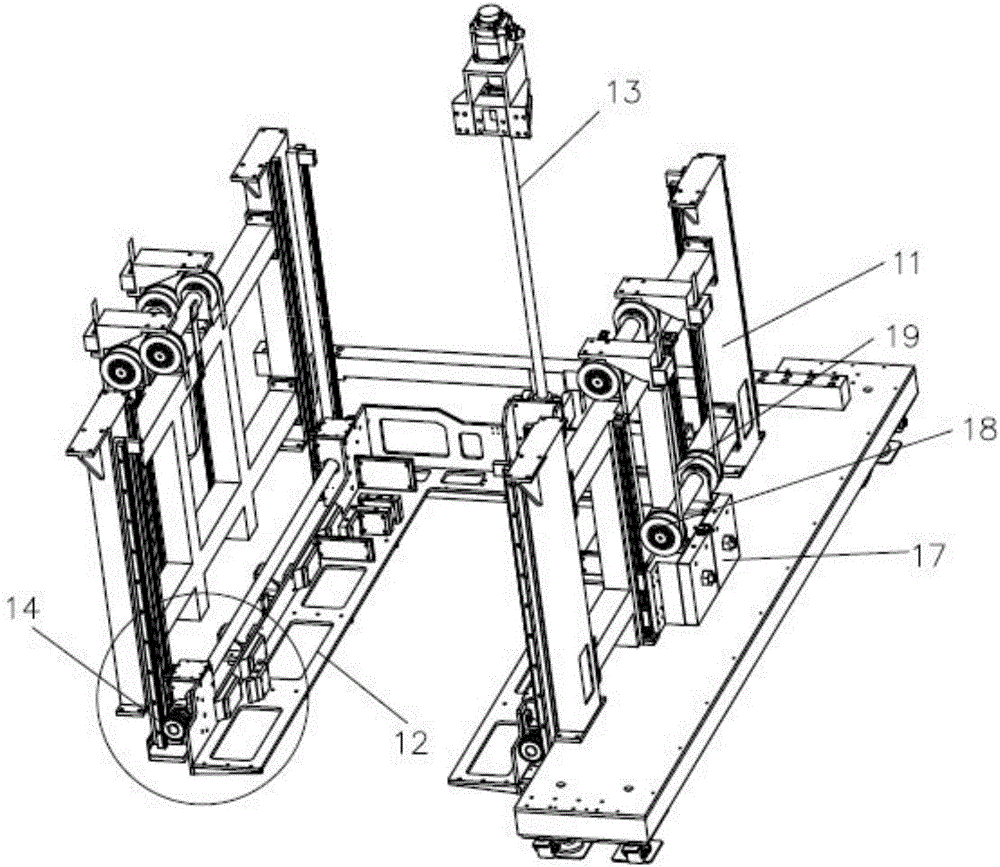

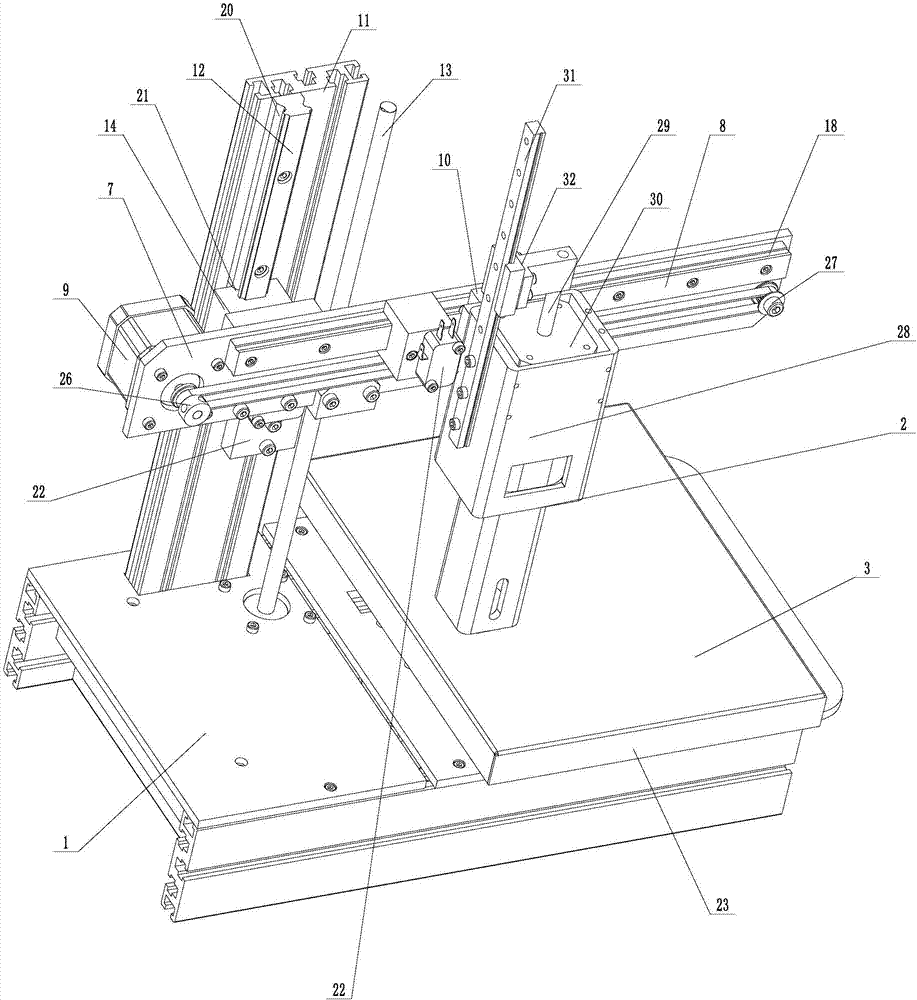

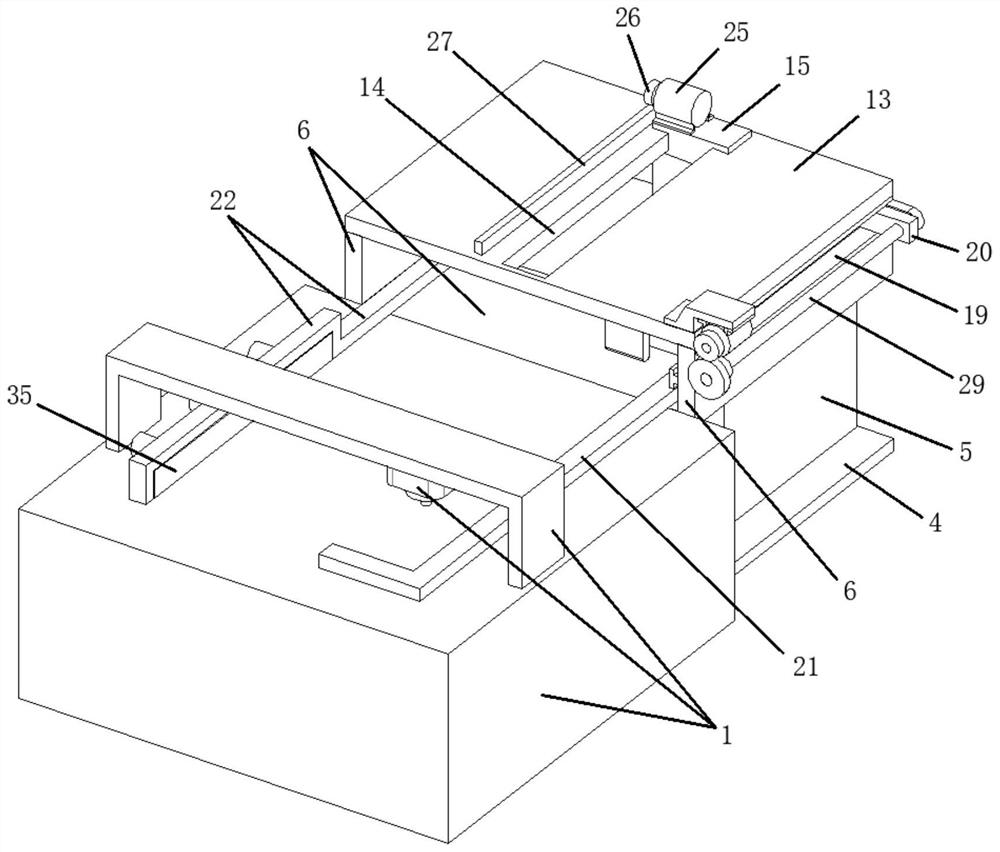

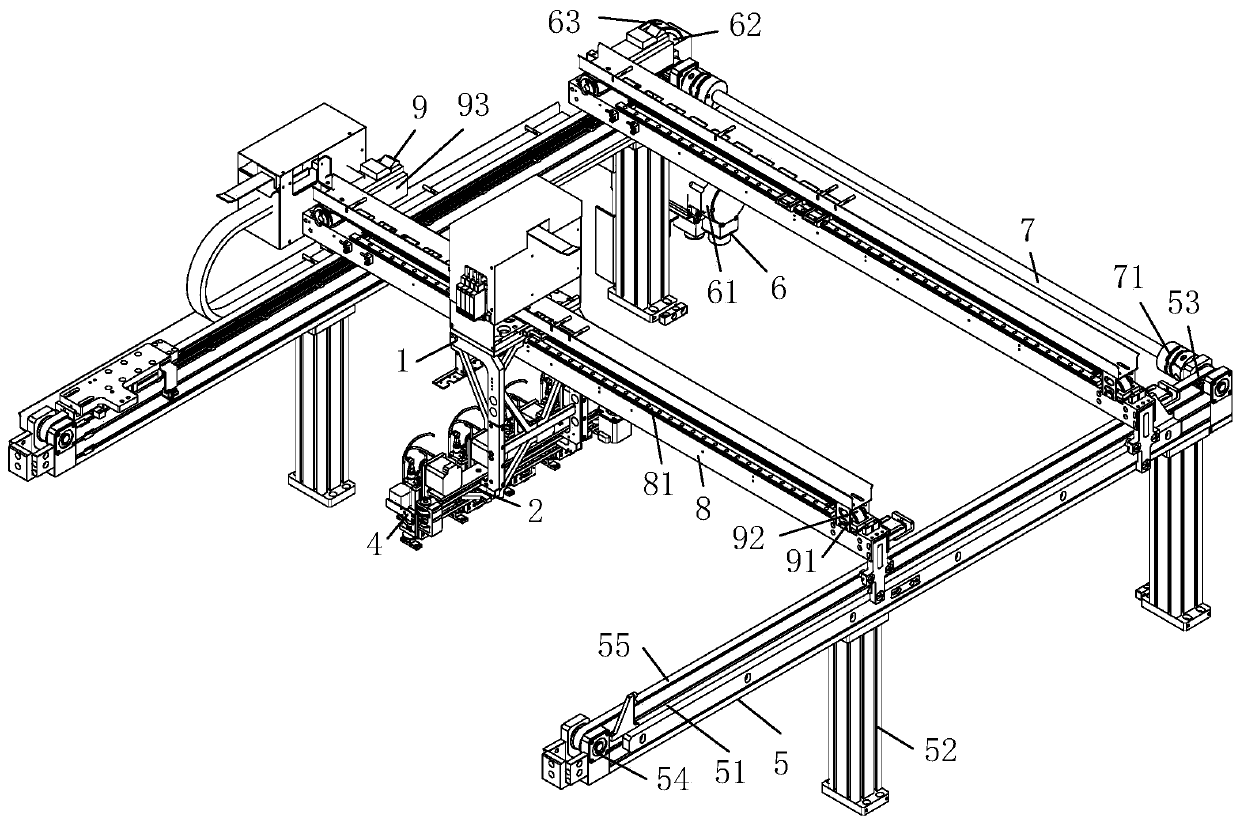

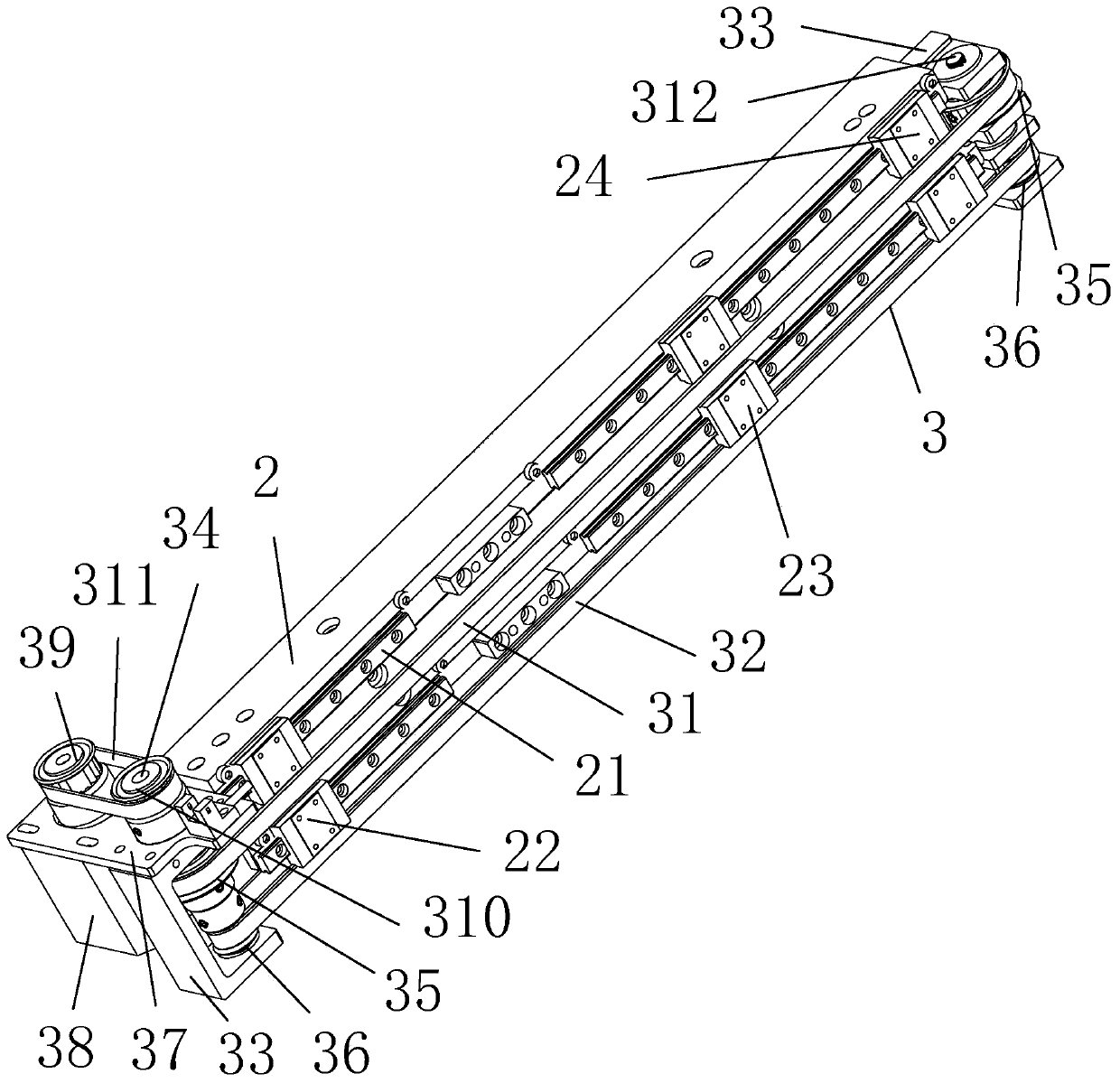

Fingerprint module test conveyor

ActiveCN107697637AHigh positioning accuracySmooth Adsorption PitchConveyorsConveyor partsEngineeringMechanical engineering

The invention aims to provide a fingerprint module test conveyor, which comprises an adsorption device of a connecting support, two longitudinal beams provided with longitudinal guide rails, longitudinal transmission assemblies and a plurality of supporting feet, a longitudinal drive device, a synchronous shaft, a cross beam provided with a cross slide way and two ends connected with slide blocksof the two longitudinal guide rails in a one-to-one correspondence way, and a horizontal drive device. Each longitudinal transmission assembly comprises a longitudinal transmission drive synchronizingwheel pin-jointed with one end of each longitudinal beam, a longitudinal transmission driven synchronizing wheel pin-jointed with the other end of each longitudinal beam, and a longitudinal transmission synchronous belt; one side of each longitudinal transmission synchronous belt is connected with the slide block of each longitudinal guide rail; two ends of the synchronous shaft are in transmission connection with the longitudinal transmission drive synchronizing wheels of the two longitudinal transmission assemblies in a one-to-one correspondence way; and the connecting support is connectedwith a slide block of the cross slide way. The fingerprint module test conveyor is smooth to move and higher in in-place accuracy.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

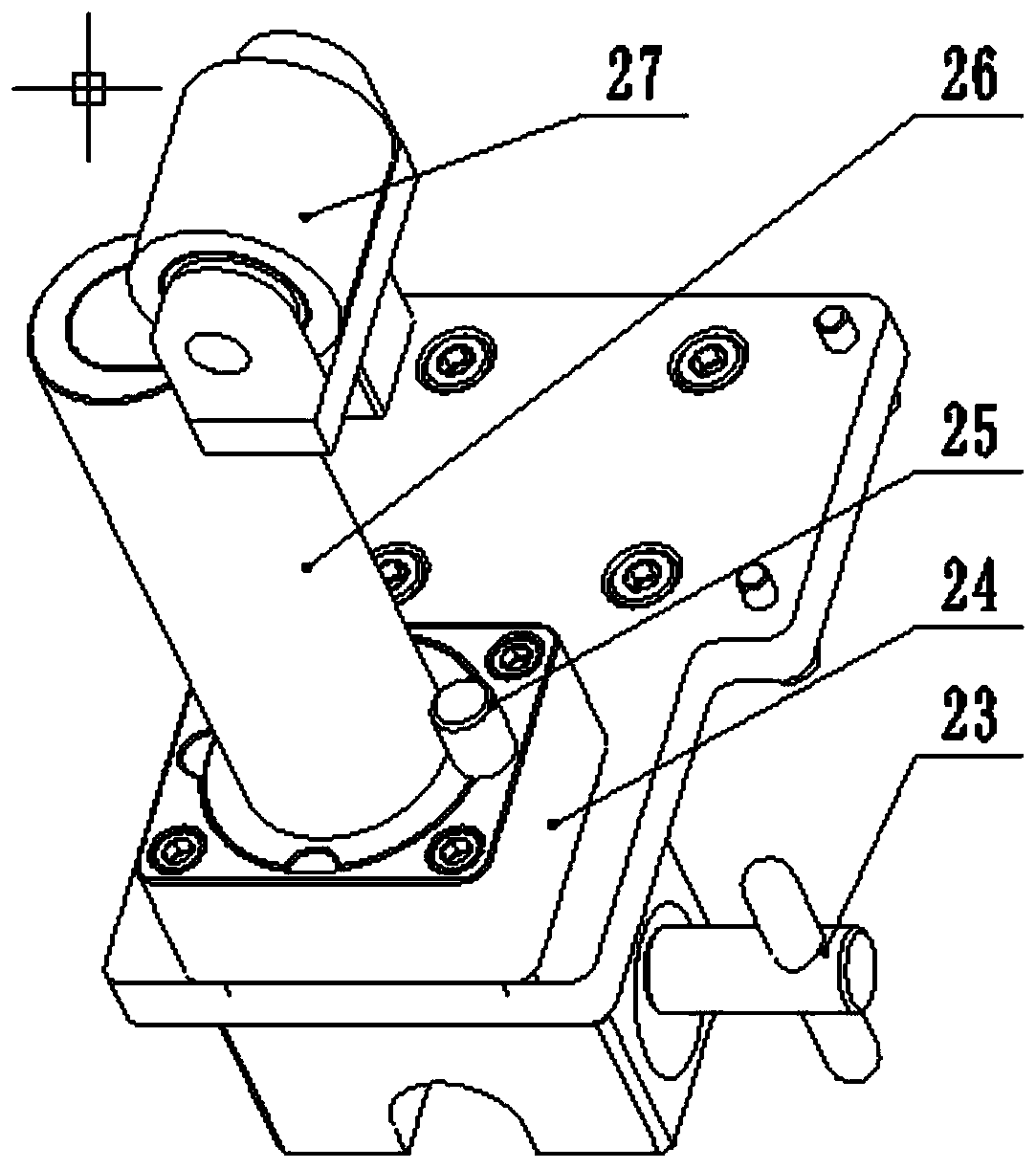

Independent guide mechanism used for road-rail motor tractor

The invention discloses an independent guide mechanism used for a road-rail motor tractor. The independent guide mechanism used for the road-rail motor tractor comprises a U-type rack, a guiding device, a hydraulic oil cylinder assembly and a guiding wheel assembly, wherein the guiding device and the hydraulic oil cylinder assembly are arranged in a triangle shape, the upper end of the guiding device is installed on the U-type rack, one end of the hydraulic oil cylinder assembly is connected to the U-type rack, the other end of the hydraulic oil cylinder assembly is connected to the guiding device, and the guiding wheel assembly is arranged on the lower portion of the guiding device. The independent guide mechanism is simple in whole structure, capable of bearing large alternating torque, high in lifting accuracy and convenient to maintain, and effectively overcomes the defects that an existing guide mechanism of the road-rail motor tractor is prone to being damaged, cumbersome in structure and not accurate enough in lifting distance.

