Patents

Literature

46results about How to "Not easy to derail" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

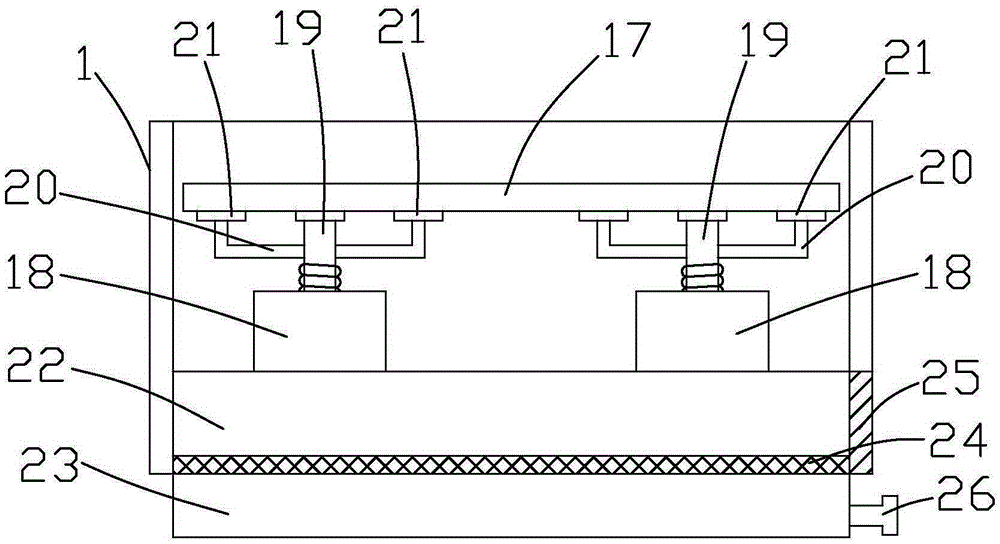

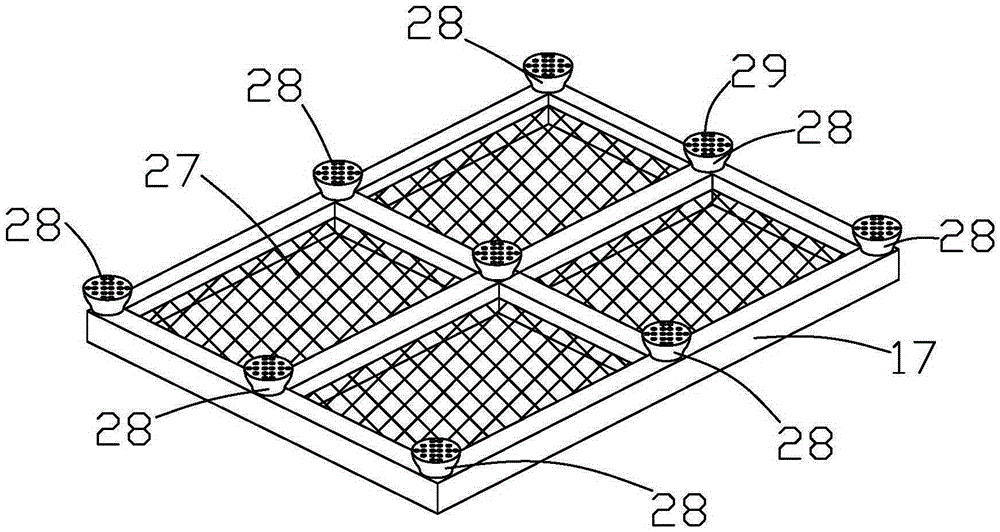

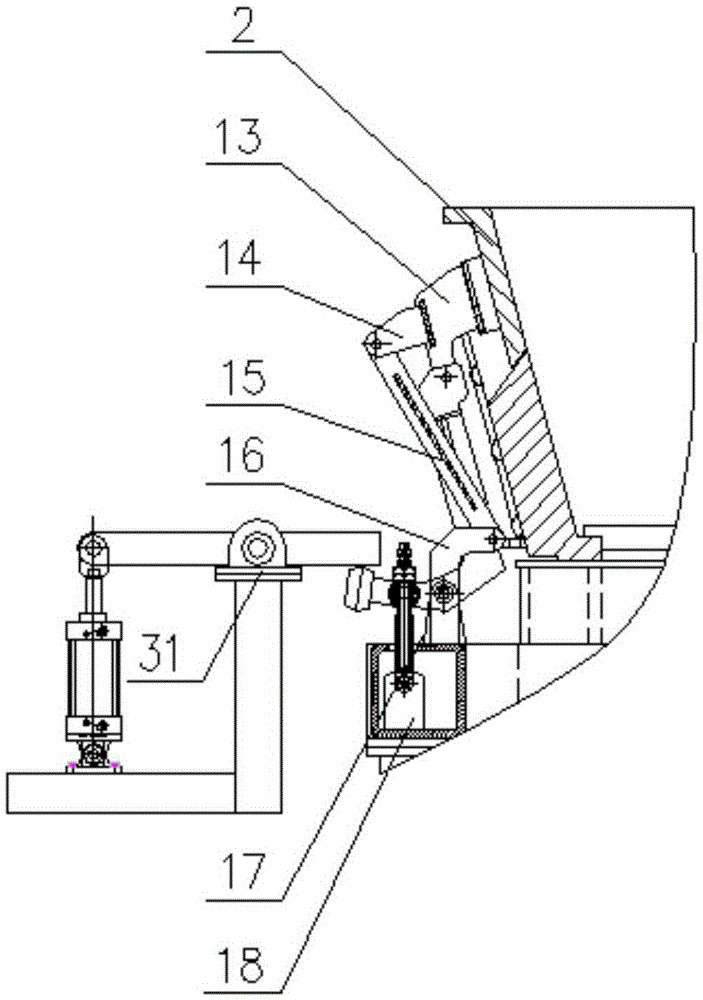

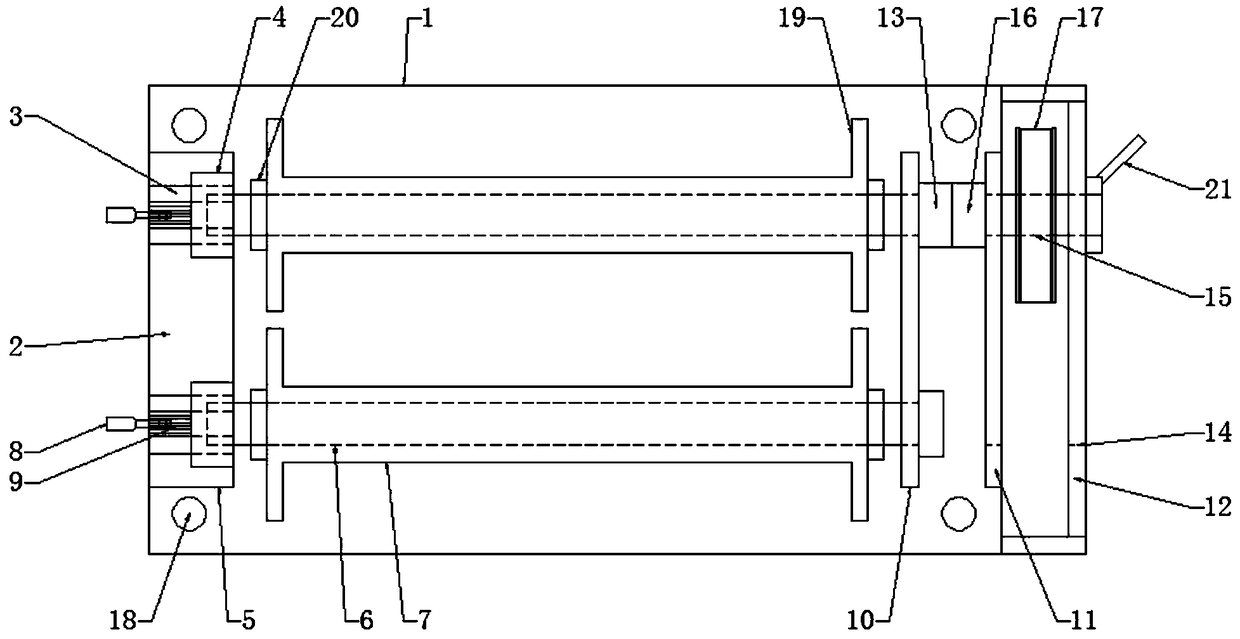

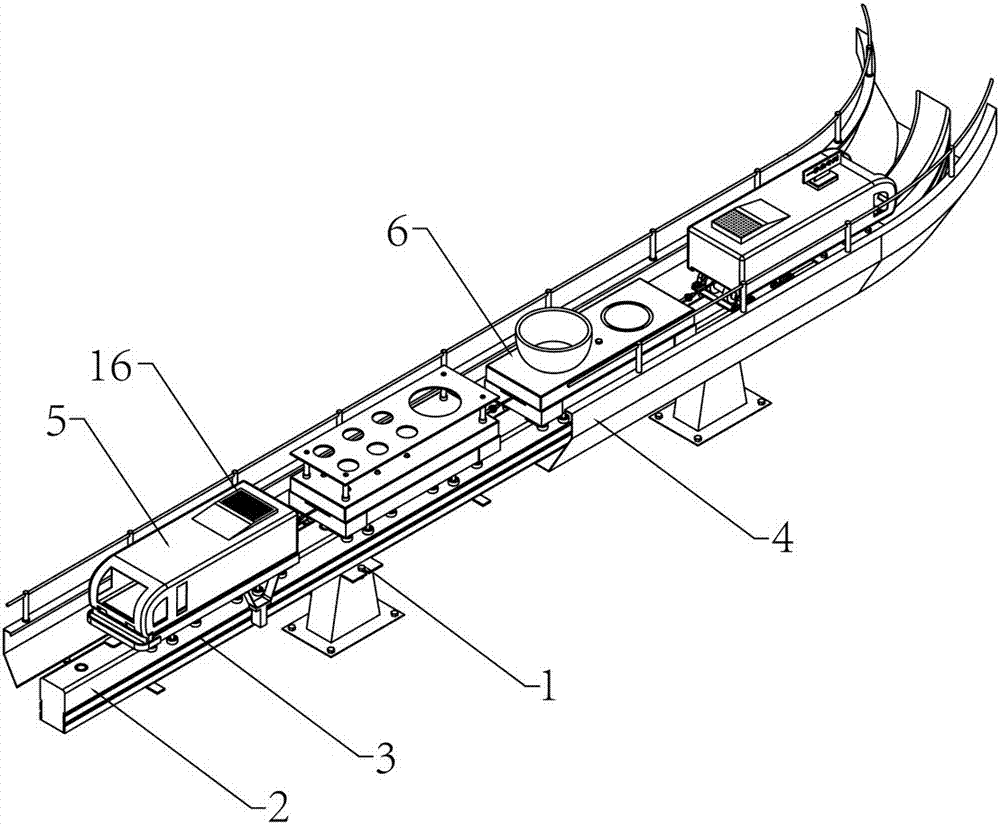

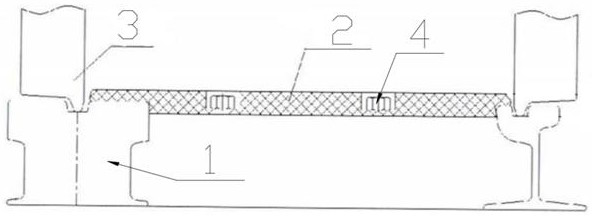

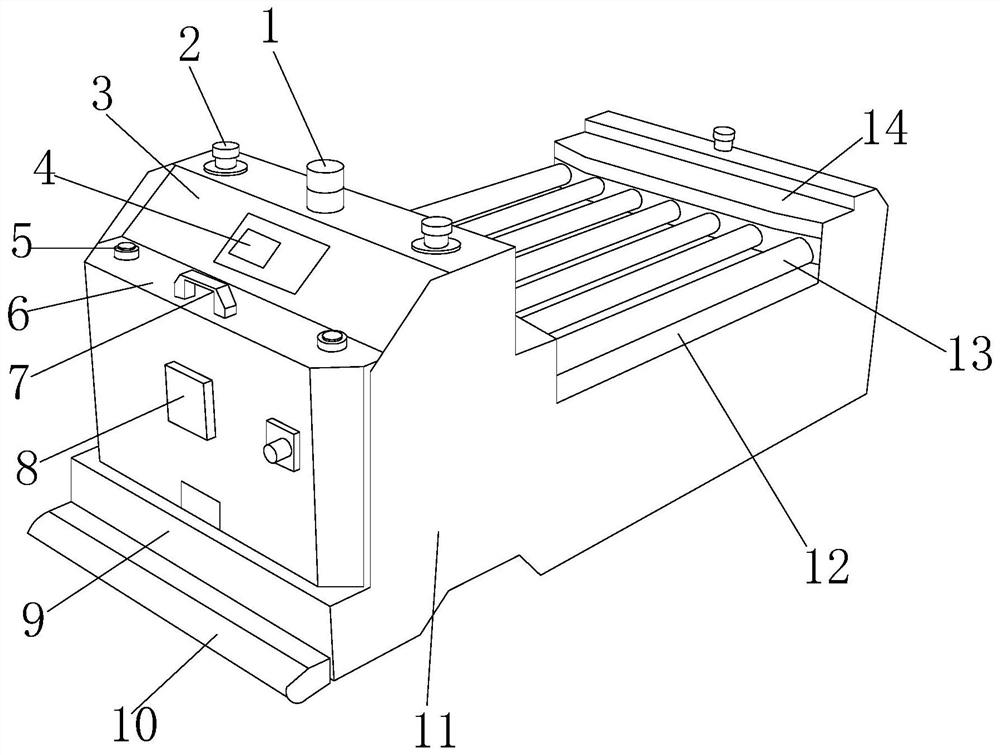

High-speed carving machine for plane glass

The invention discloses a high-speed carving machine for plane glass. The high-speed carving machine comprises a carving table, a fixing base and a carving mechanism. The fixing base is provided with buffering cushions, and a glass positioning groove is formed in the carving table. A glass supporting frame and synchronous driving devices are arranged in the glass positioning groove. The synchronous driving devices are connected with the glass supporting frame through main telescopic rods. Cantilevers are symmetrically arranged on the two sides of the main telescopic rods. The ends of the cantilevers and the ends of the main telescopic rods abut against the bottom face of the glass supporting frame through trays. Horizontal sliding rails which are parallel are arranged on the two sides of the carving table. The carving mechanism is movably connected to a cross beam, and glass conveying guide grooves are formed in the inner side faces of the horizontal sliding rails. Bracket mechanisms are arranged in the glass conveying guide grooves. The high-speed carving machine is simple in structure and high in practicability, glass workpieces can be positioned and prevented from moving during carving, the glass workpieces can be automatically taken and placed, machining precision is improved, carving time is shortened, meanwhile, the glass workpieces are effectively protected, and abrasion is reduced.

