Concrete wall construction joint waterproof treatment method

A technology for concrete wall and waterproof treatment, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as energy consumption and funds, affecting the normal use of building products, waterproof damage, etc., to increase the adaptability to the deformation of the base The ability to avoid groundwater leakage, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

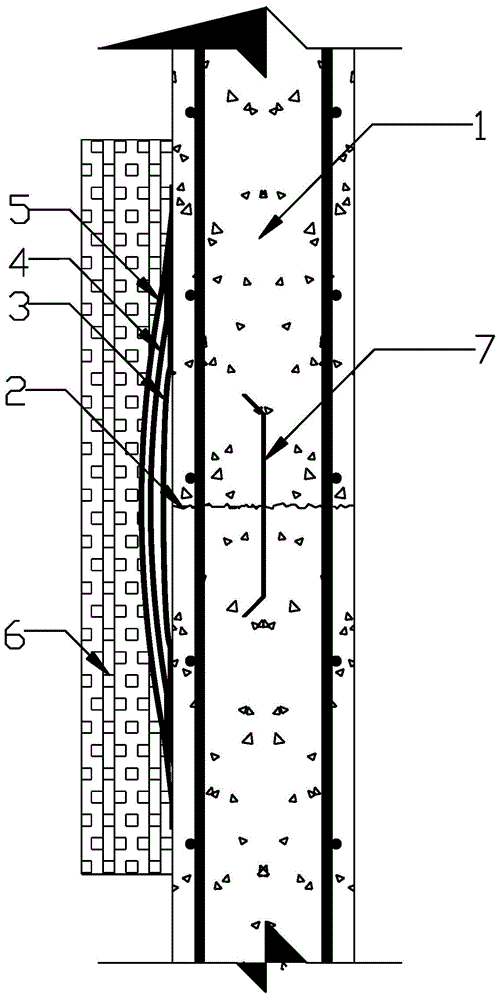

[0033] [Example 1] waterproof treatment of concrete wall 1 construction joint 2 with waterproof steel plate 7 (see figure 1 )

[0034] Clean up the concrete wall 1 within a width of 500 mm on both sides of the construction joint 2 on the water-facing surface; lay waterproof membranes according to the "Waterproof Membrane Construction Technology Standard", and the waterproof membranes are APP (APAO) modified asphalt membranes. Paving by hot-melt paste method;

[0035] Lay and paste the first layer of waterproof membrane 3, and do not paste it within a width of 50 mm on both sides of the construction joint 2 on the water-facing surface. Reserve a width of 120 mm in the middle of the first layer of waterproof membrane 3, and then stick firmly to the wall 1 on both sides, with a width of 100 mm;

[0036] Lay and paste the second layer of waterproof membrane 4, do not paste within the scope of the first layer of waterproof membrane 3, reserve a width of 330mm in the middle of the ...

Embodiment 2

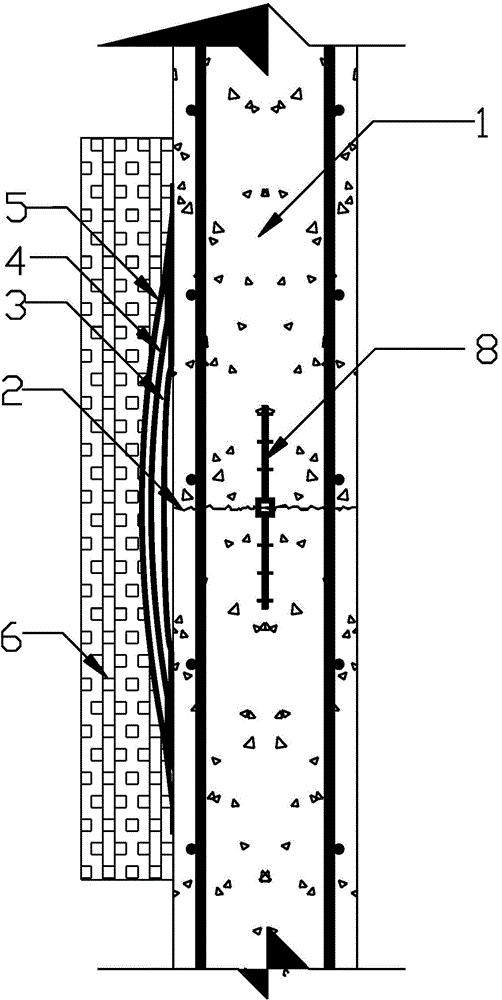

[0039] [Example 2] waterproof treatment of concrete wall 1 construction joint 2 with waterstop 8 (see figure 2 )

[0040] Clean up the concrete wall 1 within a width of 500mm on both sides of the construction joint 2 on the water-facing surface; lay and paste waterproof membranes according to the "Waterproof Membrane Construction Technology Standard", the waterproof membrane is SBS rubber modified asphalt membrane, and heat Fusion paste method paving;

[0041] Lay and paste the first layer of waterproof membrane 3, and do not paste it within a width of 50 mm on both sides of the construction joint 2 on the water-facing surface. Reserve a width of 130 mm in the middle of the first layer of waterproof membrane 3, and then stick firmly to the wall 1 on both sides, with a width of 100 mm;

[0042] 3) Lay the second layer of waterproof membrane 4, do not paste within the scope of the first layer of waterproof membrane 3, reserve 340mm width in the middle of the second layer of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com