Owner:CRRC SHANDONG CO LTD

Diving type stepping filling mechanism of vertical type bottle filler

InactiveCN101391658ASatisfy the requirements of submerged filling actionCompact structureLiquid materialLiquid bottlingMotor driveBall screw

The invention discloses a submersible step racking mechanism of a vertical racking mechanism, which comprises an electric step motor, a shaft joint, a supporting board, a slide rail frame, a ball screw, a feed screw nut, an elevating slide block, a slide rail, a fine tuning hand wheel, a connecting board and a racking head, two ends of the ball screw are arranged on the slide rail frame through a bearing, the upper end of the ball screw is connected with the electric step motor directly, and the electric step motor drives the ball screw to rotate so as to drive the racking head to move upwards and downwards, thus satisfying the submerged racking action requirement of the racking head. The submersible step racking mechanism of the vertical racking mechanism is characterized in that original complex gear shift mechanisms are replaced by the electric step motor which has compact structure and high precision of axial movement.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

Synchronous lifting device and material conveying device

InactiveCN106697898AFault-tolerantExtended service lifeConveyorsConveyor partsFault toleranceMechanical engineering

The invention discloses a synchronous lifting device and a material conveying device. A driving mechanism is adopted for being matched with a linkage mechanism for acting, a lifting material frame is synchronously lifted wholly along with the driving mechanism when the driving mechanism runs, under the condition that the cost is reduced, synchronous running stability and reliability are guaranteed, and the motion program is simple; and in addition, the mechanism accuracy has a certain fault tolerance, and the service life of elements is greatly prolonged. A balance weight mechanism is arranged, upward pull force is applied to the lifting material frame when materials are lifted, the weight of the lifting material frame can be offset, the load of the driving mechanism is reduced, and energy consumption is reduced.

