A method for preparing battery-grade iron phosphate using chloride salt as a medium

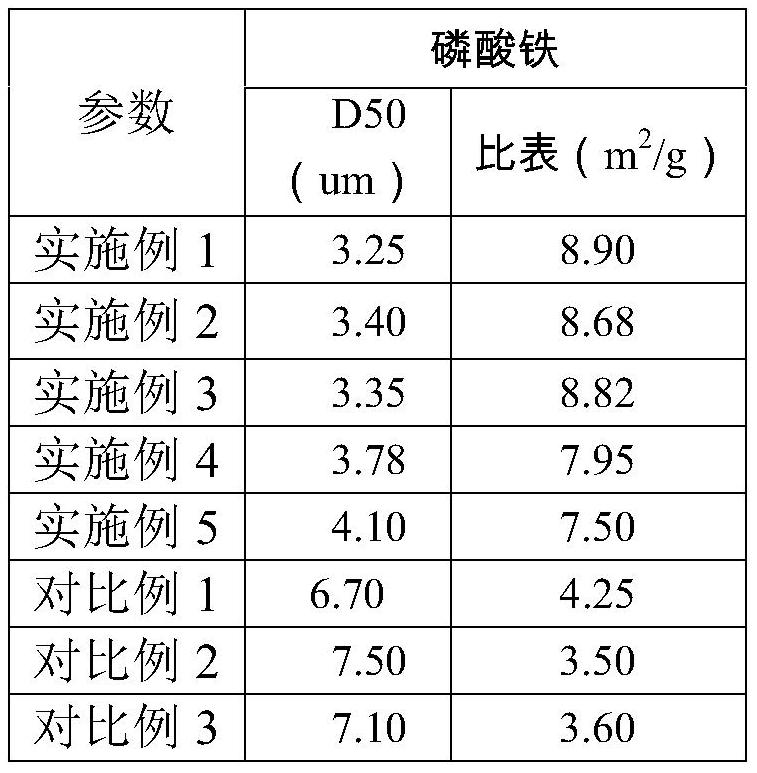

A technology of iron phosphate and chloride salt, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problems of poor performance of iron phosphate, low ion utilization rate, etc., to improve the effect of impurity removal, high purity, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

