Patents

Literature

35results about How to "Improve plastic fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites

InactiveCN102319954AImprove plastic fluidityClose contactNon-electric welding apparatusFiber bundleMetal matrix composite

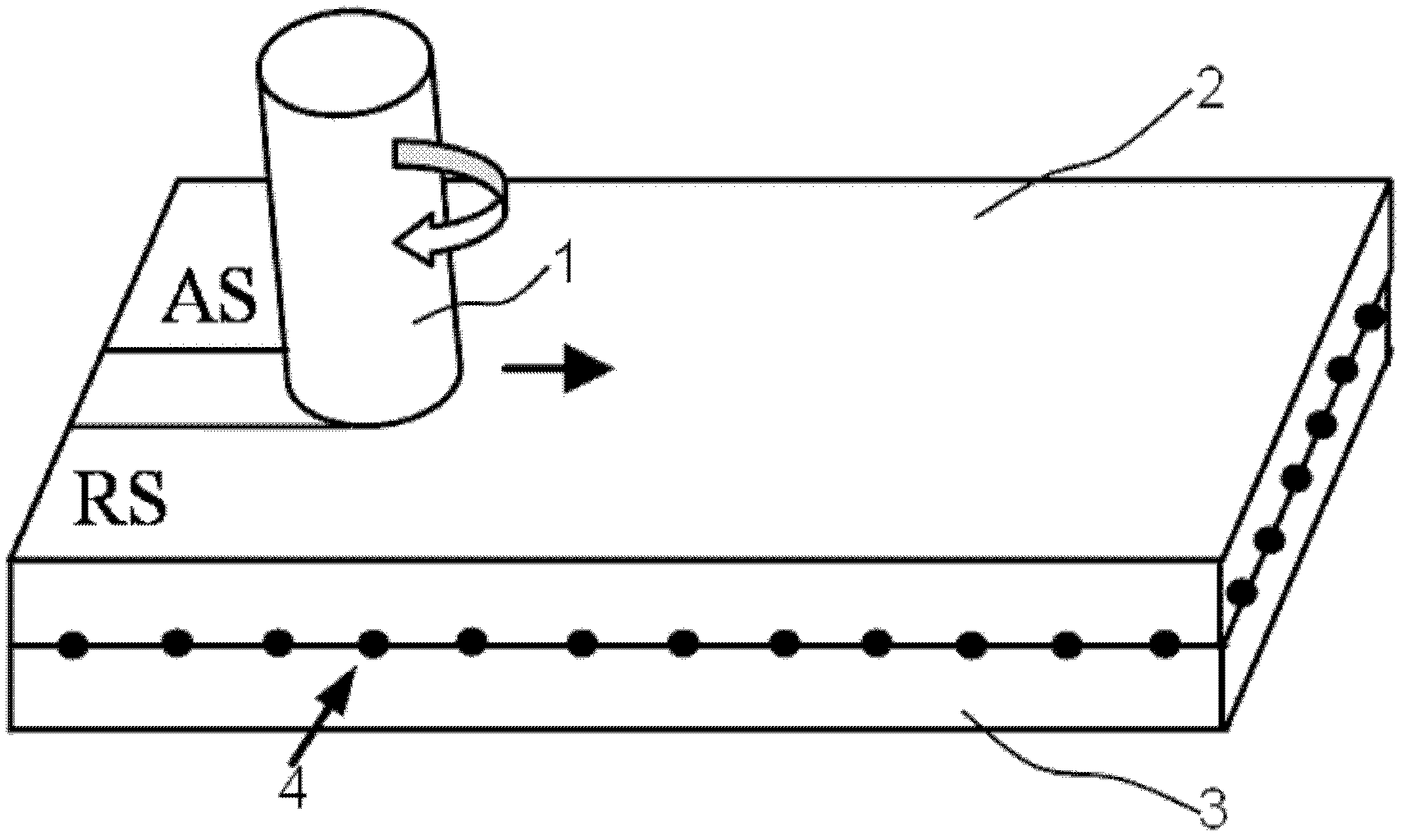

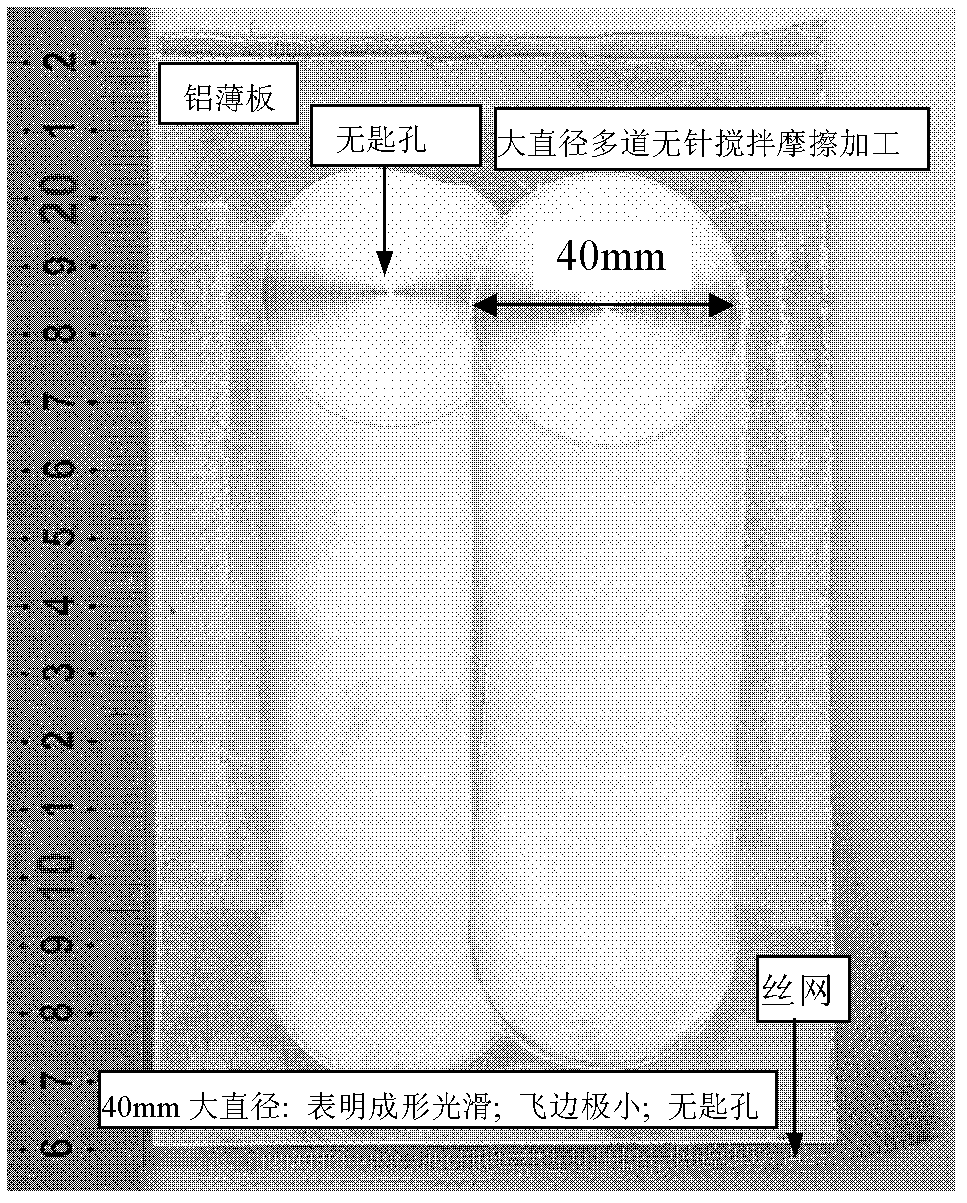

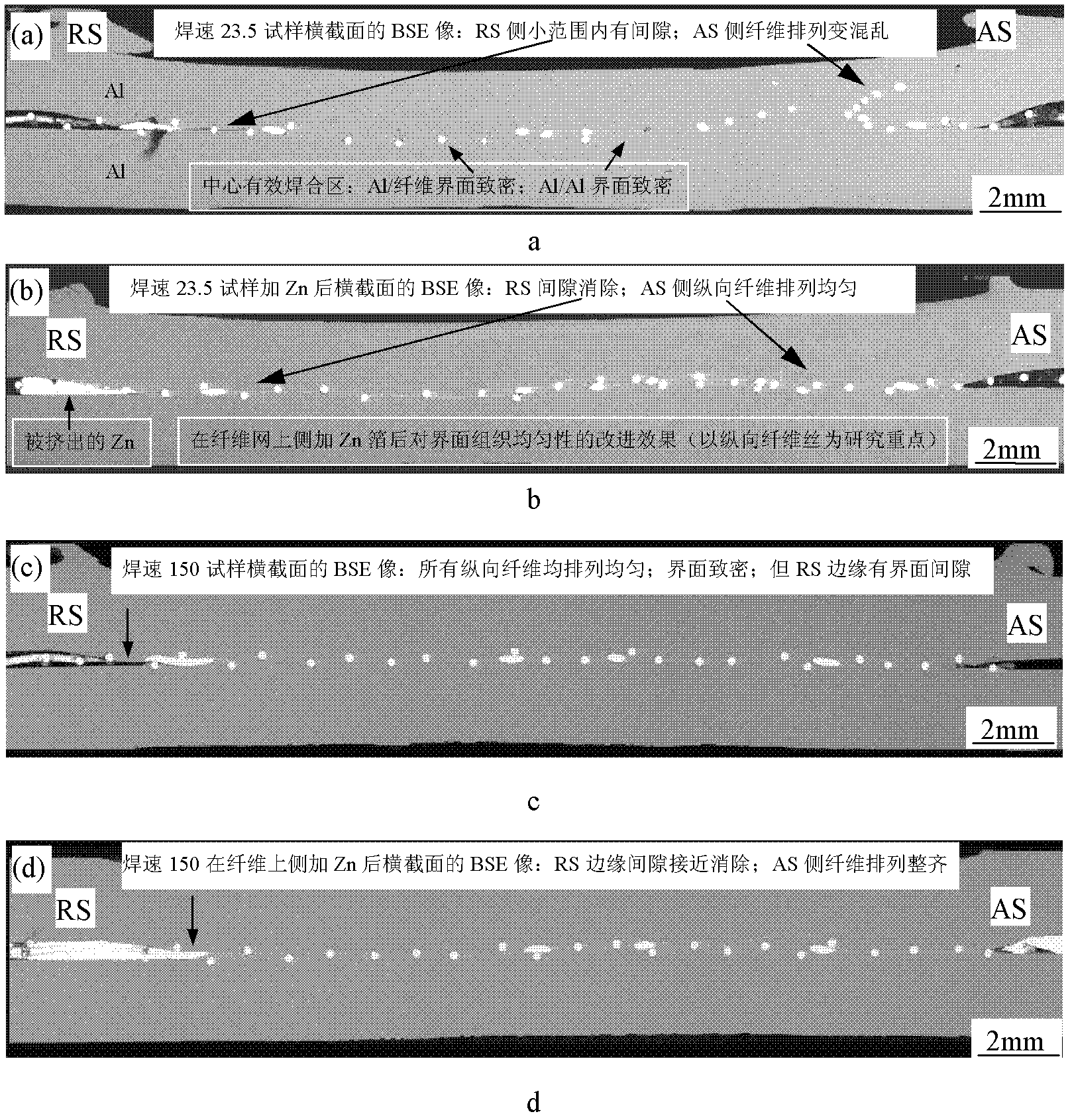