Owner:旭东机械(昆山)有限公司

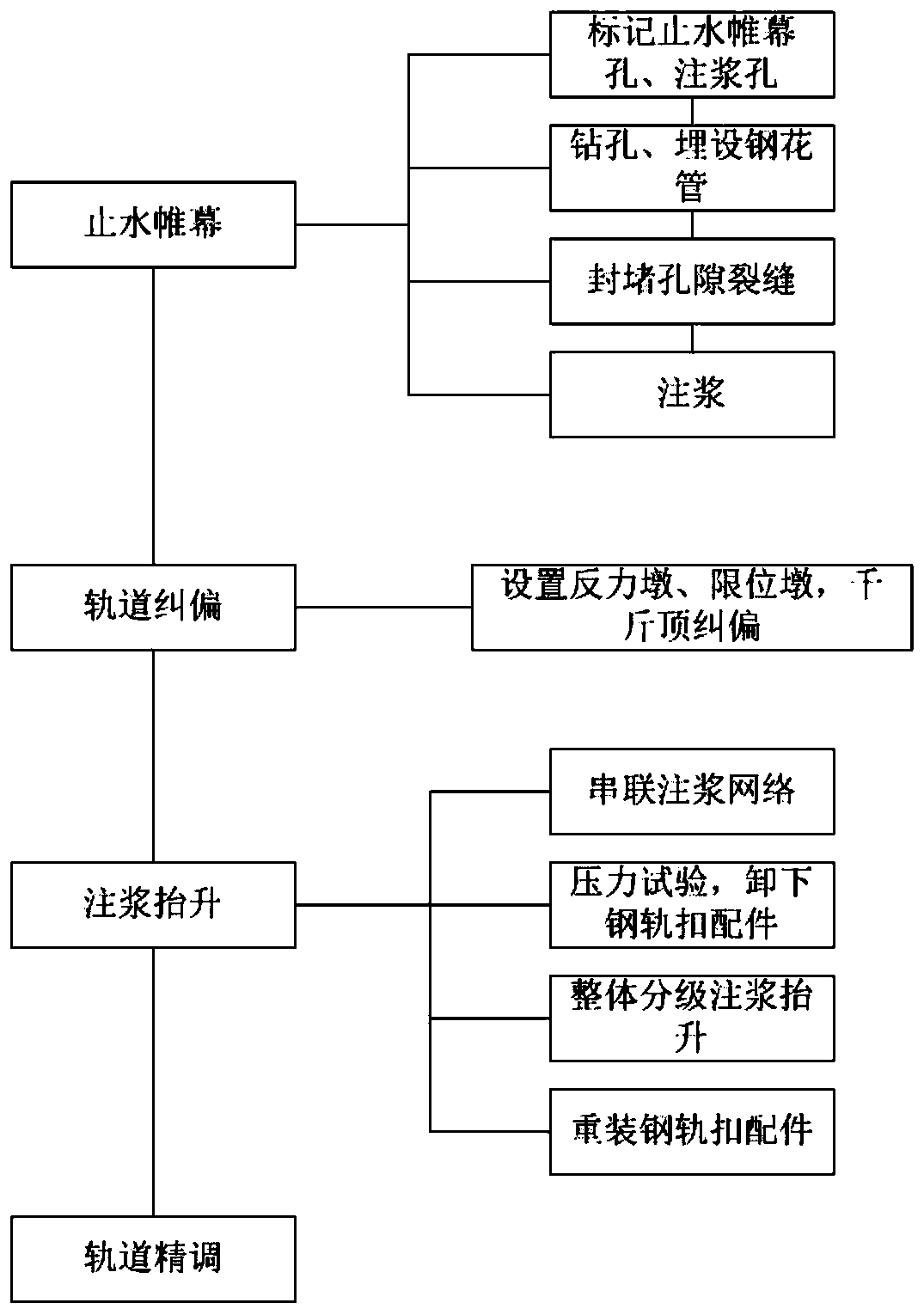

Settlement rectifying and integral lifting method for ballastless track using series pipeline grouting technology

PendingCN110725168AGuaranteed synchronous liftingDoes not affect normal operationTrack superstructureRailway track constructionTrackwayArchitectural engineering

The invention discloses a settlement rectifying and integral lifting method for a ballastless track using a series pipeline grouting technology. A series grouting network is used to connect all grouting holes in the track to be lifted in series, and a unique grouting method is adopted to keep the grouting parameters of each grouting hole consistent, so the integral synchronous lifting of the trackis ensured to the greatest extent, the lifting precision is higher, and the lifting effect is better. Moreover, the construction is relatively simple. One skylight point can complete all the construction procedures, and the normal operation of a train is not affected at all.

