Angle position test tool of clock spring installation board and ignition switch installation frame

An ignition switch, clock spring technology, applied in measuring devices, angle/taper measurement, instruments, etc., can solve the problems of large detection error, small detection error, high detection efficiency, and achieve simple and practical structure, small detection error, and detection efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

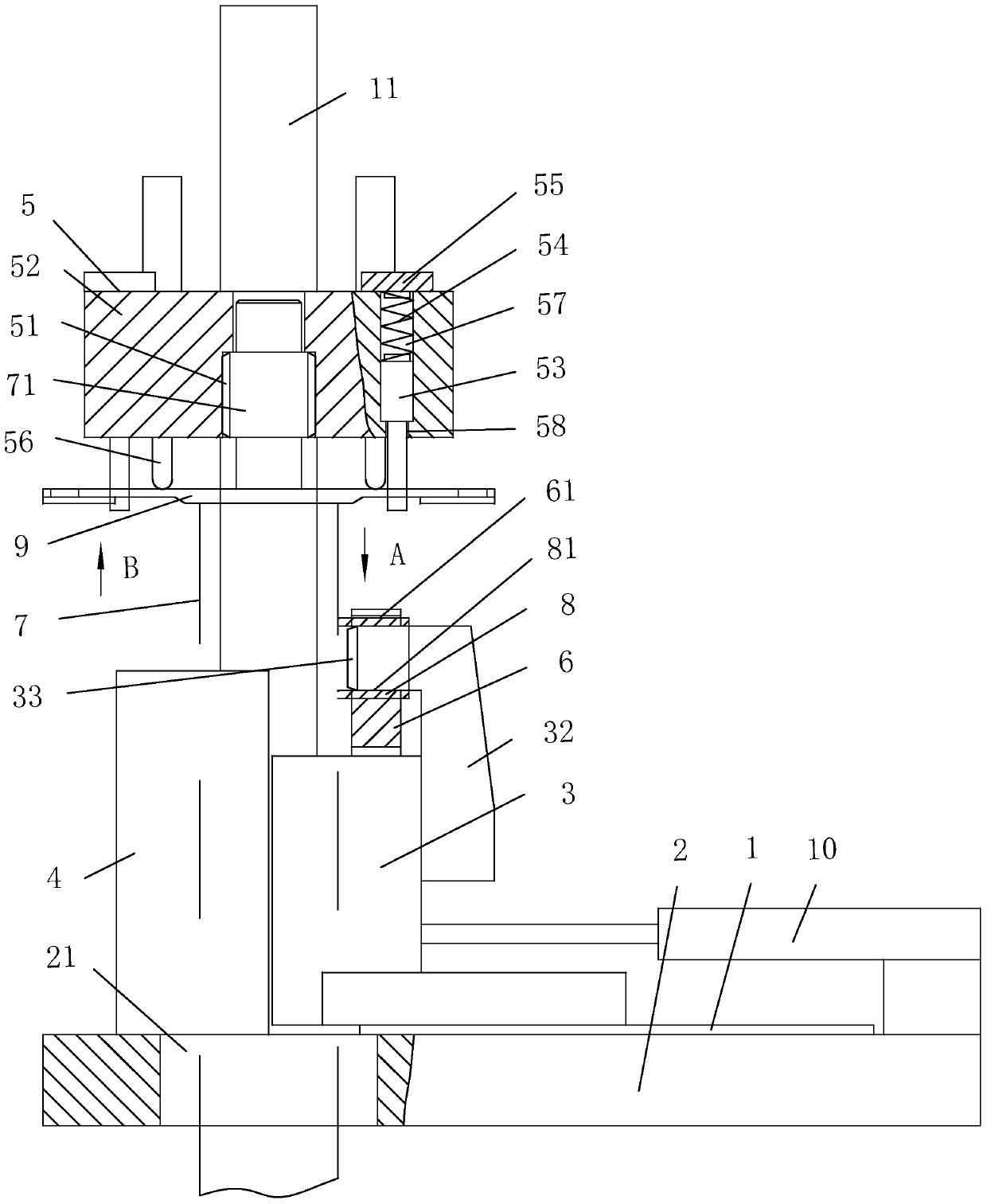