Owner:山东亚鑫华数控设备有限公司

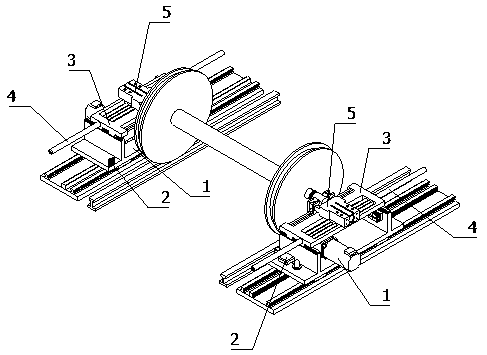

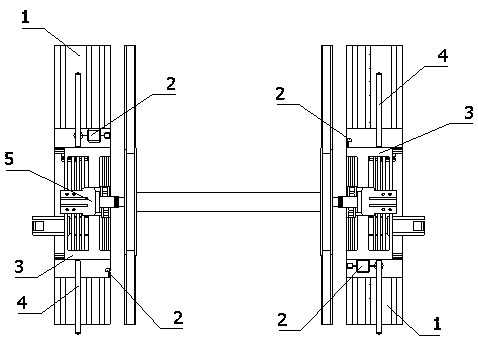

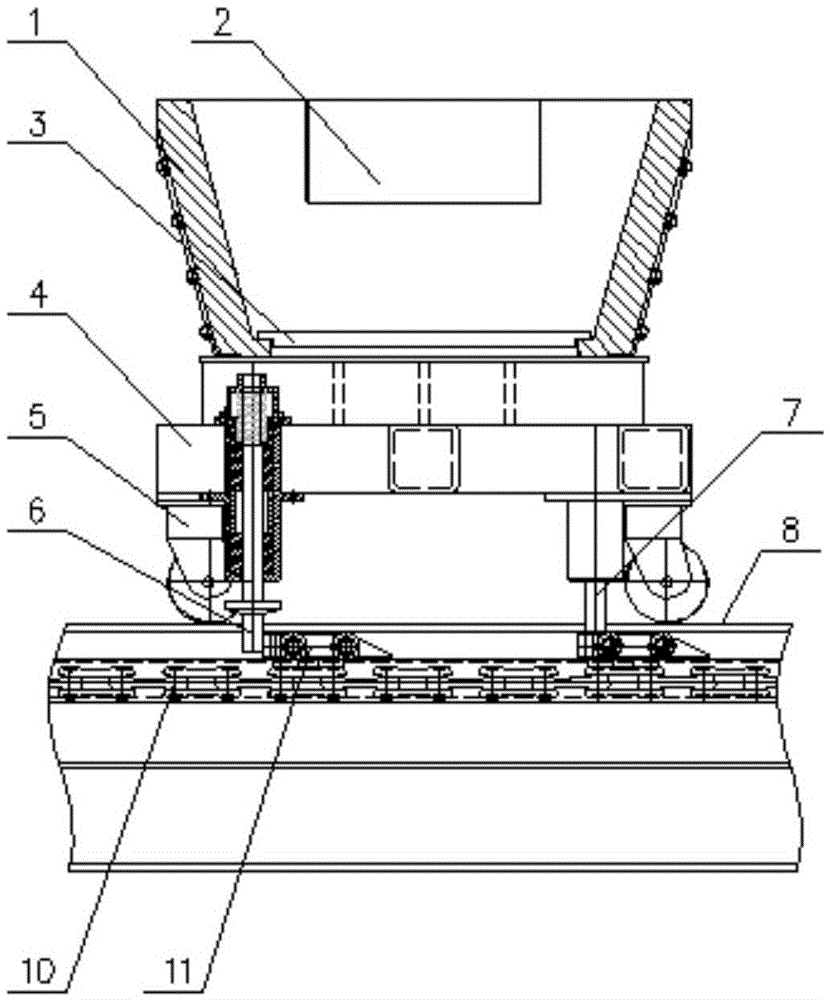

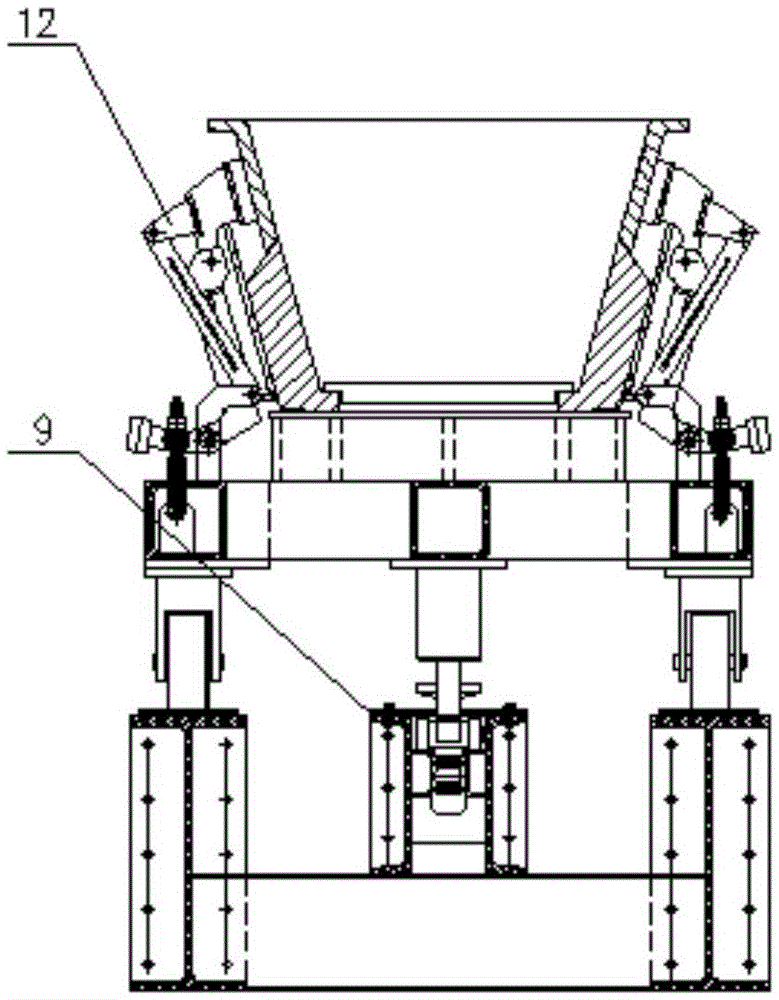

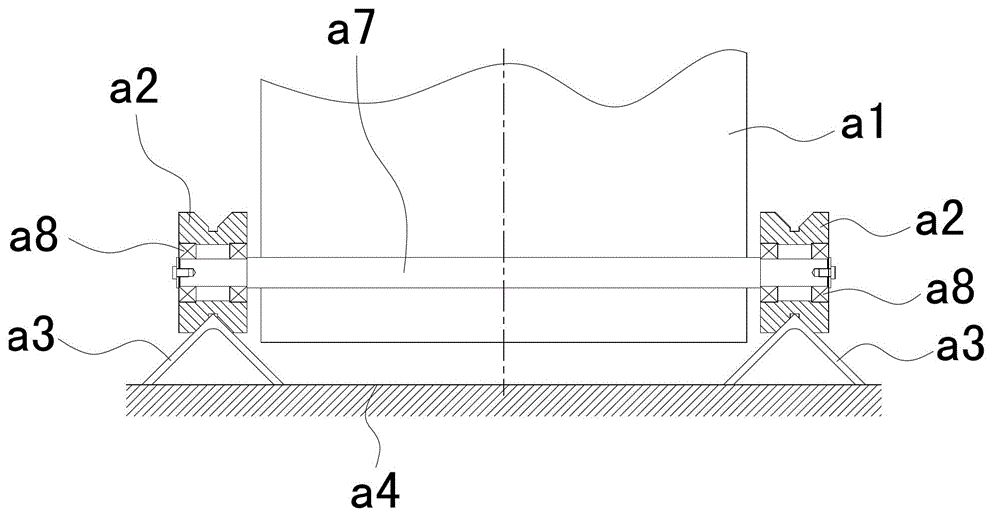

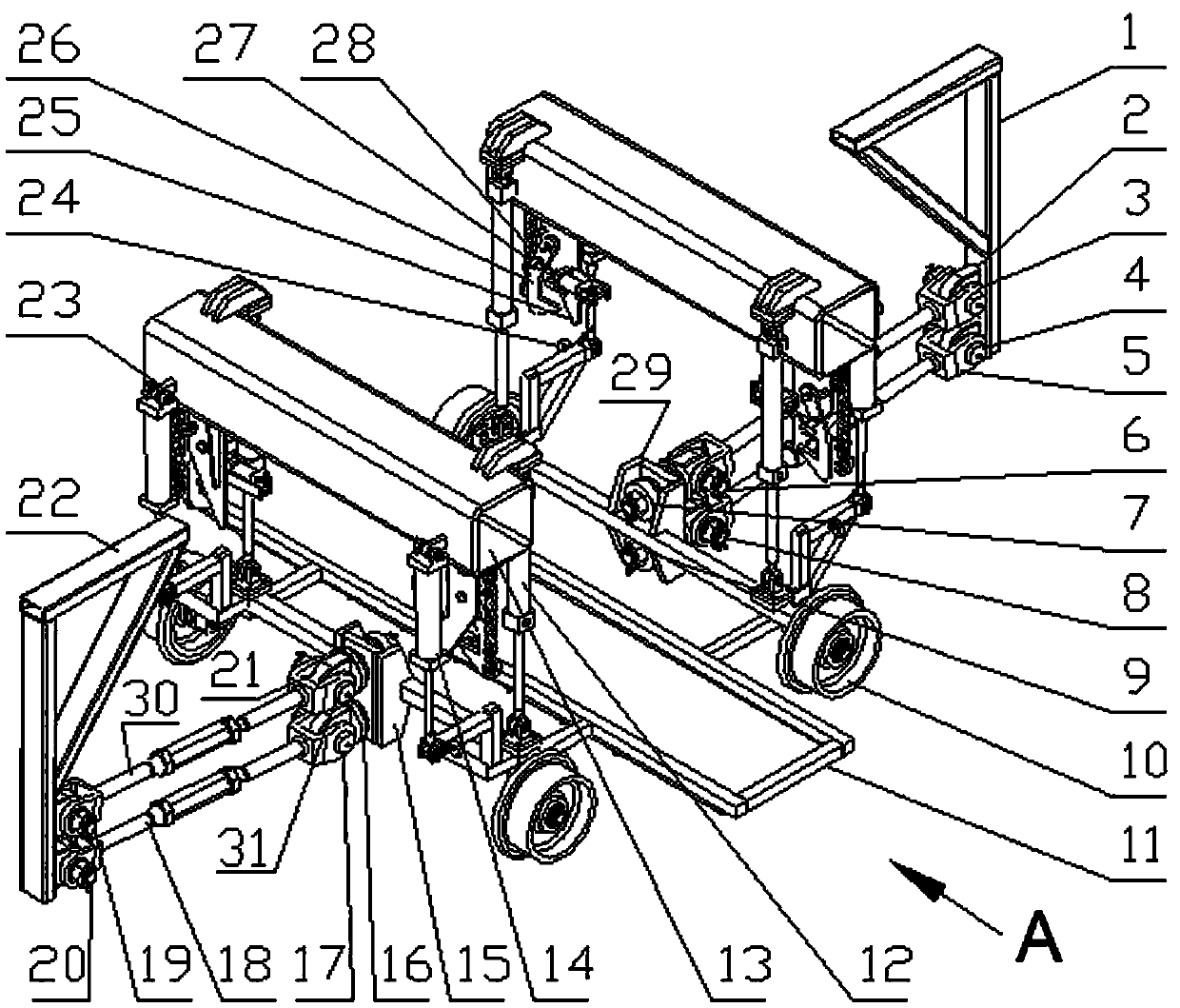

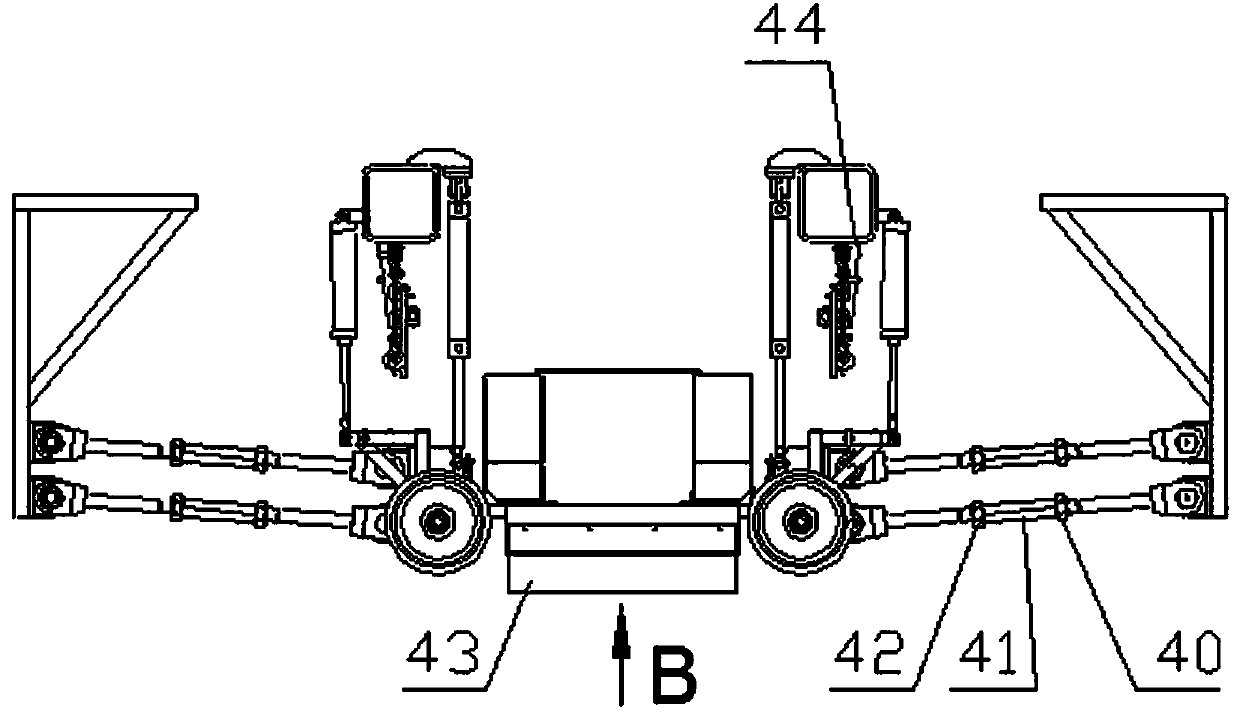

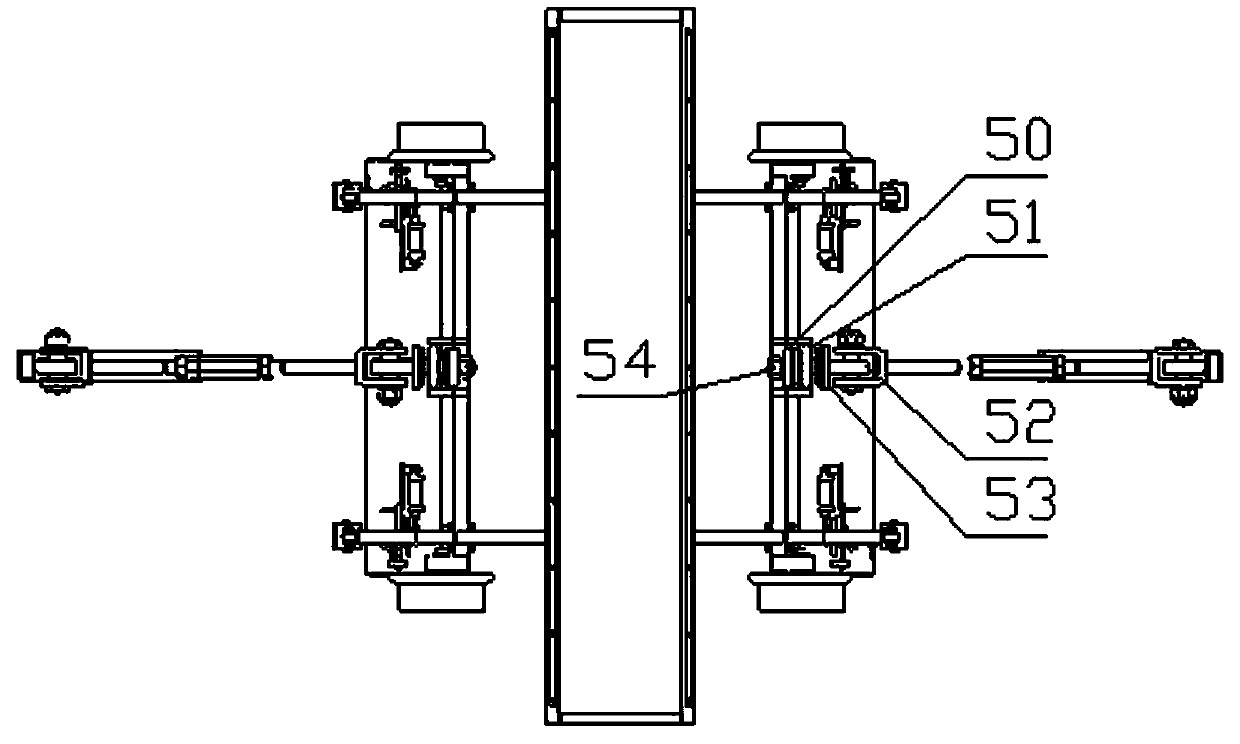

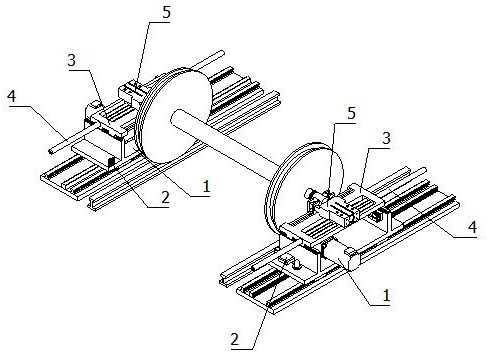

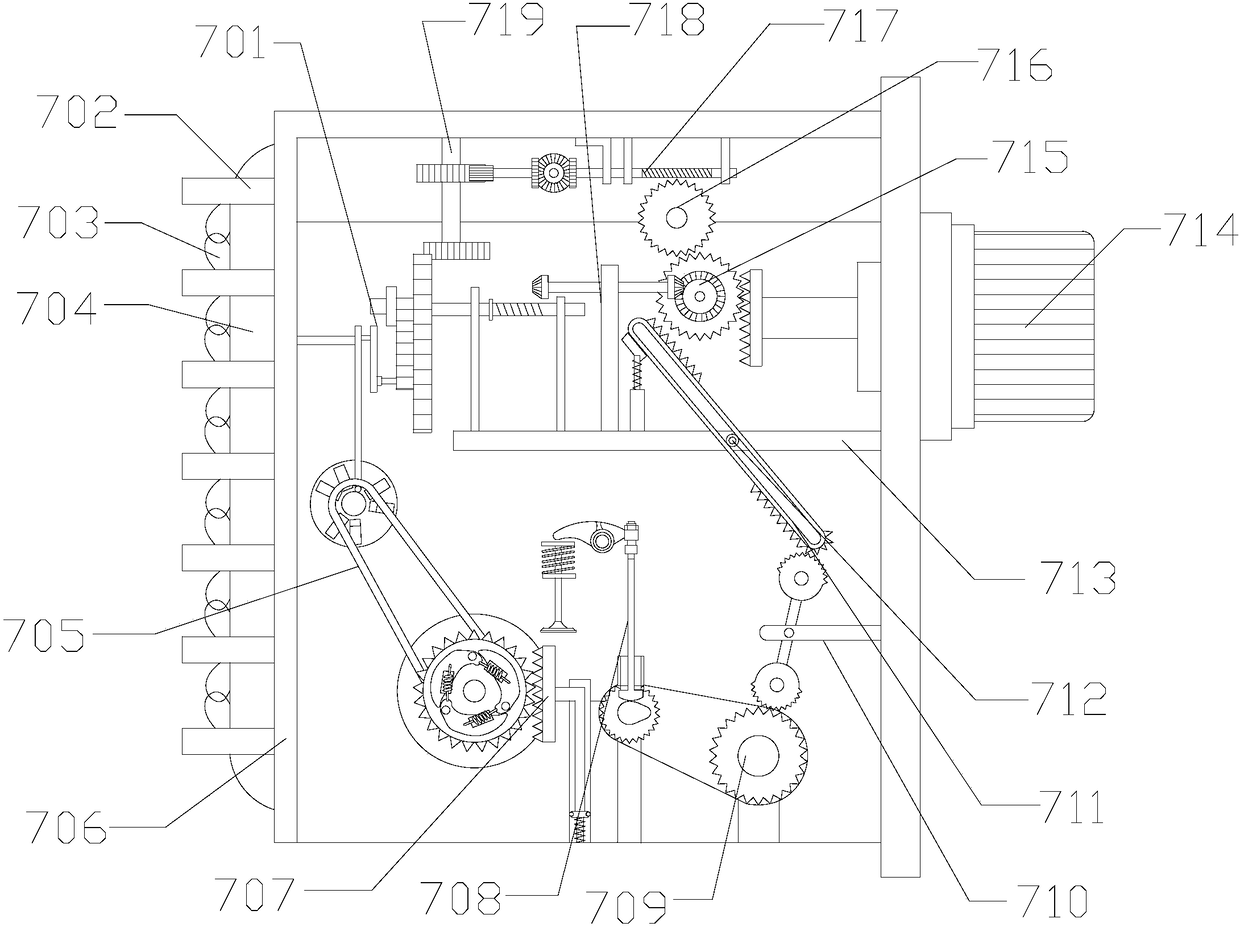

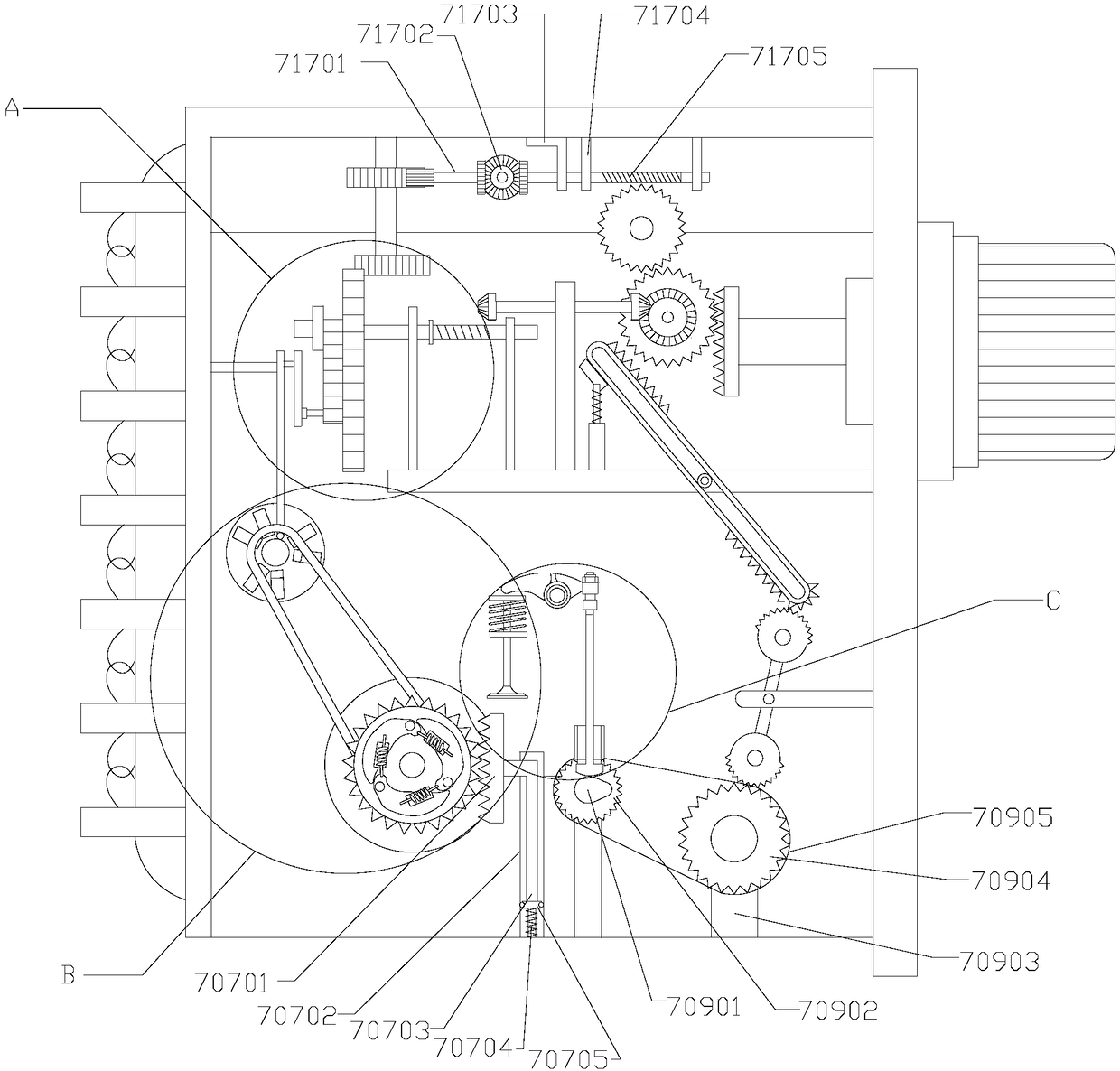

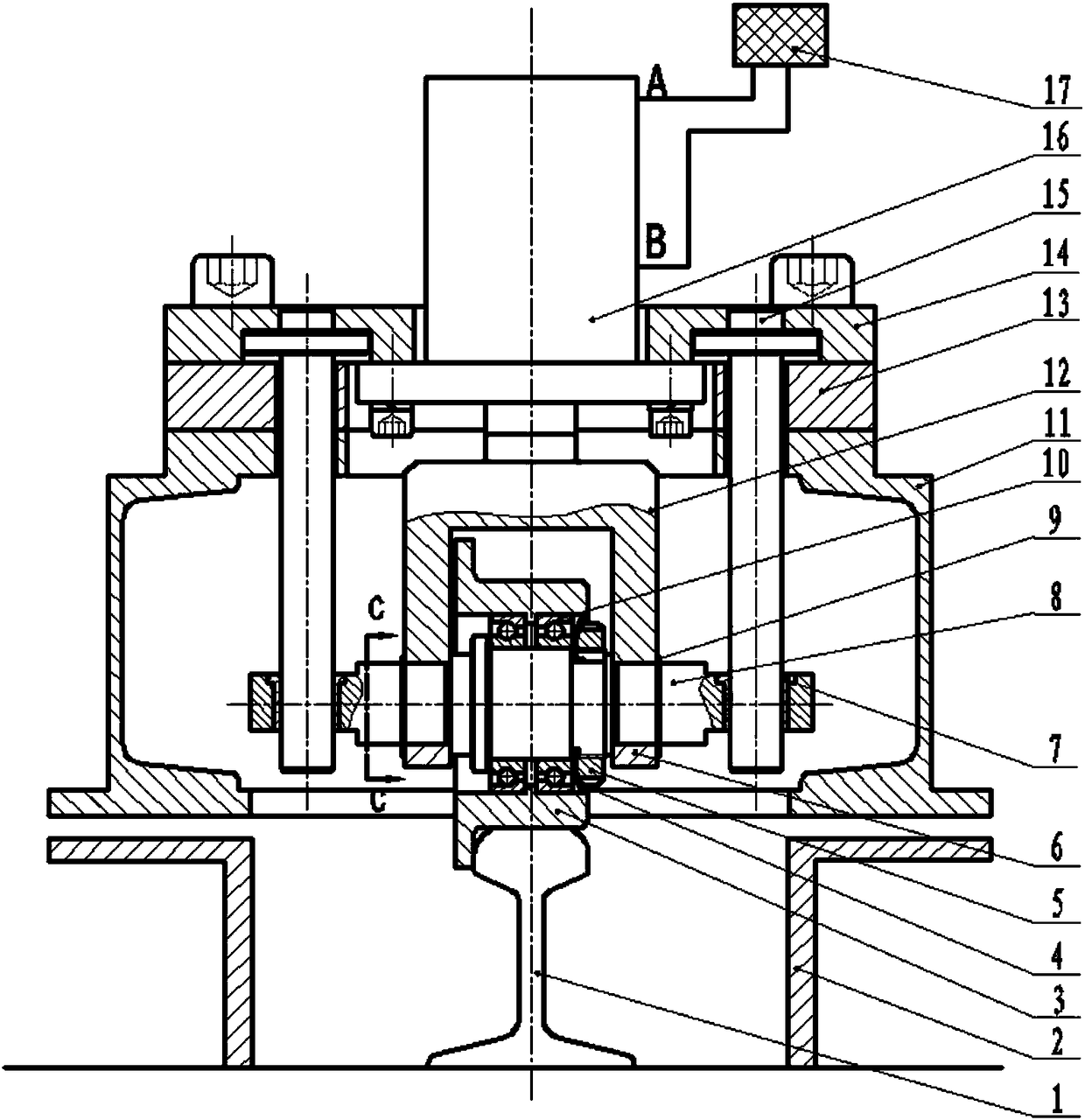

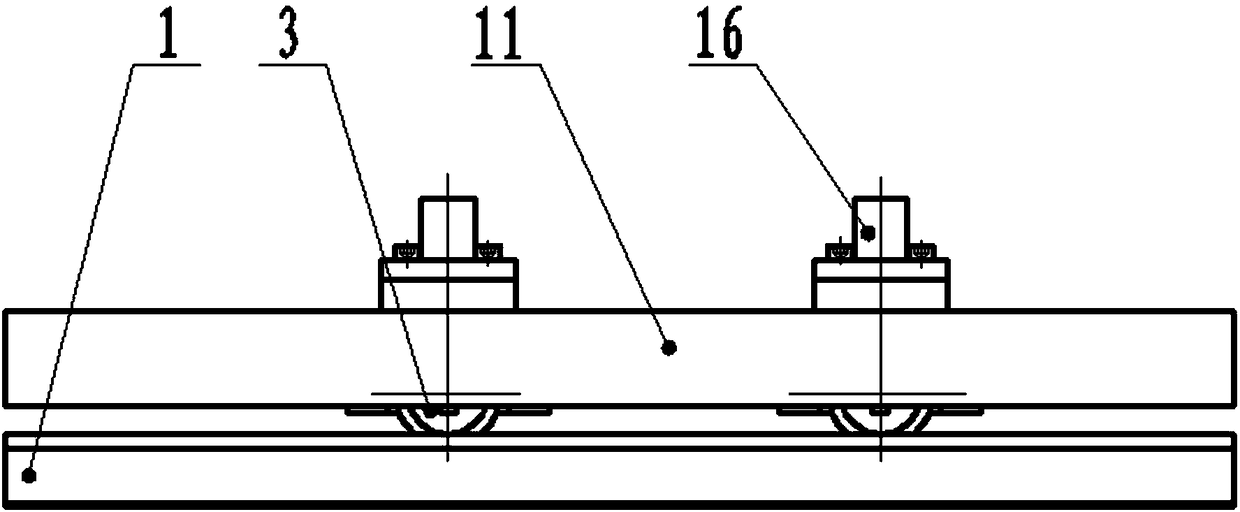

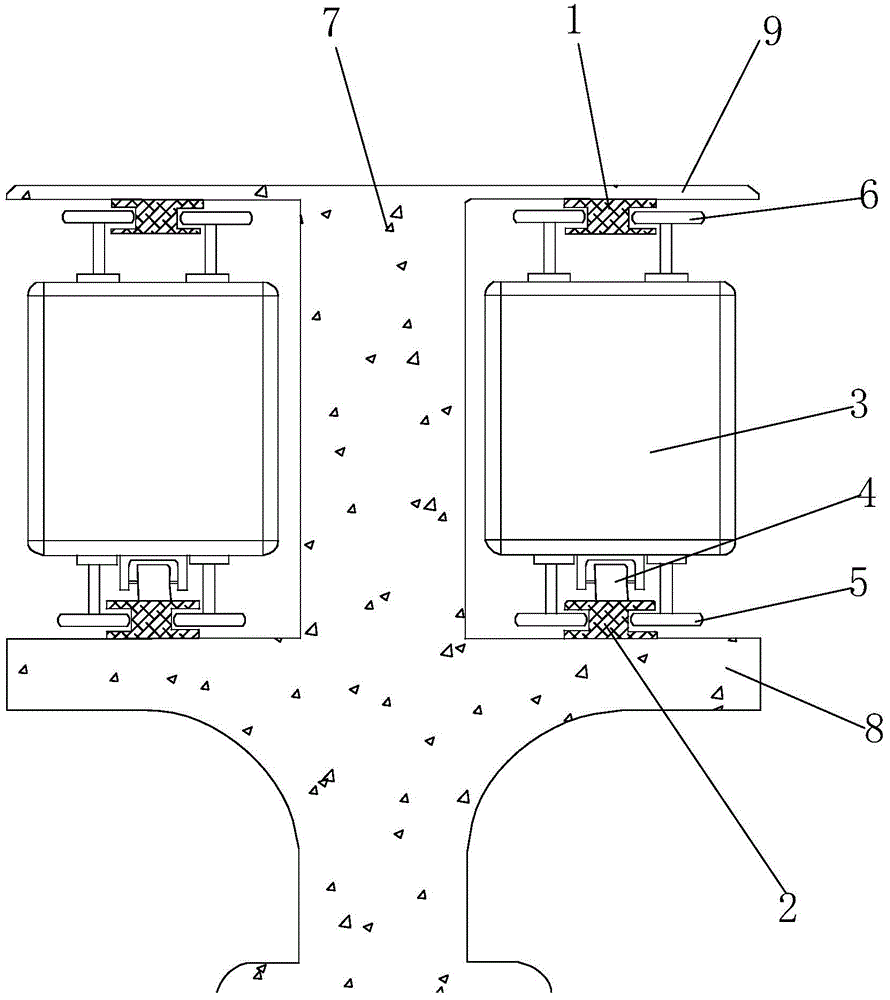

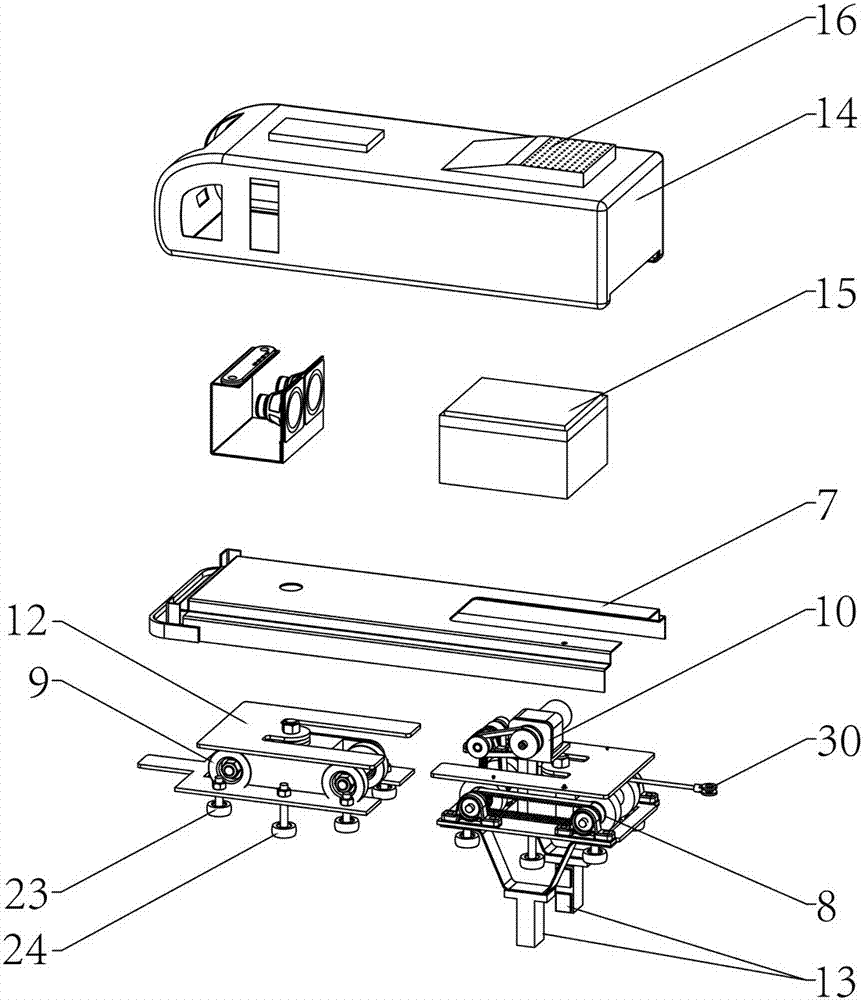

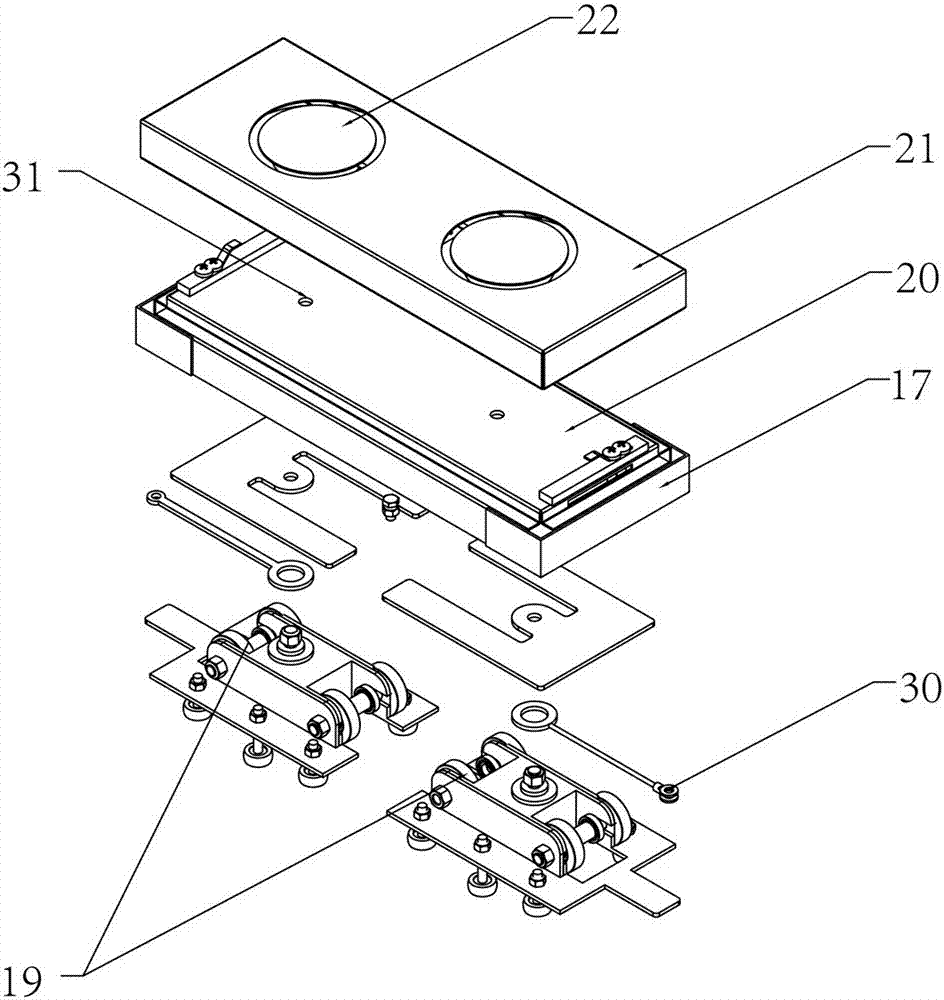

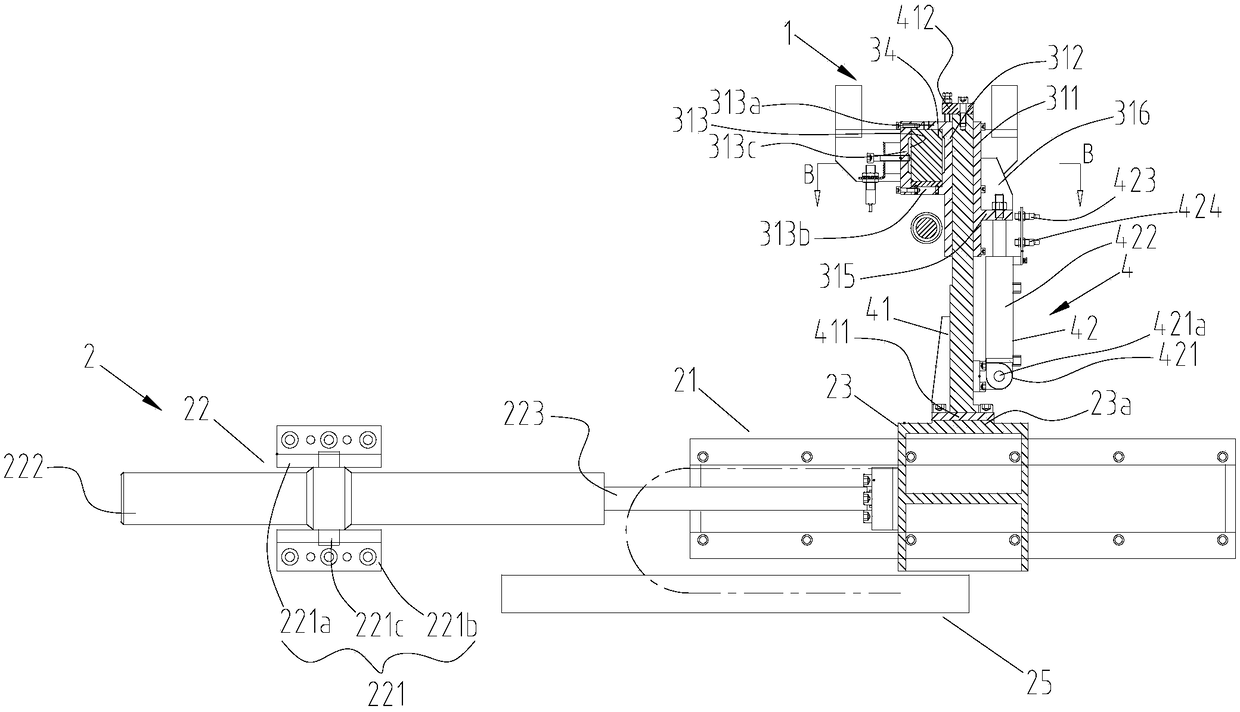

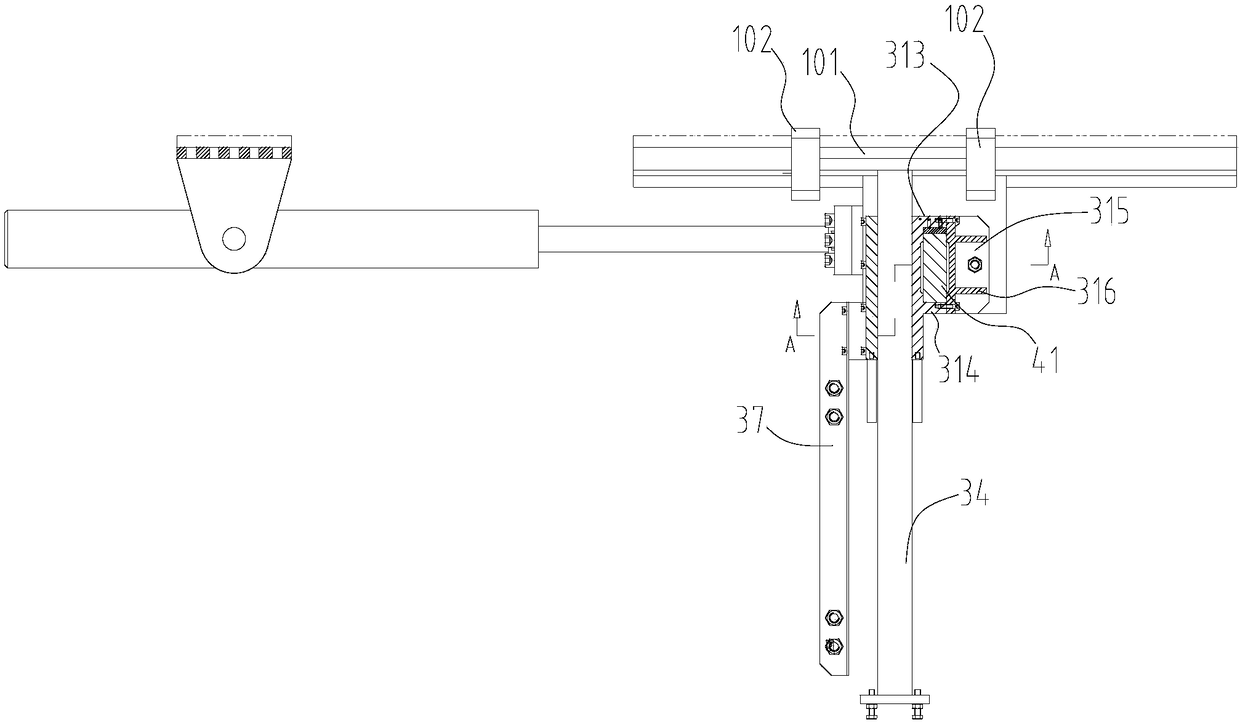

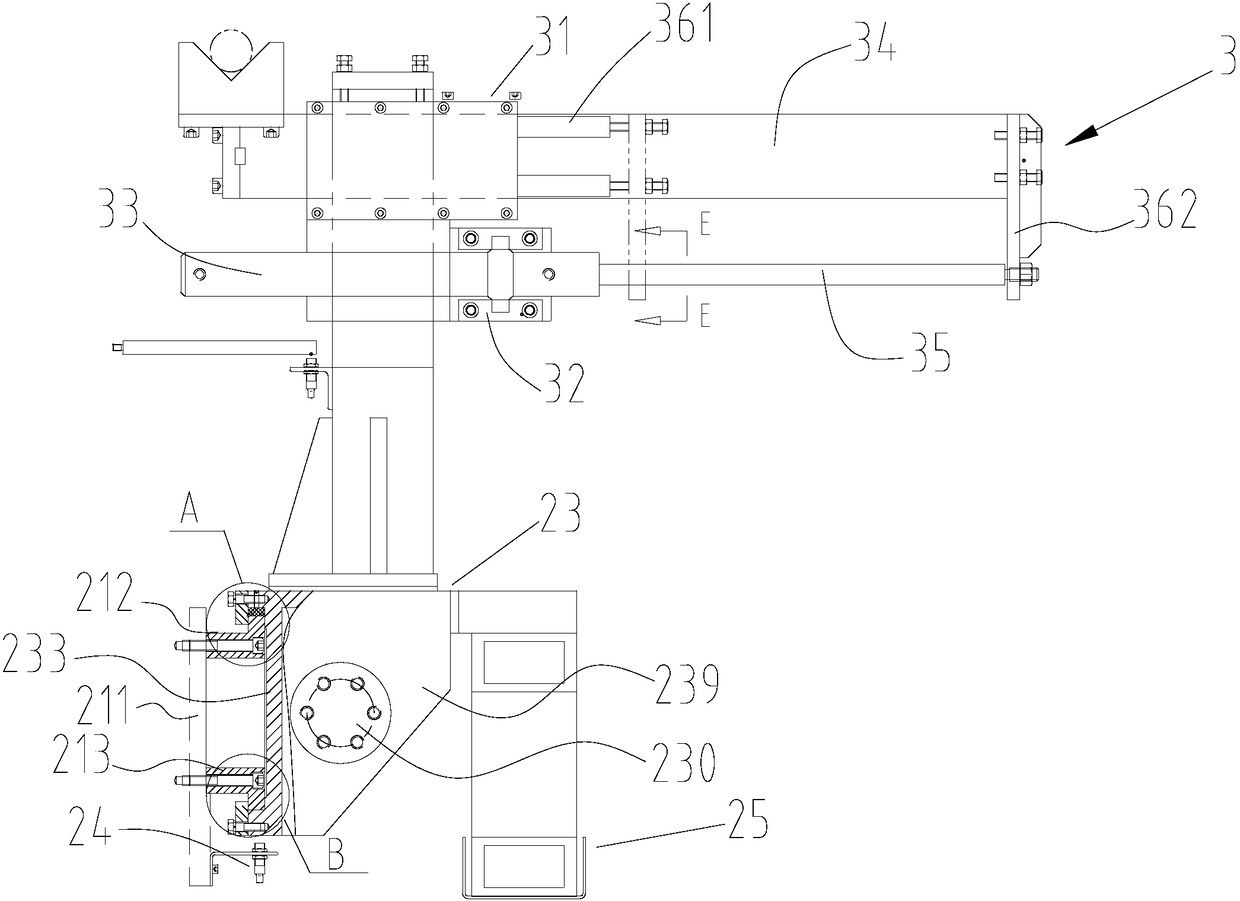

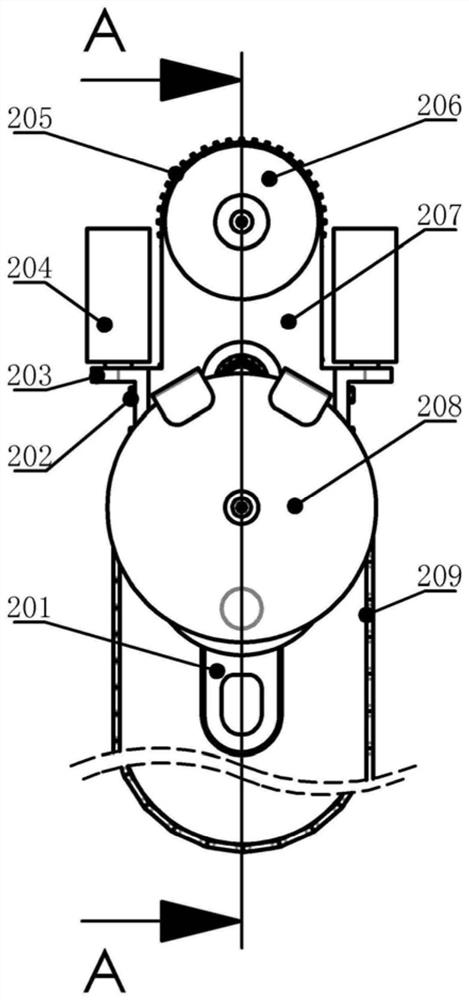

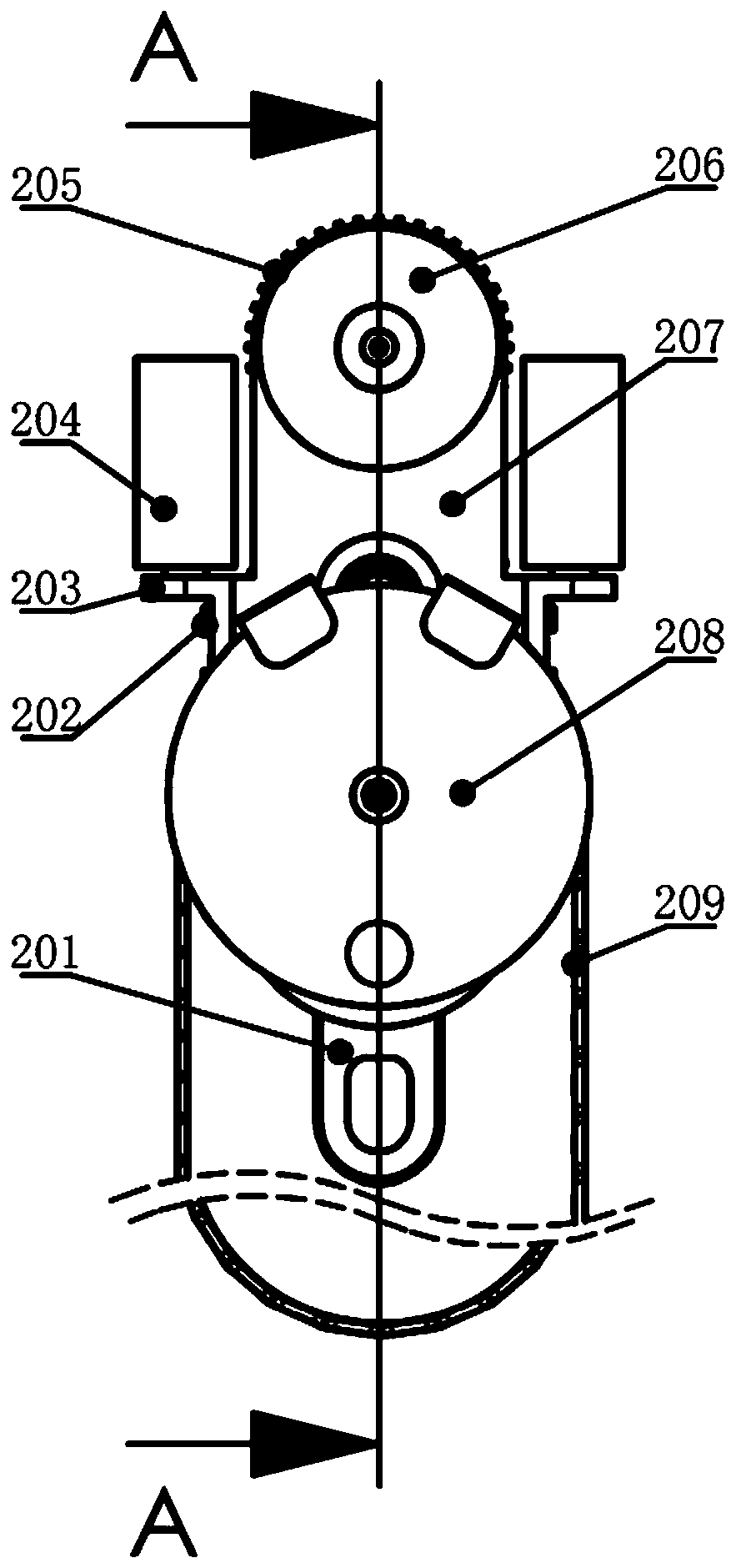

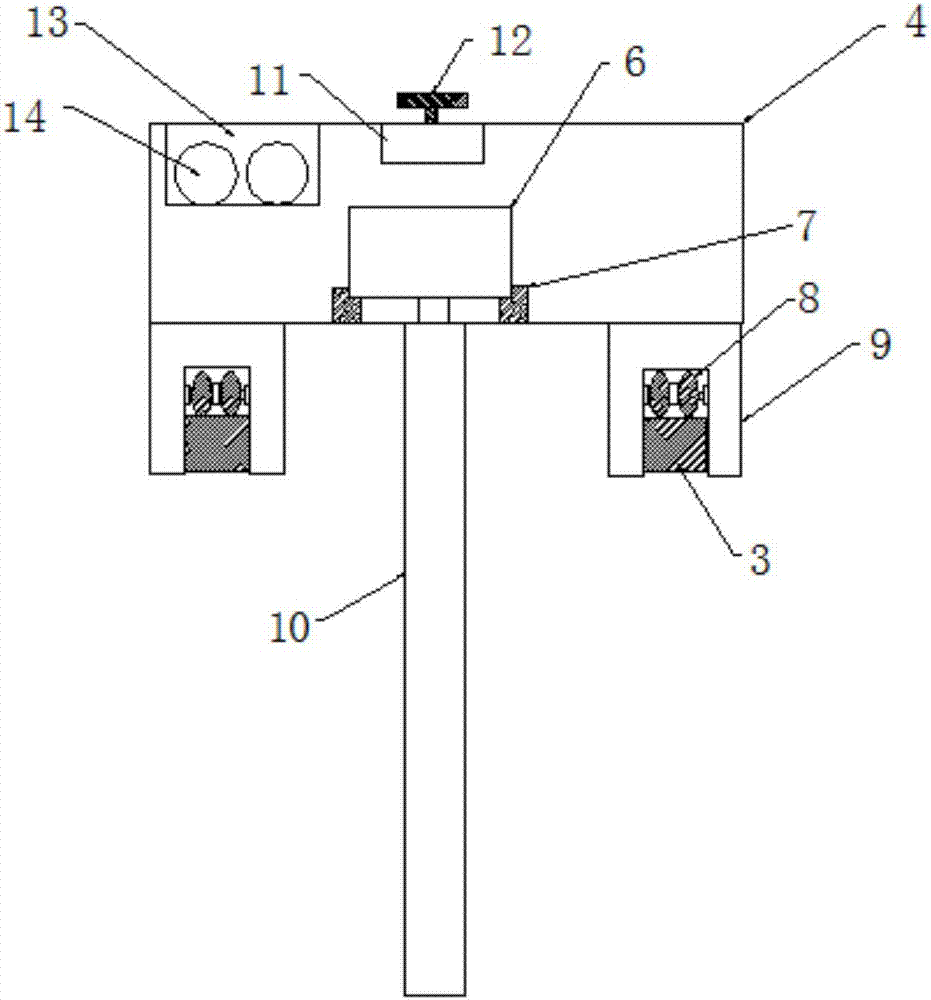

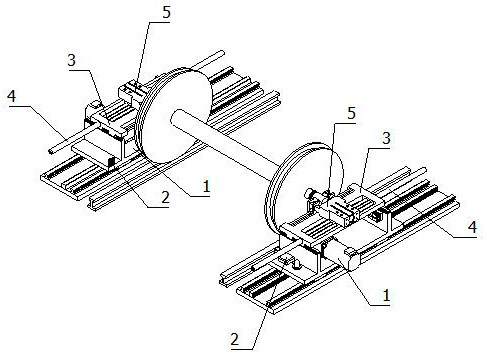

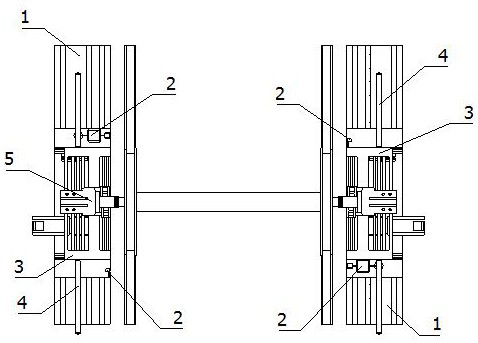

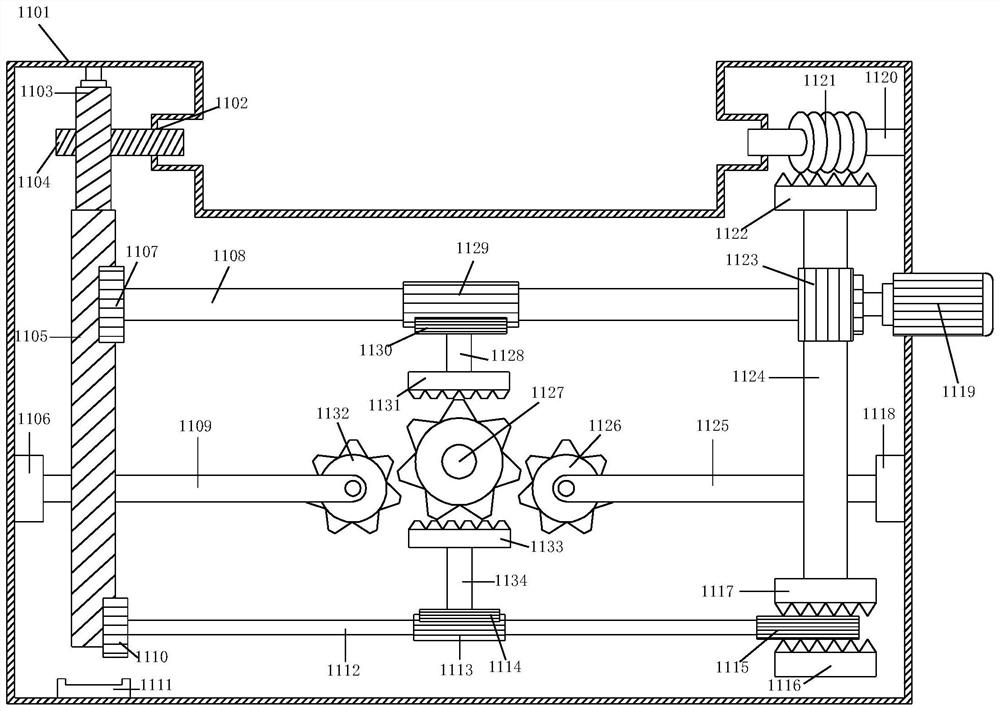

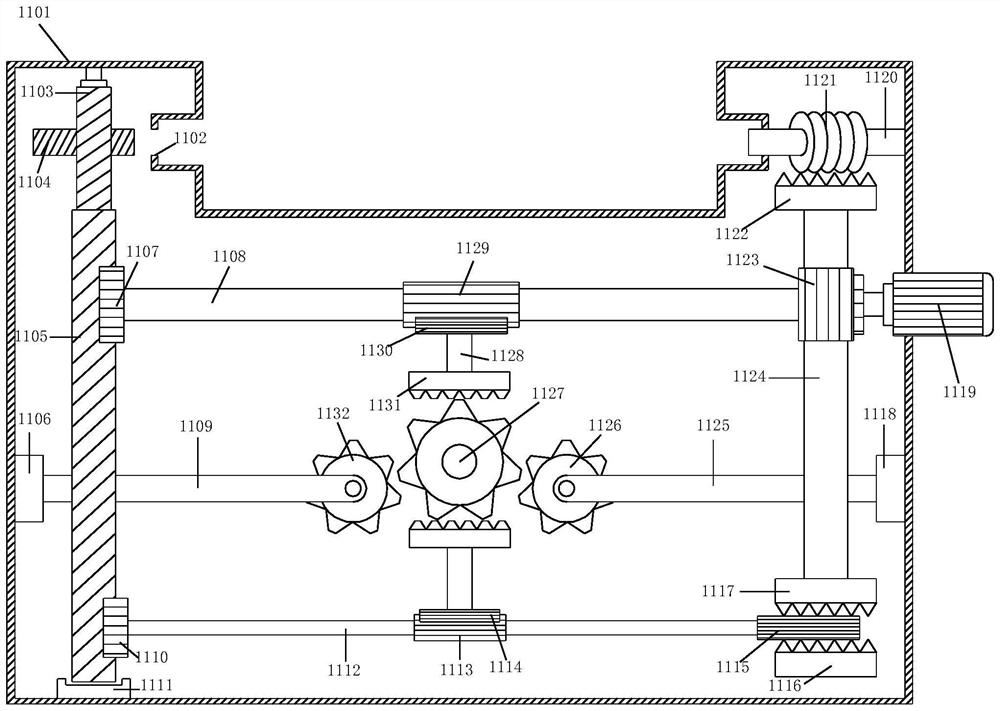

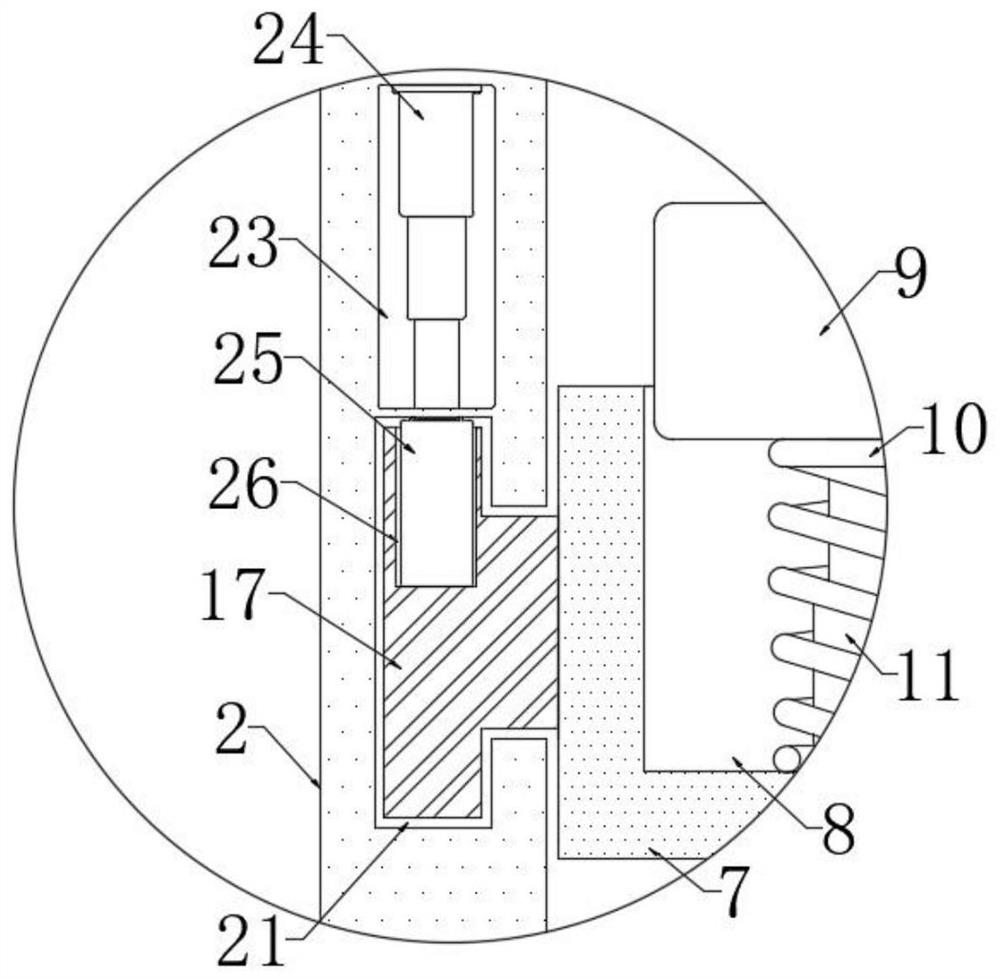

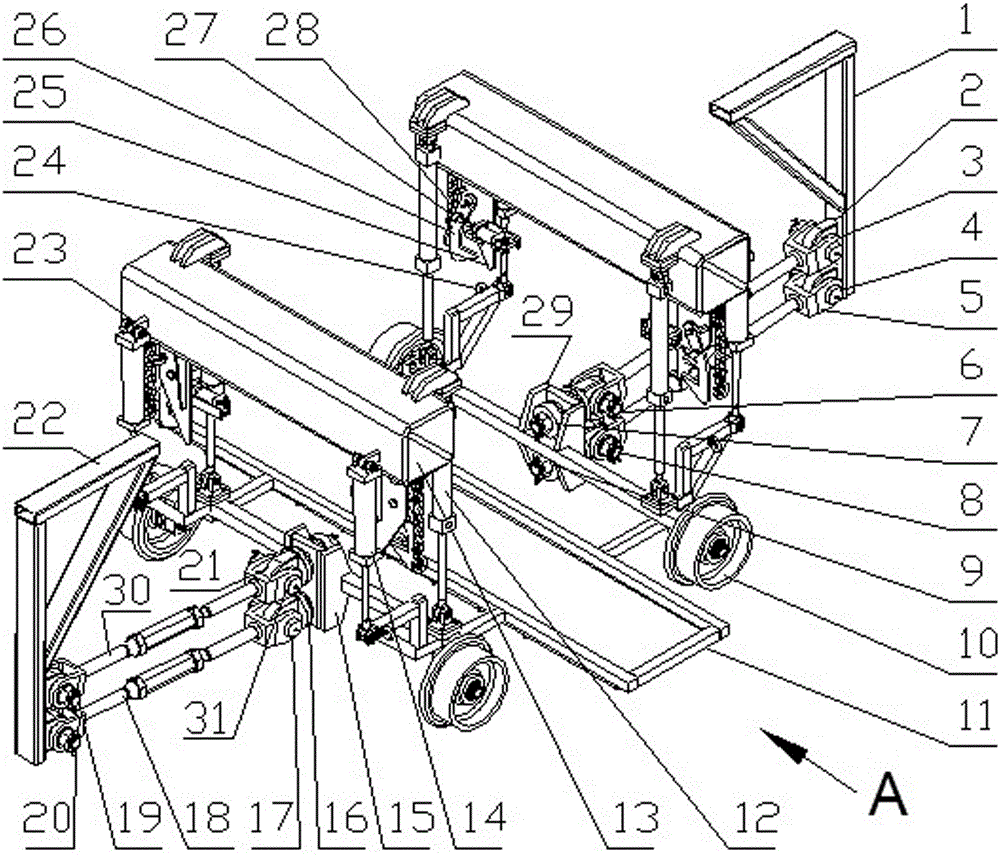

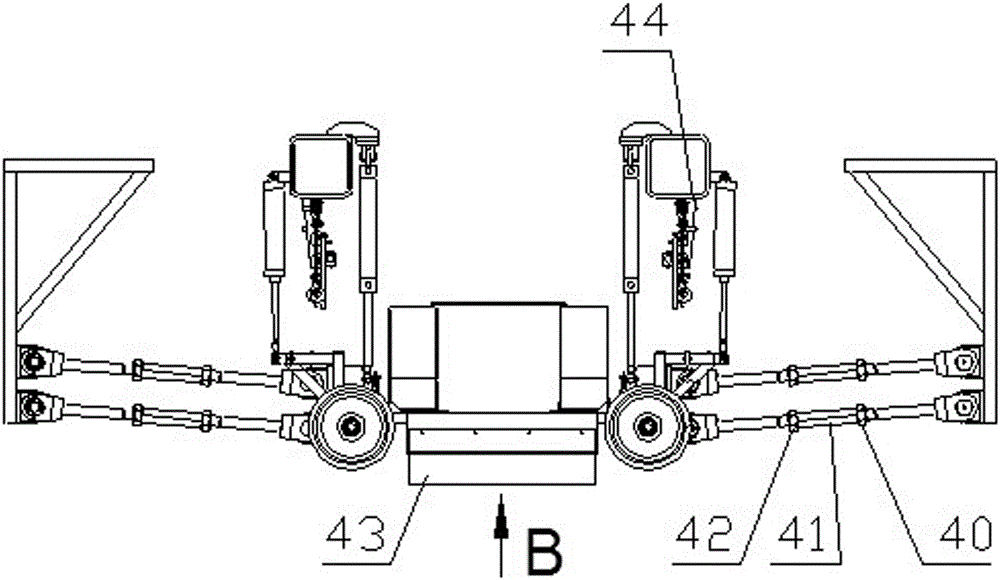

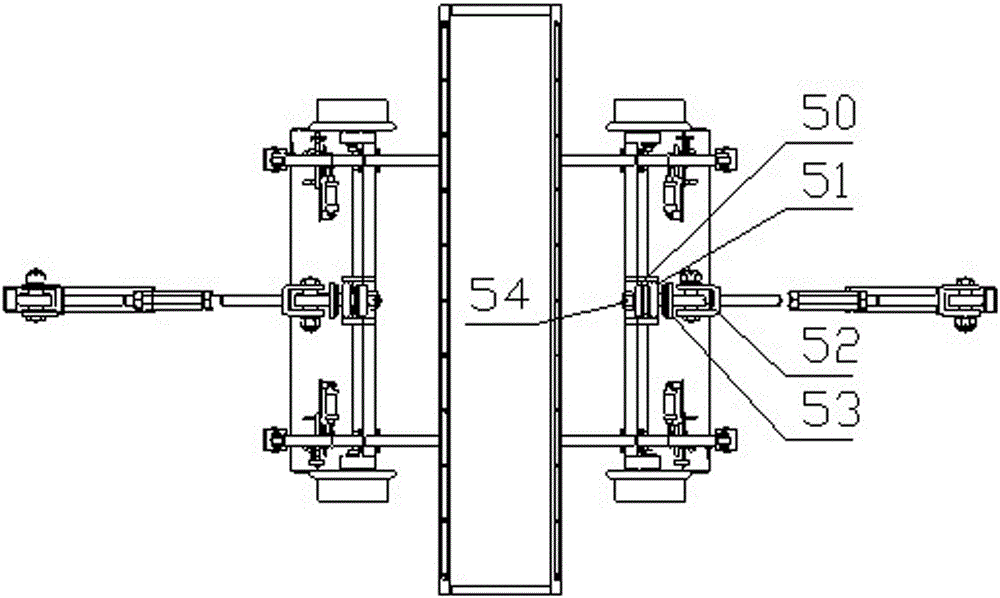

High-precision wheel set positioning and transferring mechanism for railway vehicle production

ActiveCN109987394AAutomatic speed adjustmentMobile synchronizationControl devices for conveyorsMechanical conveyorsTransfer mechanism

The invention relates to the technical field of railway production equipment, in particular to a high-precision wheel set positioning and transferring mechanism for railway vehicle production. The high-precision wheel set positioning and transferring mechanism comprises linear moving devices, a synchronous device and a wheel set positioning device, wherein the wheel set positioning device comprises a movable mechanism, a buffer mechanism and shaft positioning mechanisms, wherein a wheel set is arranged on a rail, the shaft positioning mechanisms are arranged on the two sides of the wheel set and are arranged with a rotating shaft of the wheel set in a clamped mode, the buffer mechanism is installed below the shaft positioning mechanisms, the working direction of the buffer mechanism is thesame as the conveying direction of the wheel set, the movable mechanism is installed below the buffer mechanism and drives the buffer mechanism to move towards the wheel set from the two sides of thewheel set, the synchronous device and the movable mechanism are both installed on the linear moving devices, the linear moving devices are arranged on the two sides of the rail, and the conveying direction of the linear moving devices is the same as the conveying direction of the wheel set. The mechanism does not need a high-precision rack, a safety synchronizing mechanism is installed on the linear moving devices of the mechanism, the wheel set is not prone to derailing during transportation, and the rack is not easy to damage.

Owner:江苏宁铁技术股份有限公司

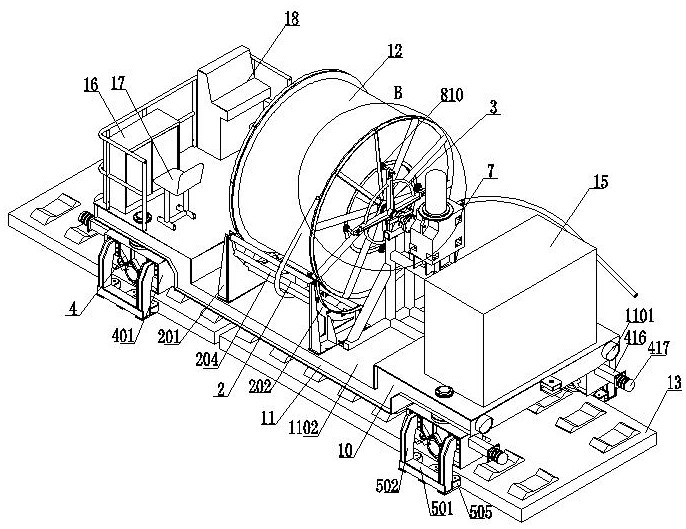

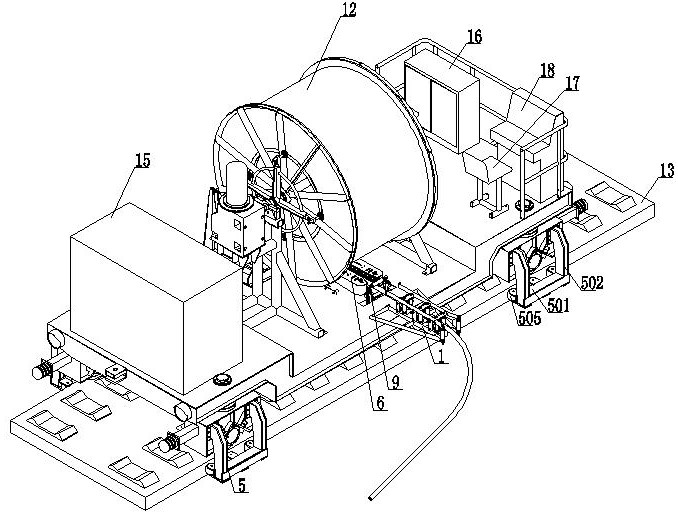