Owner:武汉比邻工程技术有限公司

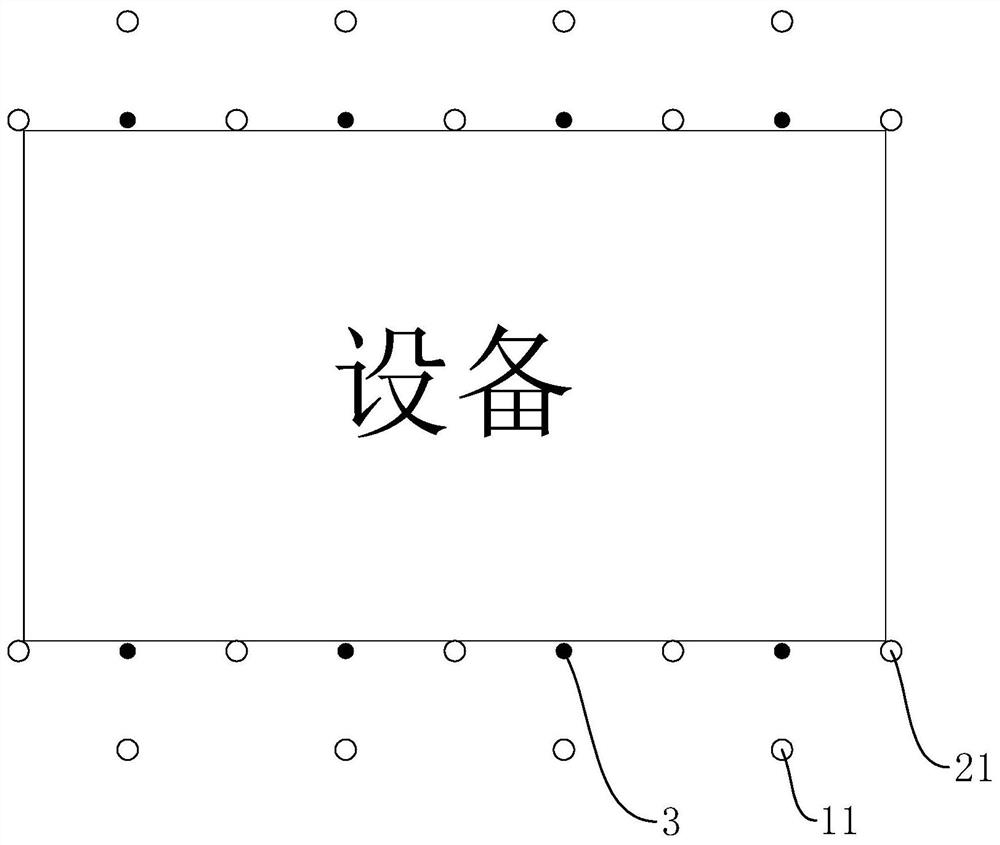

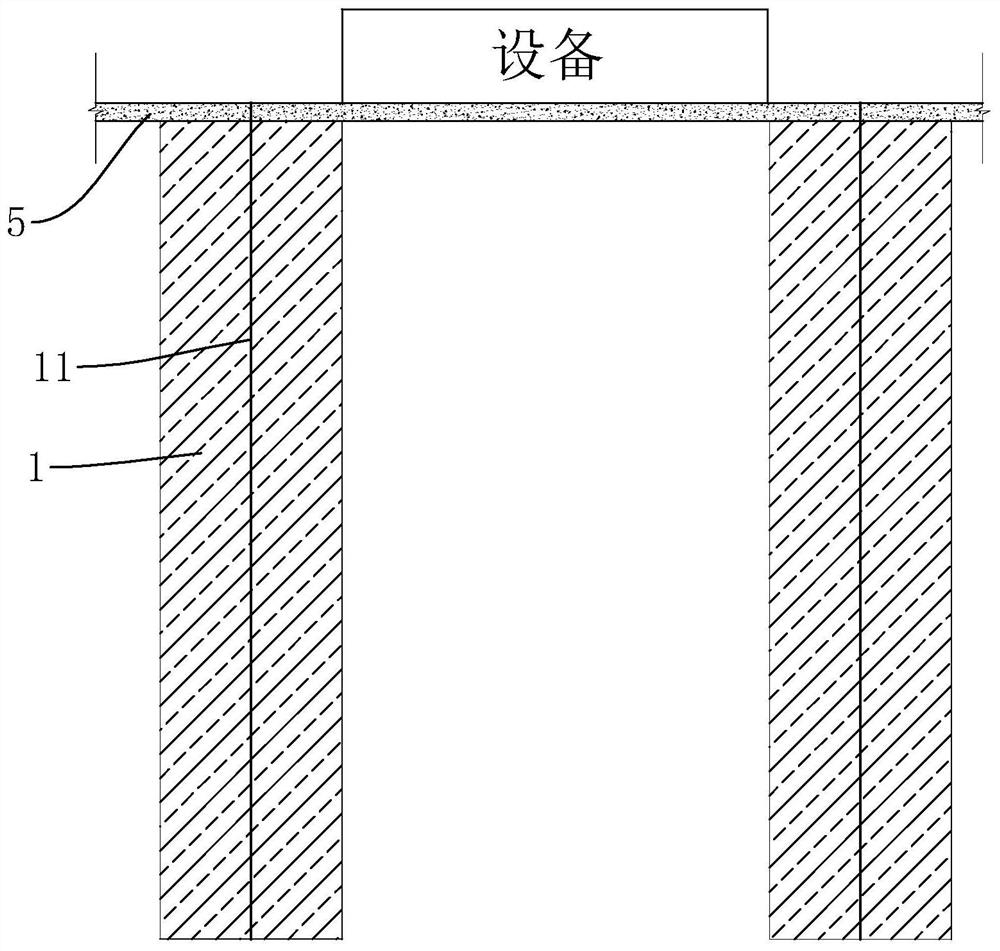

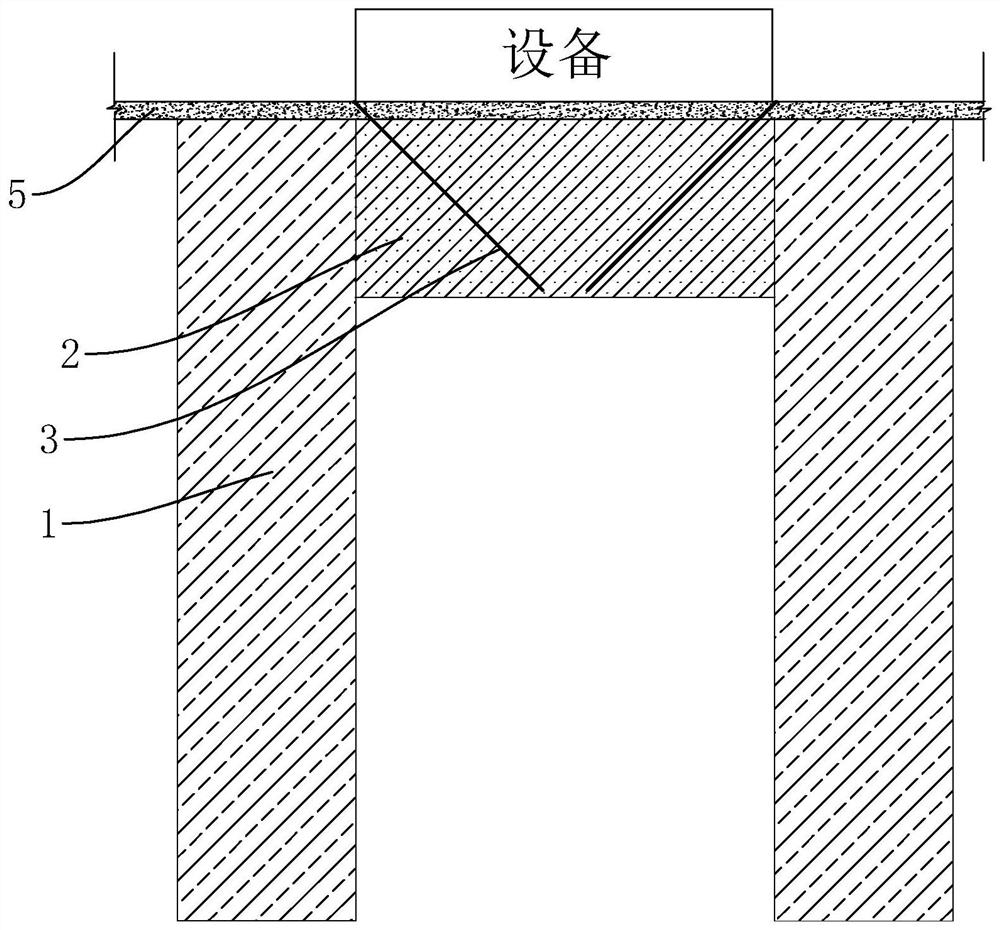

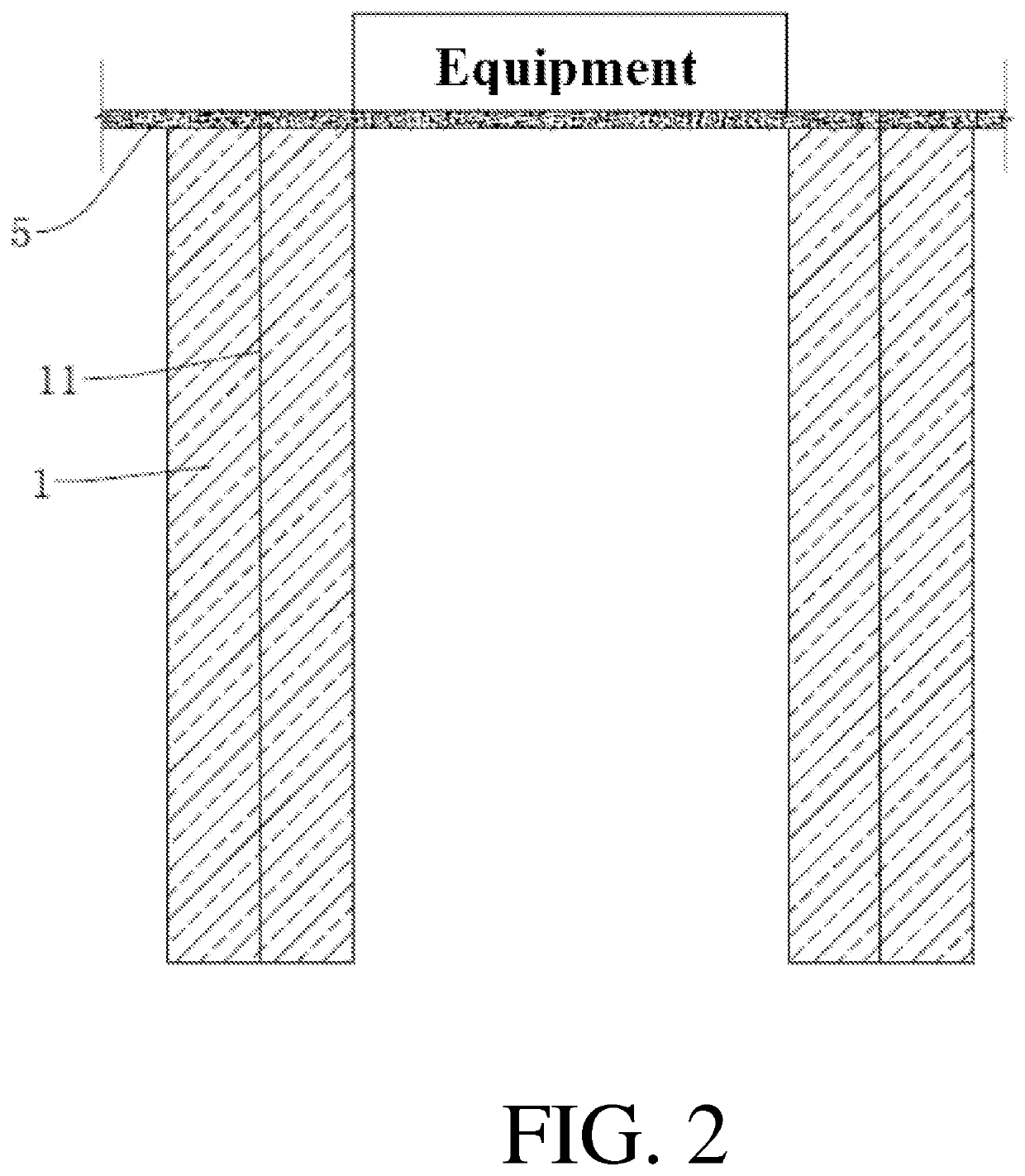

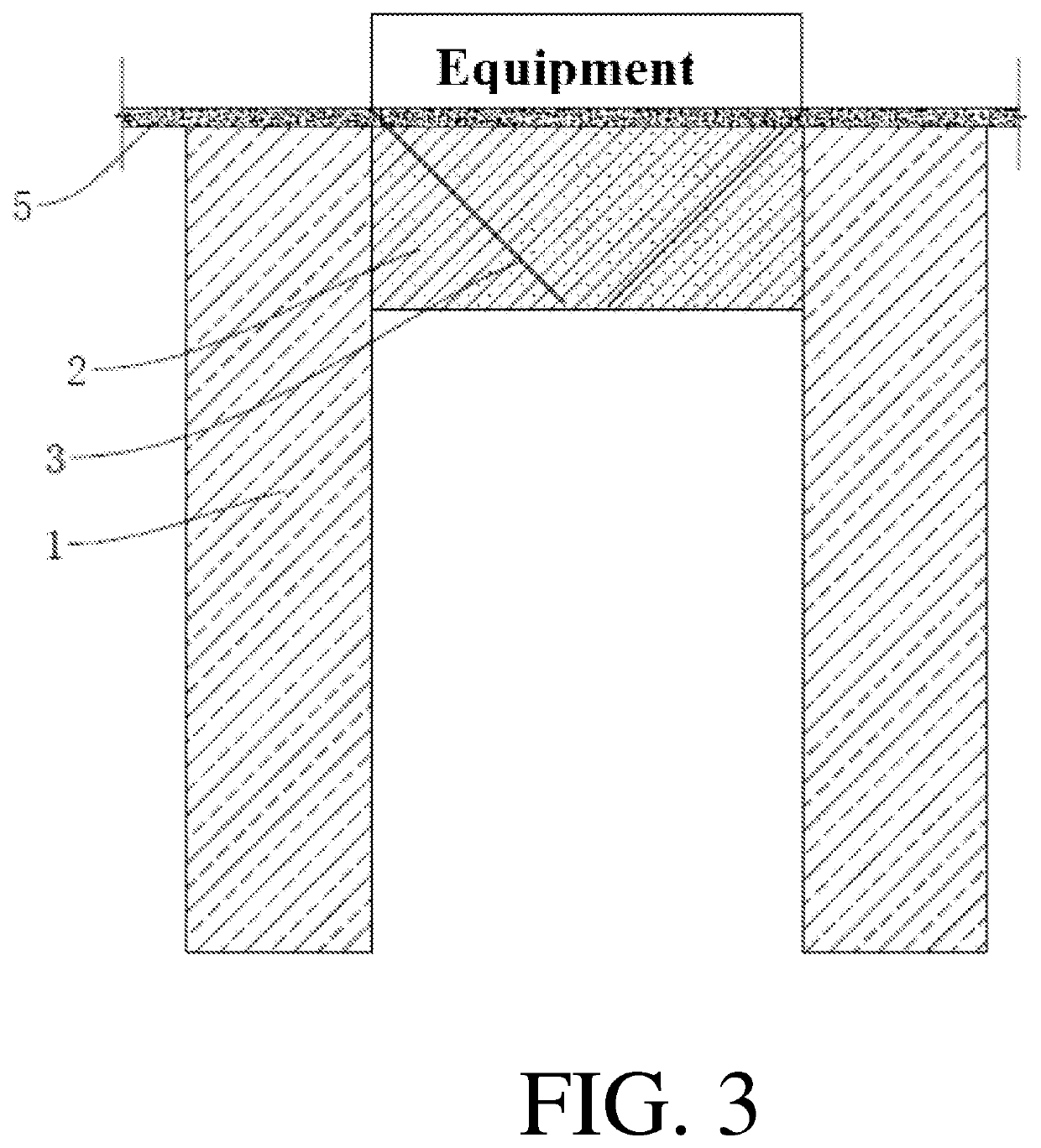

Precise lifting method for plant equipment foundation

ActiveCN112343078AReduce disturbanceImprove integrityFoundation repairSoil preservationArchitectural engineeringPressure grouting

The invention relates to a precise lifting method for a plant equipment foundation. The precise lifting method comprises the following steps that S1, curtain walls are formed, specifically, holes arevertically and downwards drilled in two sides, needing to be lifted, of the equipment to form curtain holes, and the curtain holes are grouted to form two curtain walls which are parallel to each other; S2, a reinforcing body is formed, specifically, obliquely-downward grouting holes are formed in the outer contour lines of the equipment in the length direction of the curtain walls, grouting is conducted in the grouting holes, grouting is conducted between the two curtain walls at the bottom of the equipment foundation bottom plate to form the reinforcing body attached to the lower surface ofthe bottom plate, and the reinforcing body and the two curtain walls are combined to form an n-shaped structure; and S3, lifting is conducted, specifically, the grouting hole serves as the lifting hole, a hole is obliquely drilled downwards until the hole is drilled to the position below the reinforcing body and located between the two curtain walls, pressure grouting is conducted on the bottom ofthe lifting hole to fill and reinforce the surrounding backfill layer, pressure grouting continues, retreating type grouting is adopted, and the equipment is lifted to the set lifting height. The precise lifting method has the advantages of being small in surrounding disturbance, controllable in lifting height and high in lifting precision.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

Precise lifting method and lifting and reinforcing structure for plant equipment foundation

ActiveUS20220145576A1Little disturbance to surroundingsControllability of lifting heightFoundation repairSoil preservationArchitectural engineeringPressure grouting

The present application relates to a precise lifting method and a lifting and reinforcing structure for a plant equipment foundation. The method includes the construction steps of: forming a curtain wall: drilling downwards at two sides of the plant equipment to form curtain holes and grouting the curtain holes, in which the grouting areas overlap each other to form two parallel curtain walls; forming a reinforcing body: drilling grouting holes inclining downwards, grouting the grouting holes to form the reinforcing body attached to a lower surface of a baseplate of the plant equipment foundation among a bottom of the baseplate and two curtain walls; and lifting: drilling lifting holes obliquely downwards to below the bottom of the reinforcing body and between two curtain walls; and conducting pressure grouting to the bottom of the lifting holes and then backward grouting upwards layer by layer.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

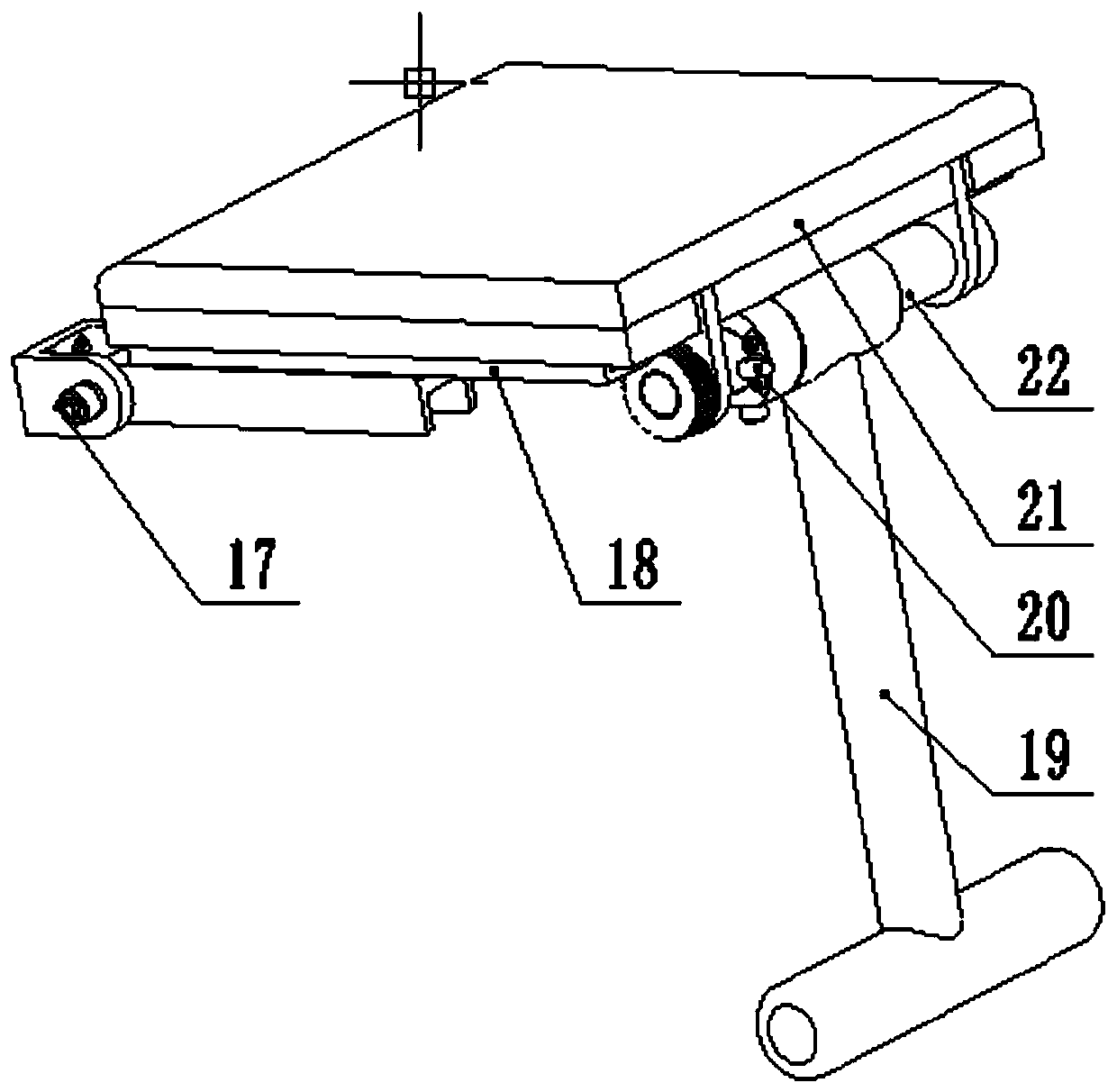

Multifunctional trolley for spaceflight product assembling

ActiveCN110405703AImprove the level of flexibilityHigh lifting precisionWork benchesSpaceflightReliability engineering

