Ballastless track structure settlement lifting device and lifting method thereof

A ballastless track, subsidence and lifting technology, applied in the track field, can solve the problems of difficult drilling and grouting, inapplicability, and difficult injection of grouting materials, etc., and achieve simple equipment and structure, high lifting precision, and easy lifting operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

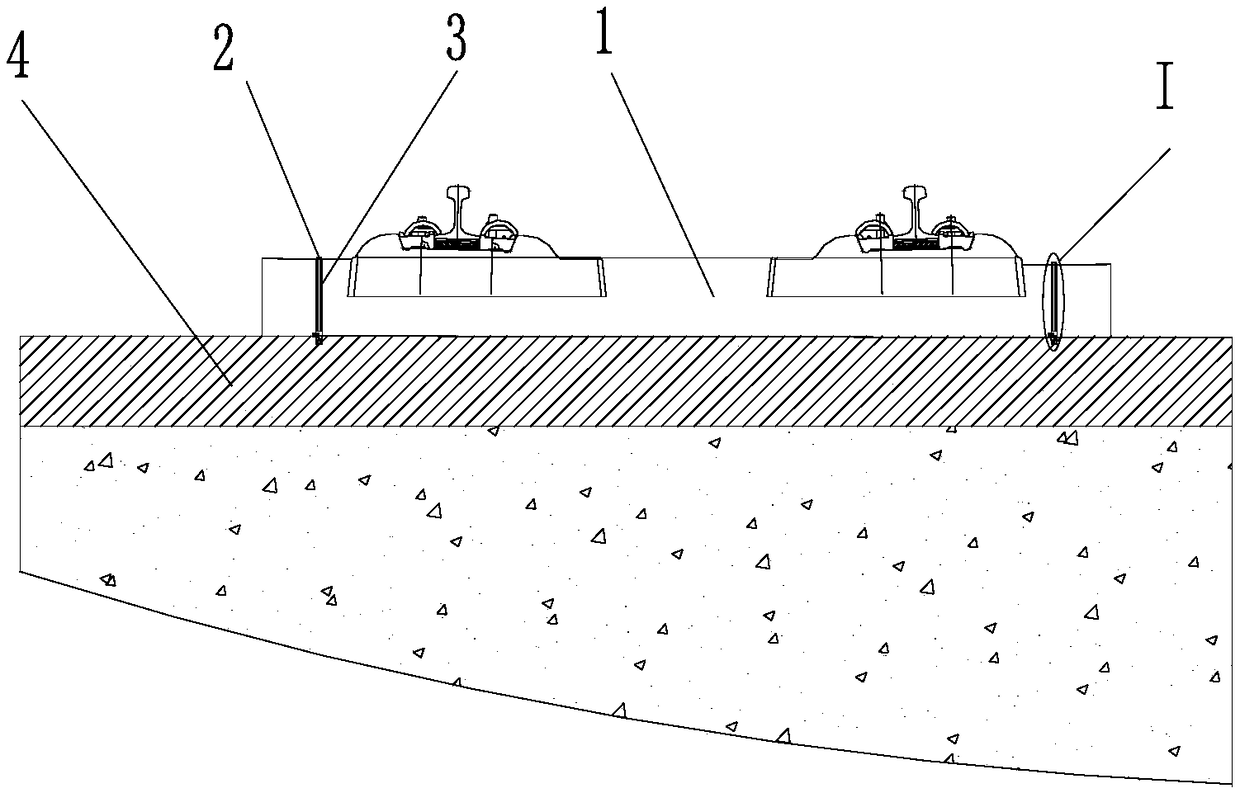

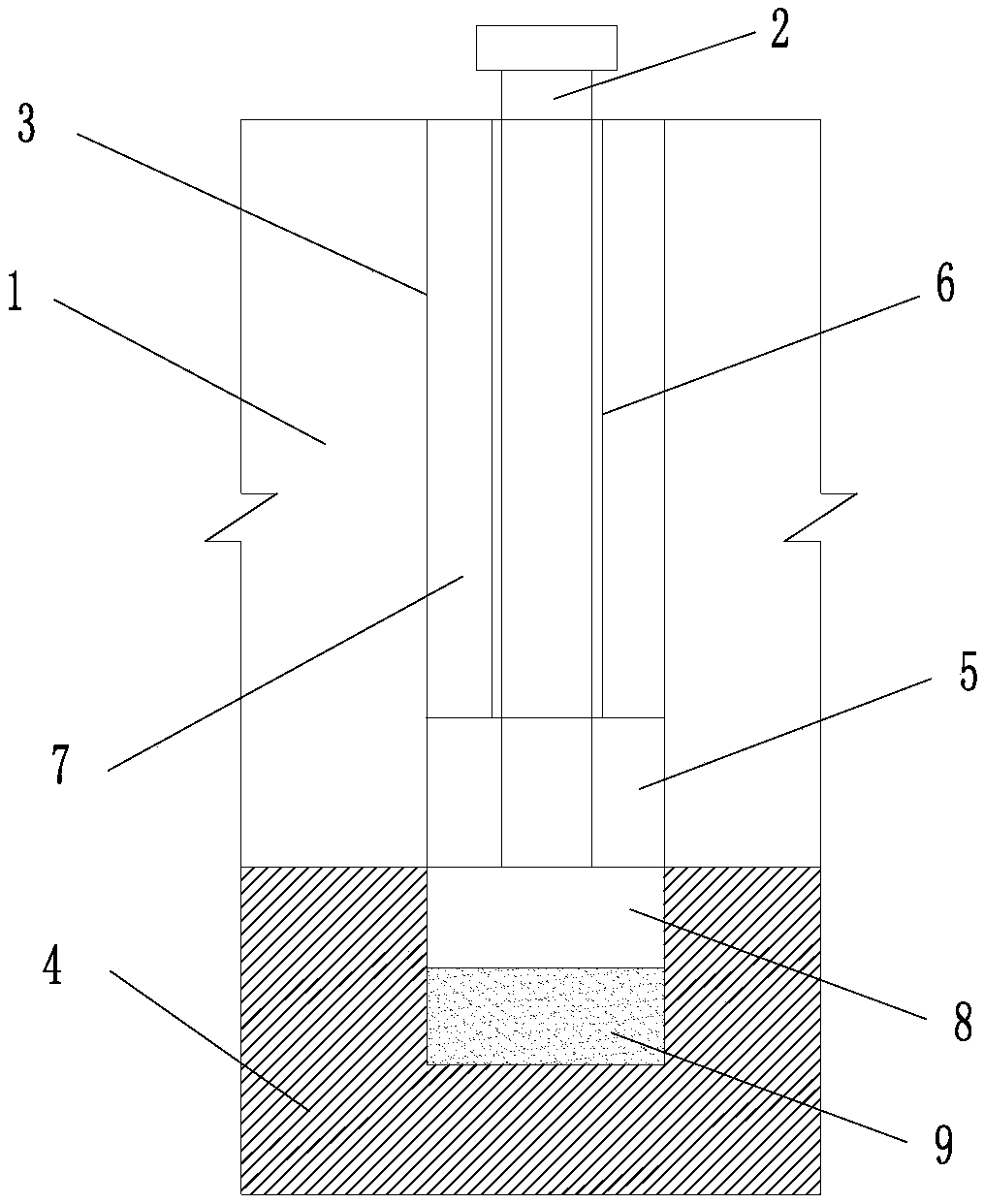

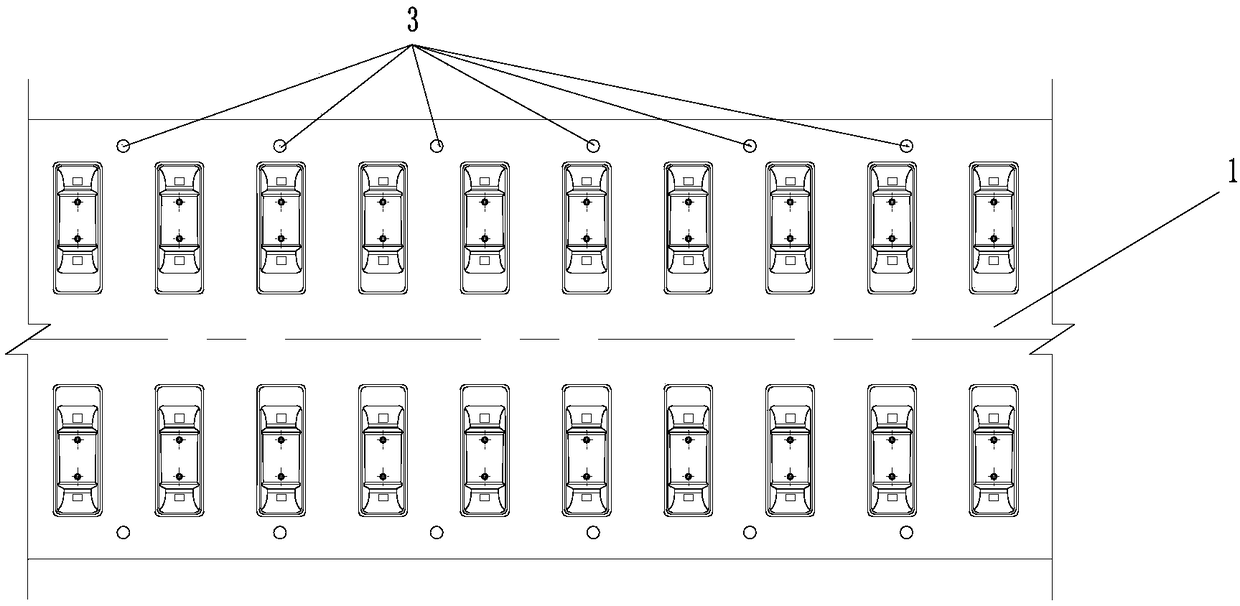

[0031] Such as Figure 1~3 The shown ballastless track structure subsidence lifting device is used to lift the ballastless track slab 1, including screw rods 2 pre-buried on both sides of the ballastless track slab 1 and arranged at intervals along its extending direction, and the ballastless track slab 1 There is a pre-embedded hole 3 for the pre-embedded screw 2, the pre-embedded hole 3 vertically penetrates the ballastless track slab 1 and extends downward to the concrete cushion 4, the screw 2 is sleeved with a nut 5 threaded with it, and the screw 2 The outer wall of the rod 2 is covered with a sleeve 6, and a mortar column 7 is poured in the annular space between the outer wall of the sleeve 6 and the inner wall of the embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com