Slurry returning method

A container and an old technology, applied in the field of ceramic manufacturing, can solve the problems of unstable performance, uncontrollable mixing ratio of returned slurry, insufficient homogenization time of old slurry, etc., to achieve the effect of eliminating slurry leakage and reducing all emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

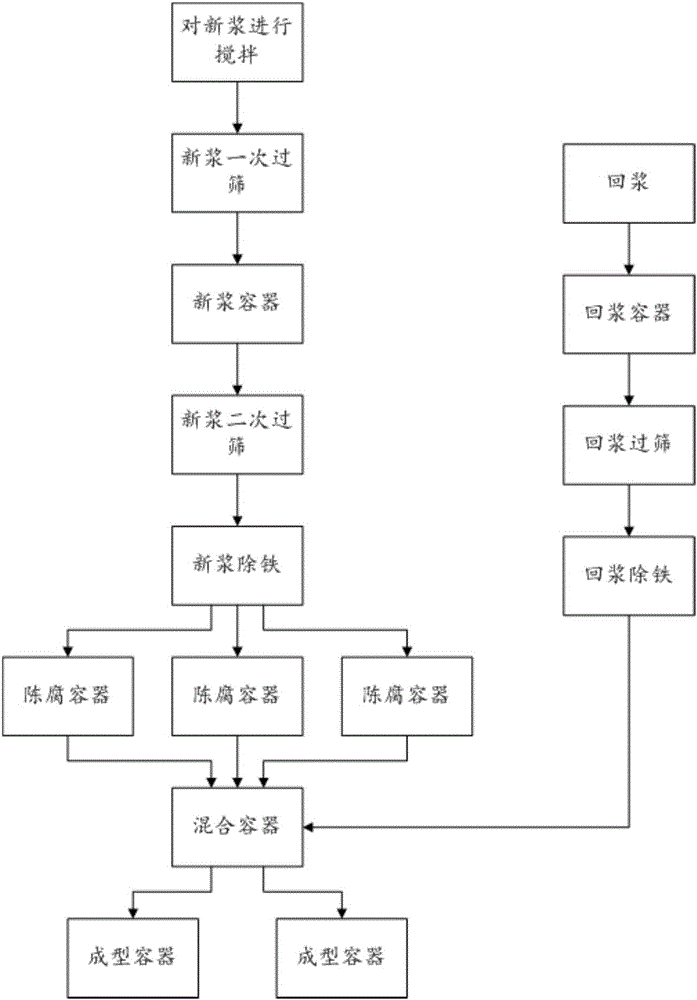

[0036] A method of resizing, comprising:

[0037] 1. Stir the new pulp.

[0038] 2. After passing through the vibrating screen with mesh 20, the new pulp after stirring is sieved once, and then poured into the new pulp container.

[0039] 3. The new pulp in the fresh pulp container is screened for the second time through a vibrating screen with a mesh size of 120.

[0040] 4. After the new pulp has been sieved for the second time by the electromagnetic separator, the new pulp is deironed, and then poured into three old containers.

[0041] 5. The new pulp is stale for 5 days in three stale containers.

[0042] 6. Pour the return slurry into the return slurry container.

[0043] 7. Pass through a vibrating screen with a mesh size of 120 to sieve the returned pulp in the returned pulp container.

[0044] 8. Use the electromagnetic separator to return the slurry after the slurry has been sieved and remove the iron, and mix it with the stale new slurry in the mixing container....