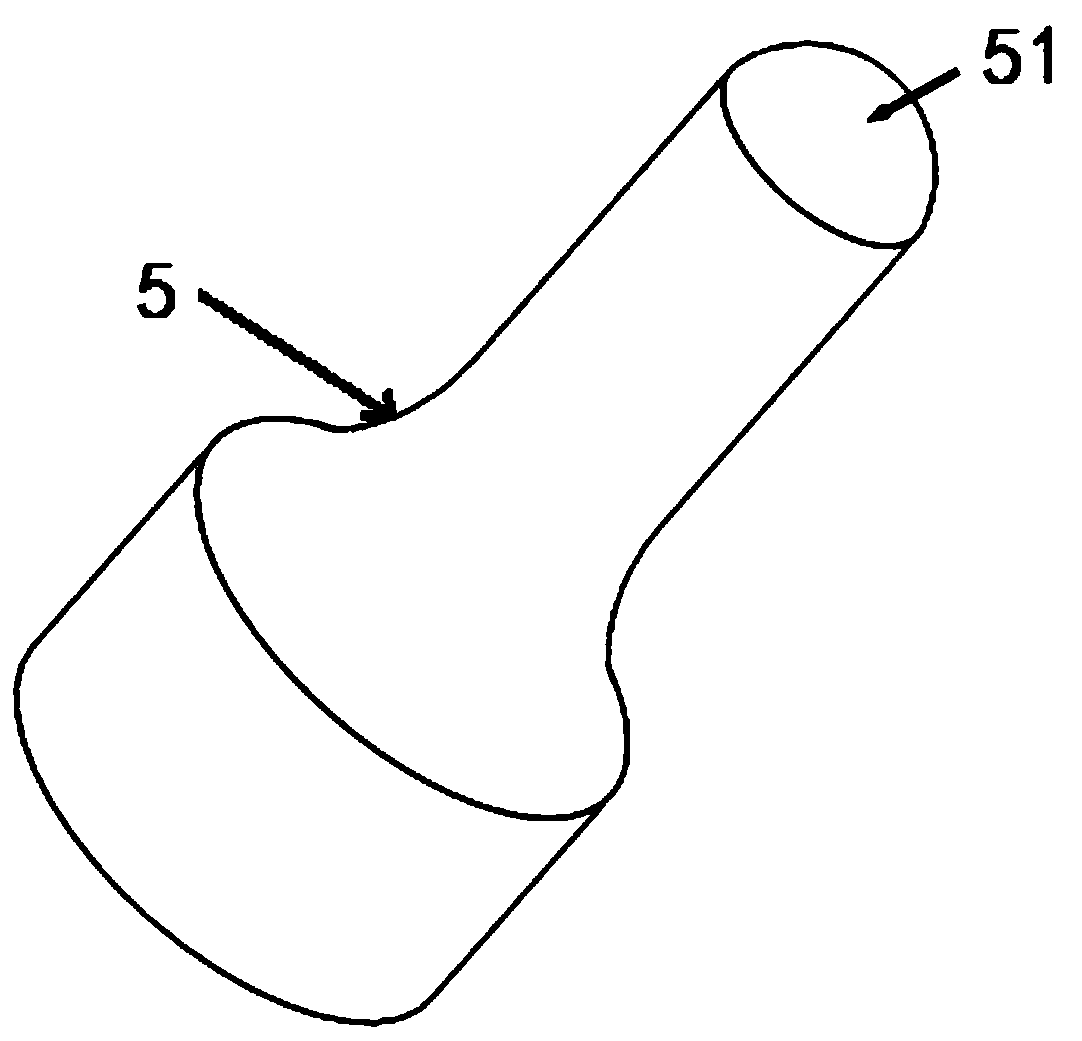

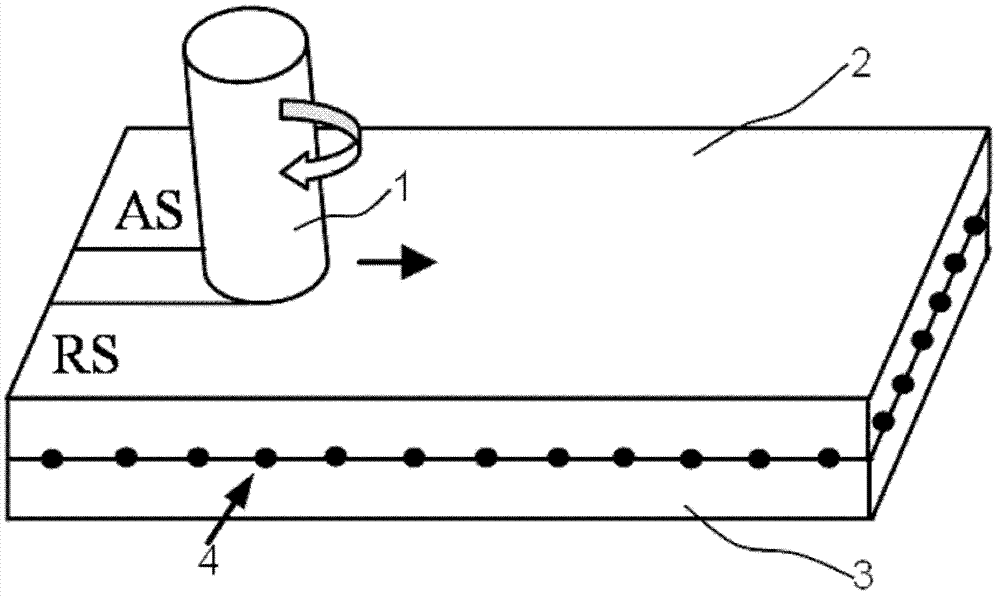

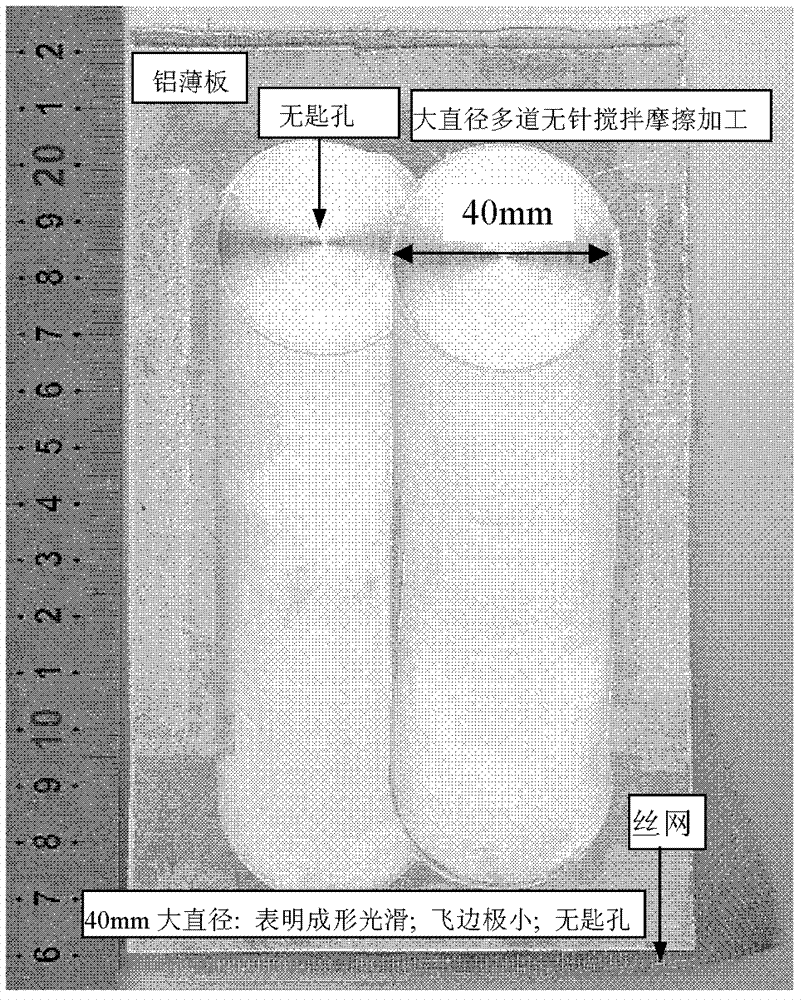

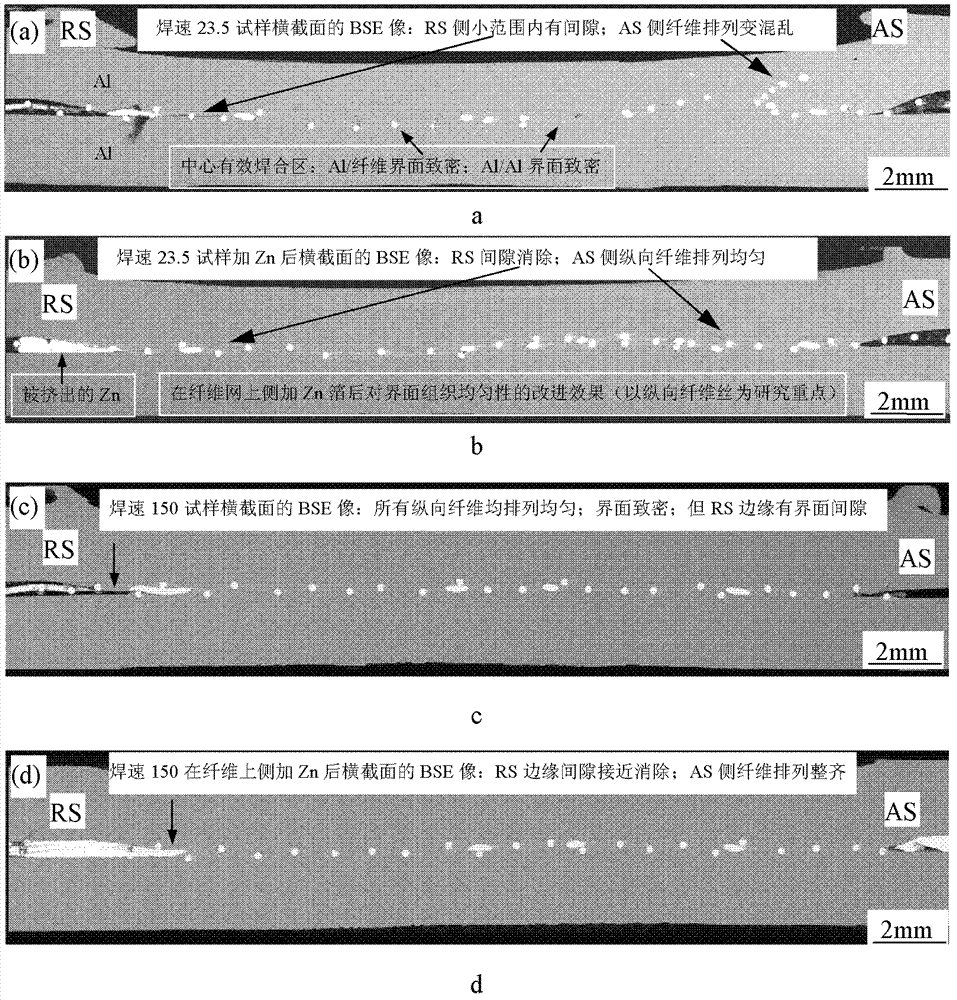

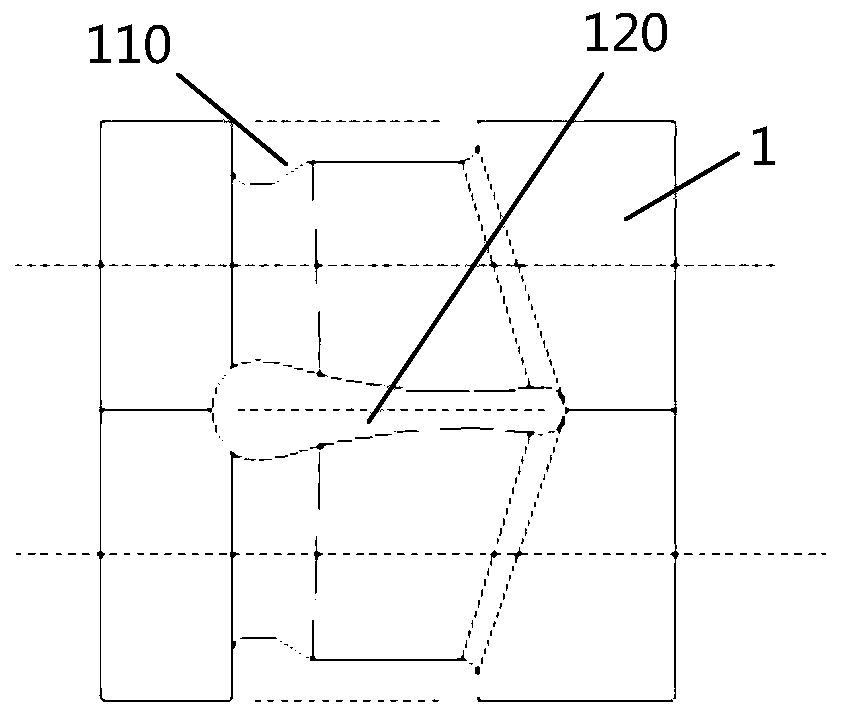

The invention discloses a large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites. Firstly, metal matrix sheets are ground and cleaned in advance; secondly, a preprocessed fiber net or unidirectional fiber bundle is clamped between the two metal matrix sheets in a prearranging manner, and needs to be completely covered and sufficiently protected by the covering sheets; meanwhile, a pin-less friction stir tool is slightly inclined and mounted; the pin-less stool is started to rotate to rub the surface of the covering sheet and move, a plastic deformation gradient field generated by the forging and torsional effects of the shoulder is utilized, consequently, not only can the oxide skin of the metal matrix interface be broken, but also the metal matrix which heats to be softened can plastically flow around the fibers to wrap the fibers, and thereby the fiber / matrix and the matrix / matrix interfaces can be compactly combined. A pin-less stir head with a large diameter more than 40mm to 50mm is adopted to carry out multi-pass multi-layer friction stir processing, and thereby a large, thick fiber-reinforced metal matrix composite plate can be produced. The addition of brazing filler metal can solve the contradiction between fiber injury and interface bonding improvement.

