Battery

A battery and electrolyte technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery performance deterioration, battery safety hazards, battery swelling, etc., to suppress battery performance attenuation, suppress gas, and avoid The effect of battery drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] In a preferred embodiment, the battery containing the positive electrode collector can also be charged and discharged to achieve the purpose of passivating the positive electrode collector. The voltage is charged to 2.1-2.4V when charging, and the voltage is released to 1.35-2.4V when discharging. 1.45V, charge and discharge times not less than 1.

[0050] In a specific embodiment, when preparing the positive electrode, in addition to the positive electrode active material, depending on the actual situation, it may be necessary to add a positive electrode conductive agent and a positive electrode binder to improve the performance of the positive electrode.

[0051] The positive electrode conductive agent is selected from one or more of conductive polymers, activated carbon, graphene, carbon black, graphite, carbon fibers, metal fibers, metal powders, and metal flakes.

[0052] The positive electrode binder can be selected from polyethylene oxide, polypropylene oxide, po...

Embodiment 1

[0102] Lithium manganese oxide LMO, conductive agent graphite, binder SBR and CMC are mixed in water according to the mass ratio of 90:5:2.5:2.5 to form a uniform positive electrode slurry. The positive electrode slurry was coated on both sides of the positive electrode current collector (50 μm stainless steel wire mesh) coated with a conductive film to form an active material layer, which was then pressed into sheets and cut into a size of 8×10 cm to make a positive electrode. The thickness of the positive electrode sheet is 0.4mm, and the surface density of the positive electrode active material is 750g / m 2 .

[0103] A zinc foil with a thickness of 50 μm was used as the negative electrode. The diaphragm is an AGM glass fiber diaphragm. The separator and negative electrode are comparable in size to the positive electrode.

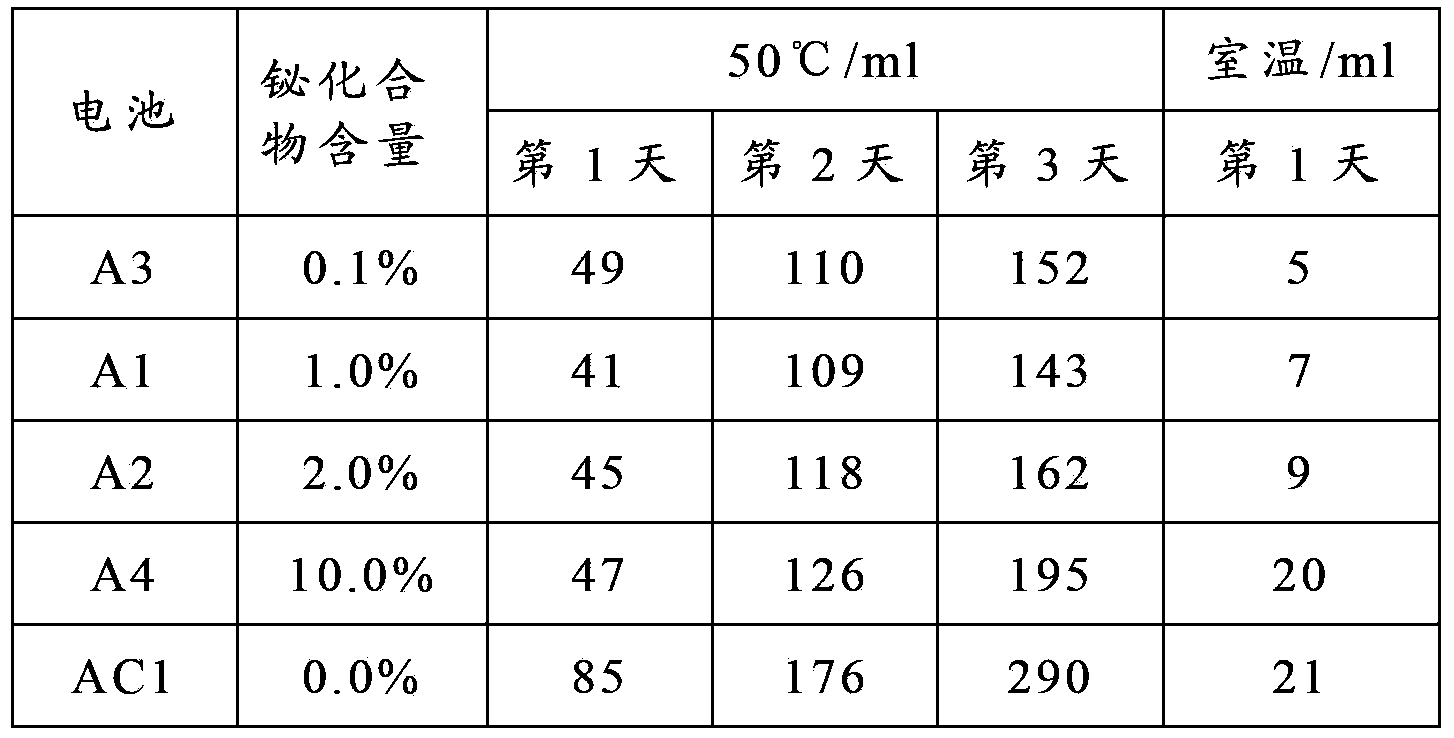

[0104] Weigh zinc sulfate and lithium sulfate of a certain quality, add them to dissolve in water, then add bismuth trioxide, configure the zinc sulfa...

Embodiment 2

[0107] The difference from Example 1 is that the content of bismuth trioxide is 2wt%, and other parts are the same as in Example 1. Get the battery and call it A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com