Transfer tool of forklift

A technology for transfer workers and forklifts, applied in the direction of lifting devices, etc., can solve the problems of inconvenient transportation, unsteady placement, large size, etc., and achieve the effect of smooth and convenient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

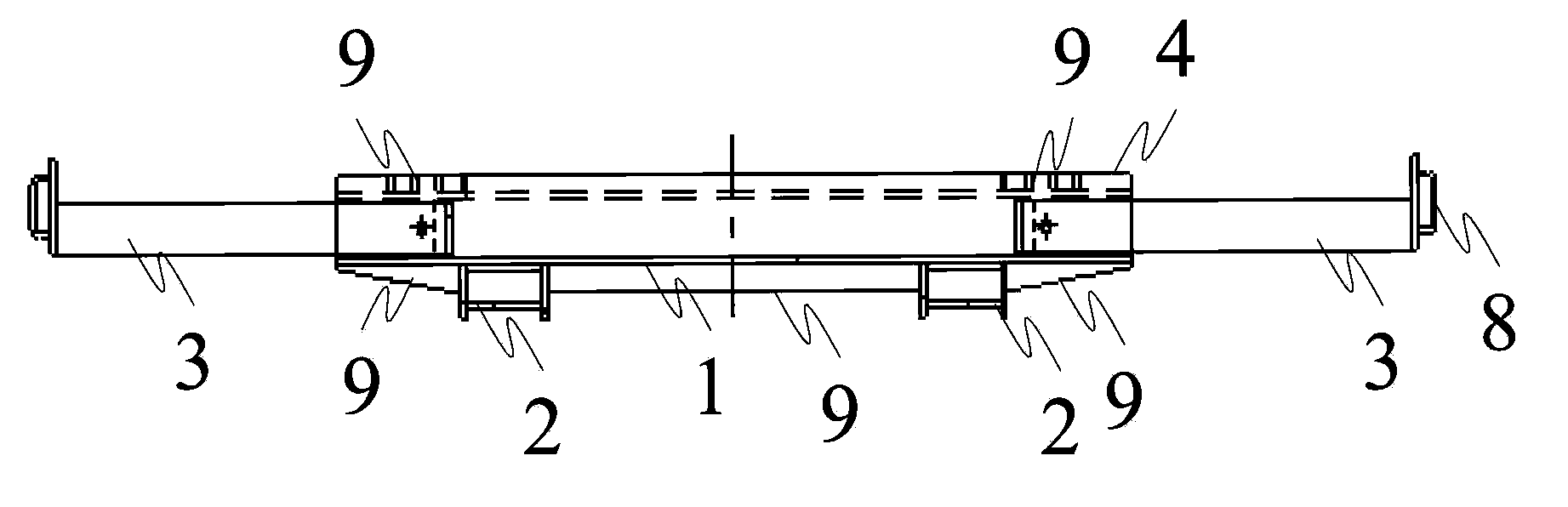

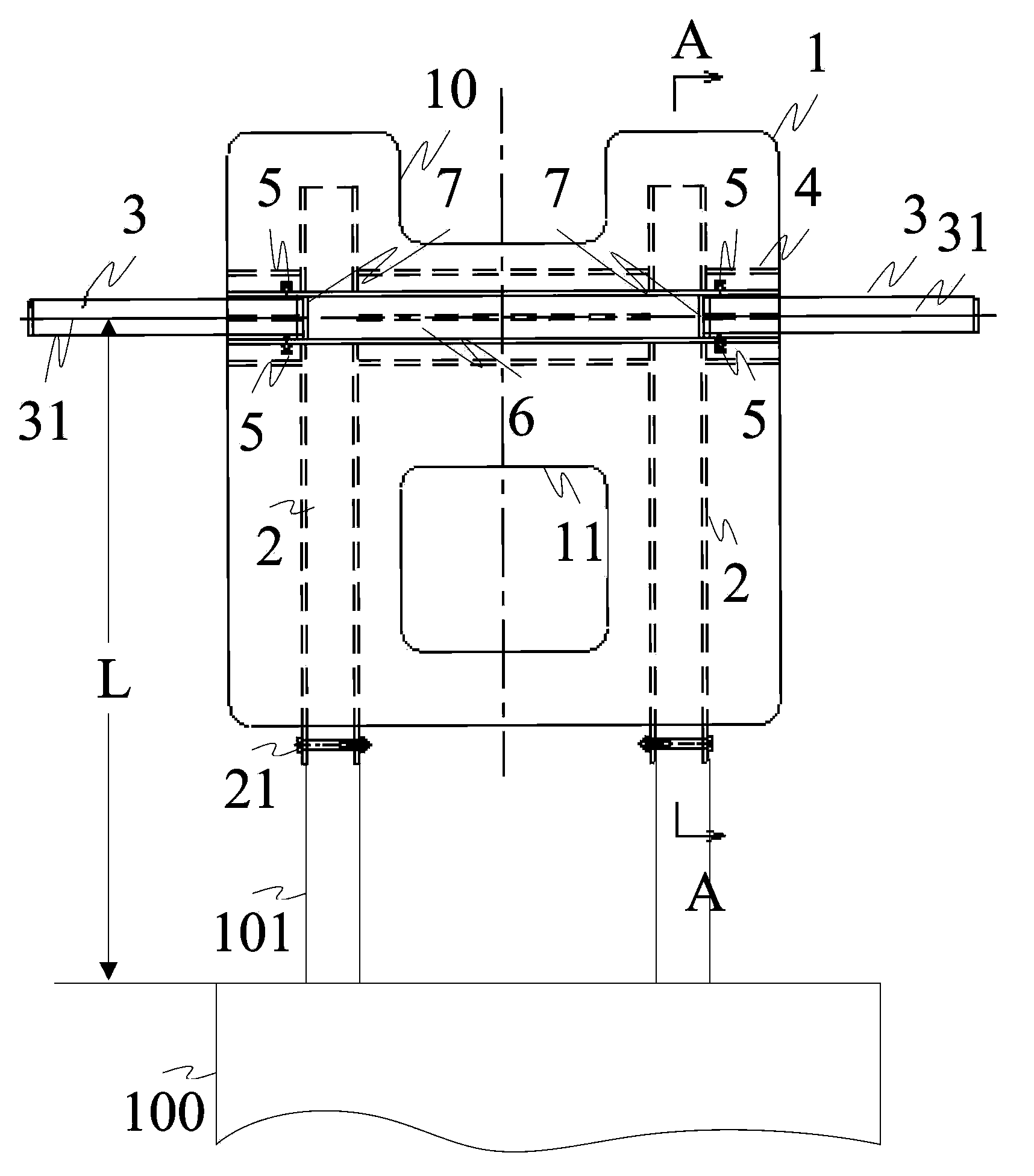

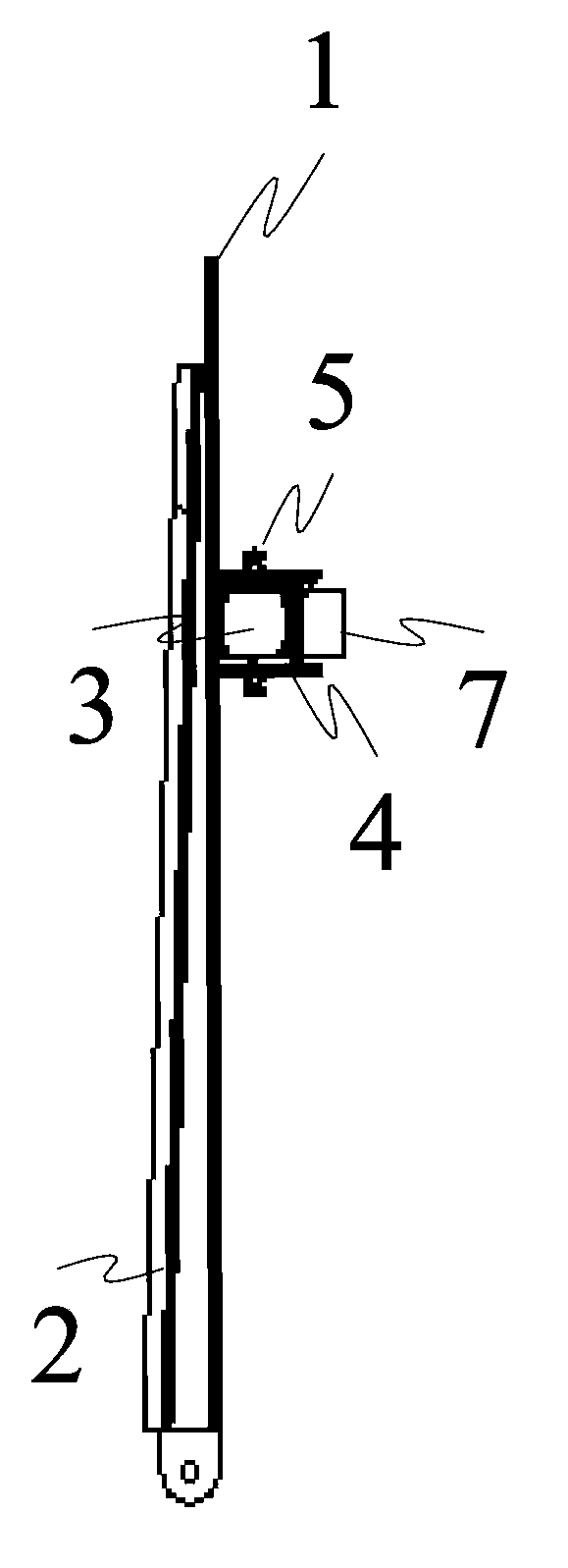

[0009] Such as Figure 1-3 As shown, the embodiment of the present invention provides a forklift transfer tool, which has a pallet 1 composed of a flat plate and whose width is smaller than the distance between the two front windows of the driver's cab steel structure; two longitudinal support beams arranged in parallel are fixed on the surface of the pallet 1 2 and two cantilevers 3 that can expand and contract in the transverse direction; one end of the two cantilever arms 3 is fixed to the pallet, and the other ends are respectively overhanging to the outside of the pallet; The bolt assembly 21 blocks the tail of the front fork, so that the tooling and the forklift are integrated, and prevent the tooling from being separated from the forklift during transportation. The two longitudinal support beams 2 and the two cantilever arms 3 can be located on the same side of the tray 1; the two longitudinal support beams can also be located on one side of the tray, and the two cantil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com