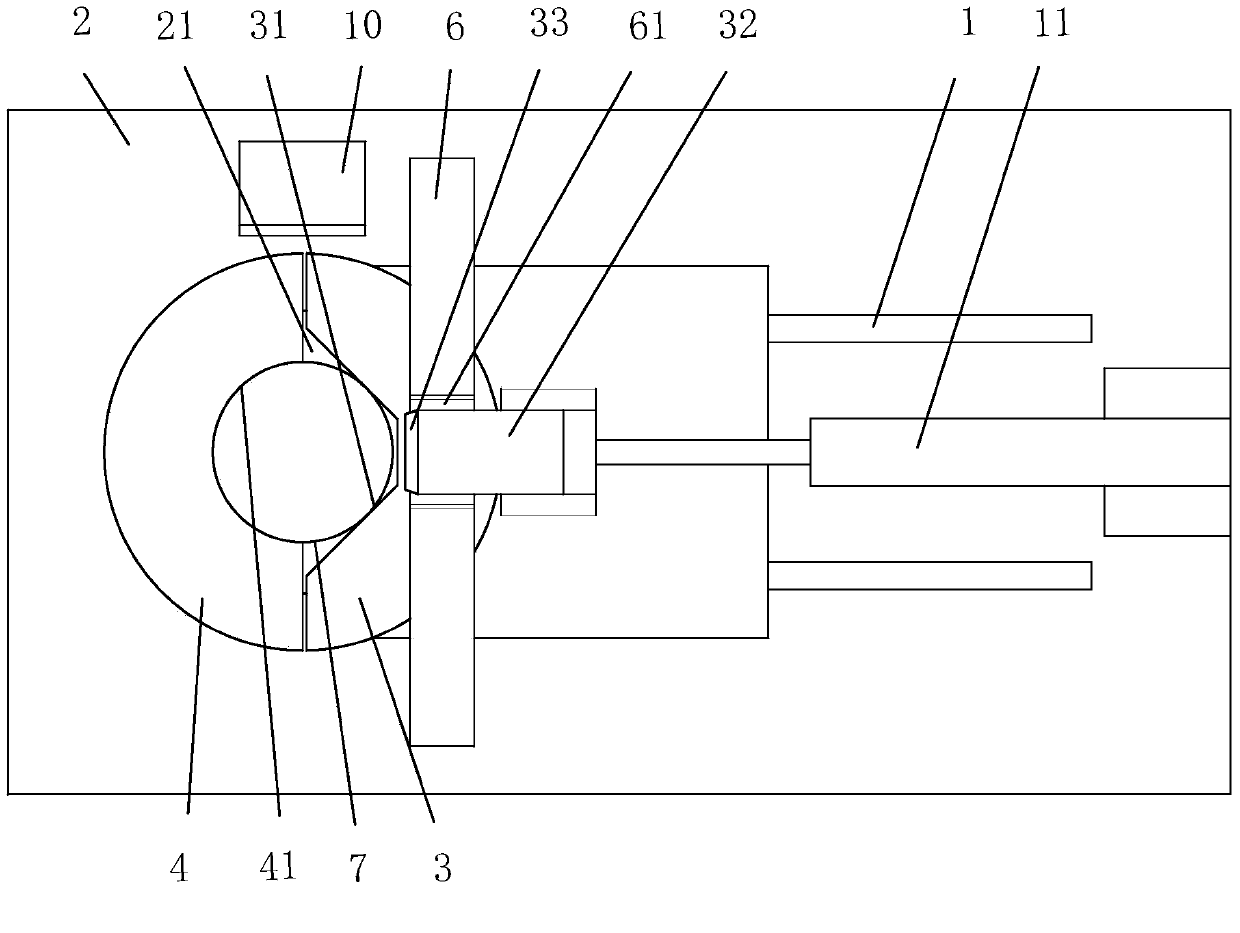

[0019] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a clock spring mounting plate and an ignition switch mounting frame angle position checker, including the base plate 2 and the right clamping block 3 connected with the base plate 2 through the slide rail 1 and having the right clamping groove 31 and the square hole positioning head 32, the right Clamp driving device 10, left clamp block 4 with left clamp groove 41 and screw