Ceramic forming slurry and high-pressure forming method

A high-pressure forming and high-pressure forming machine technology, applied in the field of ceramic manufacturing, can solve the problems of low mud viscosity, prominent stratification, insufficient permeability, etc., and achieve the effect of reducing all emptying and eliminating slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

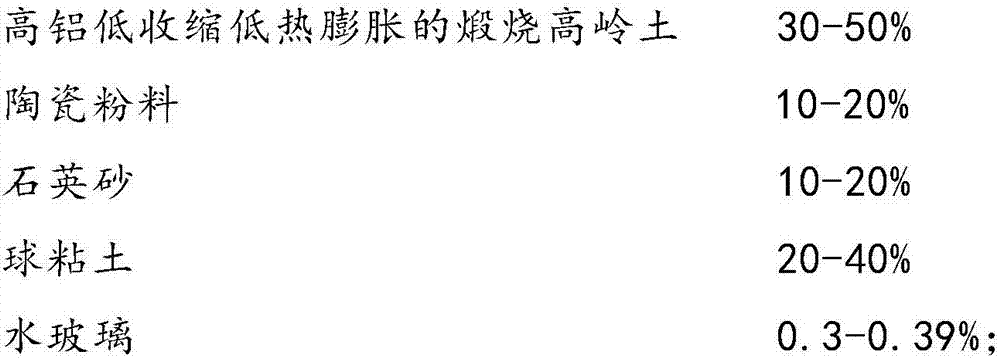

[0125] 1. Pulping: Mix 76% of raw materials by weight with 24% of water, and grind them into a slurry through a ball of aluminum balls. The ratio of the three materials to balls is: 1:1.1:0.2. The weight percentage is:

[0126]

[0127] The molar ratio of water glass is 1.5.

[0128] 2. Stale: The stale time is 3 days, and the stirring speed is 12 rpm.

[0129] 3. Molding:

[0130] One day before injection into the high-pressure molding machine, the mud needs to be heated to 42°C by means of external circulation heating;

[0131] Inject the slurry into the high pressure molding machine;

[0132] After the mud is injected into the high-pressure molding machine, the mud pressure is controlled at 1Mpa and continuously pressurized for 2000 seconds;

[0133] After the pressurization, the mud discharge starts, the mud discharge pressure is 0.25Mpa, and the mud discharge time is 30 seconds;

[0134] After the mud discharge is completed, it enters the consolidation stage, the ...

Embodiment 2

[0141] 1. Pulping: mix 80% of raw materials by weight with 20% of water, and grind them into slurry through alumina balls. The material-to-ball ratio of the three is: 1:1.2:0.25. The weight percentage is:

[0142]

[0143] The molar ratio of water glass is 3.5.

[0144] 2. Stale: The stale time is 7 days, and the stirring speed is 12 rpm.

[0145] 3. Molding:

[0146] One day before injection into the high-pressure molding machine, the mud needs to be heated to 47°C by means of external circulation heating;

[0147] Inject the slurry into the high pressure molding machine;

[0148] After the mud is injected into the high-pressure molding machine, the mud pressure is controlled at 1.1Mpa and continuously pressurized for 1500 seconds;

[0149] After the pressurization, the mud discharge starts, the mud discharge pressure is 0.15Mpa, and the mud discharge time is 60 seconds;

[0150] After the mud discharge is completed, it enters the consolidation stage, the consolidatio...

Embodiment 3

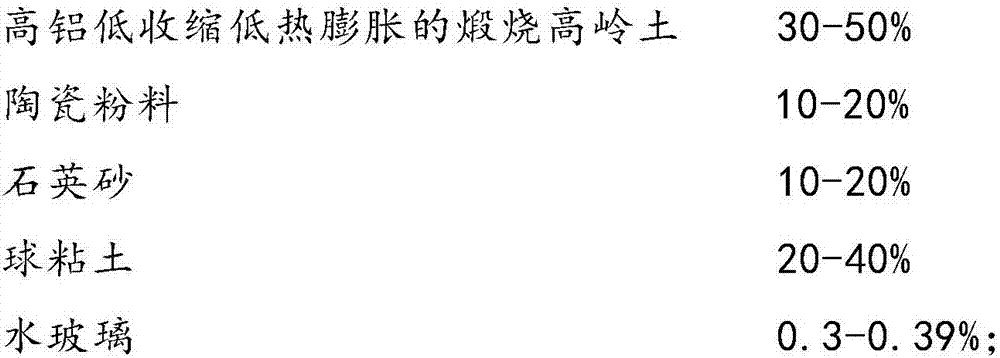

[0157] 1. Pulping: Mix 78% of raw materials by weight with 22% of water, and grind them into a slurry through a ball of aluminum balls. The material-ball ratio of the three is: 1:1.15:0.225. The weight percentage is:

[0158]

[0159] The molar ratio of water glass is 2.5.

[0160] 2. Stale: The stale time is 5 days, and the stirring speed is 12 rpm.

[0161] 3. Molding:

[0162] One day before injection into the high-pressure molding machine, the mud needs to be heated to 45°C by means of external circulation heating;

[0163] Inject the slurry into the high pressure molding machine;

[0164] After the mud is injected into the high-pressure molding machine, the mud pressure is controlled at 1.15Mpa and continuously pressurized for 1700 seconds;

[0165] After the pressurization, the mud discharge starts, the mud discharge pressure is 0.2Mpa, and the mud discharge time is 45 seconds;

[0166] After the mud discharge is completed, it enters the consolidation stage, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com