Battery

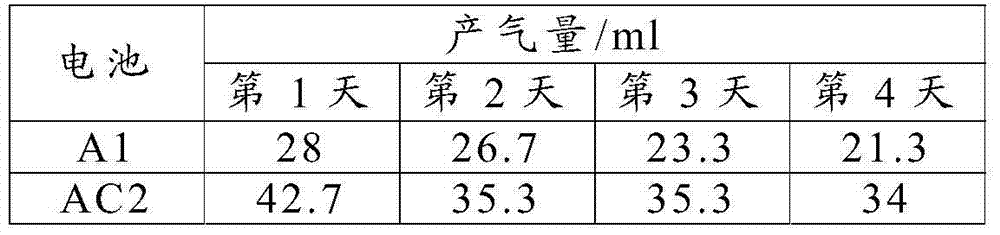

A battery and electrolyte technology, applied in secondary batteries, lead-acid batteries, circuits, etc., can solve the problems of potential safety hazards in battery use, battery bulging, and battery performance deterioration, so as to avoid bulging and inhibit gas generation. , the effect of enhancing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] In a preferred embodiment, the anions in the electrolyte include one or more of sulfate ions, chloride ions, acetate ions and nitrate ions.

[0065] The concentration of each ion in the electrolyte can be changed and adjusted according to different conditions such as different electrolytes, solvents, and battery application fields.

[0066] Preferably, in the electrolyte, the concentration of the first metal ion is 0.1-10 mol / L.

[0067] Preferably, in the electrolyte, the concentration of the second metal ion is 0.5-15 mol / L.

[0068] In order to optimize the performance of the battery, the pH range of the electrolyte is preferably 3-7.

[0069] The pH value of the electrolyte ranges from 3 to 7, which can effectively ensure the concentration of the second metal ion in the electrolyte, thereby ensuring the capacity and rate discharge performance of the battery, and can also avoid the problem of co-intercalation of protons.

[0070] The positive electrode of the prese...

Embodiment 11

[0123] Lithium manganese oxide LMO, conductive agent graphite, binder SBR and CMC are mixed in water according to the mass ratio of 90:5:2.5:2.5 to form a uniform positive electrode slurry. The positive electrode slurry was coated on the positive electrode current collector (50 μm stainless steel plate) to form an active material layer, which was then pressed into sheets and cut into a size of 6cm×6cm to make positive electrode sheets.

[0124] A zinc foil with a thickness of 50 μm was used as the negative electrode. The diaphragm is an AGM glass fiber diaphragm. The separator and negative electrode are comparable in size to the positive electrode.

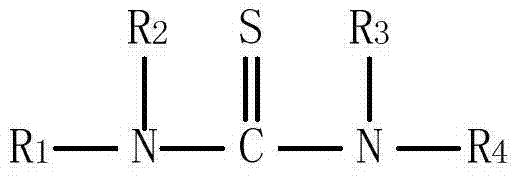

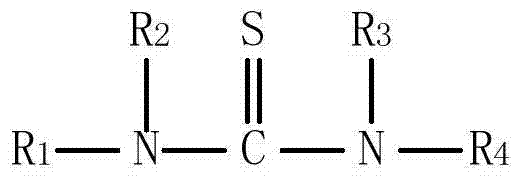

[0125] Weigh a certain quality of lithium methanesulfonate and zinc methanesulfonate and dissolve them in deionized water, then add N-methylthiourea to make 2mol / L lithium methanesulfonate, 3mol / L zinc methanesulfonate, N-methylsulfonate The content of thiourea is 0.5wt% in the electrolyte.

[0126] The positive electrode, the ...

Embodiment 12

[0128] The difference from Example 1.1 is that tetramethylthiourea is used instead of N-methylthiourea, and the other parts are the same as in Example 1.1 to obtain a battery, which is designated as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com