Diving type stepping filling mechanism of vertical type bottle filler

A filling machine and stepping motor technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of slow speed response, difficulty in precise control of downward movement, large volume, etc., and achieve precise axial movement The effect of high height and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

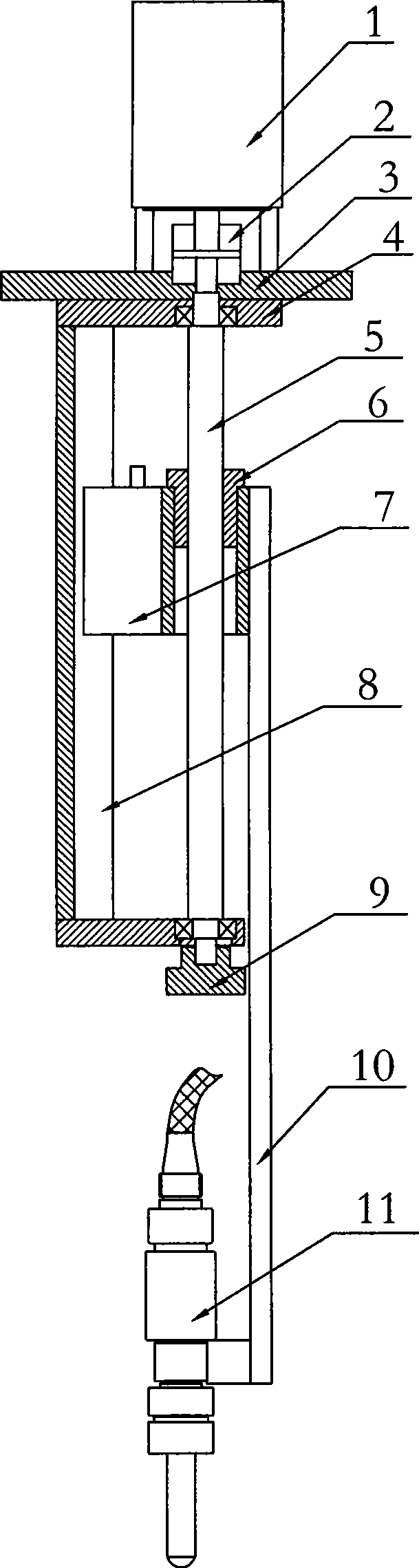

[0010] Embodiment 1: The submerged stepping filling mechanism of the vertical filling machine includes a stepping motor 1, a coupling 2, a support plate 3, a slide rail frame 4, a ball screw 5, a screw nut 6, a lifting Slider 7, slide rail 8, fine-tuning handwheel 9, connecting plate 10 and filling head 11, stepper motor 1 is fixedly installed on the upper end of support plate 3, slide rail frame 4 is fixed on the lower end of support plate 3, slide rail 8 Fixed on the slide rail frame 4, the lifting slider 7 and the slide rail 8 can be slidably moved and connected, the screw nut 6 is fixed on the lifting slider 7, the ball screw 5 is screwed in the screw nut 6, and the ball screw The two ends of 5 are installed on the slide rail frame 4 through bearings, the upper end of the ball screw 5 is directly connected with the stepping motor 1 through the coupling 2, and the lower end of the ball screw 5 is equipped with a fine-tuning hand wheel 9 and a connecting plate 10 The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com