The invention provides a multifunctional trolley for spaceflight product assembling. The multifunctional trolley comprises a chassis, trundles, a lifting bracket and a redundancy inspection component,wherein the trundles are arranged below the chassis, the lifting bracket is arranged above the chassis, and the redundancy inspection component is arranged on the lifting bracket; the redundancy inspection component is composed of an installing base, an inserting and pulling fixing pin, a supporting rod and a roller; the supporting rod is fixed on the installing base through the inserting and pulling fixing pin, and the roller is connected to the top of the supporting rod; and after the product assembly is completed, a pressure releasing valve is unscrewed to enable products to be in contactwith the roller after the products descend, and the products are rotated for carrying out redundancy inspection. According to the multifunctional trolley for the spaceflight product assembling, quickswitching function that the device quickly responds to the products with different types is realized, the flexibility level of the device is promoted, and the operation integration degree is improved;and a lifting and transferring link is removed through the arranged redundancy inspection component, so that the operation efficiency is promoted.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Hydraulic jack

InactiveCN103818846AGuaranteed stability and securityReduce weightLifting devicesDrive motorEngineering

Owner:HENAN UNIV OF SCI & TECH

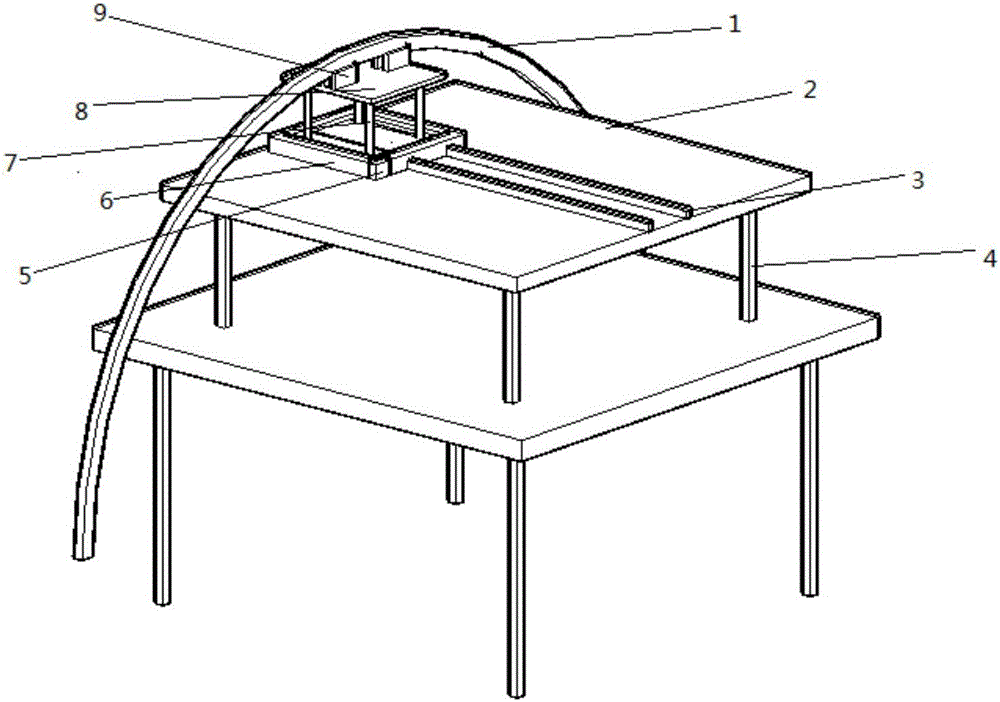

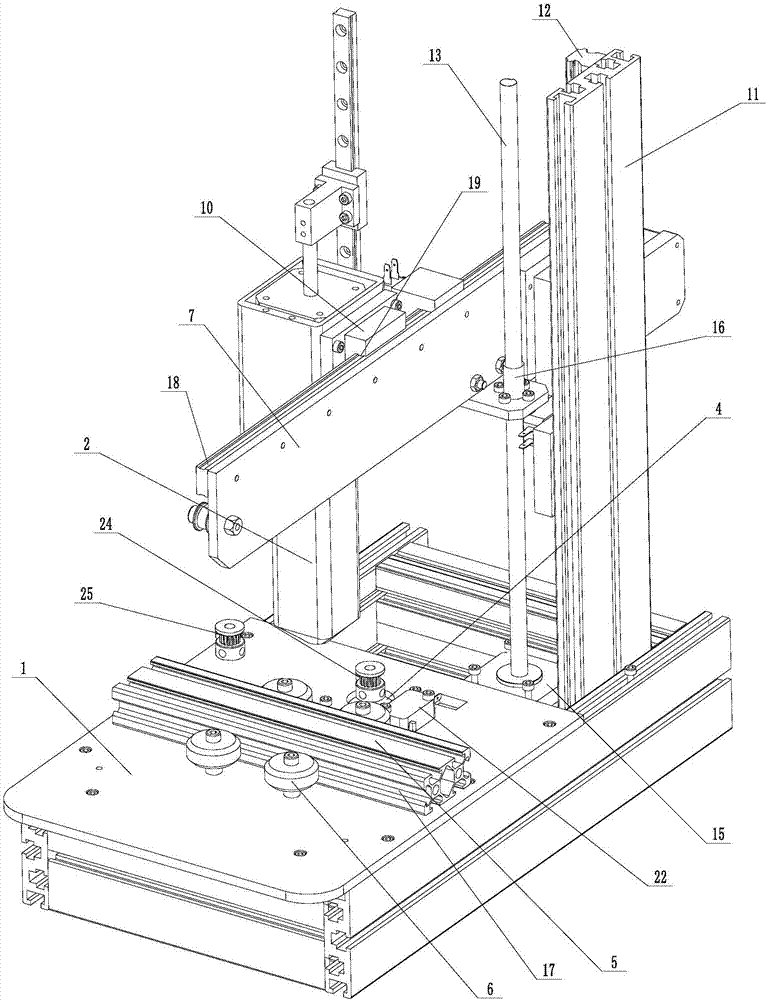

3D printer

ActiveCN107455786AHigh movement accuracySimple structureAdditive manufacturing apparatusFood shapingSpray nozzle3d printer

The invention discloses a 3D printer, and aims at solving deficiencies of complex structures, large size and low printing accuracy of 3D food printing equipment. The printer comprises a host, a spray nozzle, an X-axis assembly, a Y-axis assembly, and a Z-axis assembly. The X-axis assembly comprises a printing table and an X-axis motor; sliding rails supported by the host is arranged on the lower surface of the printing table; two sides of the sliding rails on the host are equipped with a plurality of guide wheels; and the lower surface of the printing table is connected to an X-axis synchronous belt. The Y-axis assembly comprises a Y-axis guiding beam, Y-axis guiding rails, and a Y-axis motor; a Y-axis sliding block is slidably mounted on the Y-axis guiding rails; the Y-axis sliding block is connected to a Y-axis synchronous belt; and the spray nozzle is mounted on the Y-axis sliding block. The Z-axis assembly comprises a Z-axis guiding beam, Z-axis guiding rails, and a Z-axis motor; a Z-axis sliding block is slidably mounted on the Z-axis guiding rails; the Z-axis sliding block is fixedly connected to the Y-axis guiding beam; the Z-axis motor is connected to a lifting screw; a lifting threaded sleeve is arranged on the Y-axis guiding beam; and the lifting threaded sleeve is adaptively connected to the lifting screw.