Two-way cable laying operation vehicle for highway

InactiveCN111994710AAvoid derailed situationsImprove securityFilament handlingApparatus for laying cablesVehicle frameAgricultural engineering

The invention relates to a two-way cable laying operation vehicle for highway. The operation vehicle comprises a chassis assembly, wherein the chassis assembly comprises a frame; the middle part of the frame is fixedly connected to an unwinding device for unwinding cables; the bottom of the frame is equipped with four groups of travelling trolleys for driving the frame to travel; each group of travelling trolleys comprises trolley frames and travelling wheels; two groups of travelling trolley are mounted at one end of the bottom of the frame, and are recorded as active travelling trolleys; thetravelling wheels on the active travelling trolleys are connected to drive assemblies for driving the travelling wheels, and the other two groups of travelling trolleys are recorded as driven travelling trolleys; and the driven travelling trolleys are mounted at the other end of the bottom of the frame. The two-way cable laying operation vehicle reduces labor cost, reduces labor amount of a worker, shortens a construction period, improves work efficiency, is convenient for flexible steering according to arrangement of a railway rail plate, is not liable to cause derailing, achieves guide effect for cables by reducing friction between the cables and the frame in an unwinding process, and guarantees quality of the cables.

Owner:河南江河特种车辆科技有限公司

Independently-driven on-line unloading type calcium carbide furnace discharging transport cart

ActiveCN105480660ASmall turning radiusSave layout spaceMechanical conveyorsControl systemRunning time

The invention provides an independently-driven on-line unloading type calcium carbide furnace discharging transport cart. The independently-driven on-line unloading type calcium carbide furnace discharging transport cart comprises a transmission device, a plurality of ishinabe trolleys, a plurality of opening and closing mold calcium carbide bowls and a stopping control system. The independently-driven on-line unloading type calcium carbide furnace discharging transport cart is characterized in that the transmission device comprises driving stand rods and guide stand rods which are arranged in front of and at back of the bottom of the trolleys. According to the cart, the trolleys are individually controlled and driven, compared with an overall row driving manner, the rail turning radius can be smaller, and the arrangement space can be saved; and meanwhile, as waiting is not needed between the trolleys, the running time can be saved, the running efficiency is greatly improved, the number of the trolleys is reduced, and the plant arrangement area is saved.

Owner:WISDRI ENG & RES INC LTD

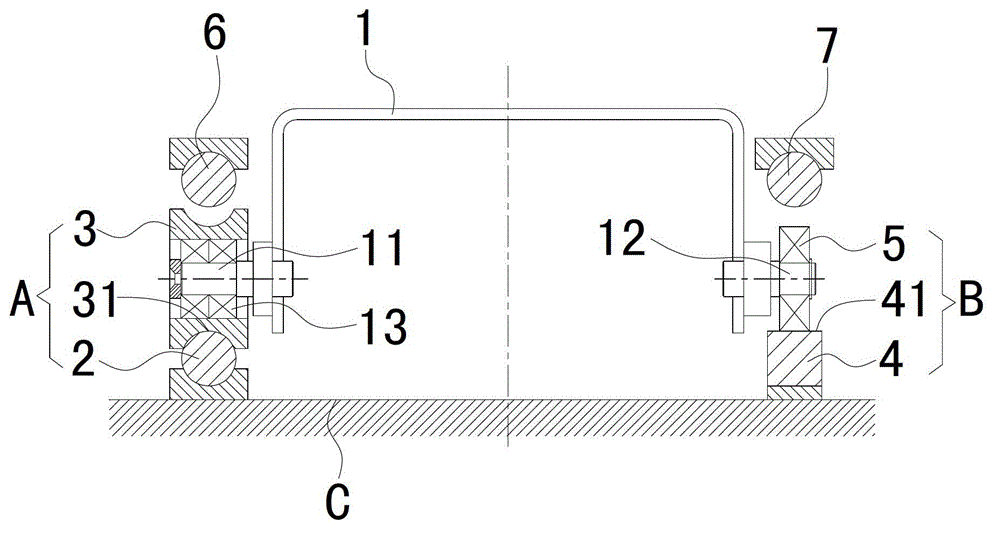

Horizontal movement device for hoisting machine

InactiveCN102976230AIncrease the upper limit positionPrevent derailmentLifting framesEngineeringSupport surface

