A method and system for separating excess sulfur in the production process of carbon disulfide

A carbon disulfide, production process technology, applied in the direction of carbon disulfide, carbon sulfur compounds, etc., can solve the problems of carbon disulfide loss, high consumption of public works, complicated operation, etc., and achieve the effects of avoiding energy waste, ensuring efficient removal, and ensuring high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

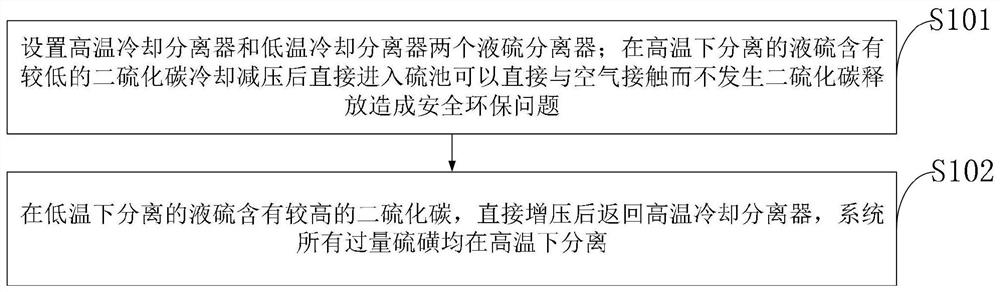

[0049] The high-temperature mixed raw material gas from the carbon disulfide reactor contains carbon disulfide, hydrogen sulfide, excess sulfur, etc., firstly mixed with the low-temperature cooling separator and the material returned from the separation tower, and then passed through the high-temperature cooling separator. After the liquid sulfur is separated at ~1.2MPa, it is directly sent to the sulfur pool after cooling down and depressurizing. The uncooled non-condensable gas is sent to the low-temperature cooling separator to continue cooling the excess liquid sulfur at 120-200°C, and the liquid material obtained after cooling and separation is pressurized and sent to the high-temperature cooling separator together with the raw material gas from the reactor . The uncooled non-condensable gas is sent to the rectification tower to separate carbon disulfide and hydrogen sulfide.

[0050] The operating pressure of the high-temperature cooling separator is 0.6MPa, and the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com