Construction trolley for lagging jack in tunnel and underground construction and construction method

A construction trolley and underground engineering technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of consuming manpower and material resources, reducing work efficiency, and arch shaking, so as to reduce the consumption of manpower and material resources and avoid potential safety hazards , Improve the effect of jacking precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and example the present invention will be further described:

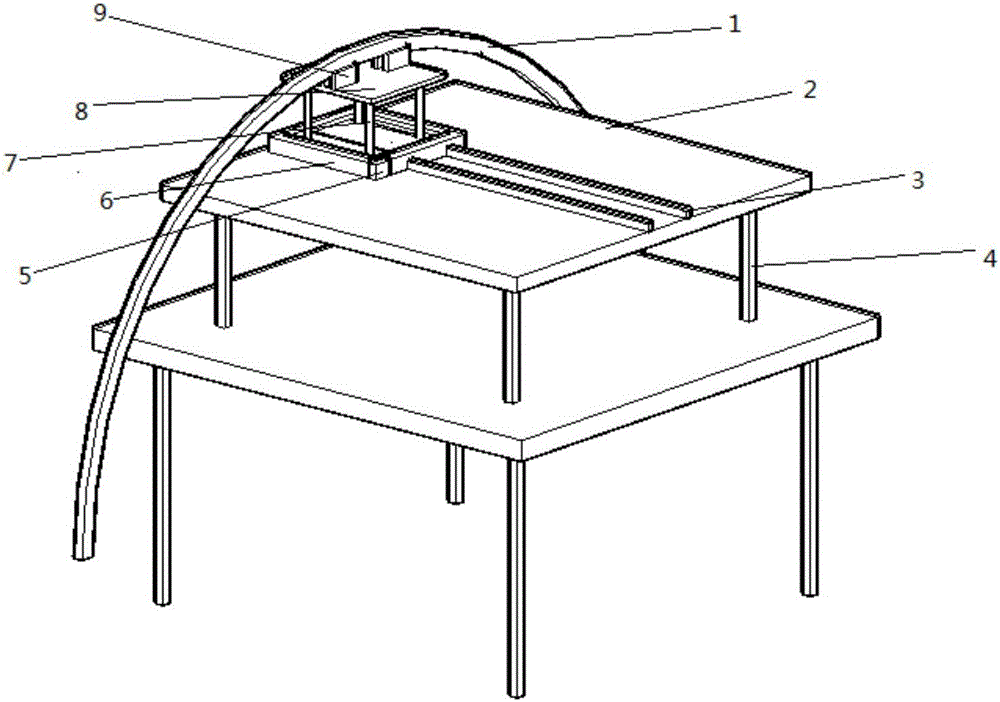

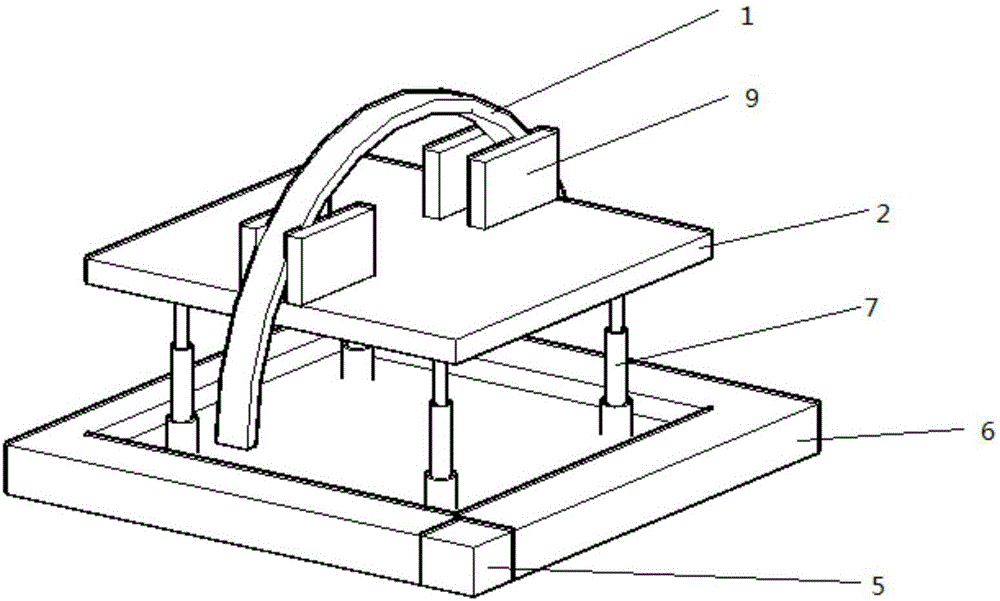

[0037] As shown in the figure, a construction trolley for arches in tunnels and underground works includes a bottom support structure, a middle support structure and an upper lifting structure, wherein,

[0038] The underlying support structure refers to the lowest support structure, and its functions are as follows:

[0039] First, the construction platform is used for supporting structures such as jacking arches. The arches are generally steel arches or concrete steel pipe arches, which have relatively heavy weight. In order to ensure the stability and safety of the jacking process, construction is required. The platform has high strength and a low center of gravity, so stricter requirements are put forward for the underlying support structure. The underlying support structure should have a larger volume, heavier weight, and higher strength to function as a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com