Owner:XI AN JIAOTONG UNIV

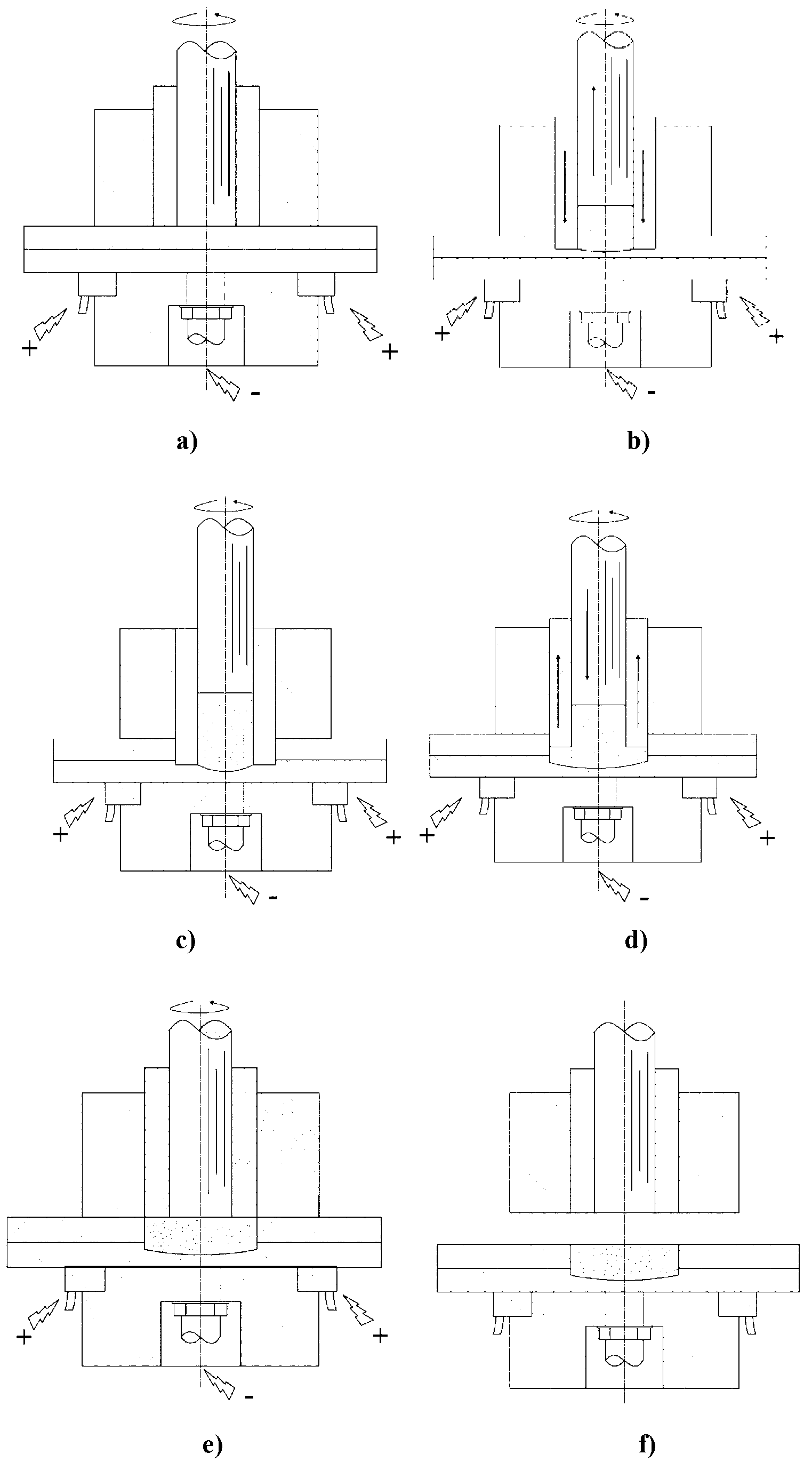

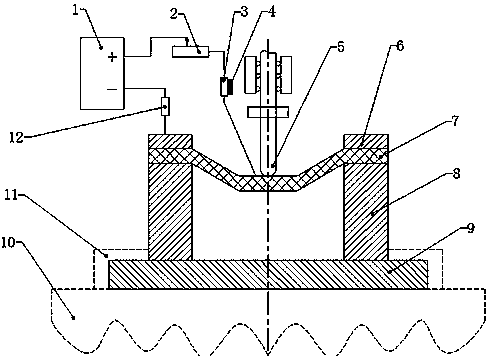

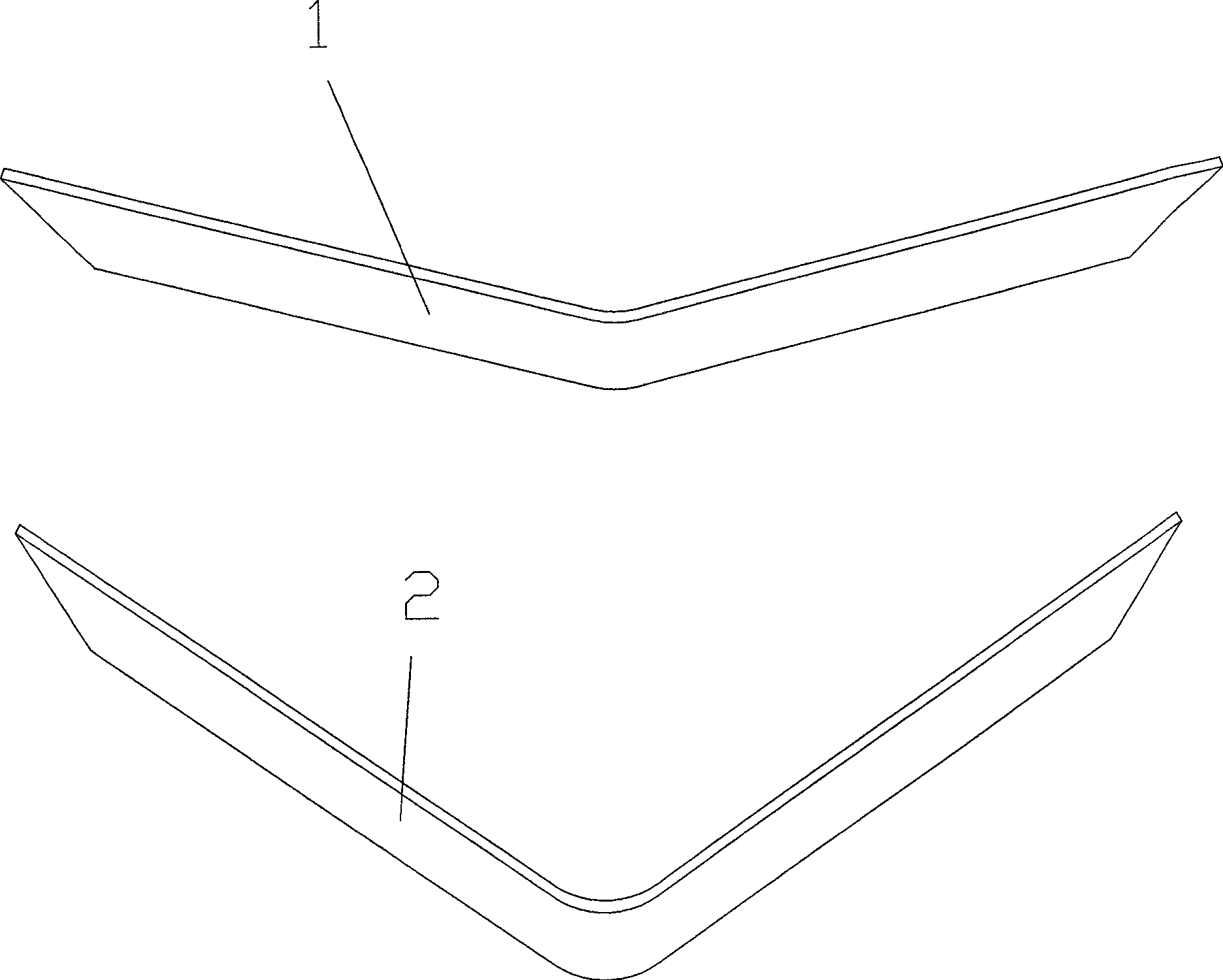

Metal plate electromagnetic pulse local flow incremental forming device and method

InactiveCN104475531AOvercome the flaw of crackingImprove plastic fluidityShaping toolsMetal-working feeding devicesElectromagnetic pulseEngineering

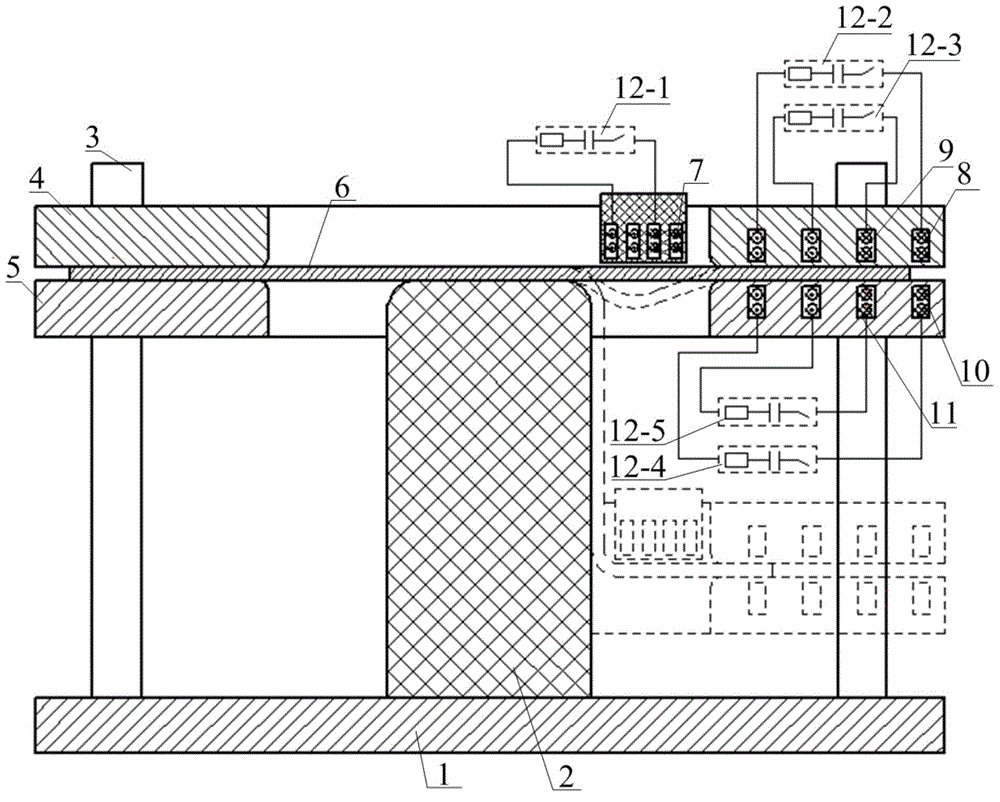

The invention discloses a metal plate electromagnetic pulse local flow incremental forming device which comprises a base, a mould forming mechanism, a pressing plate and an electromagnetic forming coil, wherein the mould forming mechanism is arranged on the base, the pressing plate is matched with the mould forming mechanism and used for pressing a plate, and the electromagnetic forming coil is driven to move by a power device. A radial side push coil for applying thrust to the outside edge of the plate is mounted on the pressing plate and / or the mould forming mechanism, and a power system supplies power for the electromagnetic forming coil and the radial side push coil. The local area of the plate has small deformation by the aid of the electromagnetic forming coil and the radial side push coil in each discharging process, so that the requirement for the sizes of the coils and equipment energy is reduced, and the device solves the problem that traditional large plate forming needs a high-cost forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

