Hydraulic jack

A hydraulic jack and jack technology, applied in the field of hydraulic jacks, can solve problems such as unfavorable safety and stability of hydraulic jacks, shortening the service life of hydraulic oil, easy leakage of hydraulic oil, etc. ability, the effect of ensuring security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

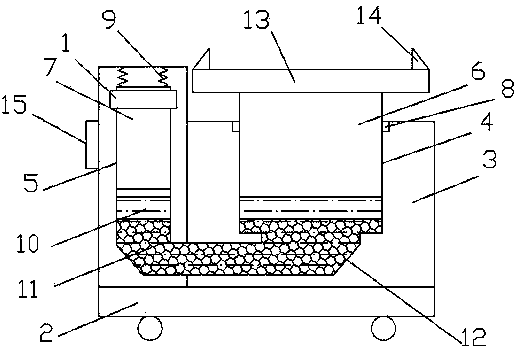

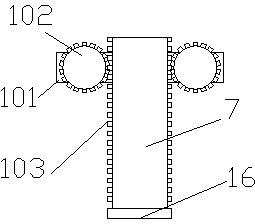

[0024] As shown in the figure, a hydraulic jack includes a driving device 1, a base 2 and a cylinder 3 that is movably connected to the base 2. The cylinder 3 is provided with a main lifting groove 4 and an auxiliary lifting groove 5 that communicate with each other at the bottom. The bottoms of the main lifting groove 4 and the auxiliary lifting groove 5 are respectively provided with chamfers 12 not less than 45°, and the main lifting blocks 6 that can be lifted and lowered along the inner wall of the groove are respectively arranged in the main lifting groove 4 and the auxiliary lifting groove 5 and the auxiliary lifting block 7, and are respectively connected by the sealing device I8 and the sealing device II16. Hydraulic oil 10 and pressure-bearing rolling balls 11 for enhancing the pressure-bearing performance of hydraulic oil 10. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com