The invention relates to a horizontal movement device for a hoisting machine. The horizontal movement device comprises a first guide rail pair arranged at the left side of the hoisting machine and a second guide rail pair arranged at the right side of the hoisting machine; the horizontal movement device is characterized in that the first guide rail pair comprises a first guide rail arranged on the ground and a plurality of first rolling wheels which are pivoted at the left side of a rack; an annular groove which is blocked on the first guide rail is arranged in the external surface of each first rolling wheel; each first rolling wheel is blocked on the first guide rail and moves along the direction of the first guide rail; the second guide rail pair comprises a second guide rail arranged on the ground and a plurality of second rolling wheels which are pivoted at the right side of the rack; the second guide rail is parallel to the first guide rail; the second guide rail is a plane guide rail and is provided with a supporting surface extending along the direction of the second guide rail; and each second rolling wheel is pressed on the supporting surface in a rolling way. According to the horizontal movement device provided by the invention, the requirements on the center distance of the guide rails and the precision of the guide rails are low; the requirement on the coaxial precision of the rolling wheels is low; the installation and adjustment are convenient, and the running of the device is safe and reliable.

Owner:YU TUNG ZHONGSHAN ENG

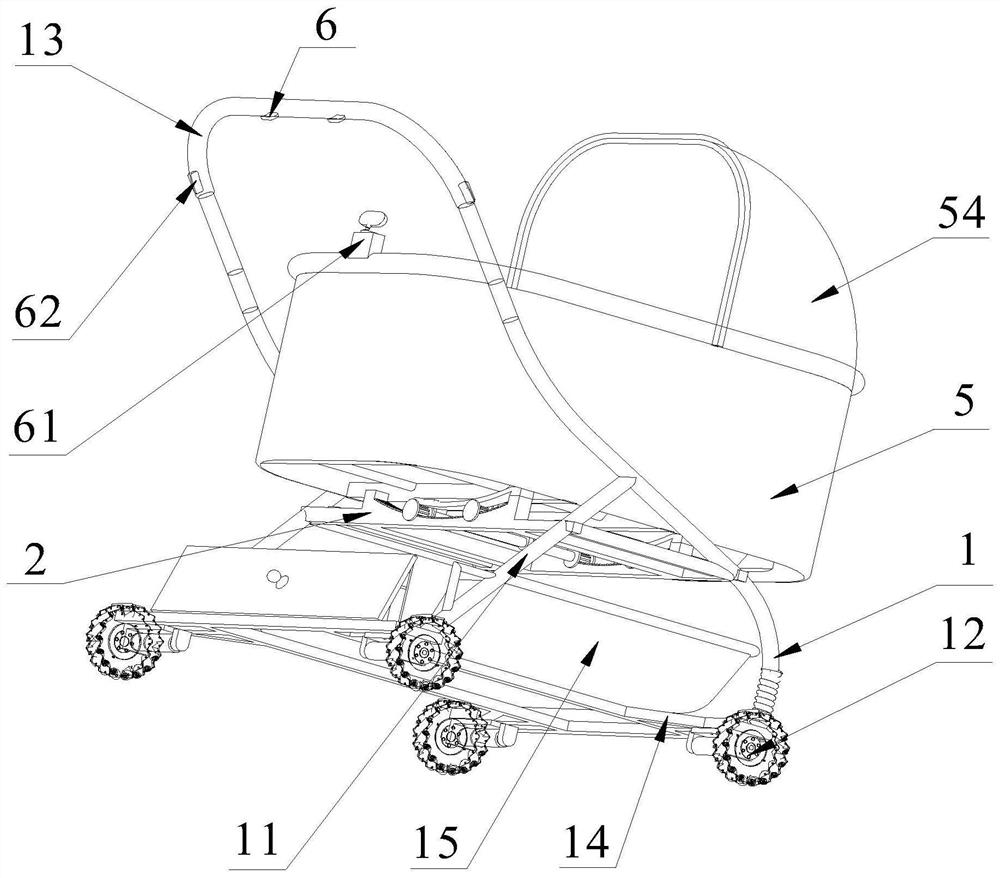

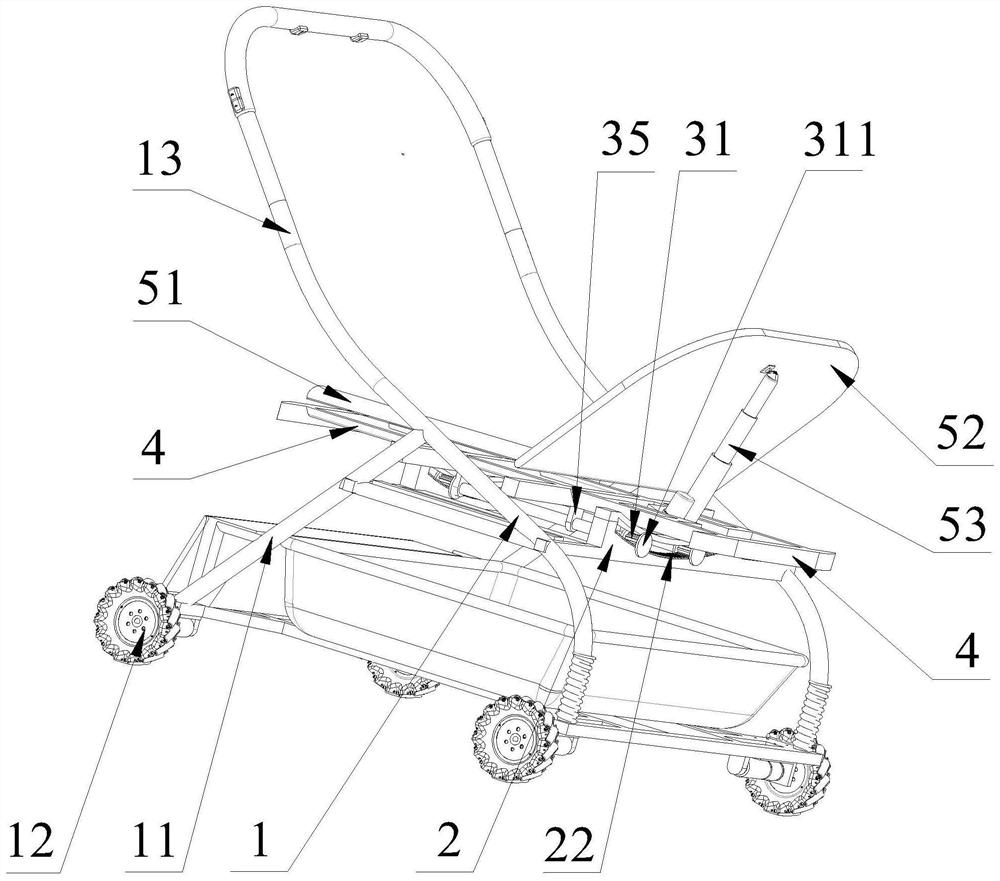

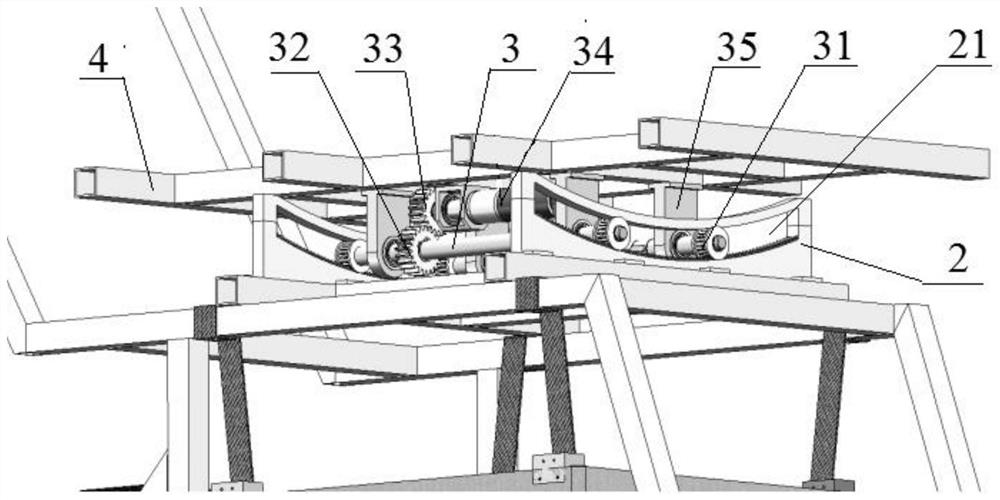

Multifunctional baby carriage

InactiveCN113085986AImprove securityImprove comfortCarriage/perambulator accessoriesCarriage/perambulator with multiple axesVideo transmissionGear wheel

The invention is applicable to the technical field of baby carriages, and provides a multifunctional baby carriage. The baby carriage comprises a carriage body, a language recognition module, a video transmission module, a temperature and humidity sensor and a humidifier are arranged at preset positions of the carriage body, and a distance measuring part is arranged on each wheel; a shaking bed comprises bed surroundings and a bed board, and the bed board comprises a horizontal bed board and a lifting bed board which are hinged to each other; a track structure comprises a track seat and two rotating shafts, track grooves are formed in the front side and the rear side of the track seat, and toothed belts are arranged on the bottom sides of inner grooves of the track grooves; and walking gears meshed with the toothed belts are arranged at the two ends of the rotating shafts, the rotating shafts are rotationally connected with a bed base, and the preset positions of the rotating shafts are further connected with a driving structure. Therefore, the shaking amplitude and the shaking frequency of the shaking bed can be automatically controlled, and the safety and the stability are relatively high; and meanwhile, the baby carriage can be intelligently controlled, the safety, comfort, functionality and convenience of the baby are improved, the labor intensity of baby nursing is reduced, and the application range is wide.

