Jacking mechanism with good stability

A technology of lifting mechanism and stability, applied in the direction of lifting device, etc., can solve the problems of affecting the lifting accuracy, complex equipment structure, and high failure rate, and achieve the effect of ensuring service life, benefiting safety performance, and high lifting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

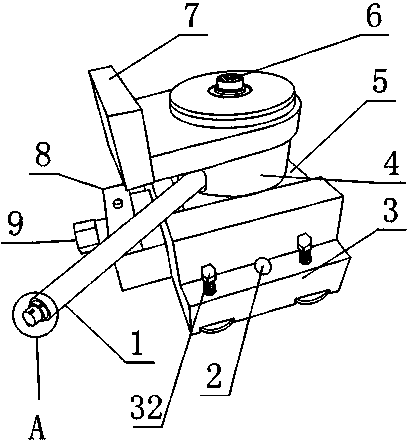

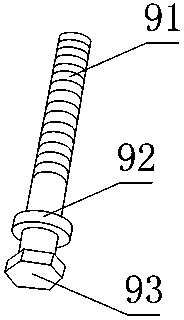

[0035] Such as Figure 1 to Figure 7A jacking mechanism with good stability provided by the present invention includes a base 3, a traversing part that can move laterally along the base 3 and a lifting part arranged on the traversing part, and the traversing part includes a traversing seat 5 And the traversing handle 9, the base 3 is provided with a rotating seat 8, and the rotating seat 8 is provided with a ring convex cavity 83, and the traversing handle 9 includes a braking part 93 sequentially from one end to the other end, an annular protruding 92 and the threaded section 91, the annular protrusion 92 is located in the ring convex cavity 83, the lower end of the traversing seat 5 is in contact with the upper end of the base 3, and the traversing seat 5 is threadedly connected with the traversing handle 9;

[0036] The lifting part includes a cylindrical internal thread seat 4, a lifting handle 1 and a jacking rod 6, the internal thread seat 4 is provided with an internal ...

Embodiment 2

[0040] This embodiment is further limited on the basis of embodiment 1: as Figure 1 to Figure 7 , in order to facilitate the installation of the traversing handle 9 and simplify the structure of the present invention, which is beneficial to processing, manufacturing and assembly, the rotating seat 8 includes an upper cover 82 and a lower cover 81 connected by bolts, and the upper cover 82 and the lower cover 81 Grooves are provided on the connecting sides, and the two grooves constitute the ring convex cavity 83 .

Embodiment 3

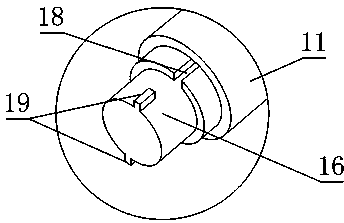

[0042] The present embodiment is further limited on the basis of embodiment 1: as Figure 1 to Figure 7 , the lifting handle 1 includes a driving sleeve 11 and a brake lever 16 sleeved in the driving sleeve 11, one end of the driving sleeve 11 is hingedly connected with the jacking rod 6, and the driving sleeve 11 can go around the top When the lifting rod 6 rotates in the circumferential direction, one end of the brake rod 16 that penetrates into the drive sleeve 11 forms an oblique cutout 7 , and the other end of the brake rod 16 protrudes relative to the drive sleeve 11 .

[0043] The set driving sleeve 11 is convenient for fixing the relative position of the lifting handle 1 relative to the jacking rod 6: even if the brake rod 16 interacting with the axial teeth 41 is always located in the radial direction of the jacking rod 6, the set inclined The notch 17 makes the structural relationship between the lifting handle 1 and the axial tooth 41 a ratchet structure. By adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com