Application of Chang'e steel in preparation of valve guide pipe or multi-step complex structural member, valve guide pipe, multi-step complex structural member and preparation of valve guide pipe and multi-step complex structural member

A technology of valve guides and complex structures, which is applied to mechanical equipment, engine components, lift valves, etc., and can solve problems such as uneven density, complex shapes of structural parts, and multiple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the present invention, there is no special limitation on the preparation process of the Chang'e steel, and it is enough to adopt the process well known to those skilled in the art and obtain the alloy with the above-mentioned composition ratio.

[0047] In the present invention, the Chang'e steel has high strength and toughness, high energy absorption, low magnetism and corrosion resistance.

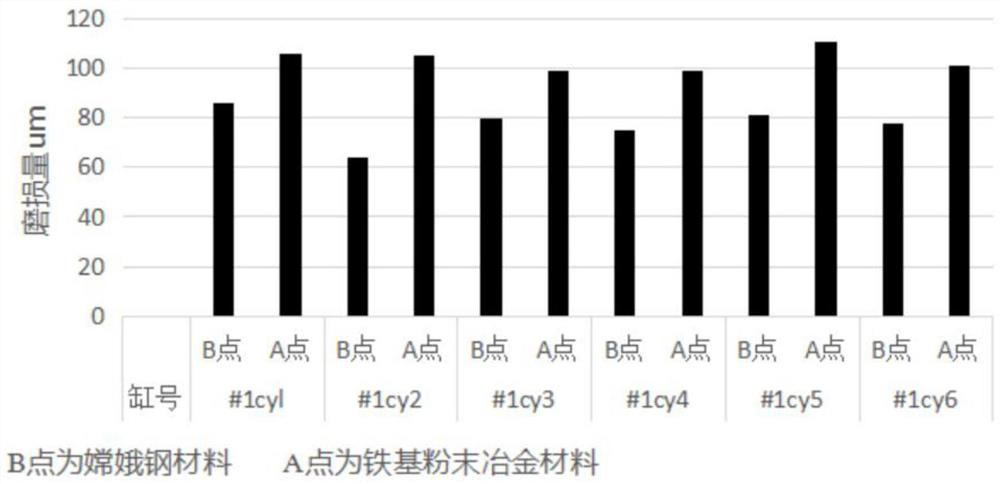

[0048] In the present invention, the elongation after fracture of the Chang'e steel is 70-110%, the yield strength is 250-800MPa, and the tensile strength is 550-1350MPa (when the tensile strength is 550MPa, the elongation after fracture is ≥70%; When the tensile strength is 1350MPa, the elongation after fracture is ≥10%), the low-cycle fatigue life is 80 times that of iron-based powder, and the material flow rate is > s / 80g (the flow rate of traditional powder metallurgy materials is > s / 50g);

[0049]The strong-plastic product (the product of tensile strength and elongation a...

Embodiment 1

[0110] Chang'e steel: C 1.2%, Cu 35%, Cr 8.7%, Mo 11.5%, Co 15.3%, Ni 3.8%, V18.50%, W4.8% and Mn 1.2%;

[0111] 25% Chang'e steel powder, 1.4% graphite powder, 1% copper powder, 2.2% molybdenum powder, 1.2% nickel powder, 2.4% ferromanganese powder (the mass ratio of manganese and iron is 4:100) and 64.8% iron-based powder Mix; obtain alloy powder;

[0112] Spray 2.0% high-temperature lubricant (P11 release agent and zinc stearate with a mass ratio of 1:1) in the alloy powder by high-pressure spraying to obtain valve guide precursor powder;

[0113] The valve guide precursor powder is sequentially hydroformed (temperature is 140°C, pressure is 62KN, time is 4s, and the compacted density after forming is 7.3-7.5g / cm 3 ), to obtain molded parts;

[0114] The molded parts obtained after the warm pressing molding are placed in a sintering mold for vertical push rod sintering: protective atmosphere: the flow rate of ammonia decomposition gas is 8Nm 3 , the nitrogen flow rate is...

Embodiment 2

[0117] Chang'e Steel: C 1.5%, Cu 37%, Cr 8.8%, Mo 12.2%, Co 15.8%, Ni 3.7%, V 16%, W3.5%, Mn 1.5%;

[0118] 25% Chang'e steel powder, 1.4% graphite powder, 1.0% copper powder, 2.2% molybdenum powder, 1.2% nickel powder, 2.4% ferromanganese powder (the mass ratio of manganese and iron is 4:100) and 64.8% iron-based powder Mix;; Obtain alloy powder;

[0119] Spray 2.0% high-temperature lubricant (P11 release agent and zinc stearate with a mass ratio of 1:1) in the alloy powder by high-pressure spraying to obtain valve guide precursor powder;

[0120] The valve guide precursor powder is sequentially hydroformed (the temperature is 135°C, the pressure is 63KN, the time is 4s, and the compacted density after forming is 7.3-7.5g / cm 3 ) to obtain molded parts;

[0121] The molded part obtained after the hydroforming is placed in a sintering mold for vertical push rod sintering: protective atmosphere: the flow rate of ammonia decomposition gas is 8Nm 3 , the nitrogen flow rate is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com