Ceramic body grouting molding method

A ceramic body and grouting technology, applied in the field of ceramic manufacturing, can solve the problems of mold leakage, fast sizing speed, and the pipeline air is too late to be completely emptied, and achieves the effect of eliminating slurry leakage and reducing all emptying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

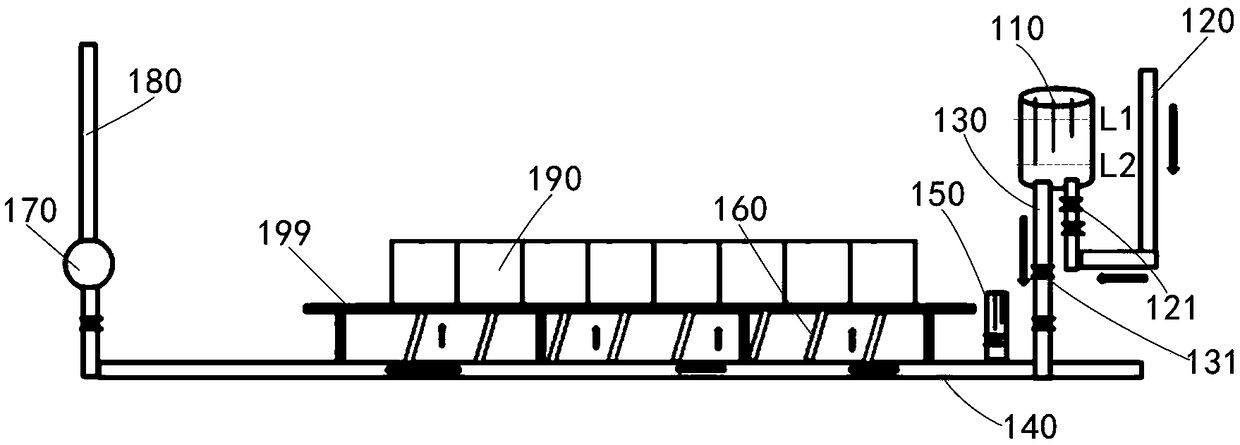

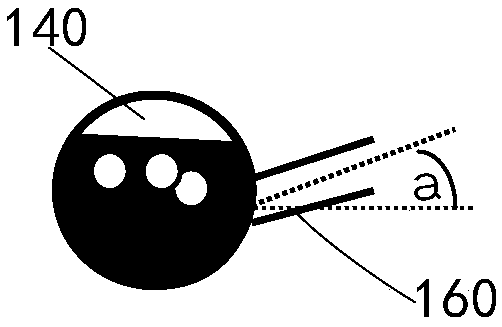

[0024] Such as Figure 1-3 Shown, a kind of ceramic green body grouting molding method comprises:

[0025] 1. Grouting: Open the grouting pipe 120, inject mud into the grouting barrel 110 connected to the atmosphere, until the mud in the grouting barrel 110 rises to the first liquid level L1, close the grouting pipe, and perform grouting .

[0026] 2. Grouting: Open the grouting pipe 130, inject the slurry into the grouting pipe 140 until the mud in the grouting barrel 110 drops to the second liquid level L2, close the grouting pipe 130, and return to the grouting step.

[0027] Three, mud injection molding preparation:

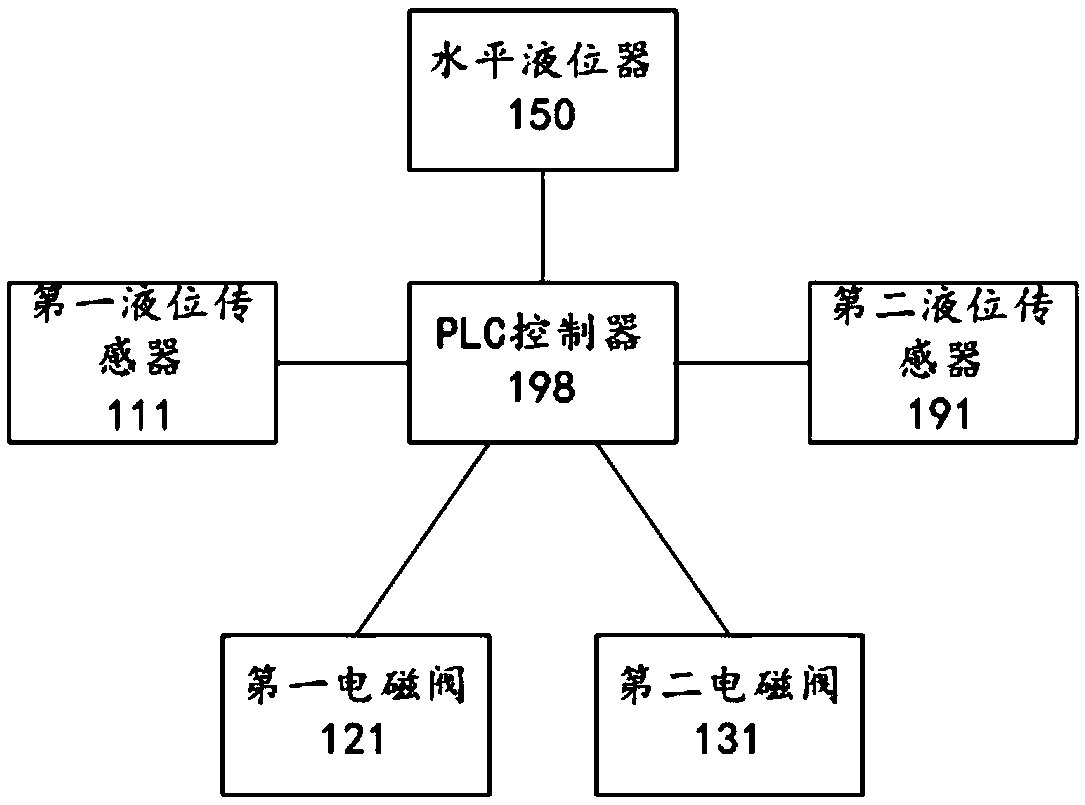

[0028] (1) During the pulping process, when the liquid level in the horizontal liquid level device 150 on the pulping pipe 140 reaches the preset liquid level, close the pulping pipe and perform step (2);

[0029] Wherein, the preset liquid level is flush with the liquid inlet of the mold 190 .

[0030] (2) After the liquid levels of the horizontal liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com