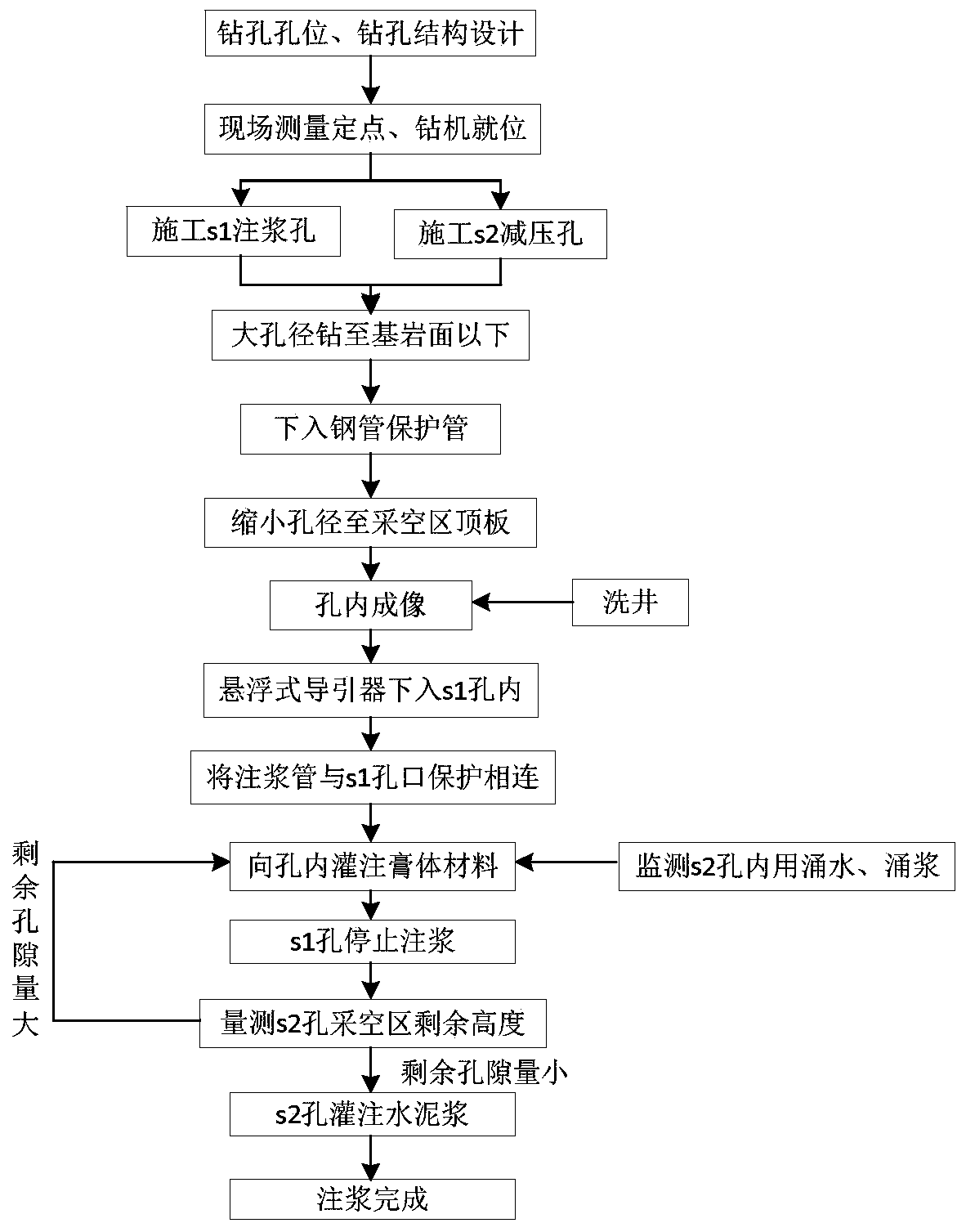

Suspension type guiding device and construction method for paste filling of underwater goaf

A paste filling and construction method technology, which is applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve the problems of easy decomposition, segregation, inability to meet the control of goaf, and unsuitable for blocking pipes, etc., so as to improve the grouting construction. quality, solving the problem of slurry segregation, and the effect of large application depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

