Double-base waterproof roll and preparation method thereof

A waterproof membrane and tire base technology, which is applied in the direction of asphalt material adhesive, adhesive type, film/sheet adhesive, etc., can solve the problem of high elongation, high strength of double tire base waterproof membrane, etc. problems, to achieve high elongation, excellent corrosion resistance and chloride ion penetration resistance, thermal dimensional change stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

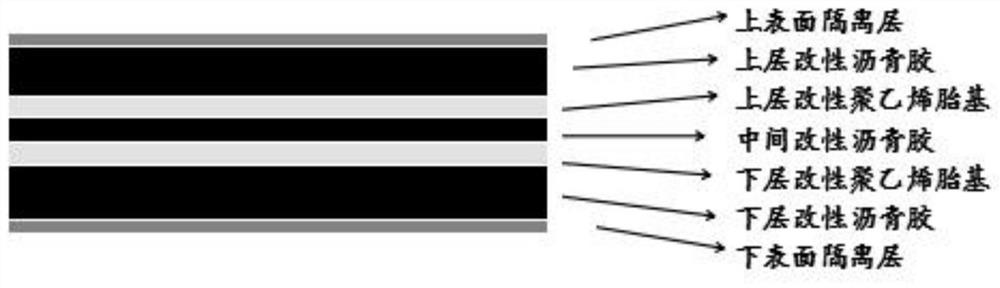

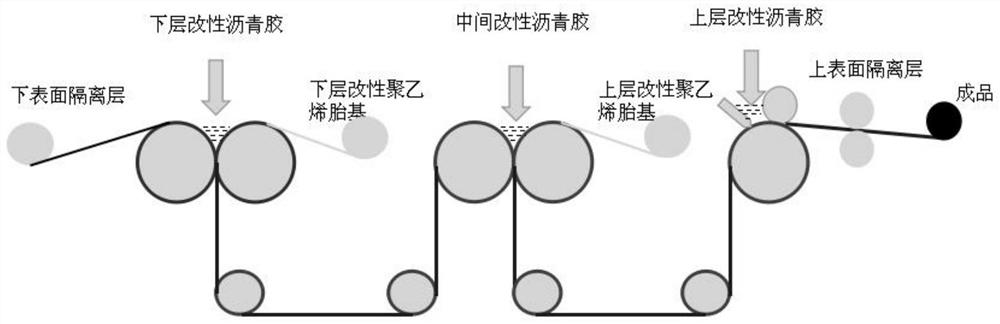

[0063] The present invention also provides a preparation method of a double-base waterproof coiled material, the preparation method comprising: forming a lower surface isolation layer, a lower layer of modified asphalt rubber and a lower layer of modified polyethylene tire base by a double-roller pouring process; The intermediate modified asphalt rubber and the upper layer of modified polyethylene tire base are formed by the roller pouring process, and finally the upper layer of modified asphalt rubber and the upper surface isolation layer are formed by the scraping process.

[0064] In the present invention, the long side of the upper surface isolation layer is preferably provided with a 6-12 cm overlapping edge, more preferably a 10 cm overlapping edge.

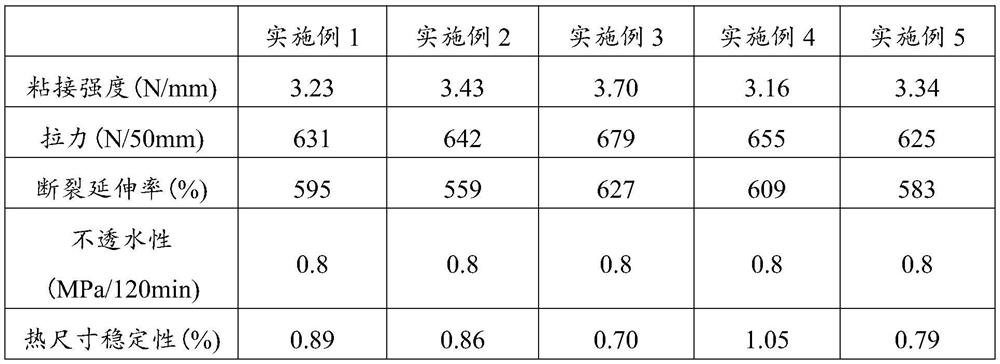

Embodiment 1

[0067] Step 1: The upper and lower surface isolation layers are both 0.018mm polyolefin elastomer film, and the upper layer modified polyethylene tire base and the lower layer modified polyethylene tire base are both 0.10mm modified high density polyethylene tires base.

[0068] Step 2: The preparation methods of the upper layer modified asphalt rubber, the middle modified asphalt rubber and the lower layer modified asphalt rubber are as follows:

[0069] (1) Open the heat-conducting oil valve of the reactor, inject 49 parts of petroleum asphalt and 10 parts of naphthenic rubber softening oil, stir slowly at a speed of 125r / min, and heat up for the first time after mixing to 120°C, then heat up The time is 1.5h, and the mixture A is obtained;

[0070] (2) After the mixture A is obtained, heat up for the second time, and mix it with 2 parts of butyl rubber after the temperature is raised to 160°C. After mixing for 60min, the rotating speed was 125r / min to obtain mixture B;

...

Embodiment 2

[0076] Step 1: The upper and lower surface isolation layers are both 0.018mm polyolefin elastomer film, and the upper layer modified polyethylene tire base and the lower layer modified polyethylene tire base are both 0.10mm modified high density polyethylene tires base.

[0077] Step 2: The preparation methods of the upper layer modified asphalt rubber, the middle modified asphalt rubber and the lower layer modified asphalt rubber are as follows:

[0078] (1) Open the heat-conducting oil valve of the reactor, pour in 50 parts of petroleum asphalt and 9 parts of naphthenic rubber softening oil, stir slowly at a speed of 125r / min, and heat up for the first time after mixing to 120°C, then heat up The time is 1.5h, and the mixture A is obtained;

[0079] (2) After the mixture A is obtained, heat up for the second time, and mix it with 1 part of butyl rubber after the temperature is raised to 160°C. After mixing for 60min, the rotating speed was 125r / min to obtain mixture B;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com