Oil tank for hand tool machine and hand tool machine with oil tank

A hand-held power tool and oil tank technology, which is applied to the oil tank field of chain saws, can solve the problems of increasing the number of parts and the susceptibility to failure, and achieve the effects of reducing the number of parts, reducing costs, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

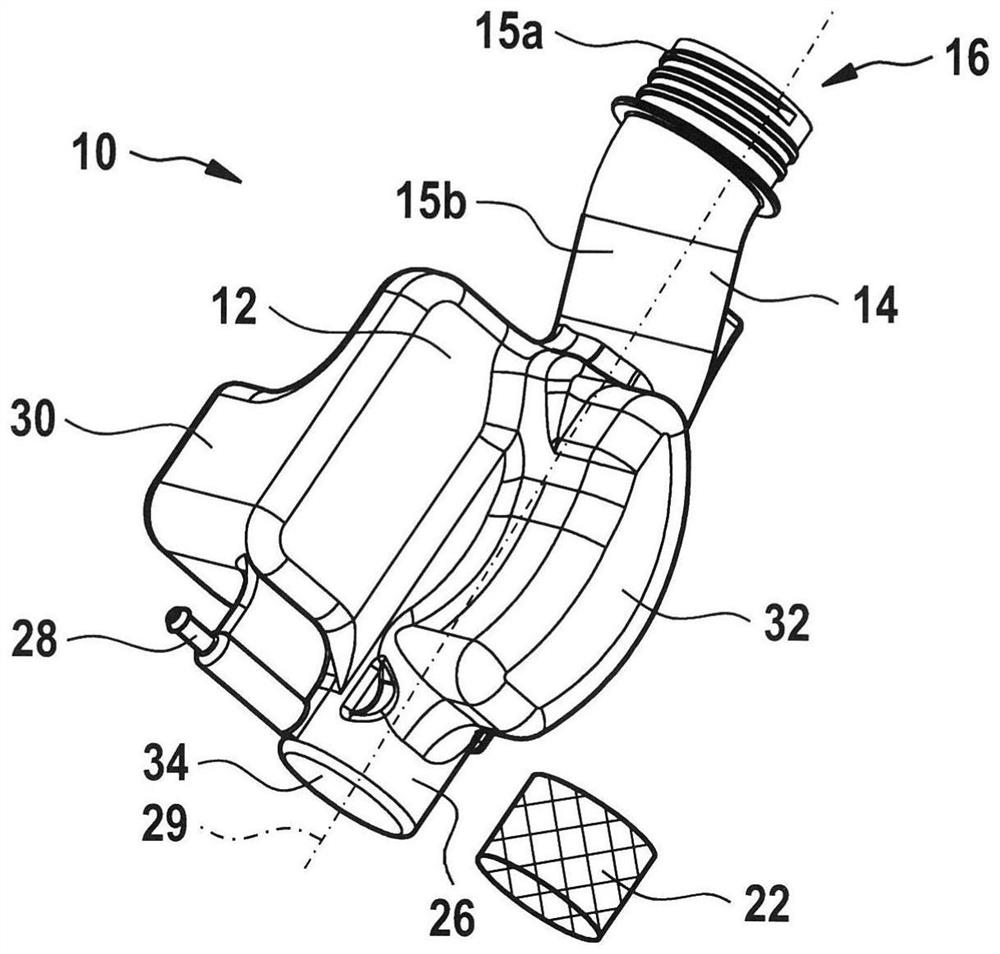

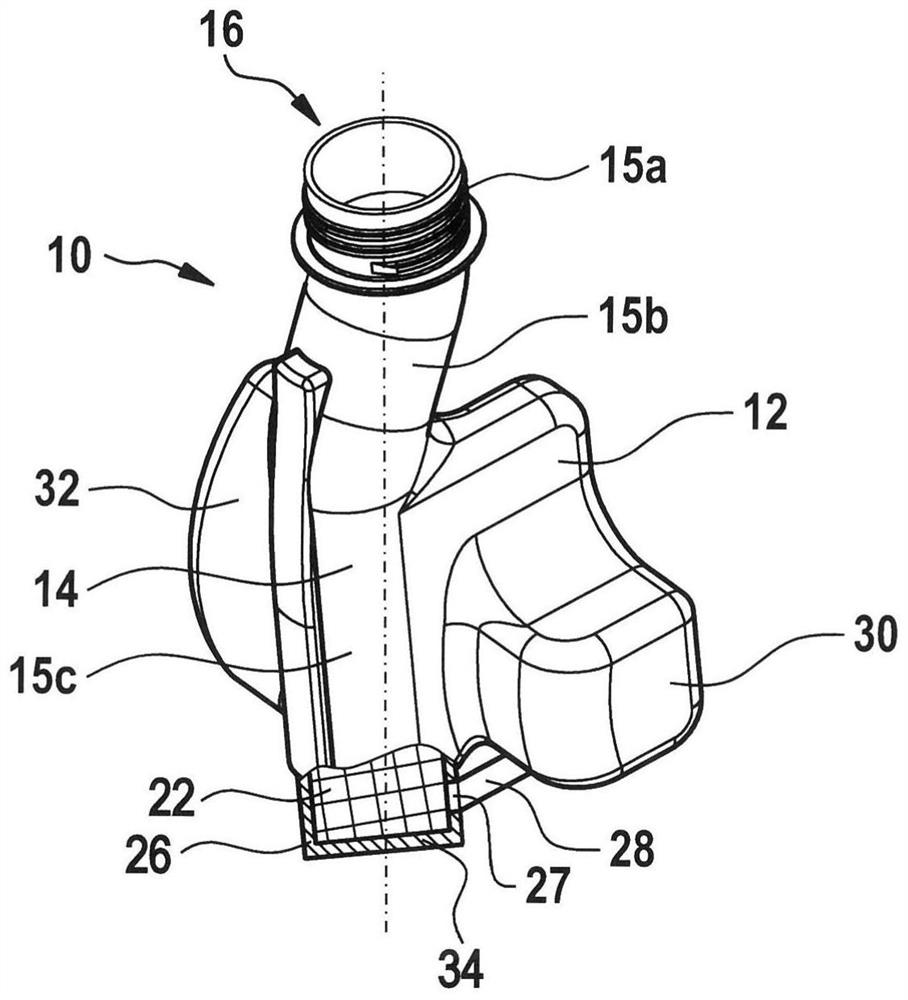

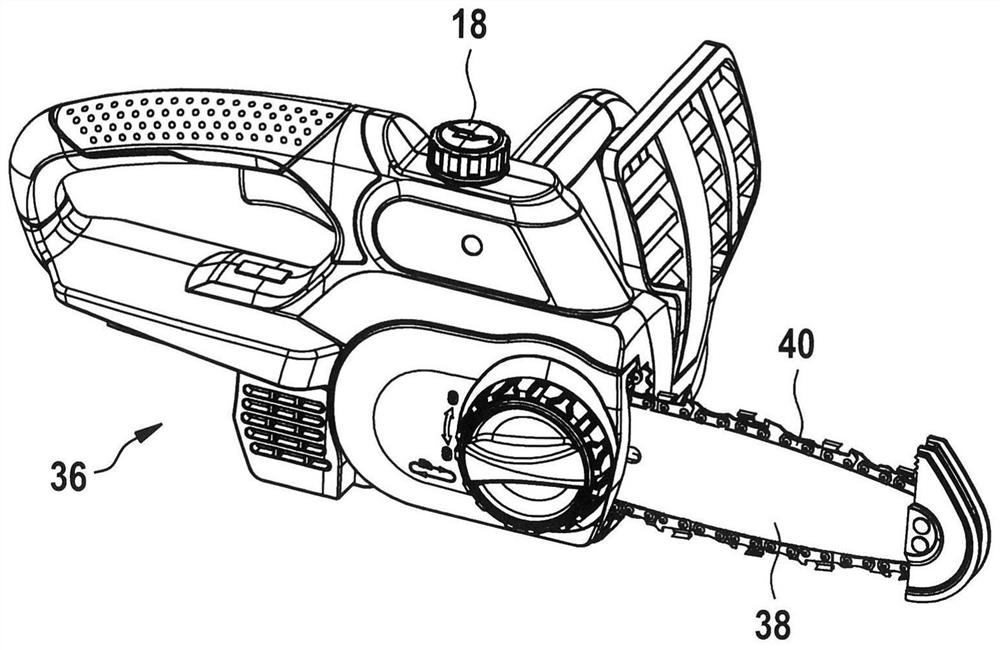

[0028] figure 1 and 2 The tank 10 is shown in each case in a perspective view. The tank 10 has a tank housing 12 and a filling connection 14 with a filling opening 16 . The filling opening 16 can be closed with a cap 18 (see image 3 ) closed. Alternatively, other closure means are also conceivable. In this case, the filling socket 14 can be configured cylindrically, but it can also have another shape or geometry, such as polygonal, funnel-shaped or the like.

[0029] filter 22 in figure 1 shown separately next to the tank housing 12 and in figure 2Shown in the sectioned area in , the filter can be introduced into the oil tank via the filling connection 14 . The filter 22 is provided for arrangement on the bottom 34 of the tank housing 12 . It can be fixed in the filter receptacle 26 . The filter 22 is formed from a porous, permeable material, especially elastic foam or sponge. Furthermore, the filter 22 is configured cylindrically. In principle, however, the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com