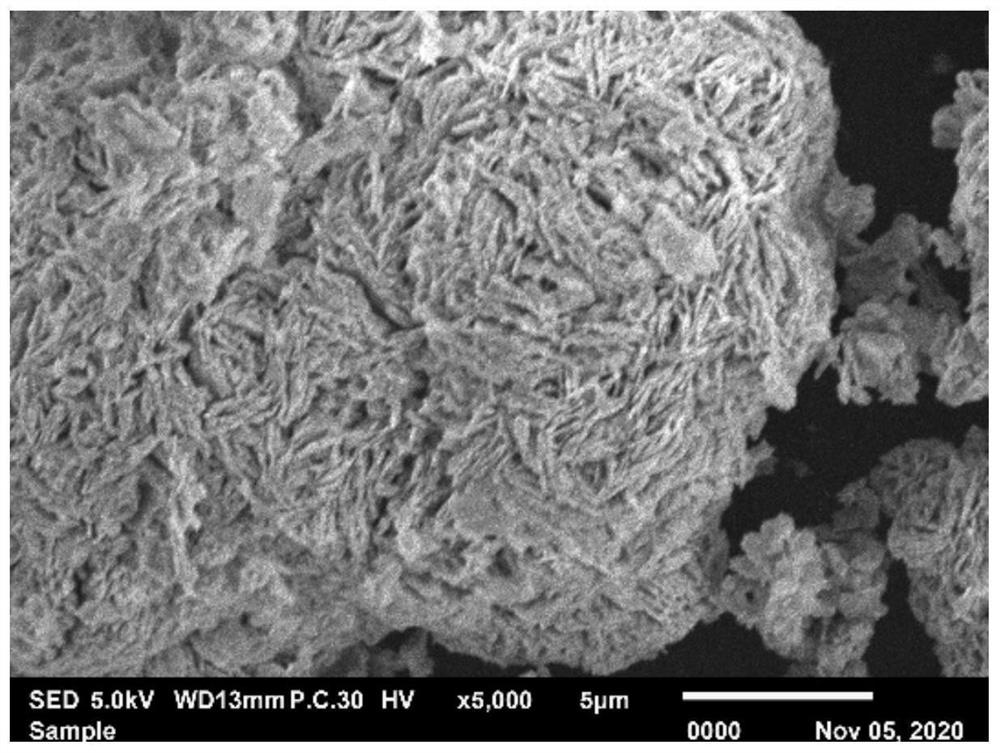

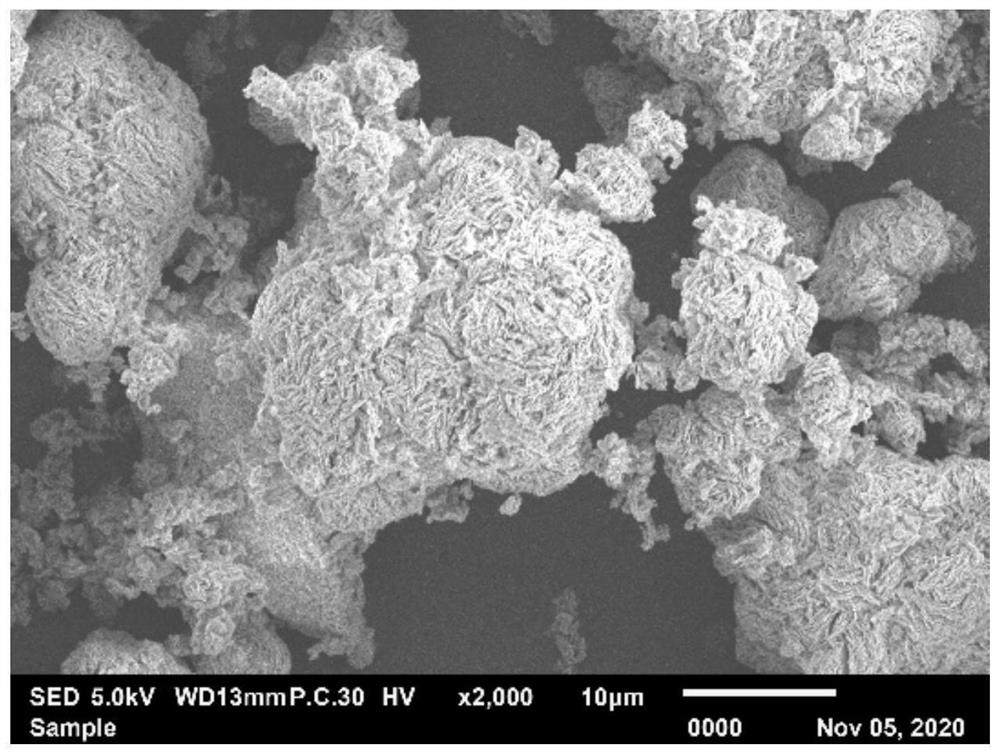

[0043] like figure 1 and figure 2 Shown, a kind of method for preparing battery-grade iron phosphate with chloride salt as medium, comprises the following steps:

[0044] S1: Take 2 mol of ferrous sulfate crystals, a by-product of titanium dioxide, add 1 L of water to dissolve, heat the reaction in a water bath at 70°C, add sodium hydroxide solution and 0.04 mol of phosphoric acid solution, adjust the pH to 2.0, react for 0.5h and then filter Washing obtains ferrous sulfate purification liquid;

[0045] S2: Add 3.0 mol of hydrogen peroxide to the ferrous sulfate purification solution for oxidation, then add a mixed solution of 2.4 mol of phosphoric acid and 2.5 mol of sodium chloride, and set the volume to 1.8 L to obtain a pre-reaction solution;

[0046] S3: Heat the pre-reaction solution at 150°C, during which deionized water is fed at a constant speed to maintain the iron ion concentration at 3.5mol / L, and the reaction time is 5h. After the heating is completed, deionize...

Embodiment 2

[0049] A method for preparing battery-grade iron phosphate using chloride as a medium, comprising the following steps:

[0050] S1: Take 2 mol of ferrous sulfate crystals, a by-product of titanium dioxide, add 1.33 L of water to dissolve, heat the reaction in a water bath at 85°C, add sodium hydroxide solution and 0.05 mol of phosphoric acid solution, adjust the pH to 1.8, and react for 1.0 h Filter and wash to obtain ferrous sulfate purification solution;

[0051] S2: Add 2.5 mol of hydrogen peroxide to the ferrous sulfate purification solution for oxidation, then add a mixed solution of 2.0 mol of phosphoric acid and 2.1 mol of potassium chloride, and set the volume to 1.1 L to obtain a pre-reaction solution;

[0052] S3: Heat the pre-reaction solution at 100°C, during which deionized water is fed at a constant speed to maintain the iron ion concentration at 4.0mol / L, and the reaction time is 4h. After the heating is completed, deionized water is fed at a constant speed, and...

Embodiment 3

[0055] A method for preparing battery-grade iron phosphate using chloride as a medium, comprising the following steps:

[0056] S1: Take 2 mol of ferrous sulfate crystals, a by-product of titanium dioxide, add 1.20 L of water to dissolve, heat the reaction in a water bath at 60°C, add sodium hydroxide solution and 0.043 mol of phosphoric acid solution, adjust the pH to 1.9, and react for 1.0 h Filter and wash to obtain ferrous sulfate purification solution;

[0057] S2: Add 2.7 mol of hydrogen peroxide to the ferrous sulfate purification solution for oxidation, then add a mixed solution of 2.2 mol of phosphoric acid and 2.2 mol of lithium chloride, and set the volume to 1.5 L to obtain a pre-reaction solution;

[0058] S3: Heat the pre-reaction solution at 140°C, during which deionized water is fed at a constant speed to maintain the iron ion concentration at 2.5mol / L, and the reaction time is 6h. After the heating is completed, deionized water is fed at a constant speed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com