Tube rail hoisting device

A technology of pipe rails and trolleys, which is applied in the direction of track systems, load suspension components, and running gears. It can solve the problems of running gear jams, cumbersome processes, and dust pollution, and achieves fast installation, high safety, and smooth operation. Caton effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

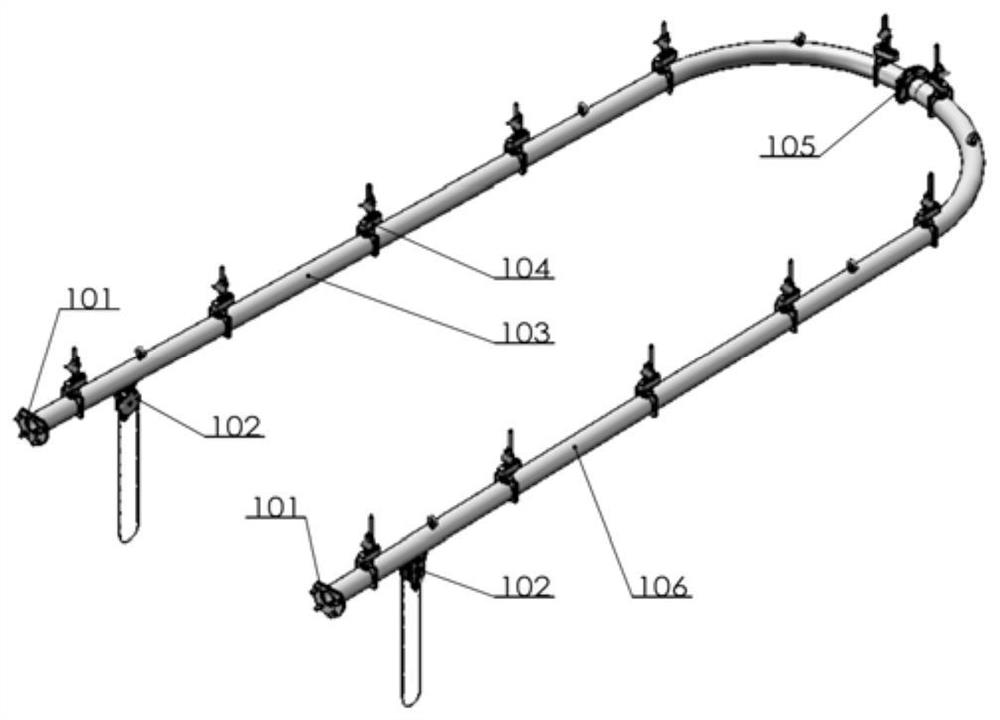

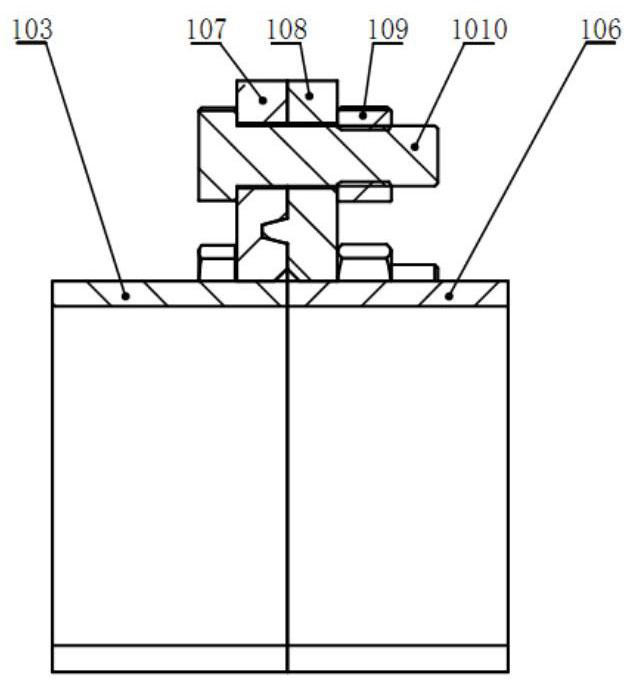

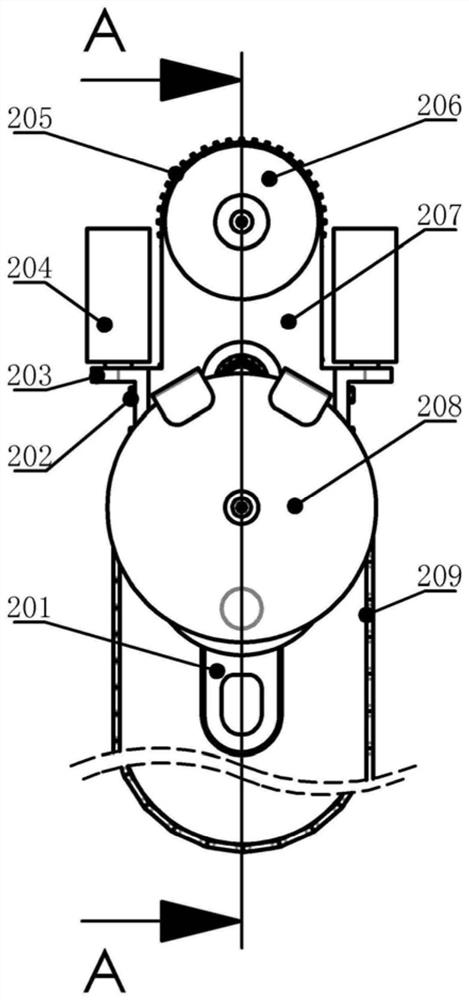

[0022] A pipe-rail crane, including a pipe rail, a ball wheel trolley, a limit flange, a connecting structure and a butt joint flange. The ball wheel trolley is mainly composed of two hemispherical wheels, two guide cylinders, two panels, a sprocket, and a gear combination Composed of structure and suspension ring, two hemispherical wheels are embedded in the pipe rail; the butt joint flange is a concave-convex flange connection structure, which is used to connect and fix the two sections of pipe rail; one side of the steel pipe is grooved, the section of the pipe rail is C-shaped, and the outer wall of the pipe rail passes through The connection structure is fixed to the rock wall or roof, the inner wall is used as the running track of the ball-wheel trolley, the outer wall of the pipe rail is fixed to the rock wall or roof through the connecting structure, and the inner wall is used as the running track of the ball-wheel trolley, and the ball-wheel trolley is mainly composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com