Adjusting and fixing mechanism and operating method thereof

A technology for fixing mechanisms and fixing components, which is applied in the direction of connecting components, mechanical equipment, and thin plate connections, etc. It can solve the problems of shaking of working parts, difficulty in direct access, and inappropriateness, etc., and achieves high lifting precision, reasonable and compact structure layout, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

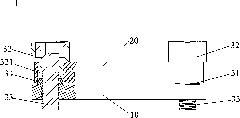

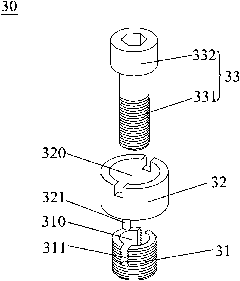

[0022] The embodiments of the present invention will now be described with reference to the accompanying drawings, in which similar element numbers represent similar elements. As described above, the present invention provides an adjustment and fixation mechanism that has high adjustment accuracy, a reasonable and compact structure, convenient installation, and a stable and reliable adjustment and fixation mechanism for working parts during position adjustment.

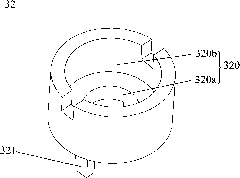

[0023] reference Figure 1-2 In a specific embodiment of the present invention, the adjusting and fixing mechanism 1 includes a reference table 10, a working table 20, and an adjusting and fixing assembly 30 connected between the reference table 10 and the working table 20. The reference table 10 Fixed bearing on the ground (not shown). The adjusting and fixing assembly 30 includes a screw sleeve 31, a gland 32, and a locking bolt 33. The screw sleeve 31 and the gland 32 are respectively provided with bolt holes 310 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com