A preparation method of electroplating coating on the surface of NdFeB rare earth permanent magnet

A rare-earth permanent magnet and electroplating coating technology, which is applied in the manufacture of permanent magnets, inductors/transformers/magnets, circuits, etc., can solve the problems of coating failure, swelling, foaming, and restricting applications, so as to increase the bonding area, Uniform current density and improved binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of the electroplated coating on the surface of the neodymium iron boron rare earth permanent magnet of this embodiment is carried out according to the following steps:

[0052] (1) Surface pretreatment of NdFeB rare earth permanent magnets:

[0053] Sandblast the surface of the neodymium iron boron rare earth permanent magnet with a size of 30mm×30mm×3mm, and use a spray gun to spray the fine sand with a particle size of 400-1000 mesh on the surface of the neodymium iron boron rare earth permanent magnet to remove the oxide layer on the surface of the magnet. Until the fresh white surface is exposed;

[0054] (2) Vacuum treatment of neodymium iron boron rare earth permanent magnets:

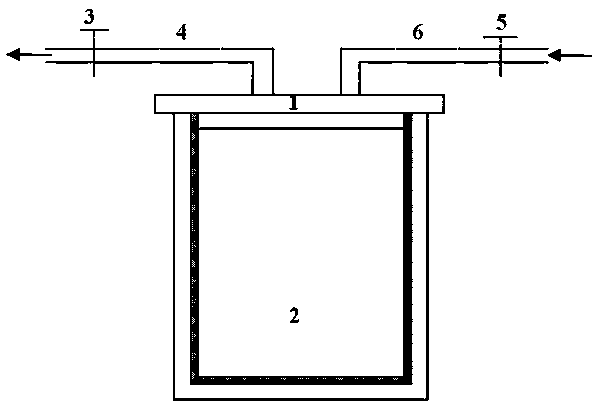

[0055] Put the neodymium iron boron rare earth permanent magnet with the surface pretreatment into a sealed tank, the inside of the sealed tank is covered with PTFE coating, the top of the sealed tank is a sealed tank cover, and the vacuum tube and the electroplating solutio...

Embodiment 2

[0059] The preparation method of the electroplated coating on the surface of the neodymium iron boron rare earth permanent magnet of this embodiment is carried out according to the following steps:

[0060] (1) Surface pretreatment of NdFeB rare earth permanent magnets:

[0061] Sandblast the surface of the NdFeB rare earth permanent magnet with a size of 40mm×20mm×3mm, and use a spray gun to spray fine sand with a particle size of 400~1000 onto the surface of the NdFeB rare earth permanent magnet to remove the oxide layer on the surface of the magnet. Until the fresh white surface is exposed;

[0062] (2) Vacuum treatment of neodymium iron boron rare earth permanent magnets:

[0063] Put the neodymium iron boron rare earth permanent magnet with the surface pretreatment into a sealed tank, the inside of the sealed tank is covered with PTFE coating, the top of the sealed tank is a sealed tank cover, and the vacuum tube and the electroplating solution inlet pipe are connected to the sea...

Embodiment 3

[0067] The preparation method of the electroplated coating on the surface of the neodymium iron boron rare earth permanent magnet of this embodiment is carried out according to the following steps:

[0068] (1) Surface pretreatment of NdFeB rare earth permanent magnets:

[0069] Sandblast the surface of the NdFeB rare earth permanent magnet with a size of 20mm×20mm×10mm, and use a spray gun to spray fine sand with a particle size of 400~1000 onto the surface of the NdFeB rare earth permanent magnet to remove the oxide layer on the surface of the magnet. Until the fresh gray surface is exposed;

[0070] (2) Vacuum treatment of neodymium iron boron rare earth permanent magnets:

[0071] Put the neodymium iron boron rare earth permanent magnet with the surface pretreatment into a sealed tank, the inside of the sealed tank is covered with PTFE coating, the top of the sealed tank is a sealed tank lid, and the vacuum tube and electroplating solution inlet pipe are connected to the sealed ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com