High-speed carving machine for plane glass

An engraving machine and glass technology, applied in decorative arts, processing models, etc., can solve the problems of inability to fix the glass workpiece, no cooling device, damage to the glass workpiece, etc., and achieve the effect of shortening the engraving time, improving the accuracy, and reducing the labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

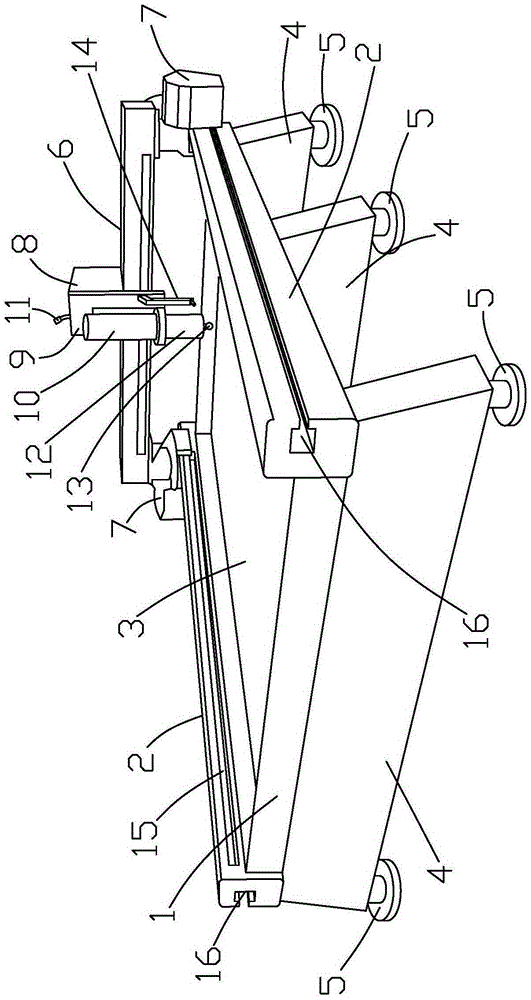

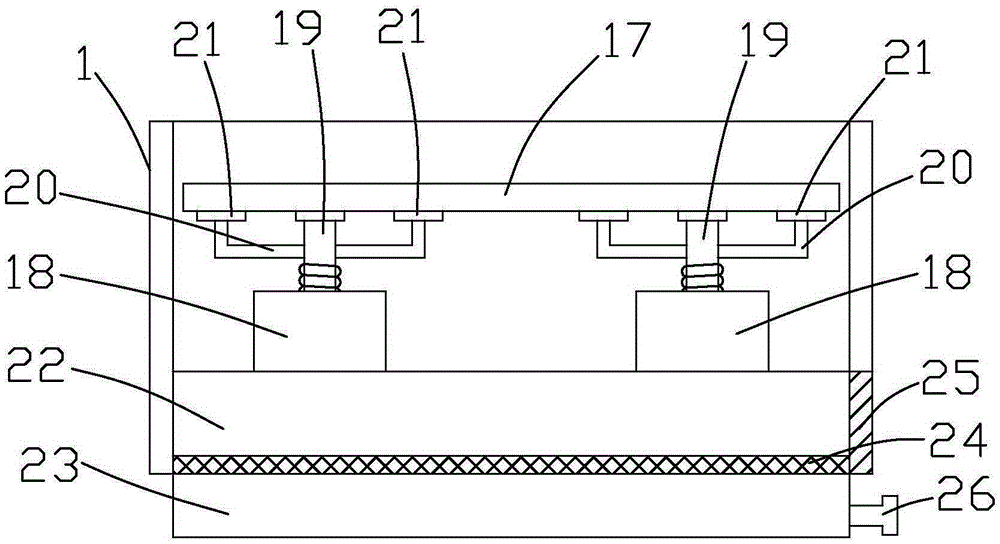

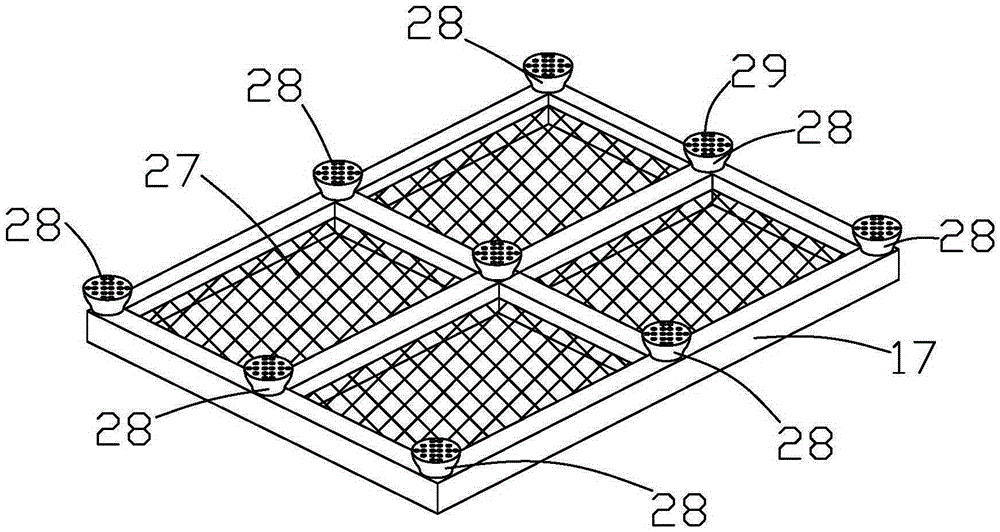

[0029] Such as Figure 1 to Figure 5As shown, it is a high-speed engraving machine for flat glass of the present invention, which includes an engraving table 1, a fixed base 4 and an engraving mechanism. 1 is provided with a glass positioning groove 3, the glass positioning groove 3 has changed the engraving method of the traditional glass workpiece, and can limit the glass workpiece in the glass positioning groove 3, preventing movement during the engraving process and affecting the final engraving effect The picking and placing of glass workpieces does not require manual handling, which greatly reduces labor intensity, improves processing efficiency, and shortens engraving time. A glass support frame 17 and a synchronous drive device 18 are arranged in the glass positioning groove 3, and the glass support frame 17 is located at Above the synchronous driving device 18, the glass workpiece can be positioned by the glass support frame 17, and under the drive of the synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com