Owner:长兴时印科技有限公司

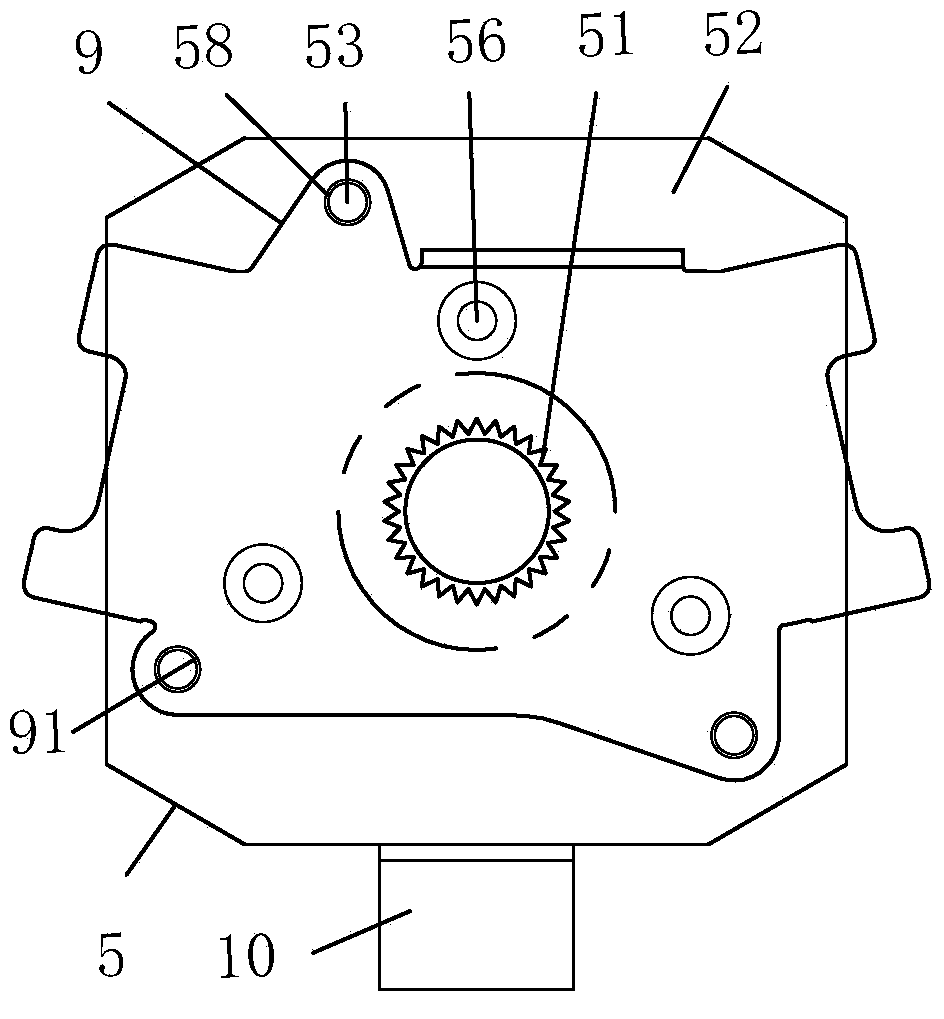

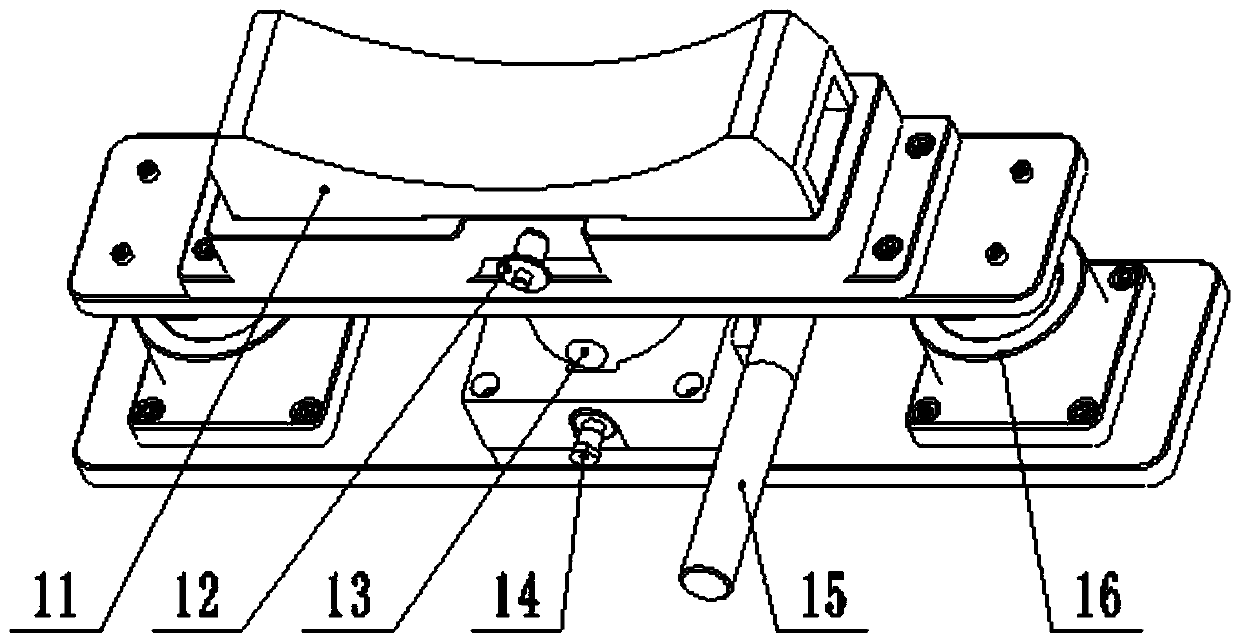

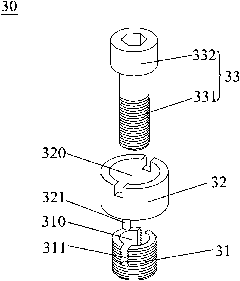

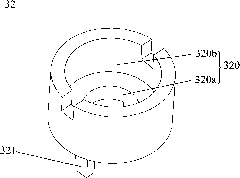

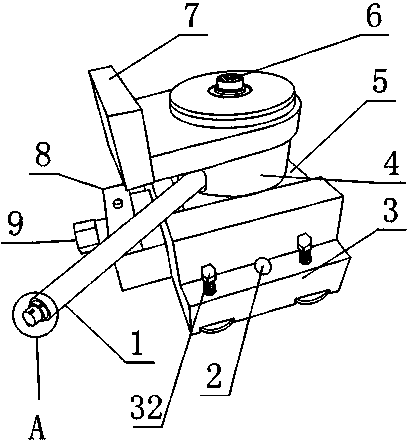

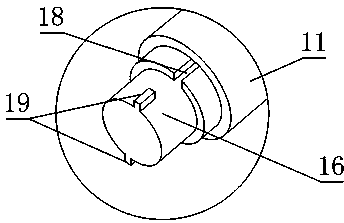

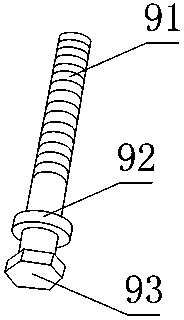

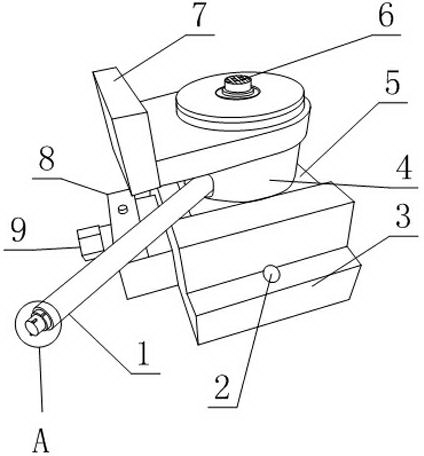

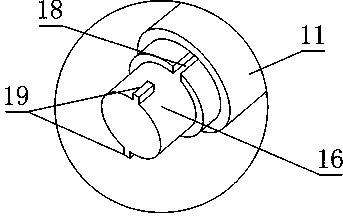

Adjusting and fixing mechanism and operating method thereof

InactiveCN101823206AHigh lifting precisionLifting is stable and reliableSpannersSheet joiningPulp and paper industryBlock match

The invention discloses an adjusting and fixing mechanism which comprises a reference platform, a working platform and an adjusting and fixing assembly connected between the reference platform and the working platform. The adjusting and fixing assembly comprises a screw bushing, a press cover and a lock bolt, and the screw bushing and the press cover are both provided with bolt holes. The screw bushing is provided with an external thread, and the upper end of the screw bushing is provided with a groove. The working platform is provided with a thread hole engaged with the external thread of the screw bushing, the thread of the screw bushing is connected into the thread hole, and the lower end of the screw bushing protrudes a certain distance from the lower surface of the working platform. The lower end of the press cover is provided with a protruding block matched with the groove. The lower end of the lock bolt is provided with a thread, the reference platform is provided with a fixed screw hole engaged with the thread of the lower end of the lock bolt, and the lower end of the lock bolt penetrates through the bolt holes of the press cover and the screw bushing and is connected in the fixed screw hole in a threaded mode. The adjusting and fixing mechanism has high precision, reasonable and compact structure and convenient, stable and reliable installation. The invention also discloses an operating method for adjusting position by using the adjusting and fixing mechanism.