Owner:WEIFANG UNIV OF SCI & TECH

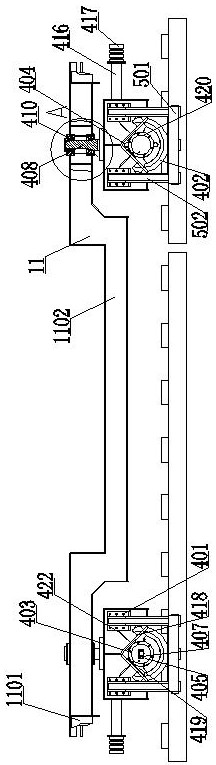

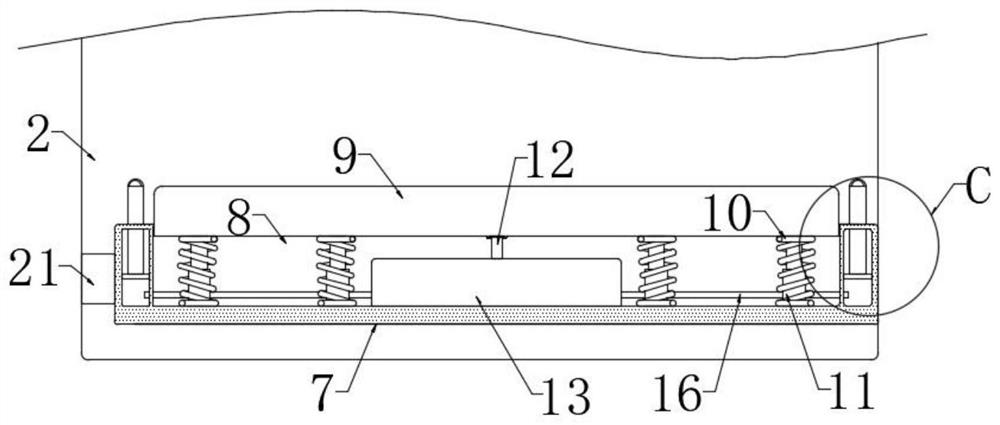

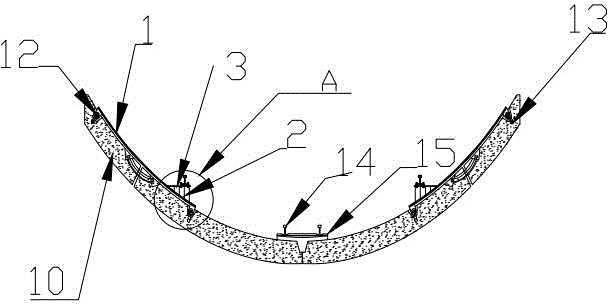

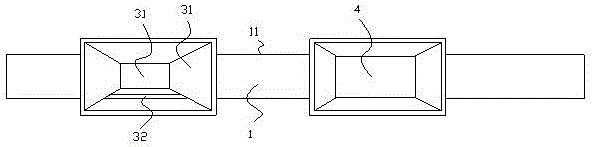

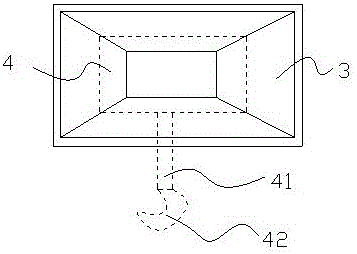

Two-way trailer wagon for railway ballast bed operation device

ActiveCN103806402AGuaranteed uptimeGuaranteed stabilityRailway cleaningHydraulic cylinderVehicle frame

The invention provides a two-way trailer wagon for a railway ballast bed operation device. The trailer wagon comprises a wagon support (11), wagon wheels (10) are installed on the two sides of the wagon support (11), a frame bottom beam (13) is installed above the wagon support (11), the front and the rear of the wagon support (11) are respectively connected with a supporting frame through traction rods, the front and the rear of the wagon support (11) are respectively provided with a traction supporting and fixing frame, the traction rods are connected with the wagon support (11) through the traction supporting and fixing frames, the wagon support (11) and the frame bottom beam (13) are connected with hydraulic cylinders, and a downward-pressing cylinder (14) is further installed between the frame bottom beam (13) and the wagon support (11). By controlling the feeding flow of each hydraulic cylinder, the trailer wagon can be obliquely lifted or descended so as to meet the requirement that the trailer wagon needs to be lifted or descended on a curved road segment, plummet loads can be applied to the trailer wagon through the downward-pressing cylinder, running stability of the trailer wagon in operation is guaranteed, the trailer wagon is not prone to running off rails, and therefore the quality of operation such as dirt suction of railway ballast beds can be improved.

Owner:CRCC HIGH TECH EQUIP CORP LTD +1

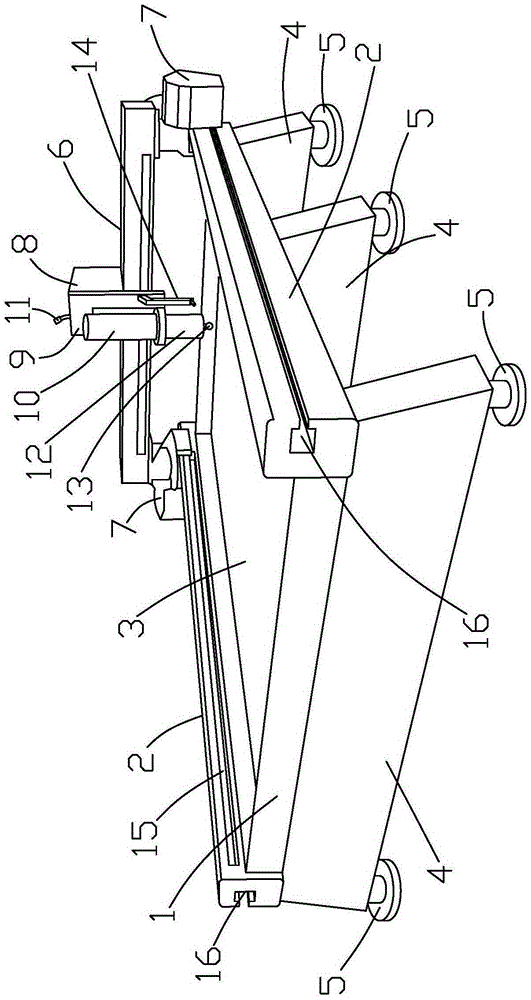

Spinning cloth rolling device facilitating replacement and detachment

InactiveCN108792708AIncrease production capacitySimple structureWebs handlingBlock matchMechanical engineering

The invention discloses a spinning cloth rolling device facilitating replacement and detachment. The spinning cloth rolling device comprises an installing plate. A fixing block is arranged on one sideof the installing plate. The side, away from the installing plate, of the fixing block is symmetrically provided with a plurality of sliding rails. The sliding rail located at the upper portion is provided with a first bearing block matched with the sliding rail. The sliding rail located at the lower portion is provided with a second bearing block matched with the sliding rail. The sides, away from the fixing block, of the first bearing block and the second bearing block are provided with first rotation shafts. The first rotation shafts are sleeved with cloth winding frames. The sides, away from the first rotation shafts, of the first bearing block and the second bearing block are provided with first handles. The bottom ends of the first handles are fixed to the fixing block and fixedly connected with the first bearing block and the second bearing block through pull rods correspondingly. The ends, away from the fixing block, of the first rotation shafts penetrate a first supporting plate and extend to the other side of the first supporting plate. The spinning cloth rolling device has the beneficial effects that the capacity is greatly improved, the structure is simple, usage is convenient, and productivity is greatly improved.

Owner:芜湖瀚德信息科技有限公司

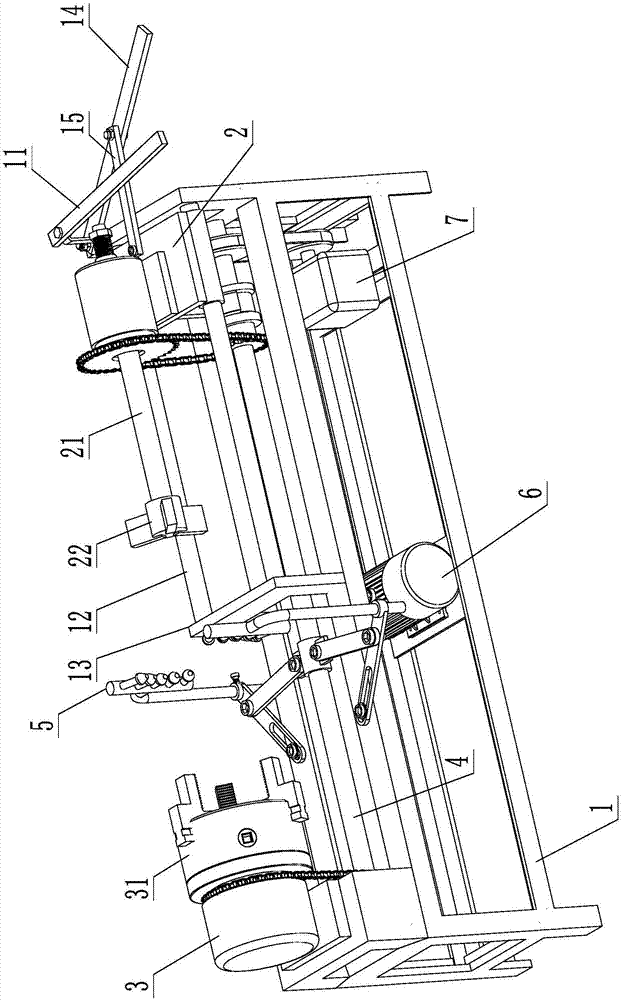

Glass cup bottom-sealing machine

ActiveCN107382042AThe connection structure is stableGuaranteed synchronous rotationGlass reforming apparatusEngineeringMechanical engineering

The invention relates to a glass cup bottom-sealing machine. Two sides of a frame between a three-jaw chuck and a rotating rod are oppositely provided with flame projectors. The two flame projectors are respectively fixed on two cranks arranged on the upper end surface of the frame. One end of each one of the cranks far away from the flame projectors is rotatably connected to a locking bolt which can be adjusted up and down and is located on the upper end surface of the frame. A rotating shaft is slidingly provided with a sliding sleeve. Two sides of the sliding sleeve are symmetrically provided with rotatably connected rocking bars. The end of each one of the rocking bars is hinged to the corresponding crank. The glass cup bottom-sealing machine can realize synchronous movement of the flame projectors in two sides of a glass tube, realizes heating of opposite positions of two sides of the glass tube, guarantees flatness of the glass cup bottom melt at a high temperature and has a high glass cup production qualification rate.

Owner:重庆欣维尔玻璃有限公司

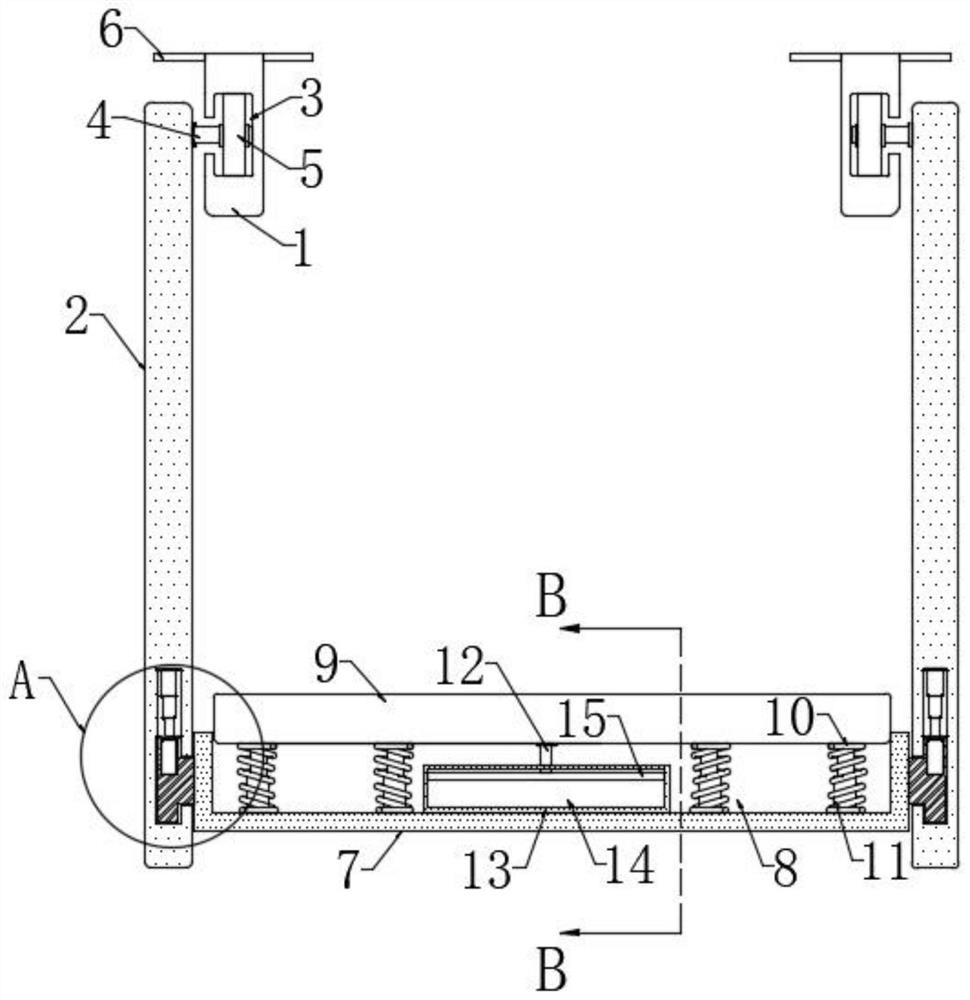

Elevator safety protection clamp

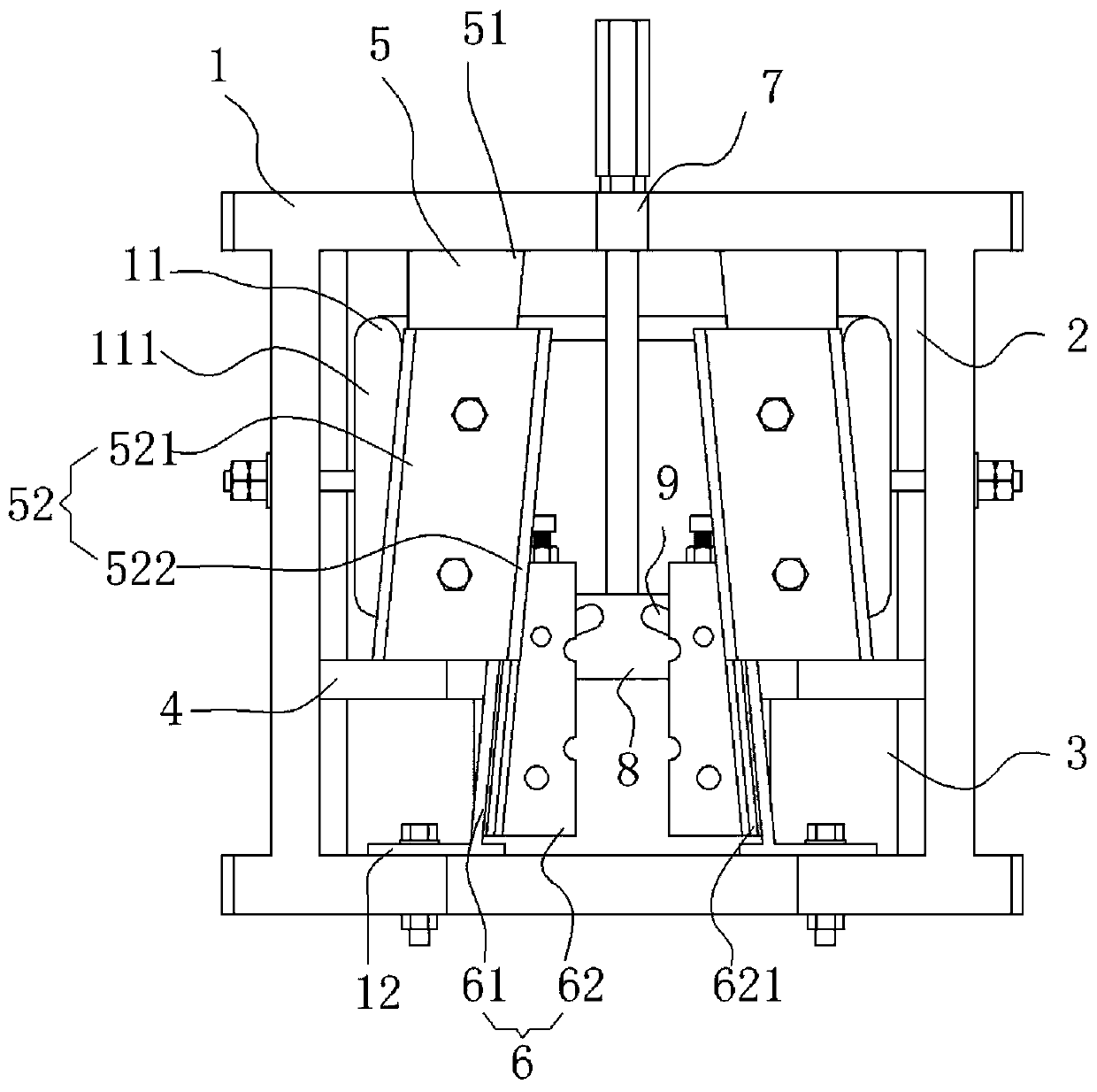

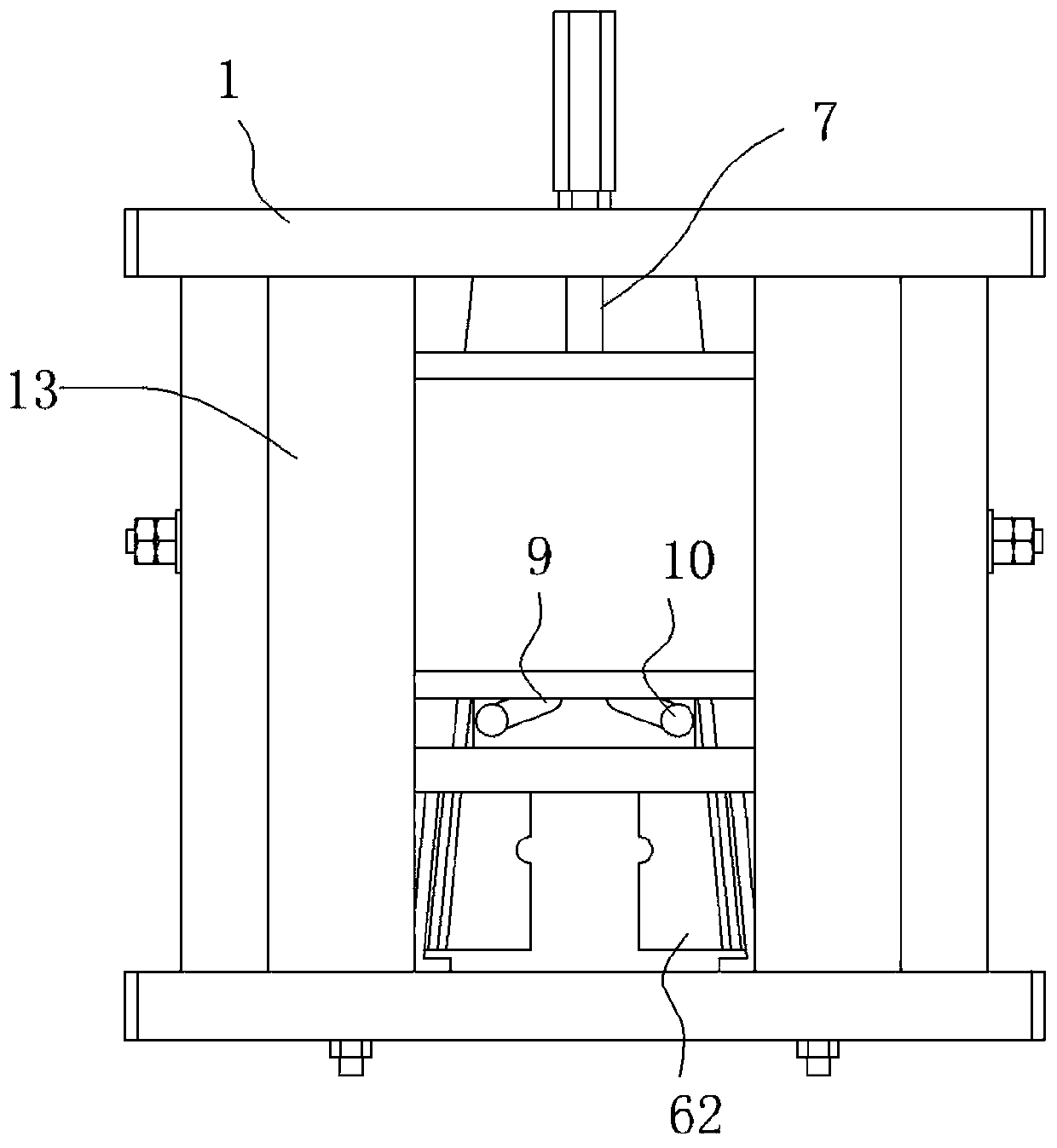

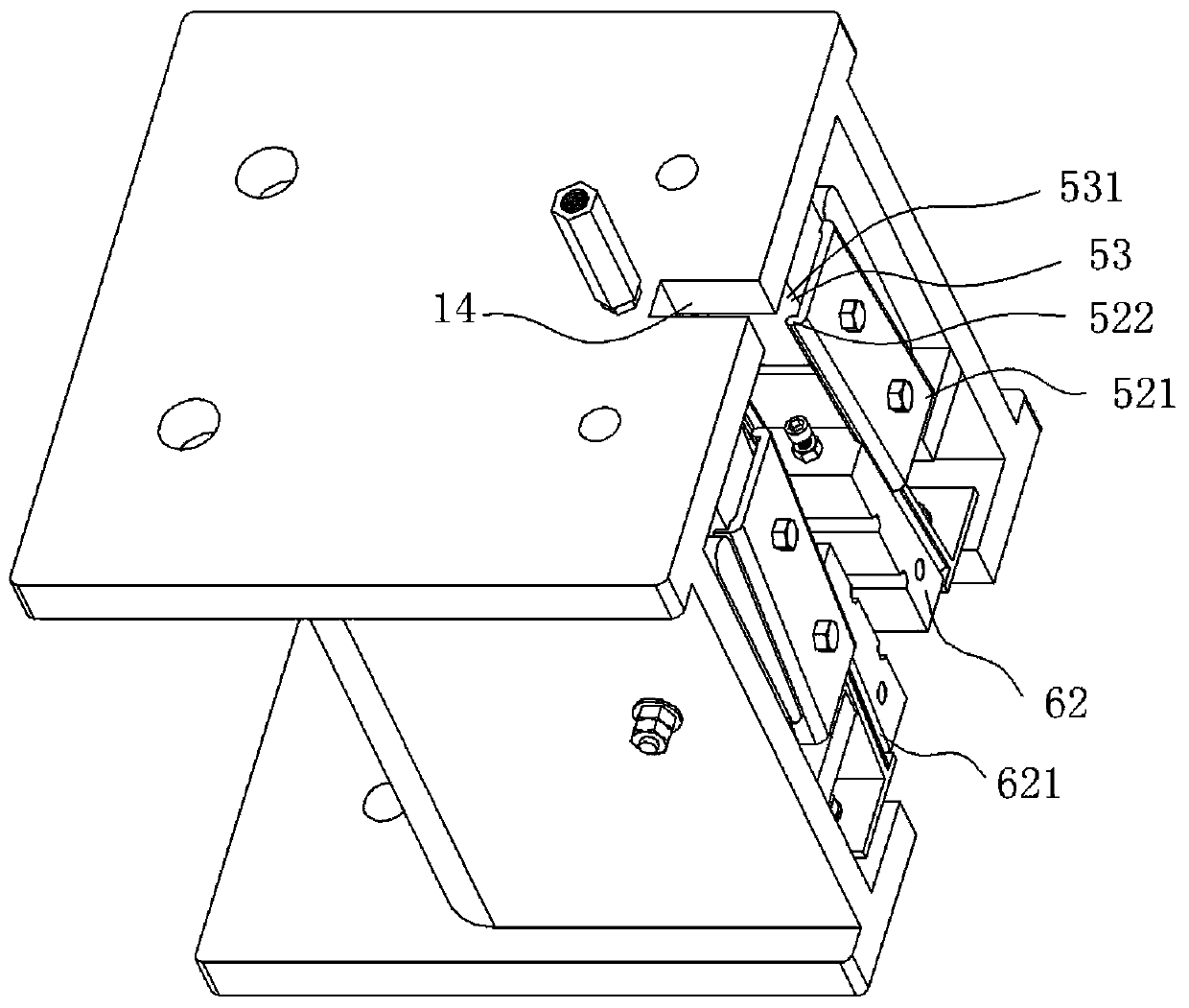

InactiveCN111017675ANot easy to derailReduce security risksElevatorsStructural engineeringMechanical engineering

The invention discloses an elevator safety protection clamp. The elevator safety protection clamp comprises a support, an upper cavity and a lower cavity, wherein the upper cavity and the lower cavityare formed in the support and connected vertically. The elevator safety protection clamp further comprises an upper clamp body arranged in the upper cavity and a lower clamp body arranged in the lower cavity, and the upper clamp body can move horizontally. The upper clamp body comprises two upper fixing clamp blocks and sliding parts arranged on the two upper fixing clamp blocks, and limiting parts are formed between the sliding parts and the upper fixing clamp blocks. The lower clamp body comprises two lower fixing clamp blocks arranged on the support and movable wedge blocks arranged on thetwo lower fixing clamp blocks, sliding part matching parts matched with the sliding parts are arranged on the movable wedge blocks, and the lower fixing clamp blocks penetrate through the upper end of a partition plate and are clamped in the limiting parts. The elevator safety protection clamp further comprises a pull rod, one end of the pull rod penetrates through the upper side wall of the support, a connecting block is connected to the other end of the pull rod, pin holes inclined upwards are formed in the connecting block, and pin shafts penetrating through the pin holes are arranged on the rear side walls on the lower fixing clamp blocks. The elevator safety protection clamp can effectively prevent digression and is high in safety.

