Blowing nozzle

A technology of blowing nozzles and nozzle boxes, applied in the direction of injection devices, injection devices, liquid fuel engines, etc., to achieve the effect of simple mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

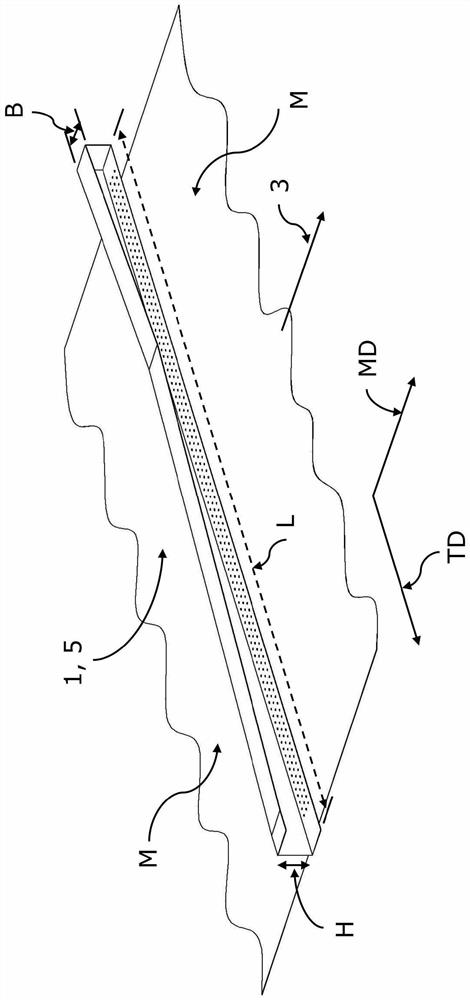

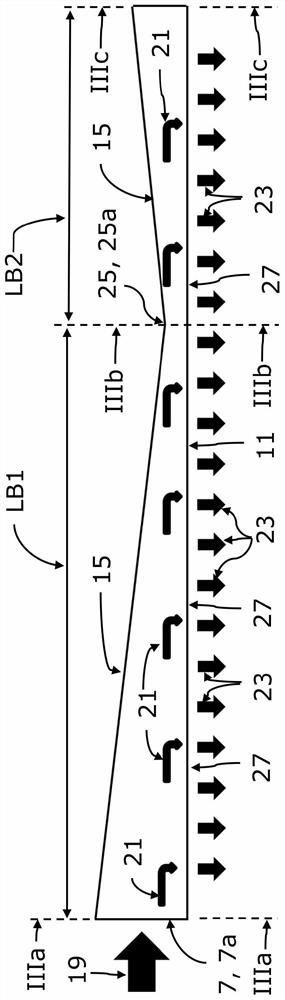

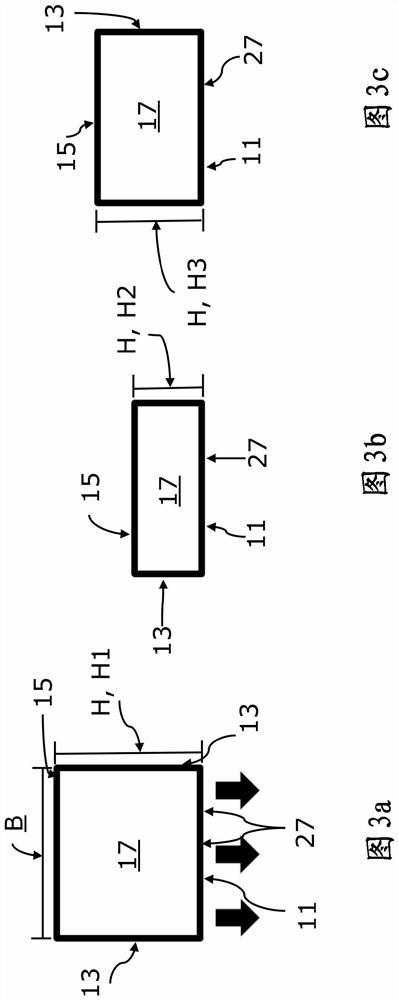

[0036] Discuss first figure 1 , which shows the blowing nozzle 1 according to the invention in a schematic three-dimensional representation.

[0037] Here, by figure 1 It can be seen that the mentioned blowing nozzle 1 is arranged, for example, above a moving material strip M which moves in the drawing-off direction in the direction of the arrow 3 . The material strip M is, for example, a plastic film stretched in a stretching device. The stretching device may be a transverse stretching device, a longitudinal stretching device or a sequential stretching device comprising, for example, longitudinal and transverse stretching stages or even a simultaneous stretching device.

[0038] exist figure 1 The blowing nozzles shown in are generally arranged not only on one side of the material strip M removed from below, but preferably symmetrically on both sides, that is to say above and below the material strip M at a distance of The mentioned is preferably arranged at a small distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com