connection with bottom plate 2 and lifting device 11, spline section connected with lifting device 11 and mounting hole detection assembly 5, with width and ignition switch mounting frame The positioning groove 61 that the width clearance of 8 fits and the positioning block 6 that is connected with the bottom plate 2 screws.

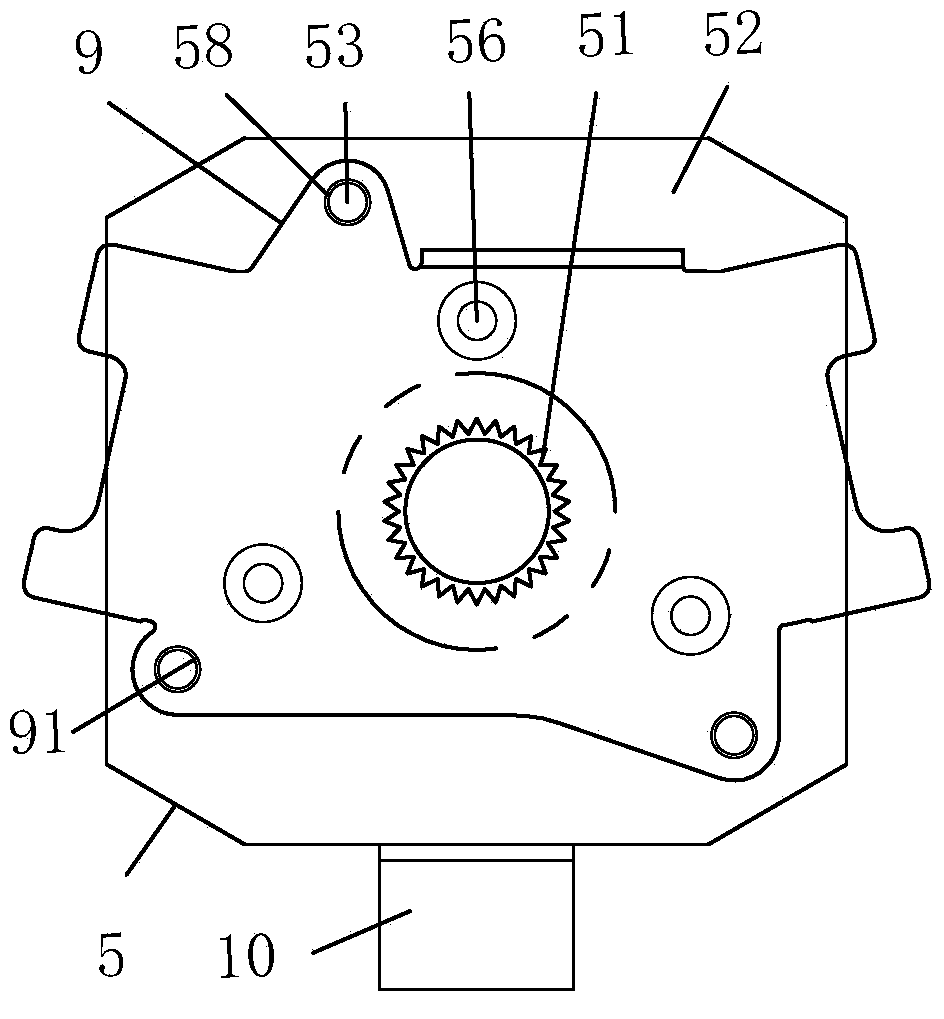

[0020] The spline segment and mounting hole detection assembly 5 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com