Building roof parapet wall flashing construction process

A construction process and parapet technology, applied in snow traps and other directions, can solve the problems of insufficient adhesion between the protective layer and the waterproofing membrane, the aging and falling off of the waterproofing membrane, and the accelerated aging of the waterproofing membrane, so as to achieve long-term and excellent protection. , The construction process is simple and easy to implement, and the construction efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

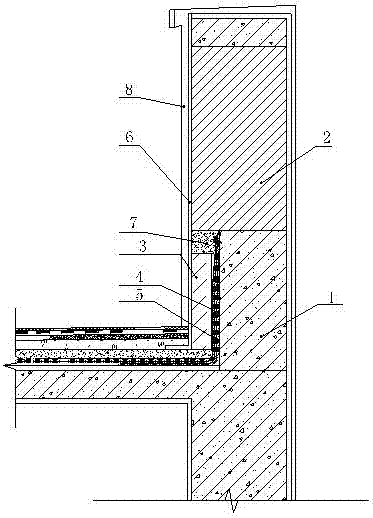

[0030] A building roof parapet flooding construction process, comprising the following steps:

[0031] Step 1: Pour a reinforced concrete structure flashing wall on the roof of the building; for the pouring of the flashing wall, it can be poured integrally with the roof structure, or it can be poured separately after the roof structure is poured .

[0032] Step 2: Lay waterproof membranes on the interior and elevation of the roof and flashing walls to form a waterproof layer, and close the upper end of the waterproof membranes;

[0033] Step 3: Use solid bricks to build a protective brick wall on the outer facade of the waterproof layer, the inner facade of the protective brick wall is close to the waterproof coiled material and the waterproof coiled material is pressed against the flashing wall above; the height of the protective brick wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com