Embodiment 2

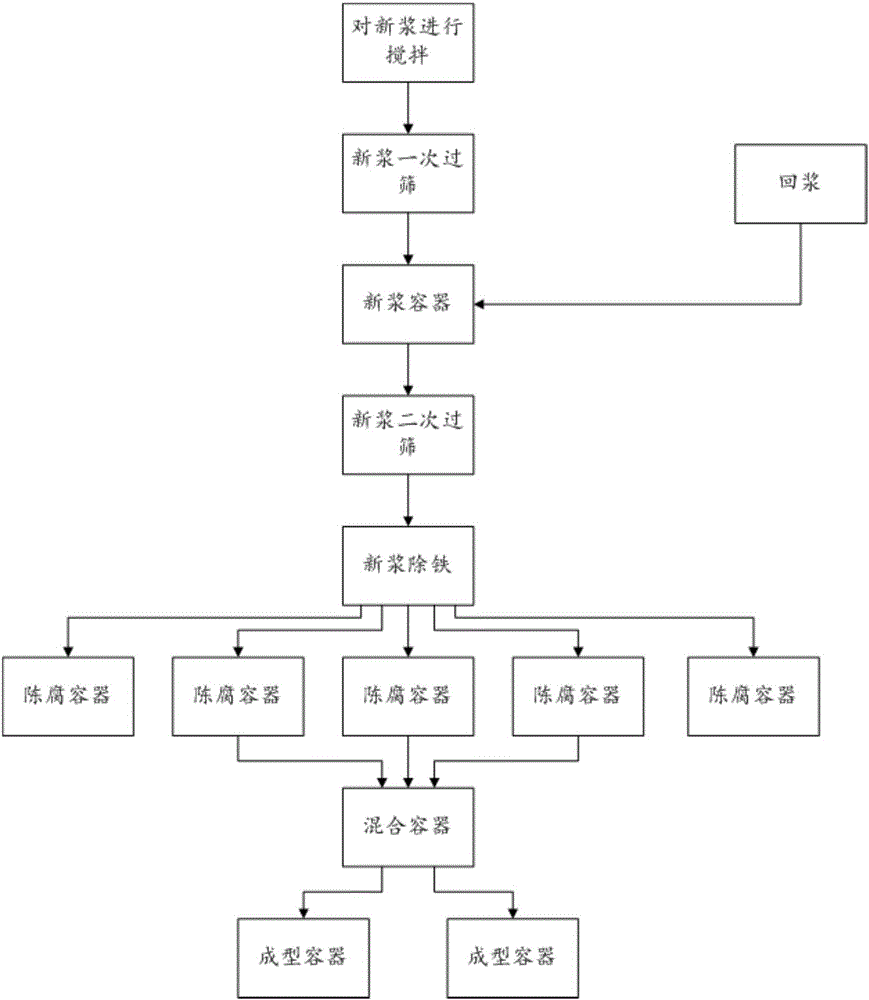

[0047] A method of resizing, comprising:

[0048] 1. Stir the new pulp.

[0049] 2. After passing through the vibrating screen with mesh 20, the new pulp after stirring is sieved once, and then poured into the new pulp container.

[0050] 3. The new pulp in the fresh pulp container is screened twice through a vibrating screen with a mesh size of 140.

[0051] 4. After the new pulp has been sieved for the second time by the electromagnetic separator, the new pulp is deironed, and then poured into three old containers.

[0052] 5. The new pulp is stale in three old containers for 8 days.

[0053] 6. Pour the return slurry into the return slurry container.

[0054] 7. Pass through a vibrating screen with a mesh size of 140 to sieve the returned pulp in the returned pulp container.

[0055] 8. Use an electromagnetic separator to return the slurry after the return slurry has been sieved to remove iron, and stir and mix with the stale new slurry in the mixing container. The stir...

Embodiment 3

[0058] A method of resizing, comprising:

[0059] 1. Stir the new pulp.

[0060] 2. After passing through the vibrating screen with mesh 20, the new pulp after stirring is sieved once, and then poured into the new pulp container.

[0061] 3. The new pulp in the fresh pulp container is screened twice through a vibrating screen with a mesh size of 130.

[0062] 4. After the new pulp has been sieved for the second time by the electromagnetic separator, the new pulp is deironed, and then poured into three old containers.

[0063] 5. The new pulp is stale in three old containers for 6 days.

[0064] 6. Pour the return slurry into the return slurry container.

[0065] 7. Pass through a vibrating screen with a mesh size of 130 to sieve the returned pulp in the returned pulp container.

[0066] 8. Use the electromagnetic separator to return the slurry after the return slurry has been sieved and remove the iron, and then stir and mix with the stale new slurry in the mixing containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com