Owner:东莞晨真光伏有限公司

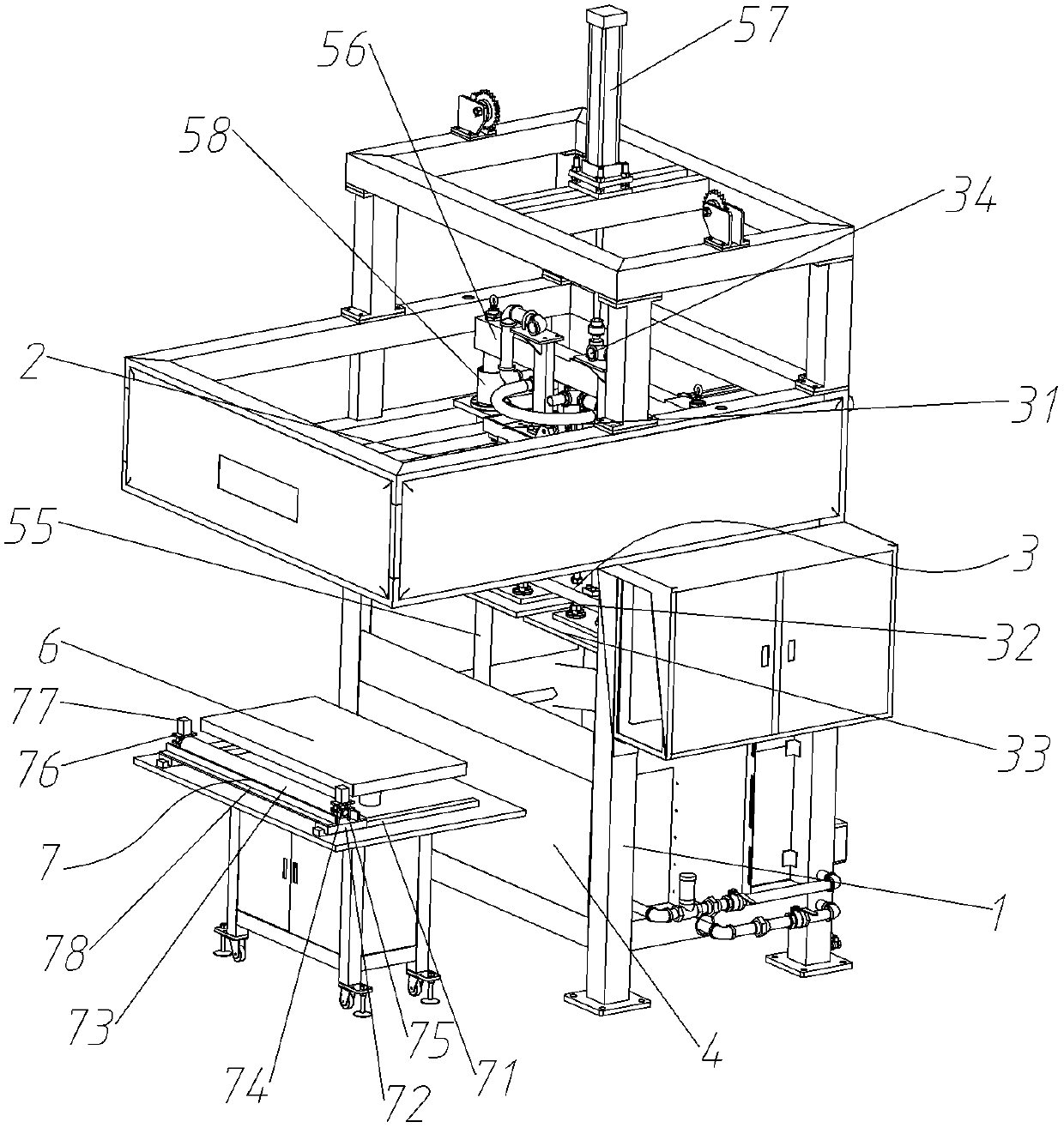

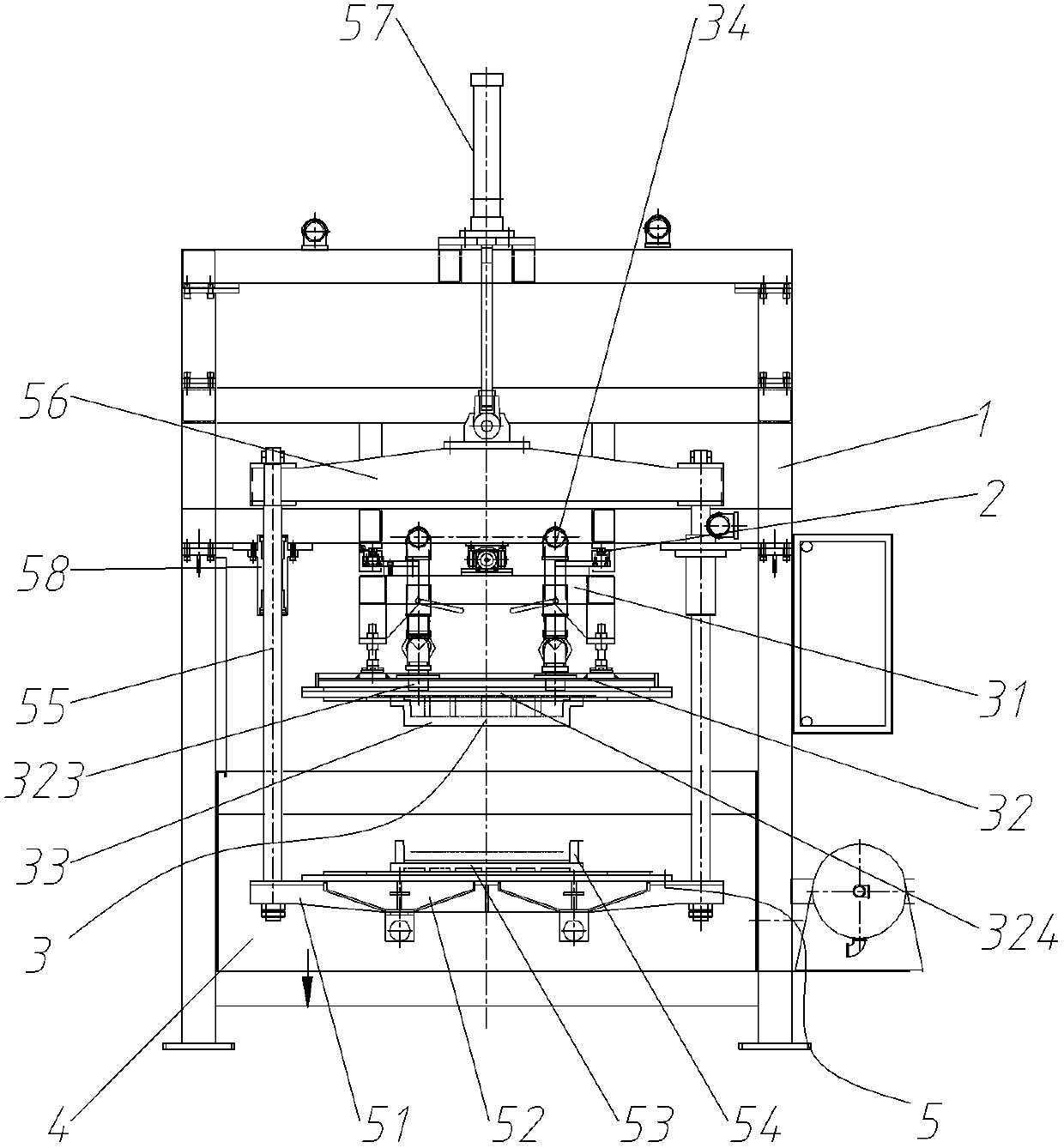

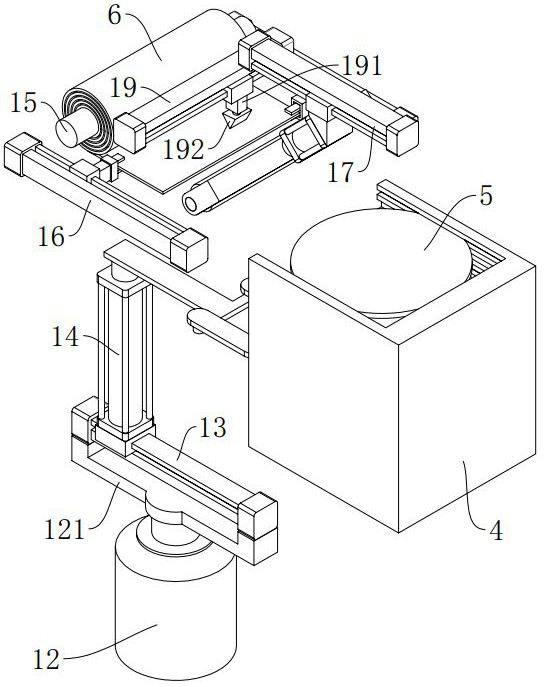

Environment-friendly aluminum silicate board vacuum adsorption forming equipment and forming method

PendingCN109760183AAvoid deformationQuality assuranceCeramic shaping apparatusAluminum silicateSlurry

The invention belongs to the technical field of aluminum silicate fiberboard forming equipment, and provides an environment-friendly aluminum silicate board vacuum adsorption forming equipment and forming method. The equipment comprises a rack, a discharging rail, an upper die, a slurry tank, a lower die and a material receiving bottom board, wherein the discharging rail is horizontally arranged on the rack, the upper die is arranged below the discharging rail in a sliding mode, the upper mold is connected with a vacuum pipeline, the slurry tank is arranged below the rack, the slurry tank is positioned at one end of the discharging rail, the slurry tank is connected with a feeding pipeline, the lower die is arranged in the slurry tank in a lifting mode, the lower die is connected with a vacuum pipeline, and the material receiving bottom plate is arranged on the rack in a lifting mode, and is positioned at the other end of the discharging rail. According to the technical scheme, the problem that in the prior art, an aluminum silicate fiberboard forming machine is prone to collide with a just-formed board material during discharging so as to influence the product quality is solved.

Owner:HEBEI GUOMEI NEW BUILDING MATERIAL CO LTD

Wafer thinning and polishing device

ActiveCN114473822AImprove efficiencySimple structureGrinding carriagesPolishing machinesLaser rangingElectric machine

A wafer thinning and polishing device comprises a rubberizing unit, a conveying unit and a thinning and polishing unit. The rubberizing unit is used for rubberizing the front surface of the wafer. The conveying unit is arranged on one side of the rubberizing unit and used for overturning and conveying the rubberized wafers. The thinning and polishing unit is arranged on one side of the conveying unit and comprises a sixth rodless linear air cylinder, a third rotating motor is arranged on one side of the sliding end of the sixth rodless linear air cylinder, a combined frame is arranged at one end of an output shaft of the third rotating motor, a pair of fourth rotating motors is arranged on the combined frame, grinding discs are arranged on output shafts of the third rotating motor, one grinding disc is a coarse grinding disc, and the other grinding disc is a fine grinding disc. A fifth rotating motor is arranged on one side face of a sliding block of the lead screw lifting assembly, a polishing wheel is arranged at one end of an output shaft of the fifth rotating motor, two sets of liquid spraying pipes are arranged on the two sides of the lead screw lifting assembly, and a plurality of laser distance measuring sensors are further arranged on one side of the lead screw lifting assembly. The wafer thinning and polishing device provided by the invention can be used for automatically gluing and transporting, and is simple in structure, low in equipment cost, high in thinning and polishing precision and relatively good in thickness uniformity of polished wafers.

Owner:四川明泰微电子科技股份有限公司

Intelligent feeding device for steel plate cutting

InactiveCN112404757AWith automatic lifting functionWith automatic precision movement functionWelding/soldering/cutting articlesMetal working apparatusEngineeringMachine

The invention relates to the technical field of cutting, in particular to an intelligent feeding device for steel plate cutting. The intelligent feeding device comprises a metal laser automatic cutting machine, a tray is arranged at one side of the metal laser automatic cutting machine, a plurality of steel plate materials are arranged at one side of the tray, and a bottom plate is fixedly connected to one side of the metal laser automatic cutting machine; and a U-shaped guide frame is fixedly connected to one side of the bottom plate, a U-shaped supporting frame is fixedly connected to one side of the metal laser automatic cutting machine, a mounting groove is formed in one side of the U-shaped supporting frame, and the U-shaped guide frame is fixedly connected to the inner side of the mounting groove. According to the intelligent feeding device, the U-shaped guide frame, the U-shaped supporting frame, a lifting plate, a servo motor A, a first transmission device, an H-shaped slidingblock, a material pushing block, an automatic back-and-forth movement device, an L-shaped material pushing frame, a one-way passing plate, a precise driving device, an L-shaped positioning frame, a guide jacking plate and an automatic jacking device are arranged, so that the intelligent feeding device has the functions of automatic feeding, automatic continuous feeding, double material pushing, automatic positioning, automatic fixing and the like.

