Fabrication method for surface electroplating coating layer of NdFeB rare-earth permanent magnet

A rare earth permanent magnet, electroplating coating technology, applied in permanent magnet manufacturing, inductor/transformer/magnet manufacturing, circuits, etc. Consistent current density and improved binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of the electroplating coating on the surface of the NdFeB rare earth permanent magnet of the present embodiment is carried out according to the following steps:

[0052] (1) Surface pretreatment of NdFeB rare earth permanent magnets:

[0053] Sand blast the surface of the NdFeB rare earth permanent magnet with a size of 30mm×30mm×3mm. Use a spray gun to spray fine sand with a particle size of 400~1000 mesh on the surface of the NdFeB rare earth permanent magnet to remove the oxide layer on the surface of the magnet. until the off-white fresh surface is exposed;

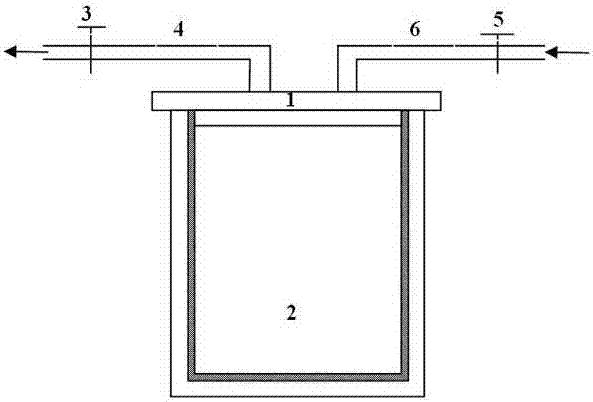

[0054] (2) NdFeB rare earth permanent magnet vacuum treatment:

[0055] Put the surface-pretreated NdFeB rare earth permanent magnet into a sealed tank, the inside of the sealed tank is covered with PTFE coating, the top of the sealed tank is a sealed tank cover, and the sealed tank cover is connected with a vacuum tube and an electroplating solution inlet tube , there are valves on the...

Embodiment 2

[0059] The preparation method of the electroplating coating on the surface of the NdFeB rare earth permanent magnet of the present embodiment is carried out according to the following steps:

[0060] (1) Surface pretreatment of NdFeB rare earth permanent magnets:

[0061] Sand blast the surface of the NdFeB rare earth permanent magnet with a size of 40mm×20mm×3mm. Use a spray gun to spray fine sand with a particle size of 400~1000 mesh on the surface of the NdFeB rare earth permanent magnet to remove the oxide layer on the surface of the magnet. until the off-white fresh surface is exposed;

[0062] (2) NdFeB rare earth permanent magnet vacuum treatment:

[0063] Put the surface-pretreated NdFeB rare earth permanent magnet into a sealed tank, the inside of the sealed tank is covered with PTFE coating, the top of the sealed tank is a sealed tank cover, and the sealed tank cover is connected with a vacuum tube and an electroplating solution inlet tube , there are valves on the...

Embodiment 3

[0067] The preparation method of the electroplating coating on the surface of the NdFeB rare earth permanent magnet of the present embodiment is carried out according to the following steps:

[0068] (1) Surface pretreatment of NdFeB rare earth permanent magnets:

[0069] Sand blast the surface of the NdFeB rare earth permanent magnet with a size of 20mm×20mm×10mm. Use a spray gun to spray fine sand with a particle size of 400~1000 mesh on the surface of the NdFeB rare earth permanent magnet to remove the oxide layer on the surface of the magnet. until the off-white fresh surface is exposed;

[0070] (2) NdFeB rare earth permanent magnet vacuum treatment:

[0071] Put the surface-pretreated NdFeB rare earth permanent magnet into a sealed tank, the inside of the sealed tank is covered with PTFE coating, the top of the sealed tank is a sealed tank cover, and the sealed tank cover is connected with a vacuum tube and an electroplating solution inlet tube , there are valves on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com