Owner:武汉晋松科技有限公司

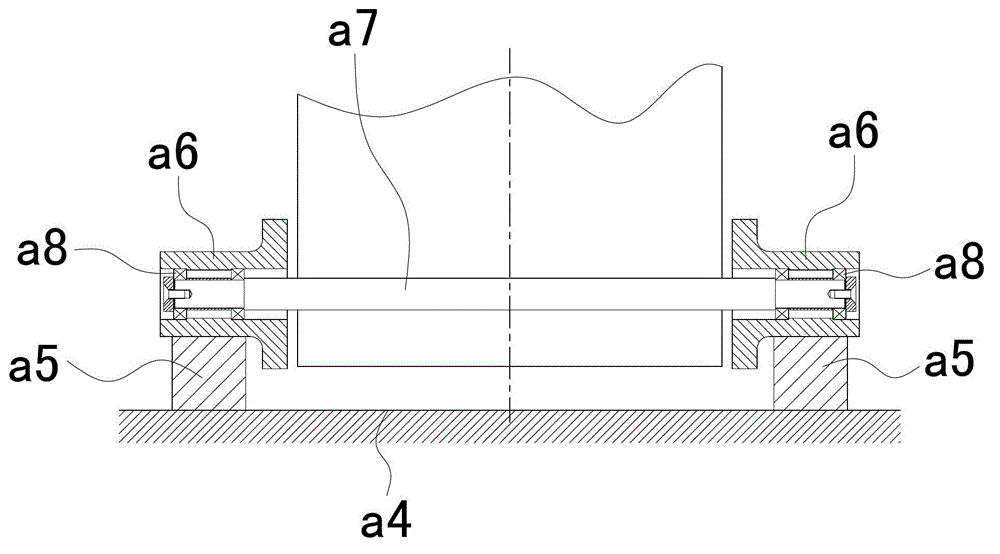

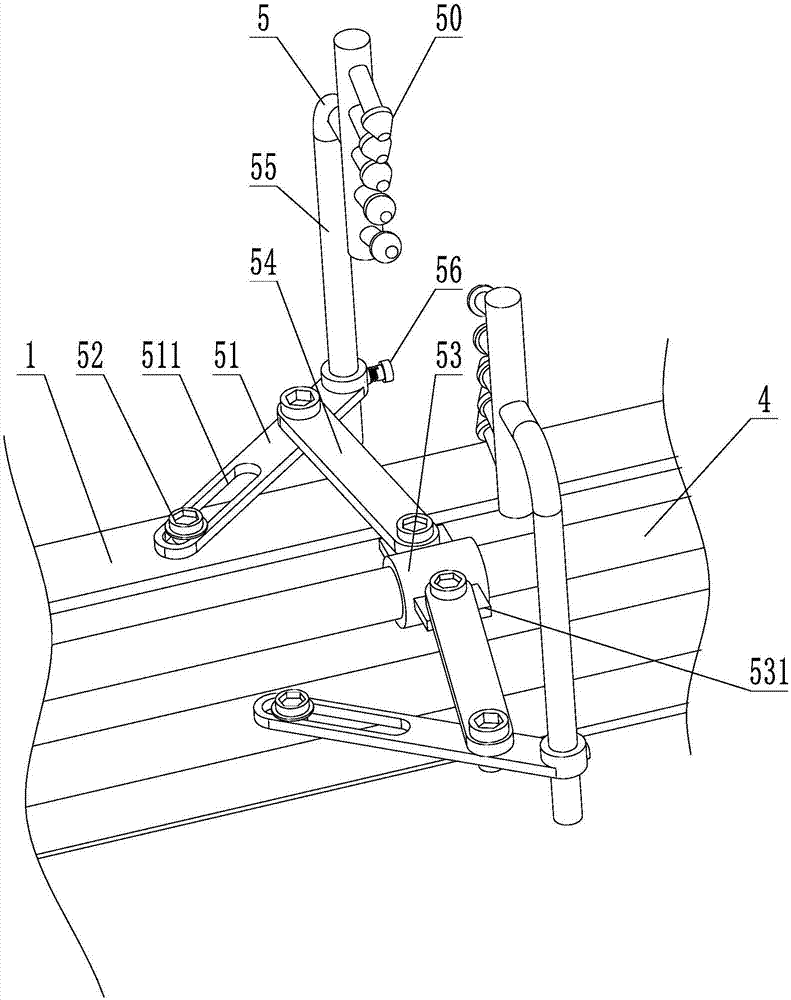

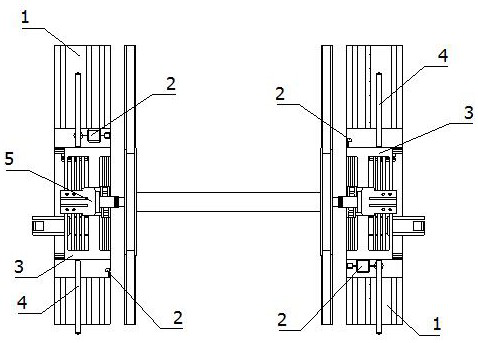

High-precision wheel set positioning and transferring mechanism for production of railway vehicles

InactiveCN111634630APrevent jumpingAutomatic speed adjustmentControl devices for conveyorsAlarmsRotational axisTransfer mechanism

Owner:殷建平

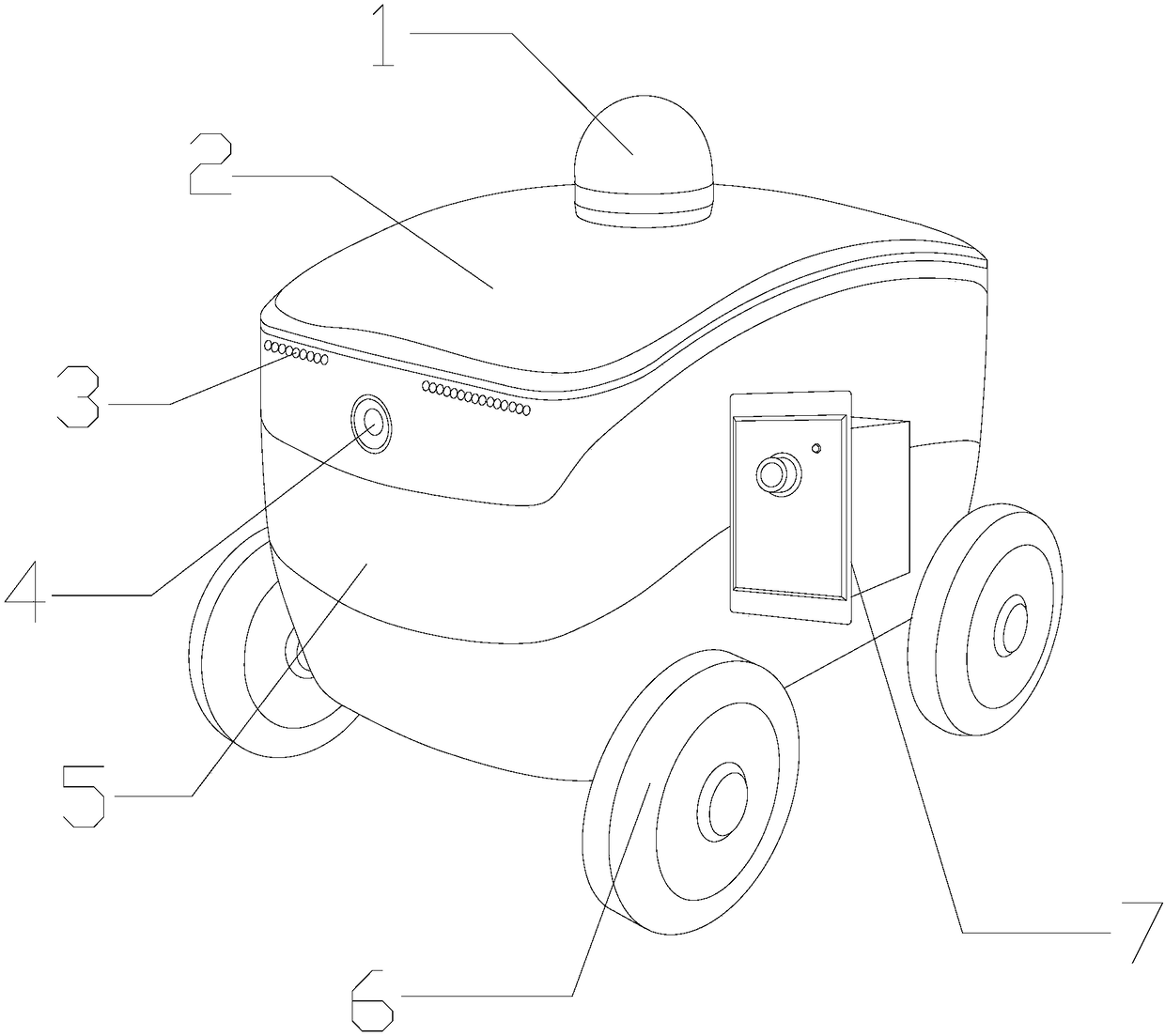

Intelligent robot for industrial transportation

ActiveCN108263510AApplicable to various transportation conditionsWide applicabilityGearing controlManipulatorInterference fitControl theory

The invention discloses an intelligent robot for industrial transportation. The intelligent robot for industrial transportation structurally comprises a warning light, an upper installation cover, driving indicator lights, a camera, a machine body, moving travelling wheels and a speed controller. The upper installation cover is in interference fit with the upper part of the machine body, the speedcontroller is in interference fit with the middle portion of the right side of the machine body, the warning light is arranged on the middle portion of the upper part of the upper installation cover,and more than two driving indicator lights are of a round structure. The driving indicator lights are evenly arranged above the front end of the machine body at equal intervals in an interference fitmode, and the camera is of a round structure and arranged on the lower parts of the middle portions of the driving indicator lights and is in interference fit with the machine body. More than two moving travelling wheels are arranged and every two moving travelling wheels are parallel to each other. The moving travelling wheels are evenly arranged on the periphery below the machine body at equalintervals and structurally provided with the speed controller. When the intelligent robot for industrial transportation is used, the transportation speed can be adjusted to be suitable for all transportation conditions, and the use applicability is wide.

Owner:扬州市苏尔电气有限公司

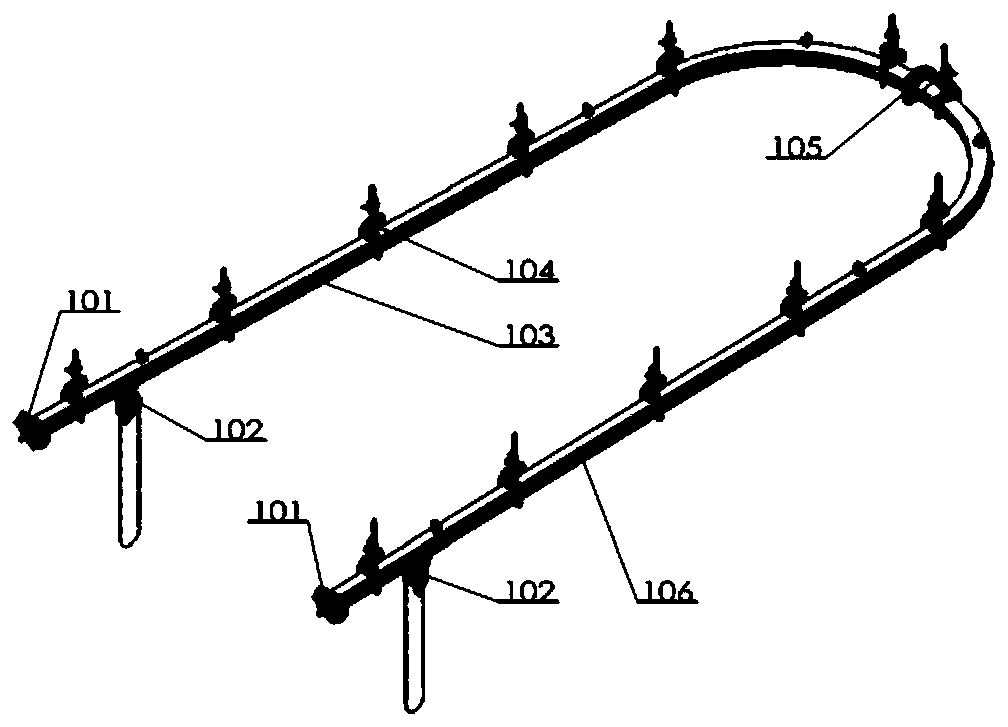

Traveling wheel mechanism with automatic lifting function and for rail trolley

Owner:CSIC NO 710 RES & DEV INST

Novel vertically parallel dual track transportation tool and layout method

InactiveCN105711598AEasy U-turnMeet the needs of public transportationRailway componentsElevated railway without suspended vehicleDrive wheelEngineering

The invention relates to the technical field of rail transportation tools, in particular to a novel vertically parallel dual track transportation tool which comprises upper rails, lower rails and haulage motors, wherein the upper rails and the lower rails are vertically parallel to one another, and each haulage motor is arranged between the corresponding upper rail and the corresponding lower rail; the bottom of each haulage motor is provided with a drive wheel, the drive wheels are supported by the lower rails, the bottom of each haulage motor is further provided with lower guide wheels clamped to the two sides of the corresponding lower rail, the top of each haulage motor is provided with upper guide wheels clamped to the two sides of the corresponding upper rail, and the novel vertically parallel dual track transportation tool further comprises a supporting support for bearing the upper rails and the lower rails.The novel vertically parallel dual track transportation tool has the advantages of being high in speed, high in passenger capacity, portable, fast, convenient, safe, not prone to derail, high in efficiency, small in occupied space, low in noise and the like and is low in building, operating and maintaining cost, it is beneficial to meet the requirement for urban public transportation, by means of a novel urban rail transportation tool layout method, cost can be lowered, space is saved, it is convenient for the haulage motors to turn back, linear expansion in the whole city is achieved easily, and the problem of urban congestion is solved.

Owner:GUANGZHOU DAODONG NEW ENERGY CO LTD

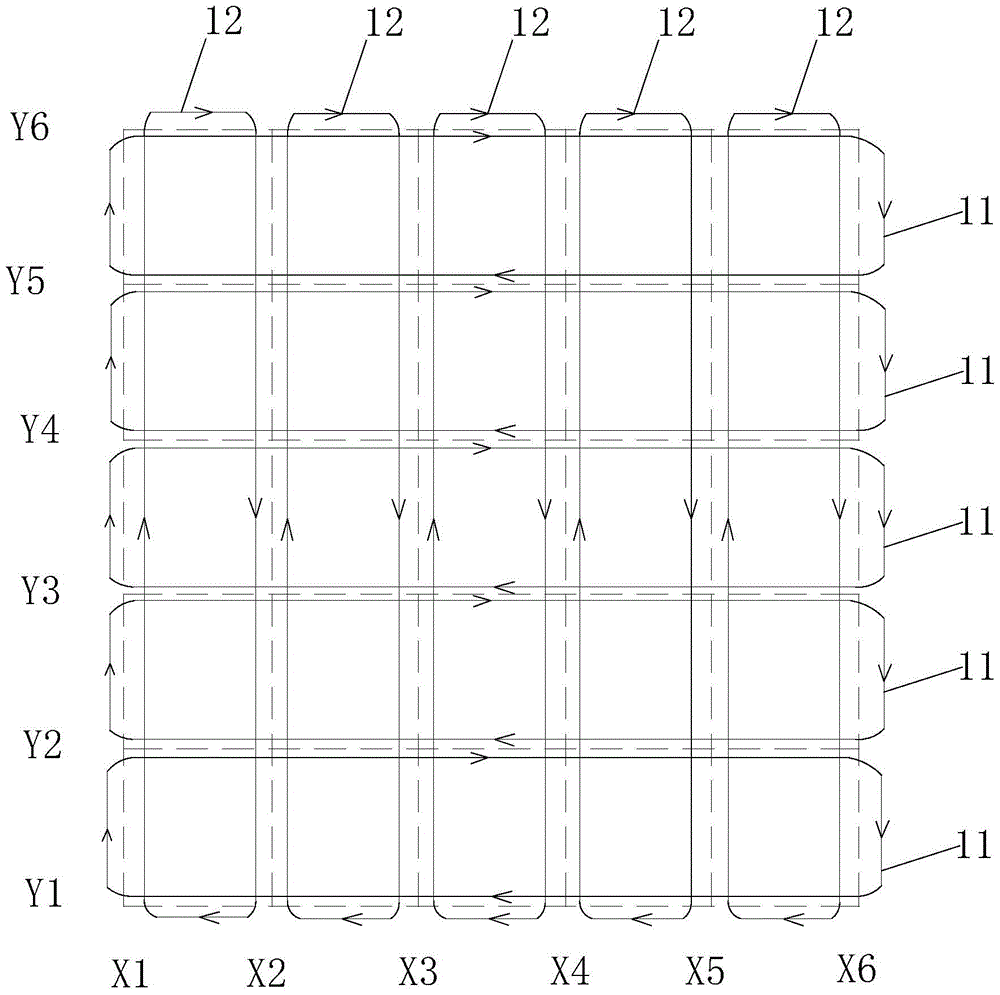

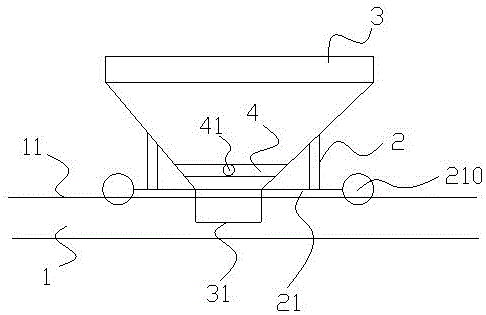

Meal automatic transmission device and automatic meal transmission method in cafeteria

The invention relates to an automatic delivery device for meals and a method for automatic delivery of meals in a restaurant. The device includes: a meal delivery track, which is a guide rail laid on a track support, and the position corresponding to each table position on the guide rail Proximity sensors are respectively provided at the corners of the guide rails and guide rails, and sliding contact lines are provided on both sides of the guide rails; the dining car includes power locomotives symmetrically arranged at both ends and several compartments connected in series between the two locomotives. The locomotives are used for traction When the whole vehicle is running, there are brushes on both sides of the bottom plate of the front, which are used to take power from the trolley line; guide wheels and balance wheels are respectively arranged on both sides of the front and the two sides of the carriage, to keep the body along the The movement of the rails and the left and right balance of the body; the console is used to control the operation of the food delivery car. The invention has high safety performance, stable operation of the food delivery car, is not easy to derail, and can deliver the food specified by the customer to the designated table, which solves the problem that the current automatic food delivery restaurant has single functions and cannot meet the different needs of customers.

