Construction Technology of Filling and Grouting in the Back Annulus of Gas Shaft Wall

A technology for vertical shaft and gas, which is applied in the field of grouting construction technology for the rear annulus of gas vertical shaft wall, can solve the problem of high engineering cost, and achieve the effects of reducing construction cost, shortening construction period and widening the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

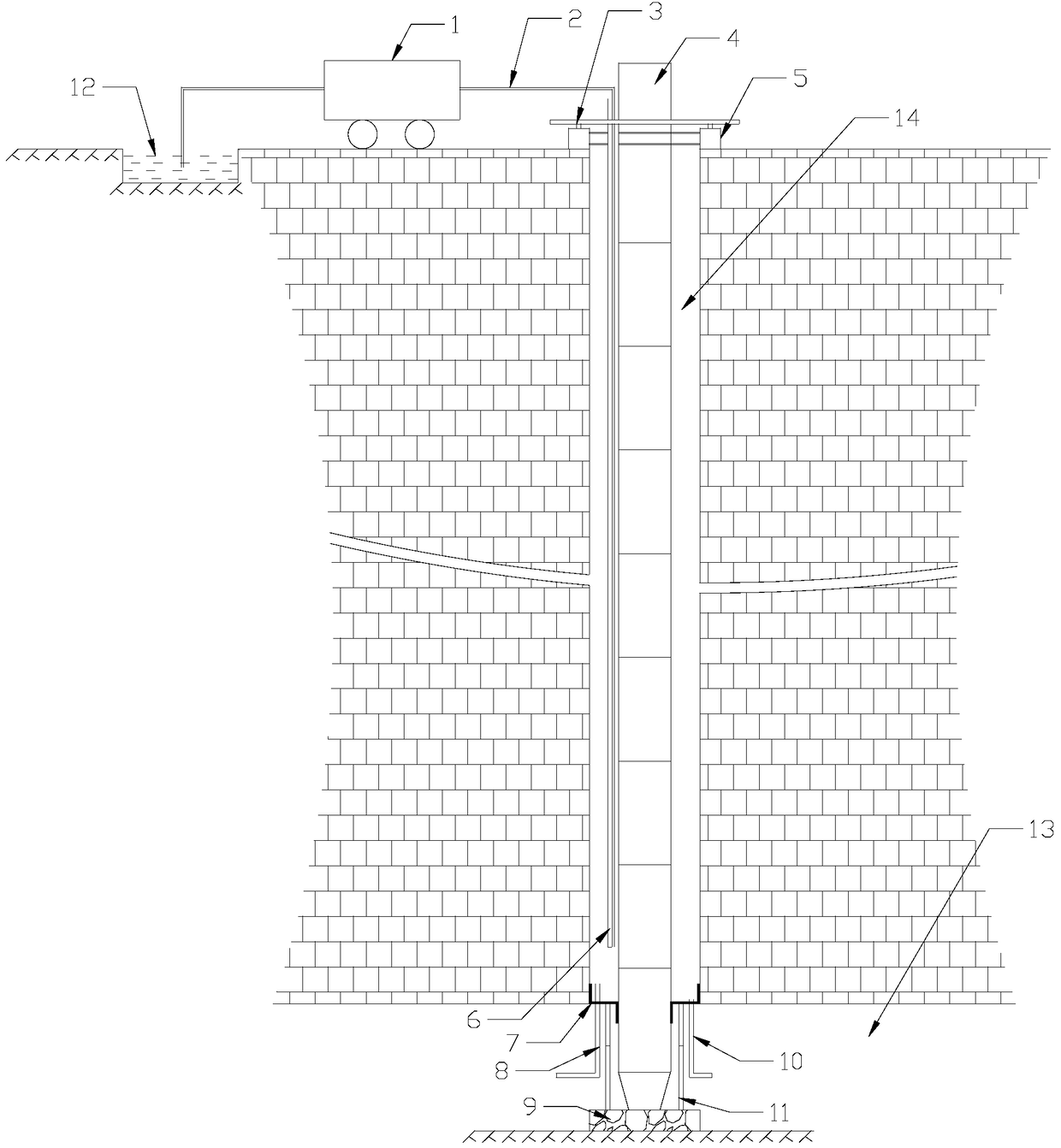

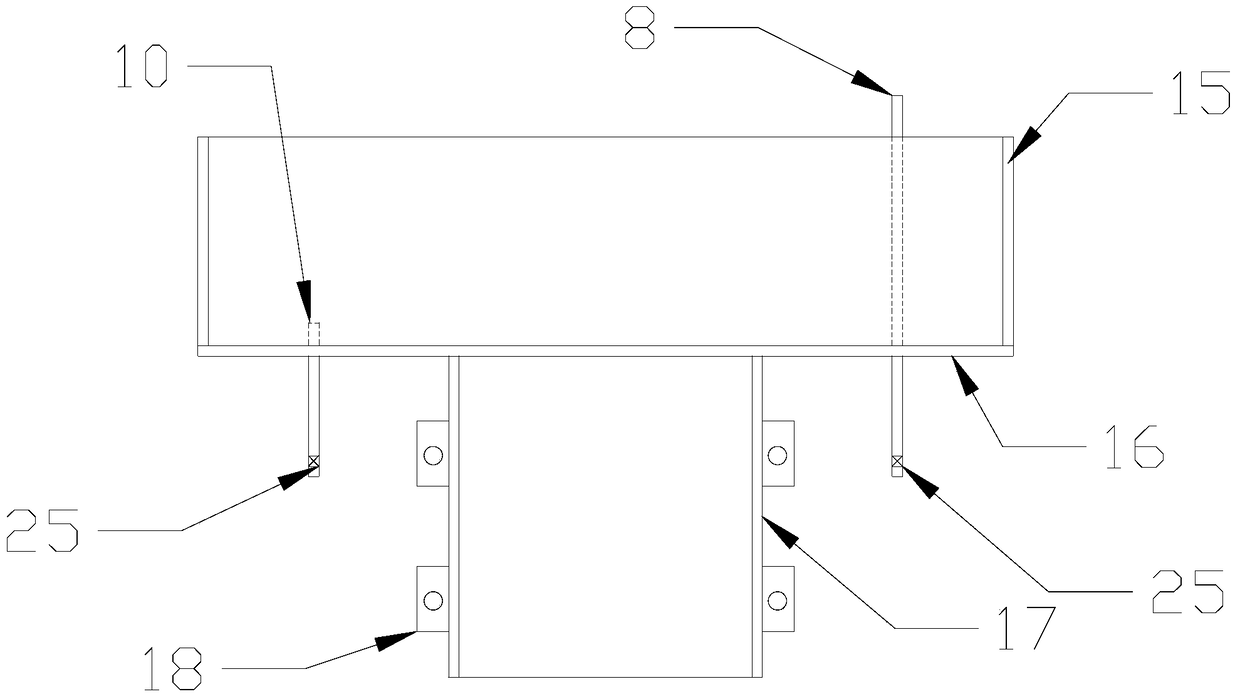

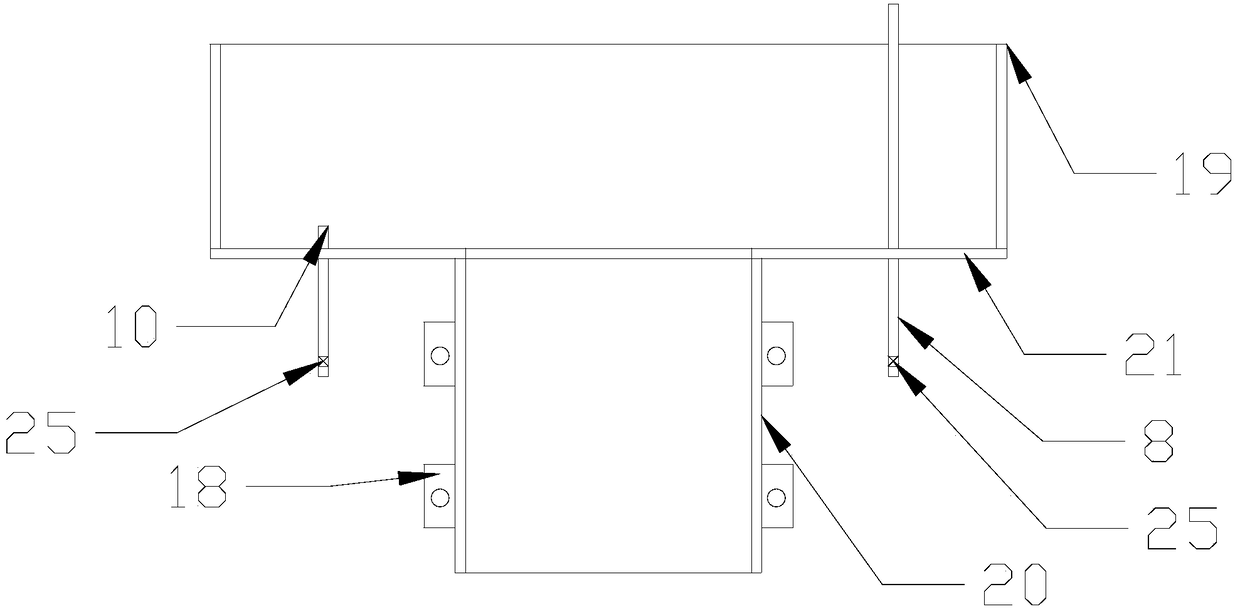

[0032] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0033] Such as figure 1 As shown, this embodiment takes the gas drainage well of Shihao Mine of Chongqing Songzao Coal and Electricity Company as an example. The construction process of filling and grouting the annulus behind the gas shaft wall of the gas drainage shaft includes the following steps:

[0034] (A) Raise drilling rig drilling method is used to expand the wellbore into a wellbore with a diameter of 1.65 meters and a depth of 305.33 meters. The water inflow of the open hole rock formation in the wellbore is abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com