Wafer thinning and polishing device

A technology for thinning polishing and wafers, which is applied to grinding drive devices, grinding/polishing equipment, and surface polishing machine tools, etc. It can solve problems such as affecting the polishing effect, slow conversion speed, and uneven liquid, so as to improve polishing effect, fast switching speed, and the effect of improving spray uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present application will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

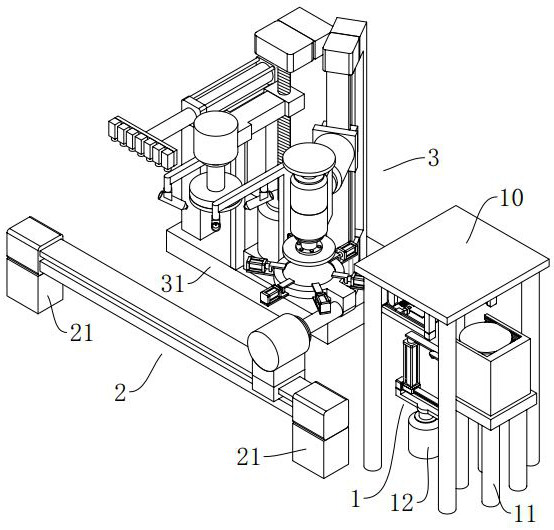

[0035] Such as Figure 1~Figure 9 A wafer thinning and polishing device shown includes a glue application unit 1 , a transport unit 2 , and a thinning and polishing unit 3 .

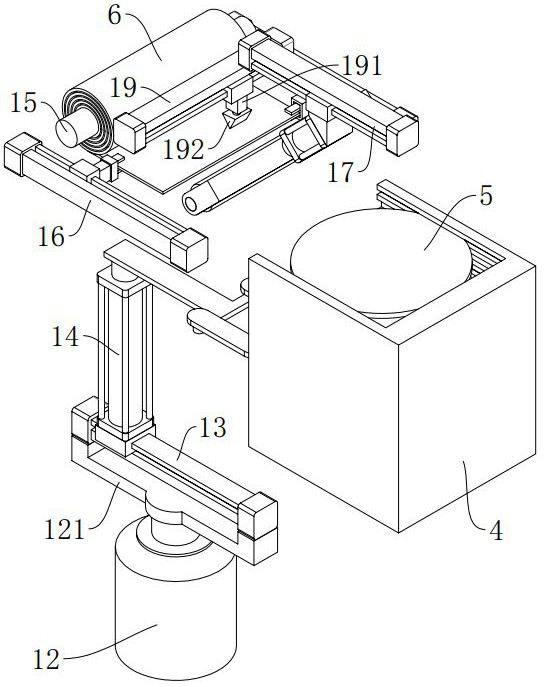

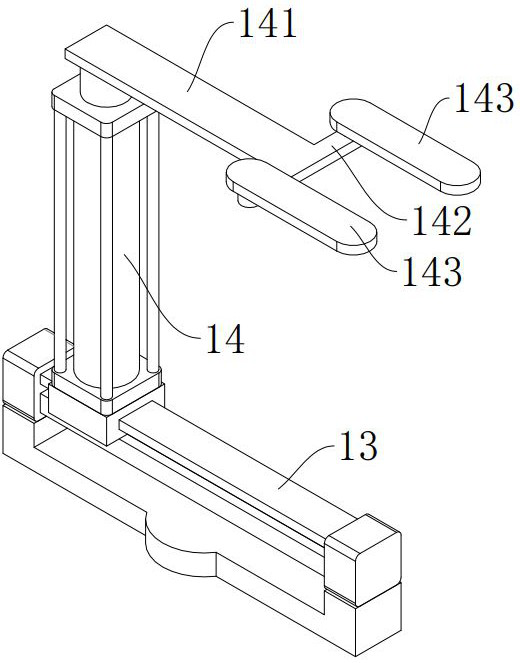

[0036] The gluing unit 1 comprises a top frame 10 and a bottom frame 11 located at the lower end, the bottom frame 11 is provided with a wafer frame 4 for placing a plurality of wafers 5, and one side of the bottom frame 11 is provided with a vertically arranged first rotating Motor 12, one end of its output shaft is provided with a bracket 121, the upper end of the bracket 121 is provided with a first rodless linear cylinder 13, and the upper end of its sliding end is provided with a vertically arranged first uniax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com