Owner:李贺顺

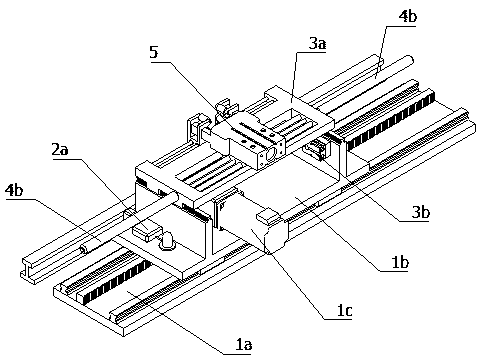

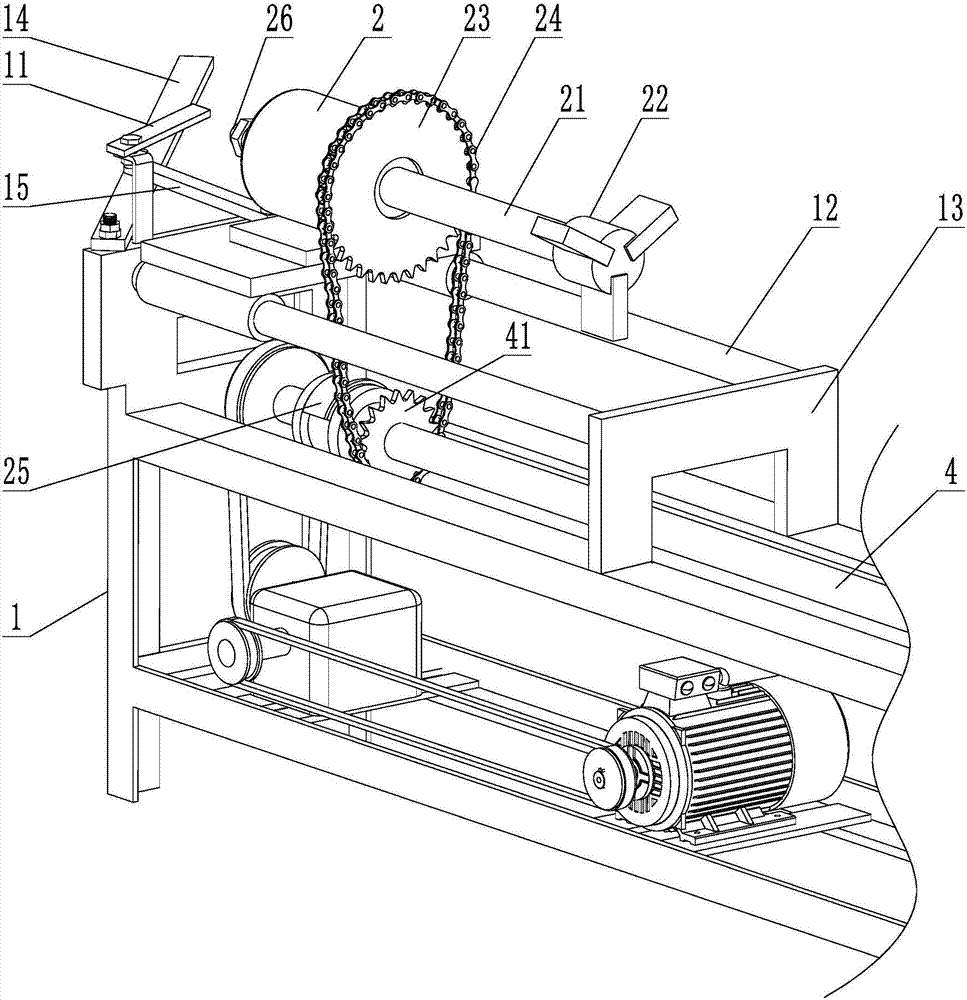

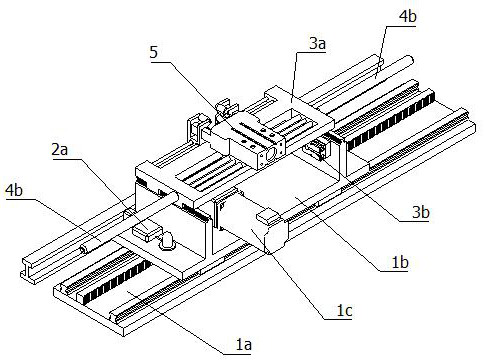

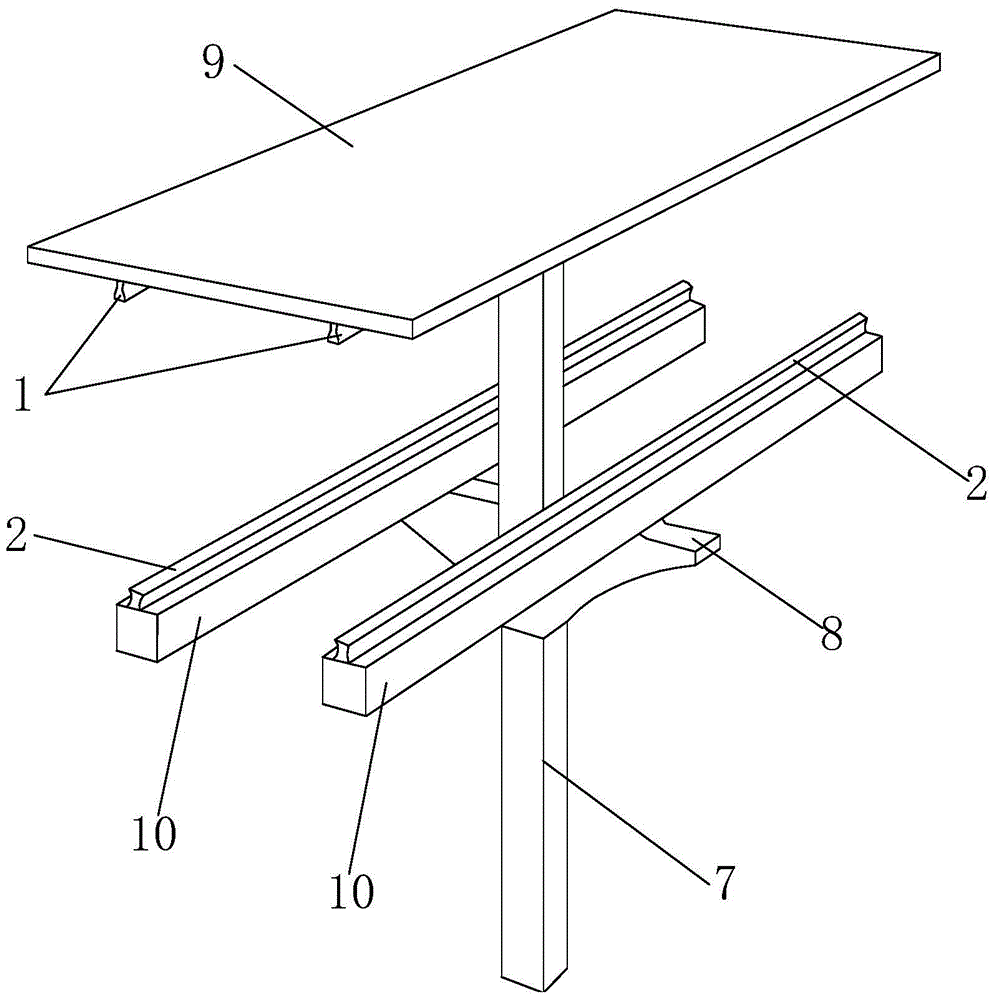

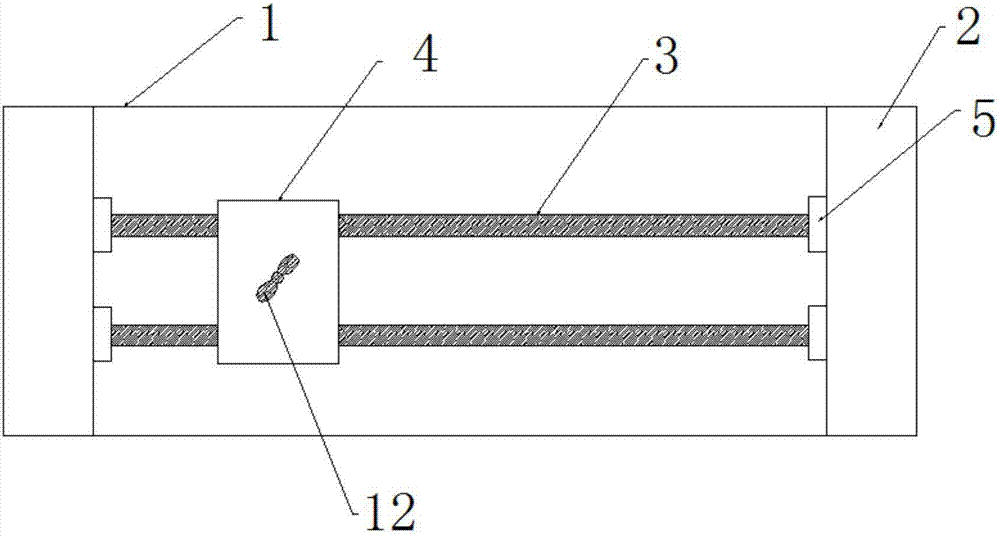

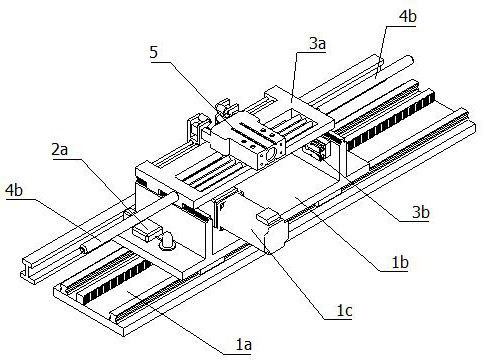

X-directional mechanism of feeding device and feeding device of extruder

The invention discloses an X-directional mechanism of a feeding device and the feeding device of an extruder. The X-directional mechanism of the feeding device of the extruder is used for enabling a Z-directional mechanism of the feeding device to perform a reciprocating motion in an X direction, so that the feeding device mounted on the Z-directional mechanism can move in the X direction. The X-directional mechanism comprises a guide rail set, an X-directional pushing mechanism arranged near a first end of the guide rail set, a movable base slidingly matched with the guide rail set and connected with an X-directional pushing end of the X-directional pushing mechanism, a first travel detecting element arranged at a first end of the guide rail set, and a second travel detecting element arranged at a second end of the guide rail set; and the guide rail set comprises a fixed plate arranged on the corresponding side of the extruder in the length direction of the extruder, and a guide railsupport set arranged on the outer side of the fixed plate. The feeding device of the extruder comprises the X-directional mechanism.

Owner:CHONGQING JIANGDONG MACHINERY

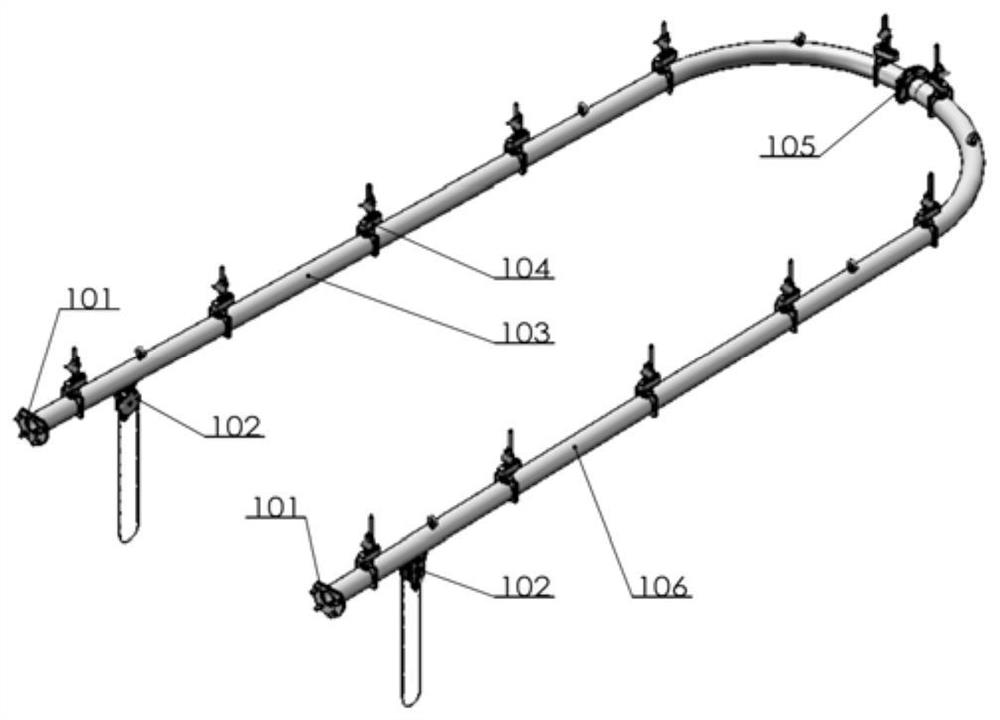

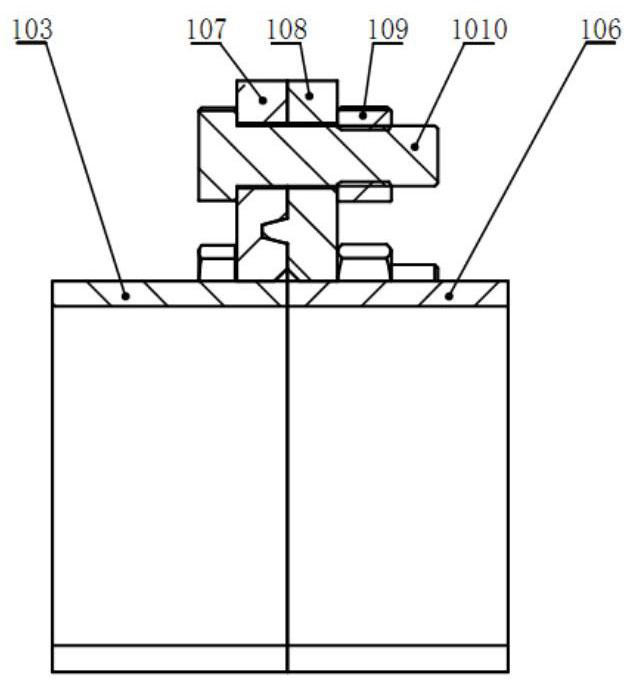

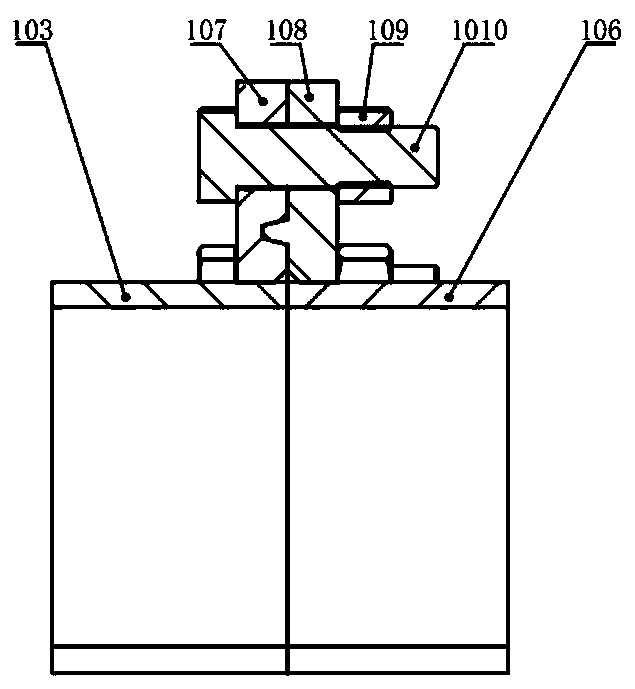

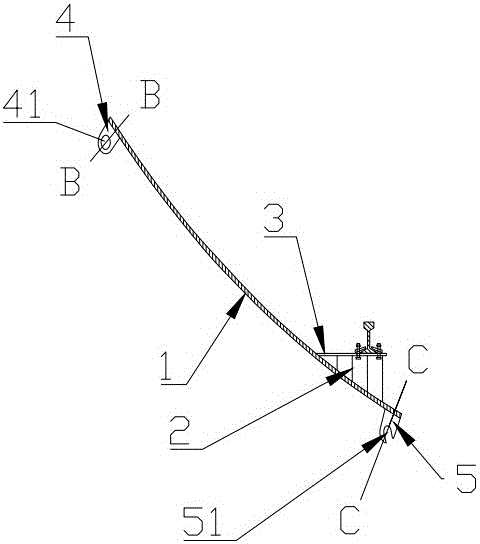

Tube rail hoisting device

ActiveCN111747299ASimple cross-sectional shapeNot easy to derailTravelling gearRunwaysControl theoryHoist device

The invention relates to novel hoisting equipment, in particular to a tube rail hoisting device which is of an integrated hoisting structure combining a tube rail and a ball wheel trolley. The tube rail hoisting device includes the tube rail, the ball wheel trolley, limiting flanges, connecting structures and counter flanges; the tube rail is composed of a plurality of sections of straight groovedpipelines and curved grooved pipelines, and the sections are connected and fixed by the counter flanges; the tube rail is fixed to the tops of an adit or buildings such as a factory through the connecting structures; the ball wheel trolley is built in the tube rail; and the limiting flanges are installed to the outermost ends of the head and tail sections of the tube rail to limit the travel of the ball wheel trolley. The tube rail hoisting device is high in safety, low in cost and simple to install and operate, and can be widely used in various medium and small hoisting places, especially inhoisting operations of various underground projects.

Owner:63653 FORCES PLA

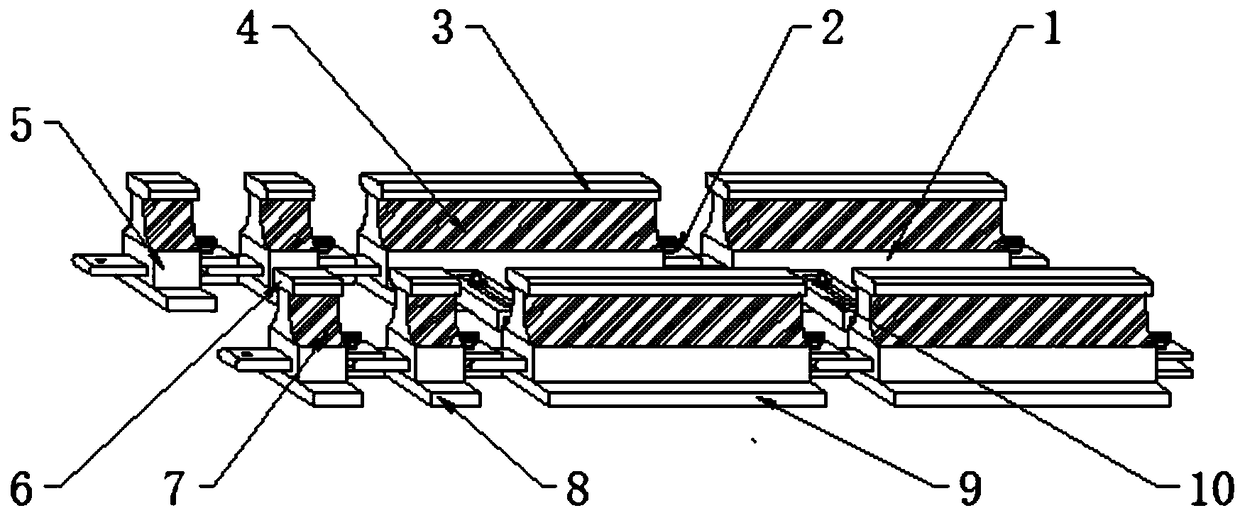

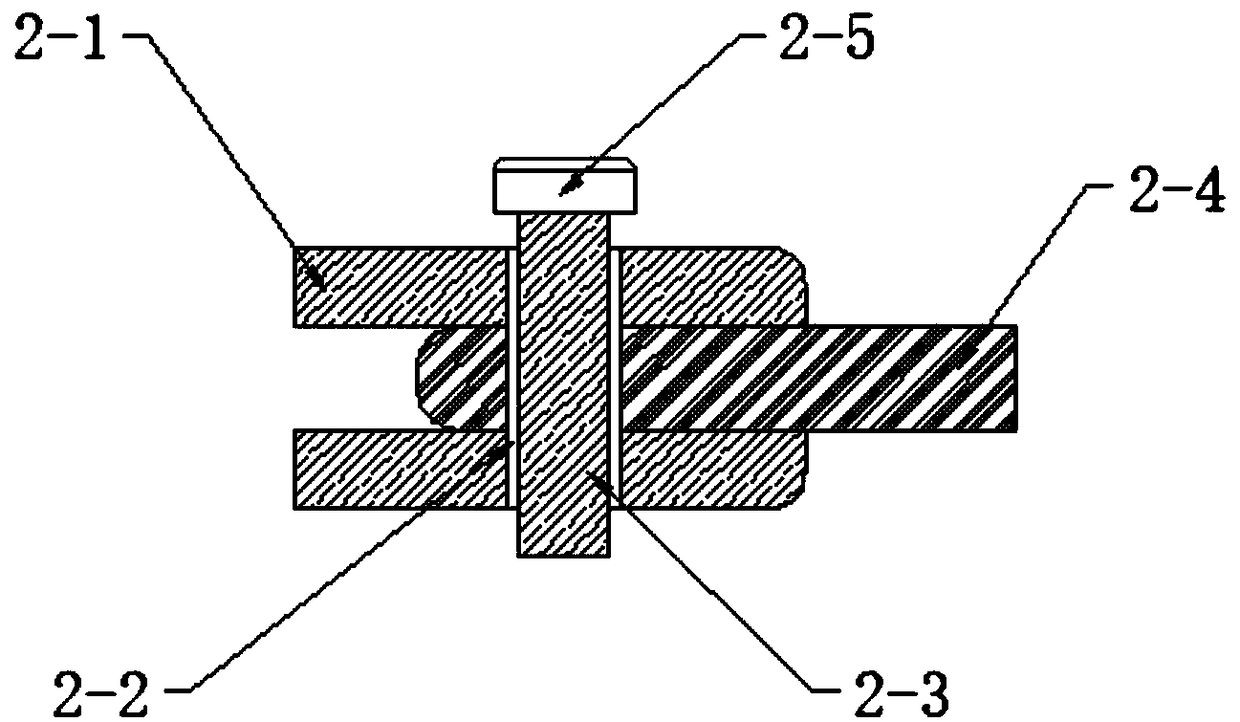

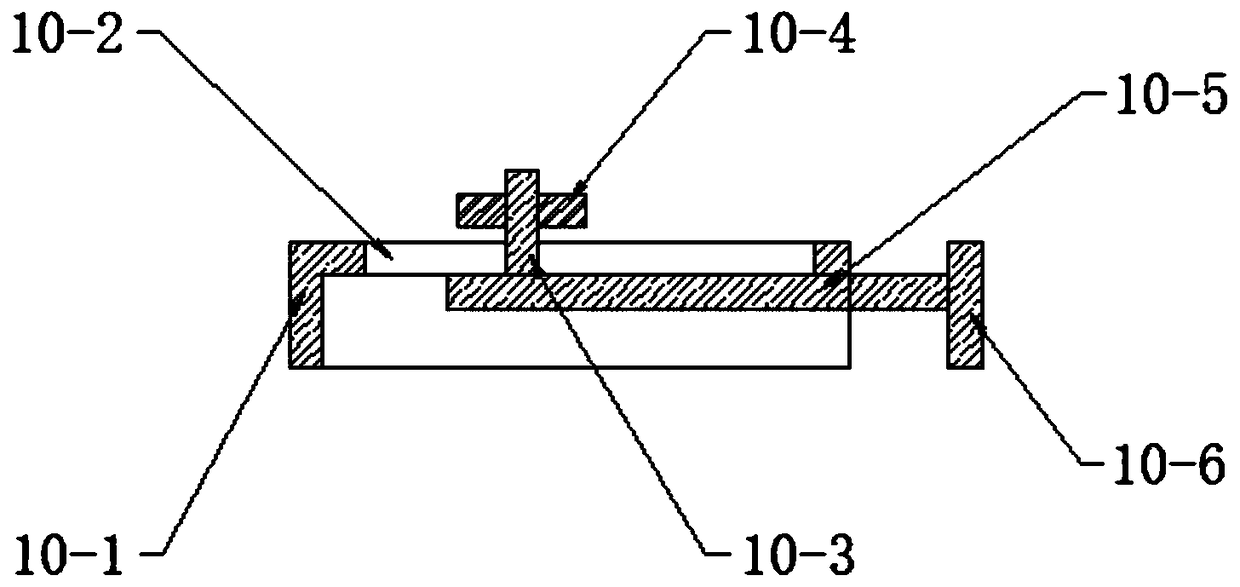

Walking robot track

The invention discloses a walking robot track, which comprises sleeper rails, connecting mechanisms, curved sleeper rails and gauge adjustment mechanisms. The adjacent sleeper rails are connected in sequence through the connecting mechanisms, the sleeper rails and the curved sleeper rails are fixedly connected by the connecting mechanisms, and the gauge adjustment mechanisms are disposed between the two parallel sleeper rails correspondingly, the gauge adjusting mechanisms are horizontally disposed on the sidewalls of the sleeper rails, and are welded to the sleeper rails, and the two parallelsleeper rails are fixedly connected by the gauge adjustment mechanisms correspondingly; each of the connecting mechanisms is composed of a slot plate, a clamping plate and a positioning bolt, and themiddle positions of the slot plate and the clamping plate are provided with through holes. The slot plates are horizontally disposed on the sidewalls of the sleeper rails and welded to the sleeper rails. The clamping plates are horizontally disposed on the opposite sides of the slot plates, and welded to the sleeper rails. The walking robot track has the advantages of being capable of quickly splicing tracks, unlikely to derail during turning and accurate in adjustment of the gauge.

Owner:亚太空列(河南)轨道交通有限公司

Pipe rail crane

InactiveCN110803624AMeet the needs of smooth trafficExtend the hoisting operation strokeTravelling gearRunwaysArchitectural engineeringFlange

The invention relates to novel hoisting equipment, in particular to an integrated hoisting structure combining pipe rails and ball wheel trolleys, namely a pipe rail crane. The pipe rail crane comprises the pipe rails, the ball wheel trolleys, limiting flanges, connecting structures and butt-joint flanges; the pipe rails are composed of a plurality of straight sections and bent sections of slottedpipelines, and the sections are connected and fixed through the butt-joint flanges; the pipe rails are fixed to the tops of buildings such as tunnels or factory buildings through the multiple connecting structures; the ball wheel trolleys are arranged in the pipe rails; and the limiting flanges are mounted at the outermost ends of the head section and the tail section of each pipe rail and used for limiting the strokes of the ball wheel trolleys. The pipe rail crane has the advantages of high safety, low cost and simple installation and operation, and can be widely applied to various small and medium-sized hoisting places, in particular to hoisting operations of various underground projects.

Owner:63653 FORCES PLA

Novel Doppler experimental teaching demonstration device

The invention discloses a new type of Doppler experiment teaching demonstration device, which comprises a water tank, a slide rail, a slider and a vibrating motor. The two opposite sides of the inner wall of the upper end of the water tank are bonded with connection platforms, and the connection platforms are arranged between There are parallel slide rails on which sliders are slidably installed, the vibration motor is fixedly installed on the base, a speed control switch is installed directly above the vibration motor, and one side of the speed control switch is fixed There is a battery installation slot, a speed control knob is arranged above the speed control switch, protruding card slots are provided on both sides of the bottom of the slider, a small roller is installed on the inner upper end of the card slot, and the slider The block and the slide rail are slidably connected by small rollers, and a vertically downward vibrator is installed at the bottom of the slide rail. The invention has simple structure, intuitive and obvious effect, simple operation and is convenient for students to understand the Doppler effect.

