Flexible waterproof mortar, preparation method and applications thereof

A flexible waterproof and mortar technology, applied in the field of building materials, can solve problems such as improper construction process, protrusion, cracking, etc., and achieve the effect of improving product construction, high flexibility and waterproofness, and improving waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1A component

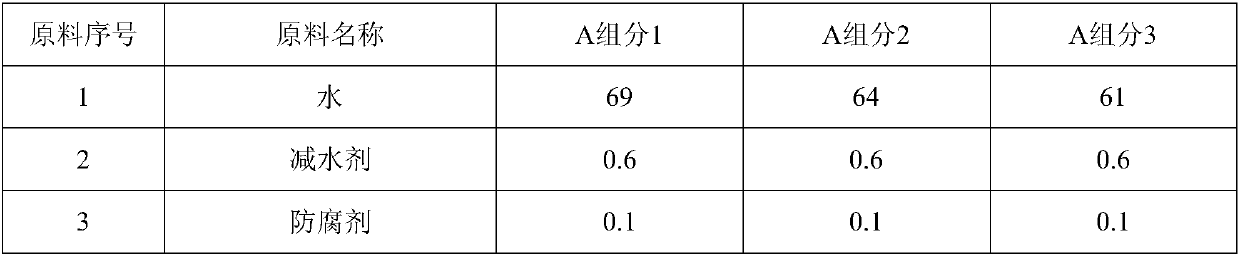

[0030] According to the ratio of the raw materials in the A component listed in Table 1, the A component 1, the A component 2, and the A component 3 are respectively prepared by the following methods: first, the raw materials of the A component are in the ratio listed in Table 1 Weigh it well, then turn on the paint mixing equipment; mix water and water reducing agent and stir for 3 minutes at a high speed of 600-800rpm to form a uniform glue without lumps, then slowly add preservatives and defoamers and stir 1 minute; then adjust the rotation speed to below 600rpm, then slowly add the emulsion and stir for 10 minutes until uniform, forming a uniform non-caking glue product, that is, 3 parts of A component, respectively A component 1, A component 2 , A component 3, respectively out of the packaging.

[0031] Table 1 Flexible waterproof mortar A component preparation formula (wt%)

[0032]

[0033]

Embodiment 2

[0034] The preparation of embodiment 2 B component

[0035] First weigh the raw materials of component B in proportion, and put in 25kg of cement, 10kg of 325-mesh talcum powder, 30kg of 325-mesh heavy calcium carbonate, 34kg of 325-mesh quartz powder, 0.3kg of cellulose ether, and 0.5kg of thixotropic lubricant. kg, water repellent 0.2kg; then turn on the powder mixing equipment, and stir for 6 minutes to form a uniform non-caking powder product, that is, component B.

Embodiment 3

[0036] The preparation of embodiment 3 flexible waterproof mortar

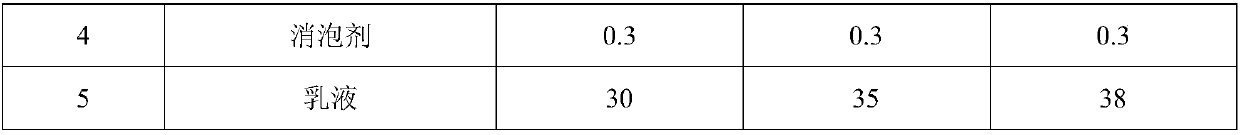

[0037] The three A components obtained in Example 1 (i.e. A component 1, A component 2 and A component 3) and the B component obtained in Example 2 are first weighed in the container according to the ratio of 1:4 by mass Prepare component A, then add component B while stirring at room temperature for mixing, and stir evenly before use. The main properties of the obtained flexible waterproof mortar are shown in Table 2.

[0038] Table 2 Main properties of flexible waterproof mortar

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com