Owner:苏州创智汇峰信息科技有限公司

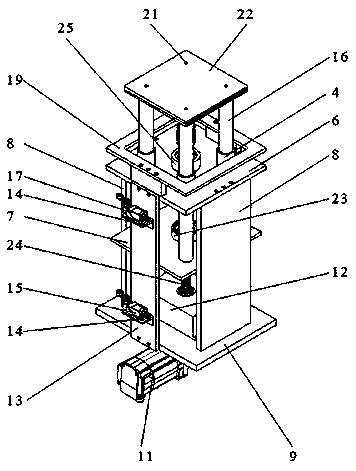

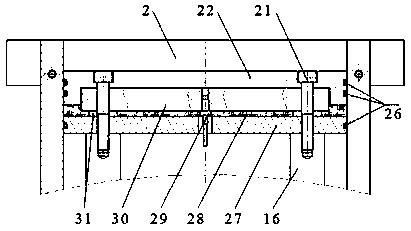

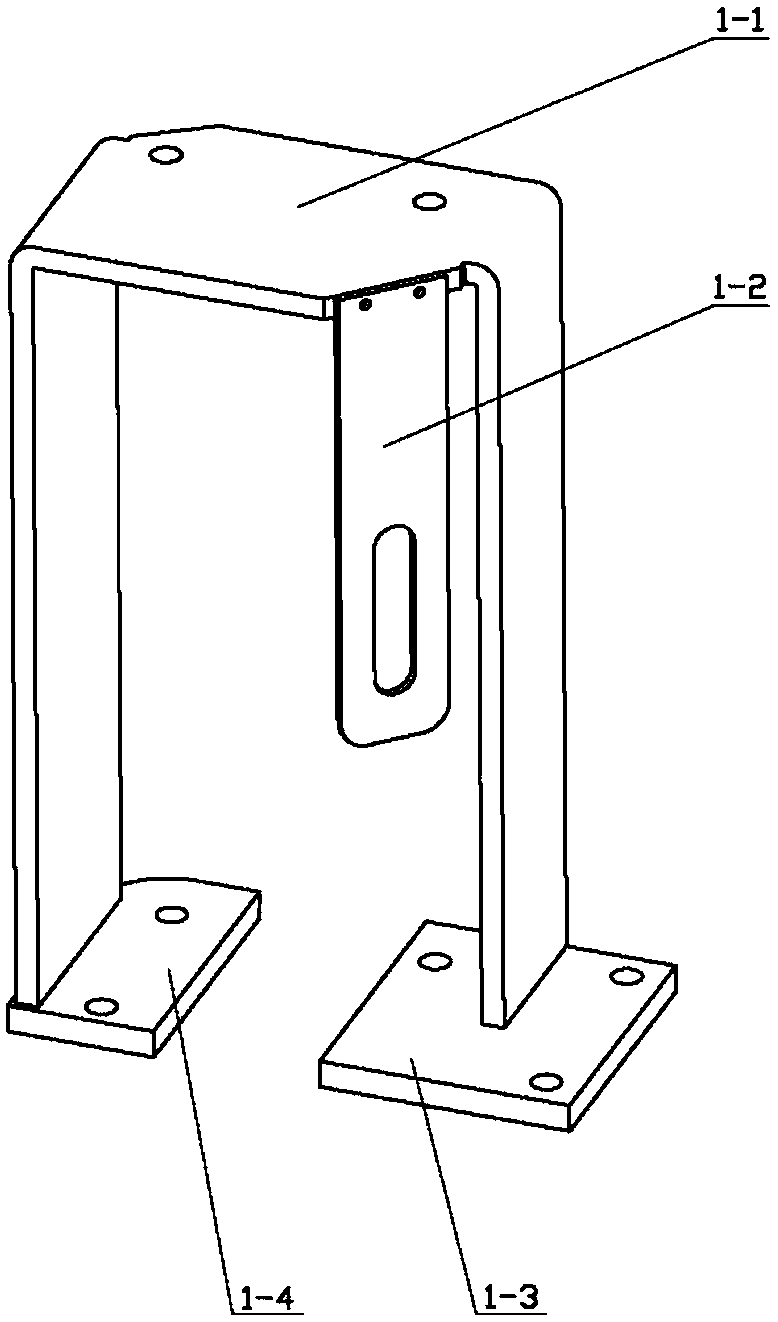

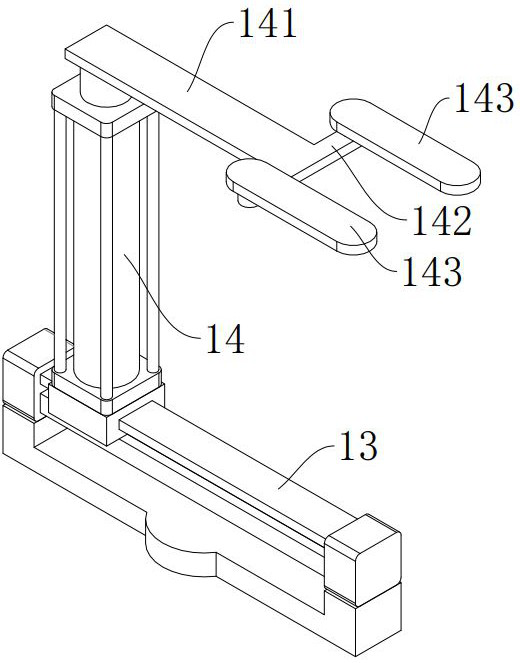

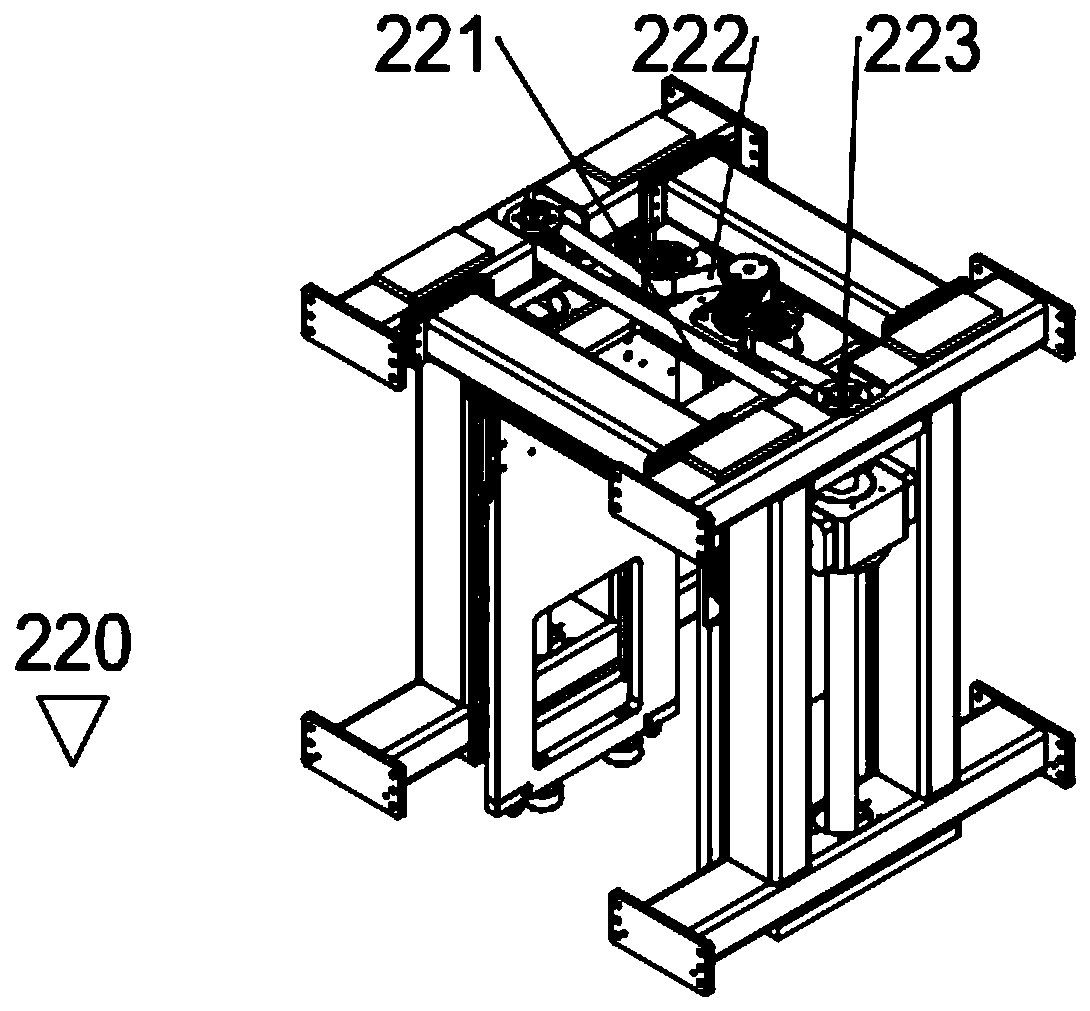

Device for connecting lifting mechanism and working box and applied to 3D printer

PendingCN111170203AHigh lifting precisionSimple structureAdditive manufacturing apparatusLifting framesComputer printingEngineering

The invention relates to a device for connecting a lifting mechanism and a working box and applied to a 3D printer. The device comprises the working box, the lifting mechanism and an even number of electric suction discs, the electric suction discs are arranged at the top of the lifting mechanism and connect the working box with the lifting mechanism through magnetic force, and the electric suction discs are symmetrically arranged at the top of the lifting mechanism; and the lifting mechanism comprises a main frame, a driving member and lifting members, the driving member is arranged inside the main frame, and the lifting members are symmetrically arranged on both sides of the main frame correspondingly. According to the device for connecting the lifting mechanism and the working box and applied to the 3D printer, the fact that an existing working box can't keep the horizontal descent or descends too slowly , and can't reach the expected position quickly and stably in the descent process is overcome, in the non-printing process, the working box is separated from the lifting mechanism, and the maintenance is facilitated; and in the printing process, the working box is connected withthe lifting mechanism through the electric suction discs, a bottom plate of the working box can reach the expected position horizontally, stably and quickly, and the device printing accuracy is improved.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

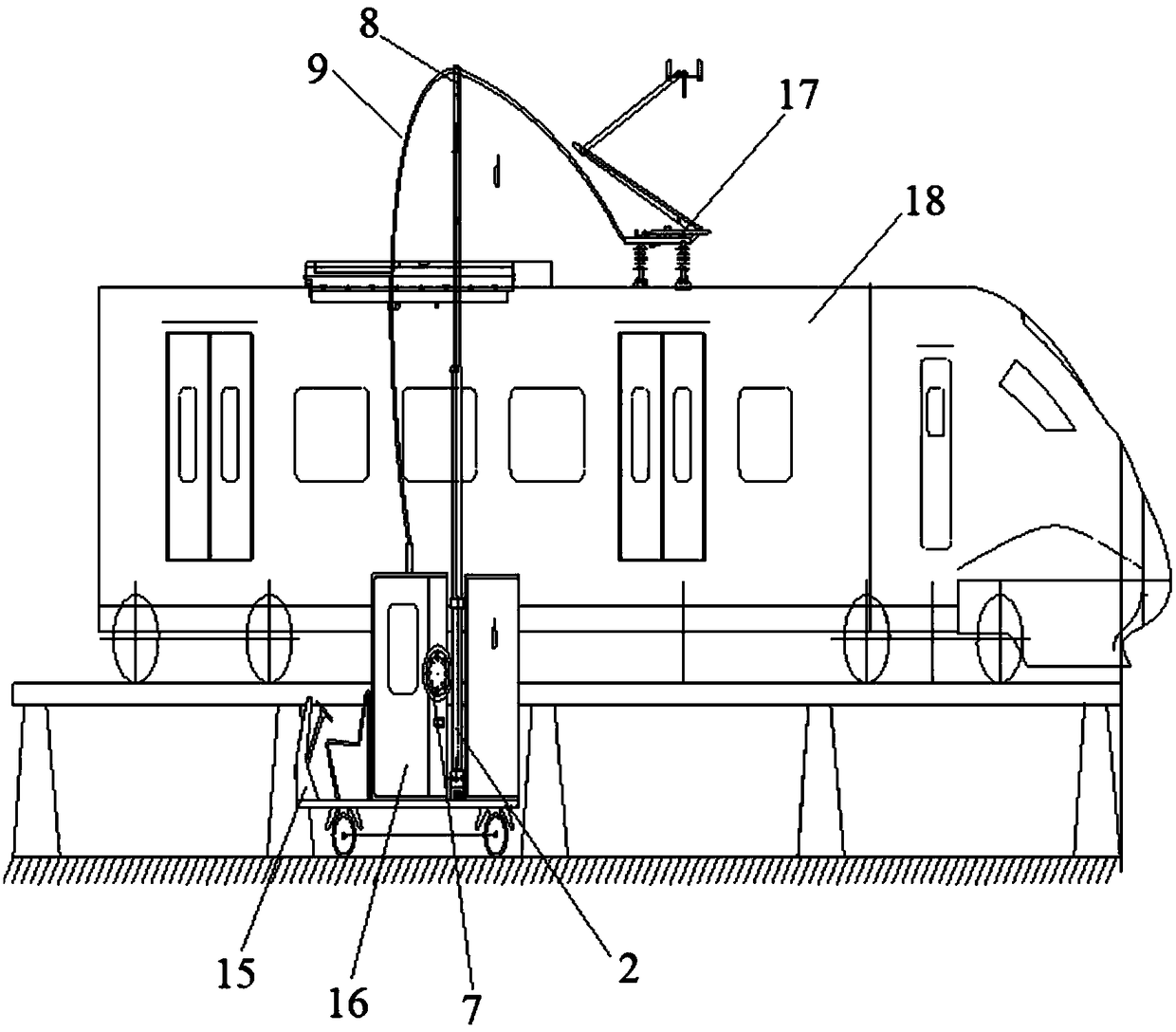

Cable lifting device used for rail car voltage withstand test, and test equipment

ActiveCN108928763AImprove securityImprove lifting efficiencyTesting dielectric strengthLifting devicesHigh pressureTest equipment

The invention relates to the technical field of rail traffic car tests, in particular to a cable lifting device used for a rail car voltage withstand test, and test equipment. The cable lifting devicecomprises a lifting device body and a drive mechanism; the lifting device body comprises a fixing rod and a lifting rod which is sleeved and connected with the fixing rod in a telescopic mode; the fixing rod and the lifting rod are connected through a first pulley assembly; the first pulley assembly is connected with the drive mechanism; the drive mechanism drives the lifting rod to ascend or descend relative to the fixing rod; and the top of the lifting rod is used for supporting a cable. The test equipment is provided with any one cable lifting device. The cable lifting device can achieve automatic ascending and descending of the cable, an operator does not need to climb to the car top to ascend or descend the cable, the operator can efficiently connect the cable for the test with a high-voltage component of the car top from the ground, and the cable ascending and descending efficiency and safety are improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Fingerprint module test delivery device

ActiveCN107697637BHigh positioning accuracySmooth Adsorption PitchConveyorsConveyor partsEngineeringMechanical engineering

The invention aims to provide a fingerprint module test conveyor, which comprises an adsorption device of a connecting support, two longitudinal beams provided with longitudinal guide rails, longitudinal transmission assemblies and a plurality of supporting feet, a longitudinal drive device, a synchronous shaft, a cross beam provided with a cross slide way and two ends connected with slide blocksof the two longitudinal guide rails in a one-to-one correspondence way, and a horizontal drive device. Each longitudinal transmission assembly comprises a longitudinal transmission drive synchronizingwheel pin-jointed with one end of each longitudinal beam, a longitudinal transmission driven synchronizing wheel pin-jointed with the other end of each longitudinal beam, and a longitudinal transmission synchronous belt; one side of each longitudinal transmission synchronous belt is connected with the slide block of each longitudinal guide rail; two ends of the synchronous shaft are in transmission connection with the longitudinal transmission drive synchronizing wheels of the two longitudinal transmission assemblies in a one-to-one correspondence way; and the connecting support is connectedwith a slide block of the cross slide way. The fingerprint module test conveyor is smooth to move and higher in in-place accuracy.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

Jacking mechanism with good stability

The invention discloses a jacking mechanism with good stability. The jacking mechanism comprises a base, a horizontal moving part and a lifting part, wherein the horizontal moving part comprises a horizontal moving seat and a horizontal moving handle; a rotating seat is arranged on the base; an annular convex cavity is formed in the rotating seat; the horizontal moving handle comprises a braking part, an annular convex part and a threaded part; the lifting part comprises an internal threaded seat, a lifting handle and a jacking rod; an internal threaded hole is formed in the internal threaded seat; external threads and a plurality of axial teeth are formed on the jacking rod; a sealing ring is arranged between the upper end of the jacking rod and the internal threaded base; at least three horizontal adjusting parts which are not located on the same straight line and are in threaded connection with the base are arranged on the base; the horizontal adjusting parts comprise leveling bolts which are in threaded connection with the base and bottom plates which are arranged below the leveling bolts; the positions of the bottom plates on the axial direction of the leveling bolts are fixed; the leveling bolts can rotate around the axes of the leveling bolts. The selection of a support point is flexible, the applicable range is wide, the jacking is reliable, the service life is long, the bearing capacity is strong, and the jacking precision is high.

Owner:API ZC PRECISION INSTUMENT CO LTD

Jacking mechanism

The invention discloses a jacking mechanism which comprises a base, a transverse movement part and a lifting part, wherein the transverse movement part comprises a transverse movement base and a transverse movement handle; the base is provided with a rotary seat which is internally provided with a ring convex cavity; the transverse movement handle comprises a braking part, a ring-shaped bulge and a thread section; the ring-shaped bulge is arranged in the ring convex cavity; the transverse movement base is connected with the transverse movement handle by screw threads; the lifting part comprises an internal thread seat, a lifting handle and a jacking rod; an internal thread hole is formed in the internal thread seat; the jacking rod is provided with external threads and a plurality of axial teeth; the length directions of the axial teeth are parallel to the axis of the jacking rod; the external threads arranged on the jacking rod are connected with the internal thread hole by screw threads; the internal thread seat is fixedly connected with the transverse movement base; the transverse movement handle is vertical to the jacking rod; a sealing ring is also arranged between the upper end of the jacking rod and the internal thread seat. The jacking mechanism is flexible in selection of a support point and can be conveniently installed relatively to a device to be jacked; furthermore, the jacking mechanism is long in service life, high in bearing capacity and high in jacking accuracy.

Owner:API ZC PRECISION INSTUMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com