Owner:WUXI JIAN AUTOMATION TECH CO LTD

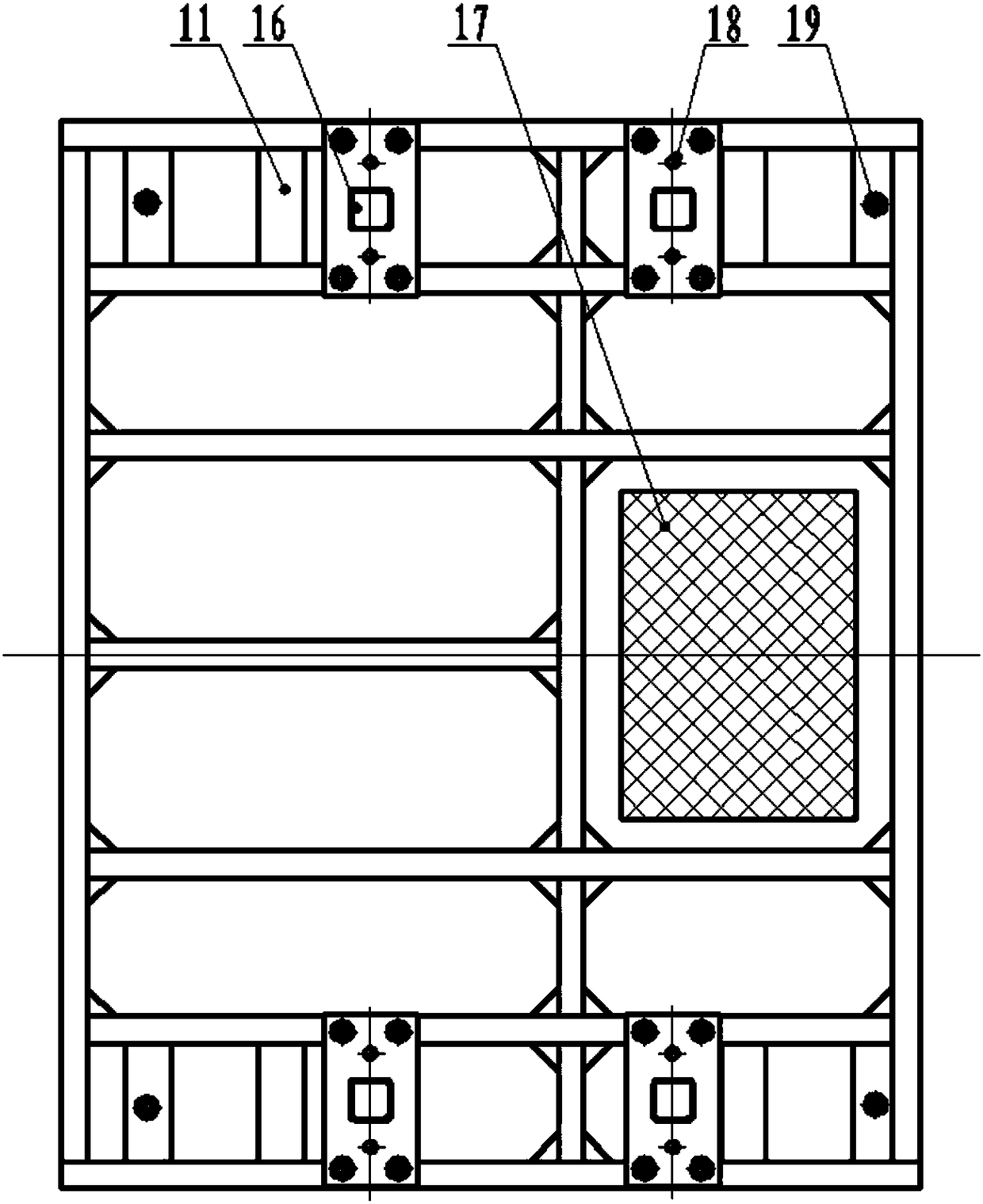

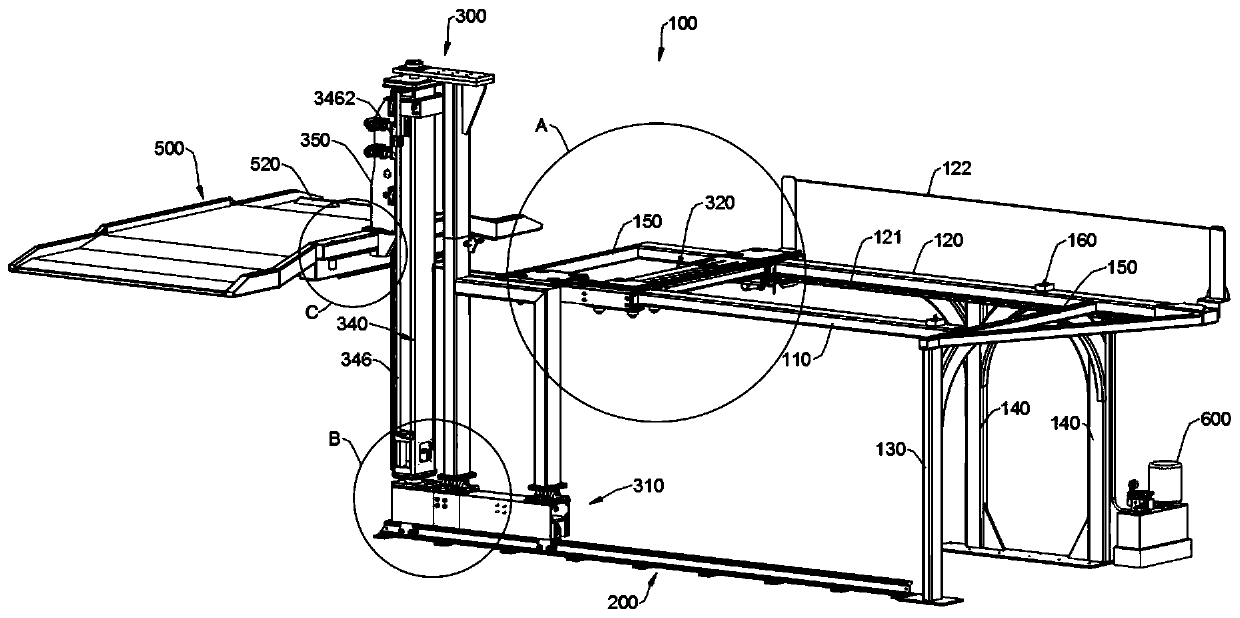

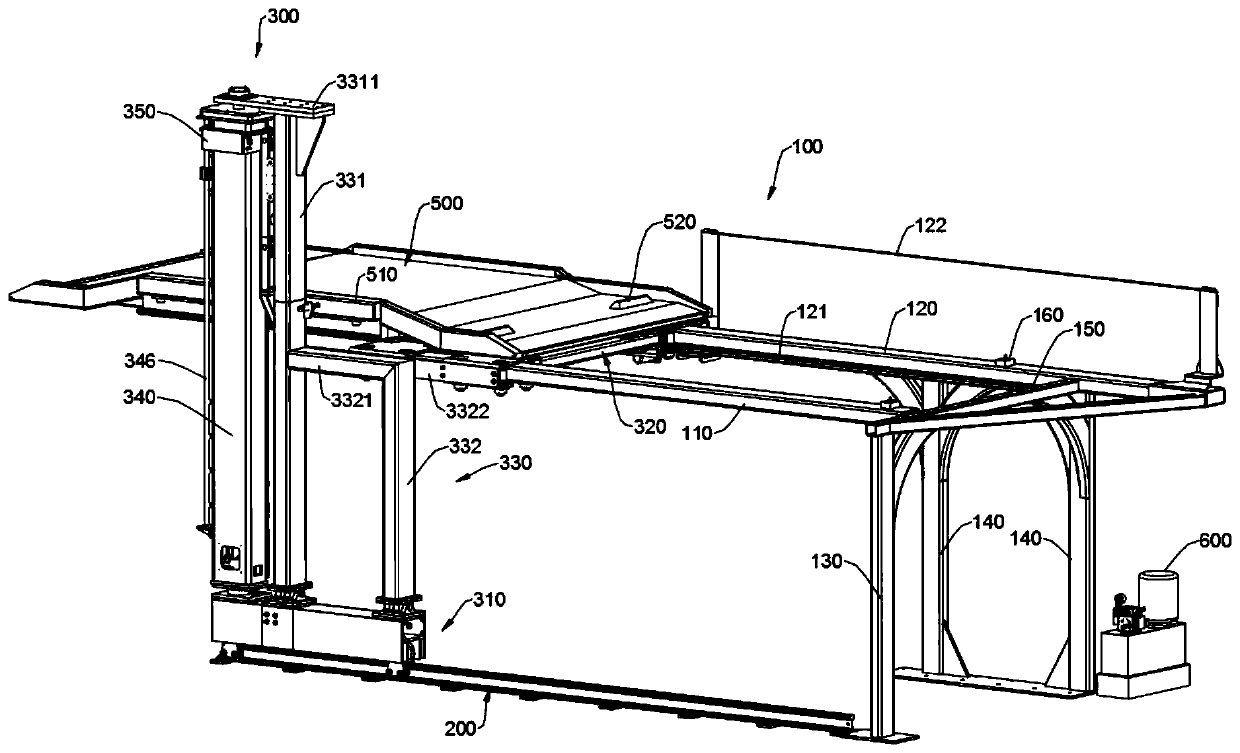

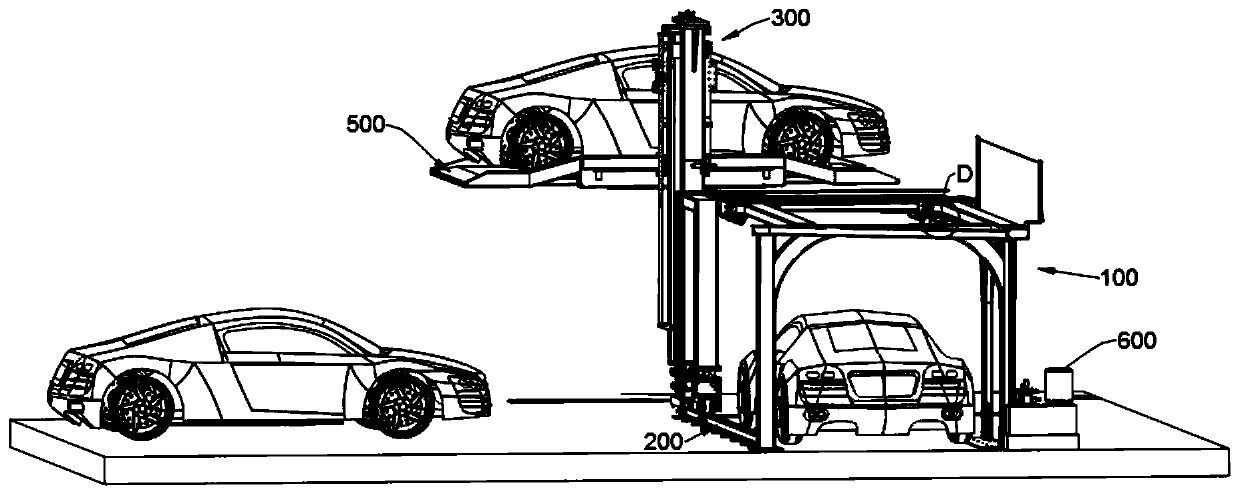

Mechanical stereo garage

PendingCN110541590ASolve instabilityEnsure safety and stabilityParkingsPortal frameAutomotive engineering

The invention relates to the field of stereo parking garages, in particular to a mechanical stereo garage. The mechanical stereo garage comprises guide rails, a portal frame and a parking device, wherein the portal frame comprises sliding beams which are parallel to the guide rails and located above the guide rails; and the parking device is used for transferring a vehicle carrying platen to the portal frame and comprises a first moving assembly, a second moving assembly, a main stand column, a lifting base and a connecting frame, the first moving assembly can move along the guide rails, the second moving assembly can move along the sliding beams, the connecting frame is connected with the first moving assembly and the second moving assembly, the main stand column is rotatably arranged onthe first moving assembly, and the lifting base can ascend and descend along the main stand column. The mechanical stereo garage is reasonable in structural arrangement, is stressed uniformly and hasno eccentric load, the first moving assembly and the second moving assembly are not easily derailed, operation is stable, safety and stability are realized in the parking process and under the stop and start conditions, the overall stability of the garage is good, and the garage does not occupy floor space.

Owner:杨智祺

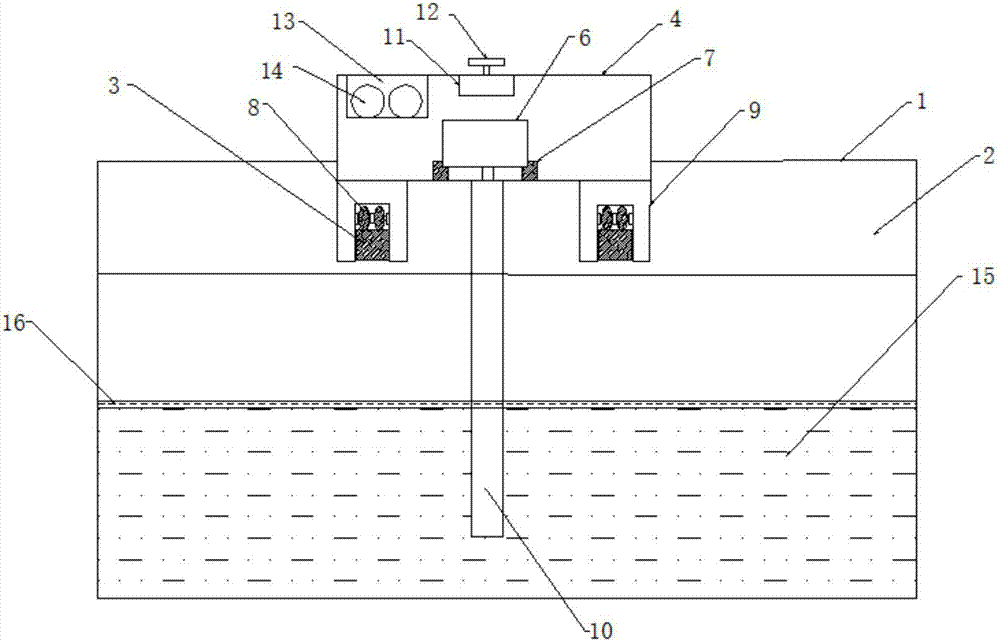

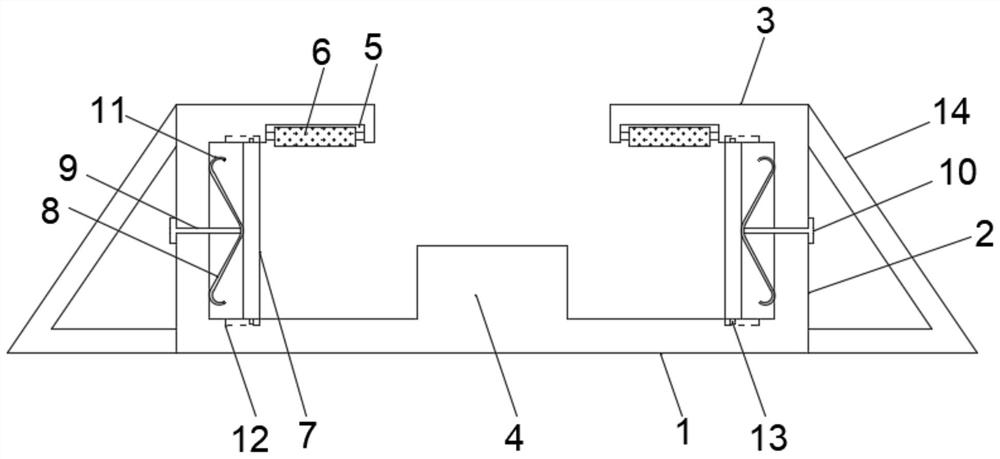

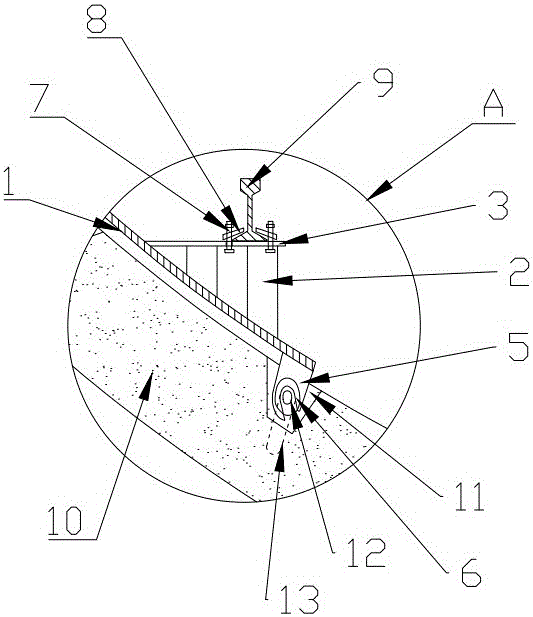

A track for underwater walking wheels that is not easy to derail

ActiveCN112030623BSmooth goingNot easy to derailWaterborne vesselsRailway tracksMarine engineeringStructural engineering

The invention belongs to the field of ship and marine engineering test facilities, and specifically discloses a track for an underwater traveling wheel that is not easy to derail, comprising a lower rail surface, a side rail surface and an upper rail surface. A number of rotating rollers are arranged; the opposite sides of the two rail surfaces are respectively provided with buffer plates, and a plurality of buffer parts are installed between each buffer plate and its adjacent side rail surfaces. The track provided by the present invention can limit the two traveling wheels of each group of traveling wheels together, and form a guide bar between the two traveling wheels to limit the offset distance of the traveling wheels, and limit the traveling wheels to the inside of the track ; The rolling contact between the roller and the running wheel greatly reduces the wear of the running wheel and the track. At the same time, the upper rail faces the floating wheel to limit the floating of the running wheel, so that the running wheel is not easy to derail. With cooperation, it can move to both sides. When the running wheel is deflected, the buffer plate can effectively buffer the deflection to prevent the running wheel from hitting the side rail surface and prevent the damage of the track.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

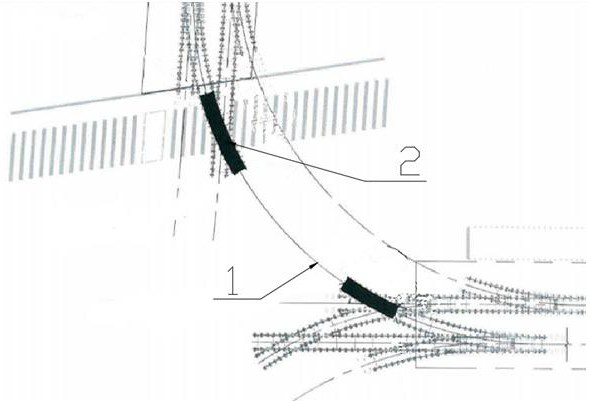

Device and method for increasing the running speed of tramcar shallow groove switch

ActiveCN111472213BGuaranteed safe operationNot easy to derailBallastwayTrack superstructureEngineeringSafe operation

The invention discloses a device for increasing the running speed of a shallow groove turnout of a tram, comprising: a ballast bed, a steel plate, and a turnout rail; A deep groove of a certain thickness is planed according to the existing turnout rail type, and the steel plate is clamped on the turnout rail through the deep groove, and the deep groove is used to limit the movement of the steel plate. The invention also discloses a method for improving the running speed by utilizing the device. When the trolley wheel pair turns quickly and passes the curved track, the increased part of the turnout rail has a better rail protection effect on the wheel rim, which ensures the safe operation of the tram. The technical solution of the present invention has a short construction period and is easy to implement , does not affect the normal operation of the electric bus.

Owner:THE FIFTH PROJECT OF CHINA RAILWAY BUREAU 14 GROUP +1

High-precision wheel pair positioning and transferring mechanism for railway vehicle production

InactiveCN111634631APrevent jumpingAutomatic speed adjustmentControl devices for conveyorsAlarmsRotational axisTransfer mechanism

Owner:殷建平

A fully automatic logistics loading and unloading device based on the Internet and highways

ActiveCN108100684BNot easy to derailEasy to useLoading/unloadingInterference fitLogistics management

The invention discloses a fully automatic logistics loading and unloading device based on the Internet and highways, the structure of which includes a light button, a driving button, an operation panel, a display screen, an operation button, a front mounting plate, a handle, a driving power supply, a front bottom plate, and a connecting block , automatic transfer table, workbench, rotating roller, rear cover, the front end of the automatic transfer table is equipped with a front-end mounting plate that is too fit, the work table is set above the automatic transfer table as an integral structure, and the light button is installed on the operation The middle part above the panel adopts interference fit. There are two drive buttons parallel to each other. The drive buttons are respectively installed at the left and right ends above the operation panel. When the guide table is in use, the rotating roller bar can be fixed and rotated, so that it is not easy to derail due to too fast rotation speed, and it is convenient to use.

Owner:徐州启峰智能科技有限公司

Sliding rail hanging bracket plate for mounting mechanical automation equipment

InactiveCN113602755ANot easy to derailQuick installation and removalVibration suppression adjustmentsMechanical conveyorsStructural engineeringIndustrial engineering

The invention discloses a sliding rail hanging bracket plate for mounting mechanical automation equipment. The sliding rail hanging bracket plate comprises two mounting plates, the front sides of the two mounting plates are provided with sliding grooves, the back sides of the two mounting plates are provided with connecting plates, the opposite sides of the two connecting plates are provided with a plurality of connecting rods, and each connecting rod is provided with a roller; and each roller wheel is slidably connected with the corresponding sliding groove, a movable plate is arranged between the two connecting plates, and a mounting groove is formed in the upper end of the movable plate. Compared with a traditional hanging bracket plate, the device is easier to disassemble and assemble, the equipment is more stable in the transportation process by arranging buffer springs, guide telescopic rods and other structures, internal parts of the equipment are prevented from being damaged due to shaking in the transportation process, meanwhile, by arranging a mounting box and other structures, when the equipment is placed, a stop lever can rise automatically, the equipment is prevented from slipping off when placed, and a connecting ring on the stop lever also facilitates further fixing of the equipment through a rope by a worker.

Owner:深圳市鑫顺康精密机械有限公司

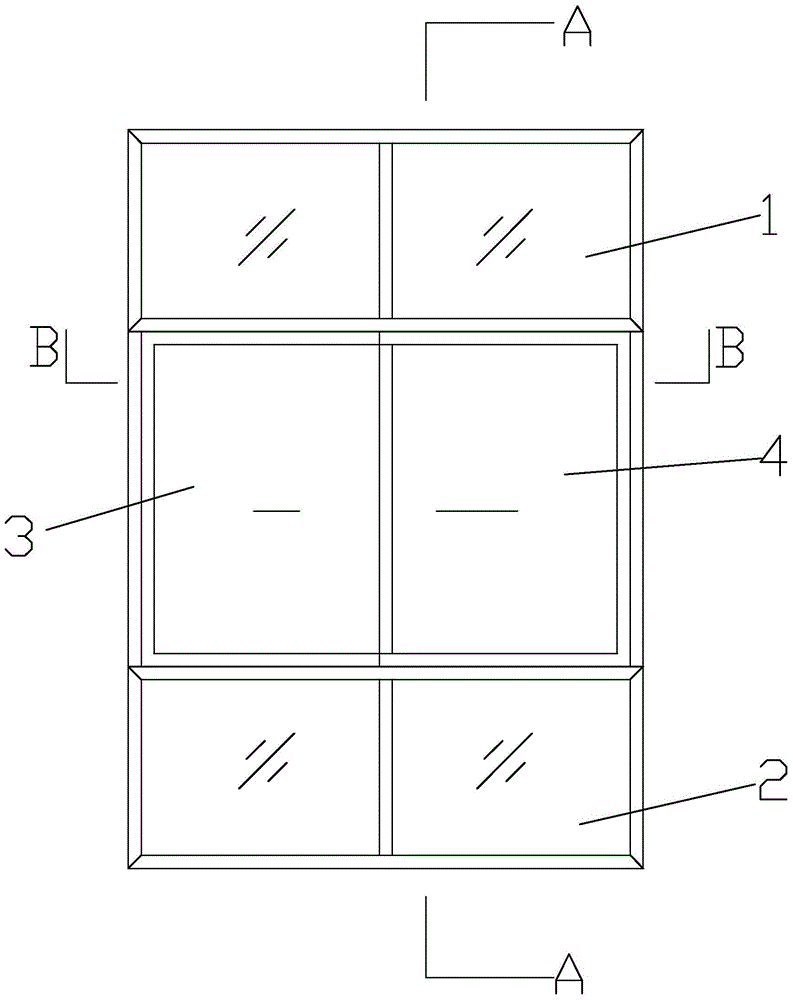

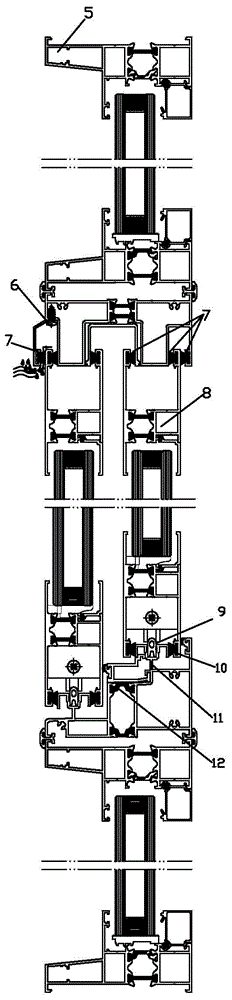

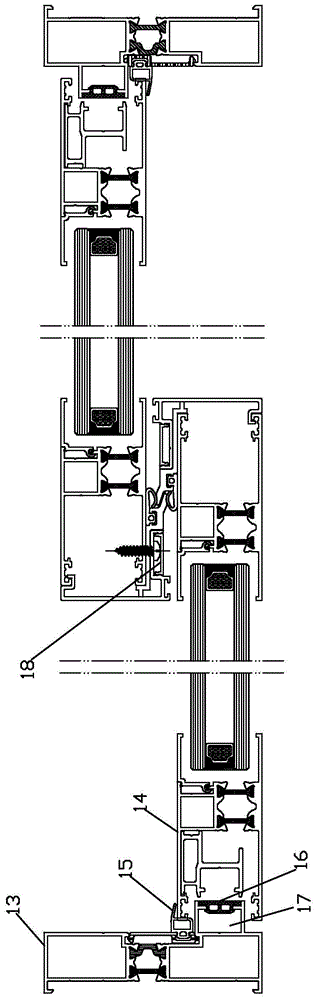

double track window

ActiveCN105134023BAvoid crackingImprove water tightnessCondensed water drain-offSealing arrangementsFixed frameSlide window

The invention relates to a dual-track sliding window. The dual-track sliding window comprises an upper fixed frame, a lower fixed frame and a sliding frame, a sliding sash comprises a left sliding sash body and a right sliding sash body which are installed in the sliding frame, combined corners are additionally arranged on the side edges of the upper fixed frame, apron flashing and upglide are fixed through a screw, sealing elements are arranged on the upper portion of the left sliding sash body and the upper portion of the right sliding sash body, corner combining is conducted on the left sliding sash body and the right sliding sash body through a corner combining machine, two-component adhesive is injected, and the bottom of the left sliding sash body and the bottom of right sash body are each provided with a balanced sliding window sealing structure. According to the dual-track sliding window, multi-seal is adopted, the balanced sliding window sealing structures and an outdoor sealing structure are additionally arranged, the water tightness, the air tightness and the wind pressure resistance are good, and the safety performance of the dual-track sliding window is increased.

Owner:ZHEJIANG JIANYE CURTAIN WALL DECORATION

A two-way traction trolley for a railway track bed operation device

ActiveCN103806402BGuaranteed uptimeGuaranteed stabilityRailway cleaningHydraulic cylinderVehicle frame

Owner:CRCC HIGH TECH EQUIP CORP LTD +1

Construction method of separate sleepers and sleepers for the follow-up trolley and battery car system of the portable shield machine

ActiveCN105369699BReduce consumptionReduce weightRailway track constructionMovable tracksUltimate tensile strengthOperation safety

The invention relates to a construction method for a dividing sleeper of a portable novel shielding tunneling machine backup trailer and an accumulator car system, which is used for separating an accumulator car sleeper from a trailer sleeper, so as to be independent from each other. The method can reduce steel consumption, effectively lighten the weight of the sleeper, and is convenient for dismounting; a shield trailer and an accumulator car can respectively work steadily and reliably; labor intensity of workers is reduced, labor efficiency of workers is improved, and occurrence rate of safety accidents of workers is reduced; the sleeper is not easy to derail after being used, a trailer running system and a platform accumulator car running system are divided into two independent running systems which do not interfere each other, the trailer and the platform accumulator car do not interfere each other and run in respective independent track systems; and the production and operation safety performance are high, the effect is remarkable, and the mechanical efficiency of operation is high.

Owner:龚金京

Feed allocation and distribution mechanism

InactiveCN106719020AReduce labor intensityFeed evenlyAnimal feeding devicesAvicultureVehicle framePush and pull

The invention provides an easy-to-move and even-feeding feed allocation and distribution mechanism. The feed allocation and distribution mechanism comprises a feed groove and a feeding vehicle, the feeding vehicle comprises a bottom and a travelling vehicle frame working in coordination with the groove wall of the feed groove, a feed hopper is arranged on the travelling vehicle frame, a spacing is arranged between the bottom opening of the feed hopper and the bottom of the feed groove, a feed blocking pulling board is arranged on inner side of the feed hopper, a slide groove is arranged in the side wall of the feed hopper, and the feed blocking pulling board passes through the slide groove and is connected with a push-and-pull rod. Through the travelling vehicle frame driving the movements of the feed hopper in coordination with the groove wall of the feed groove, the direction of the cart does not need to be manually adjusted when the materials are being fed, the travelling of the feed hopper is facilitated, and the labor intensity is reduced; each time when the materials are fed, firstly the feed blocking pulling board is pulled, after the feed falls down and fills up the space below the feed blocking pulling board and the opening and the bottom of the feed groove, the feed blocking pulling board is pushed back, and the place between the feed blocking pulling board and the bottom of the feed groove is placed with a certain amount of feed, then the travelling vehicle frame is pushed to move, in the moving process, the feed placed in the feed groove is flattened by the bottom of the feed hopper, and the evening feeding is achieved.

Owner:信宜市晓锋农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com