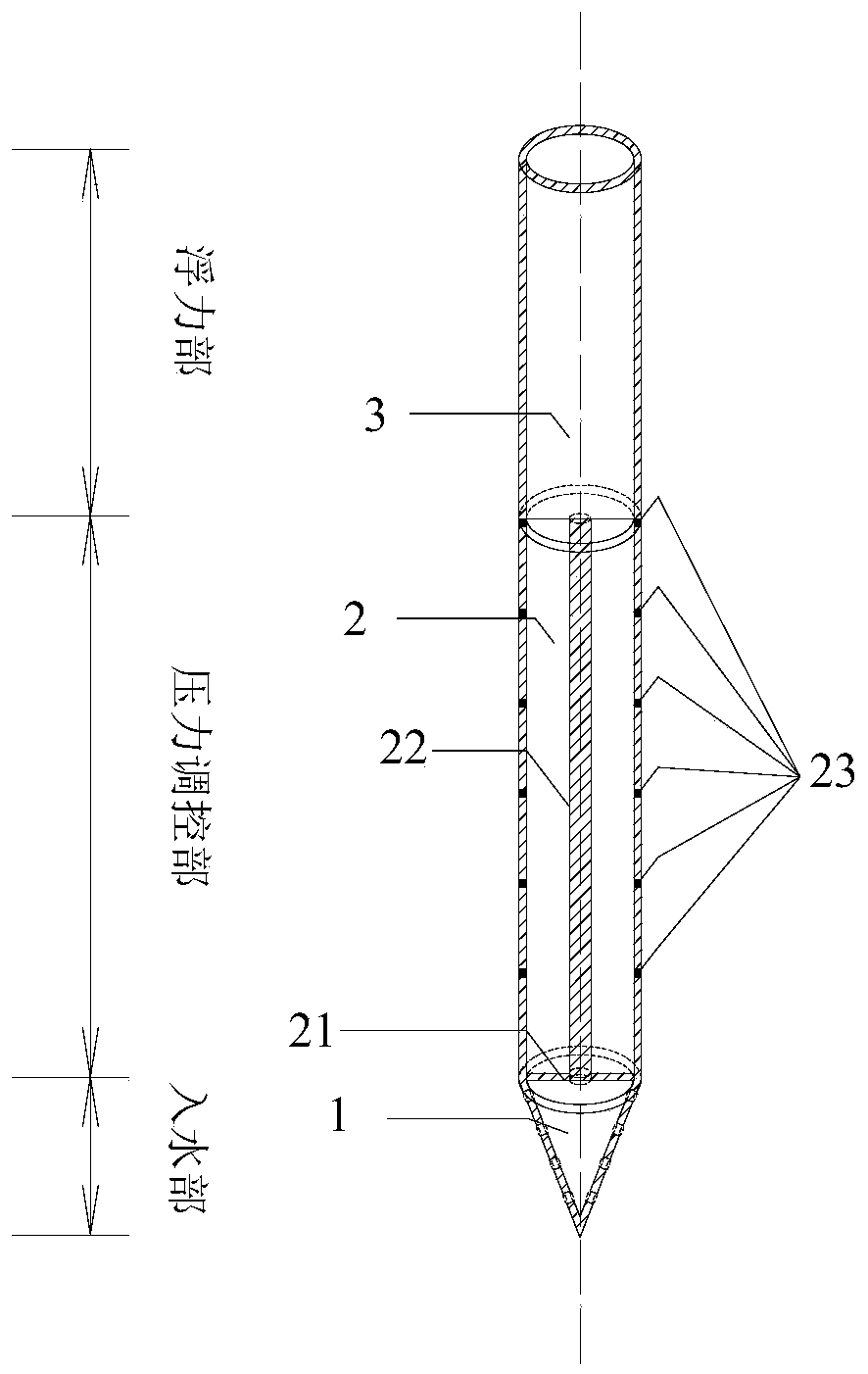

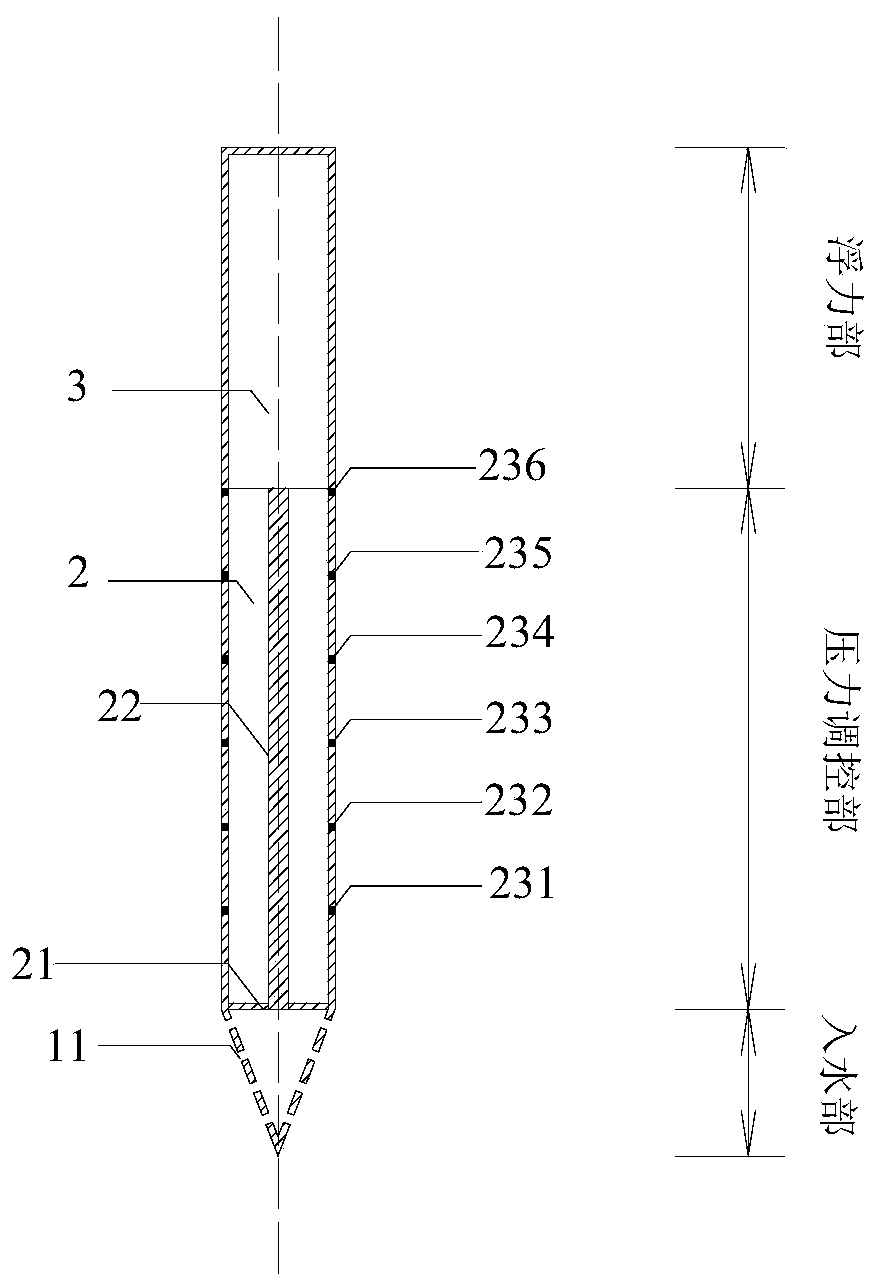

[0050] reference figure 1 , figure 2 As shown, a specific embodiment of the present application provides a suspension guide for filling the underwater goaf with paste, which is divided into a buoyancy part 3, a pressure control part 2, and a water inlet part from top to bottom. 1 There are three parts.

[0051] The water inlet 1 is hollow inside and is arranged at the foremost end of the suspension guide. Its shape is set to a cone. A water inlet 11 is provided on the cone. There are multiple groups of water inlets 11 on the wall of the cone. The holes respectively include a plurality of water inlet holes distributed in an annular array, the plurality of water inlet holes are located at the same height, and the ground water in the holes can enter the guide through the water inlet holes.

[0052] The buoyancy part 3 is located at the end of the suspension guide. The buoyancy part 3 is a hollow closed structure. Its function is to make the buoyancy of the suspension guide greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com