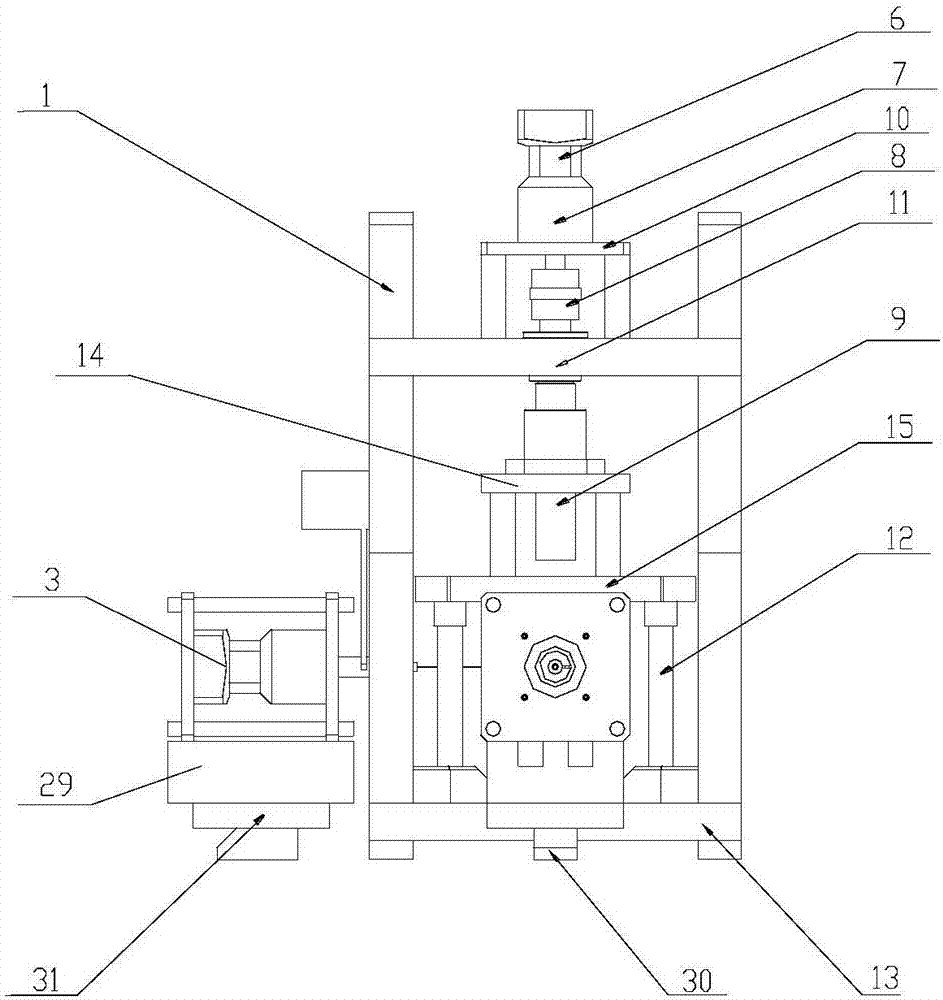

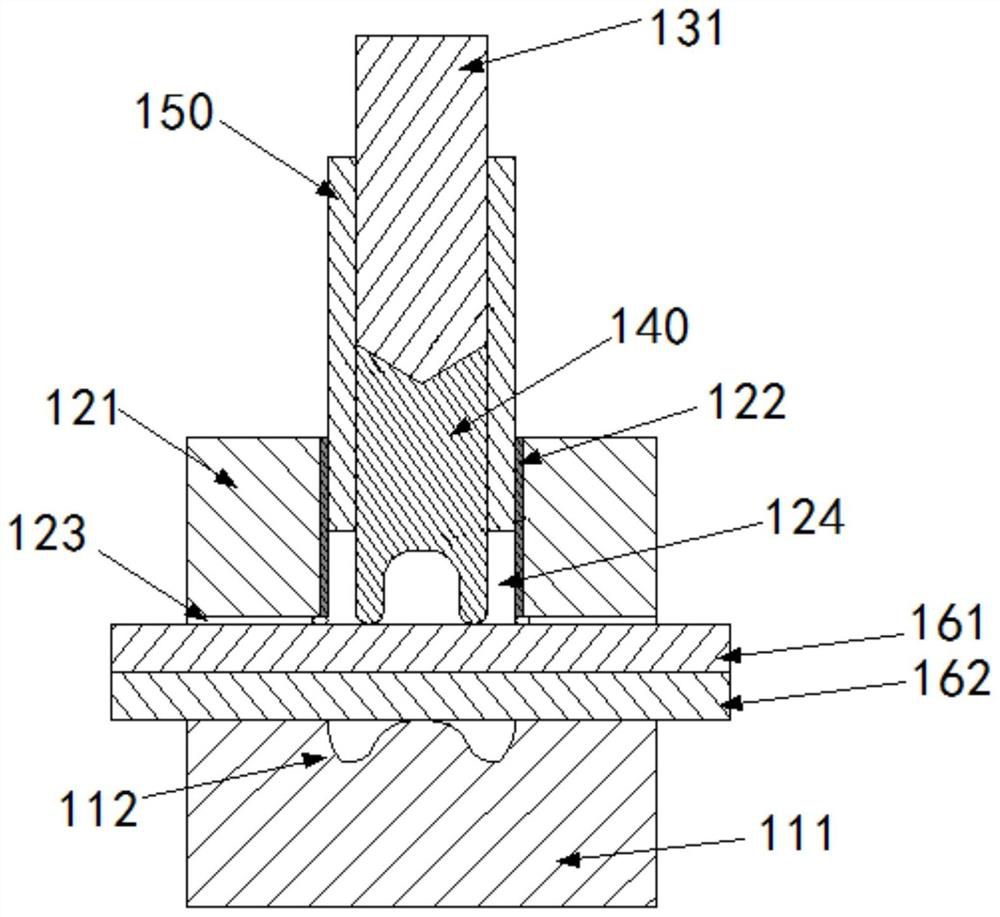

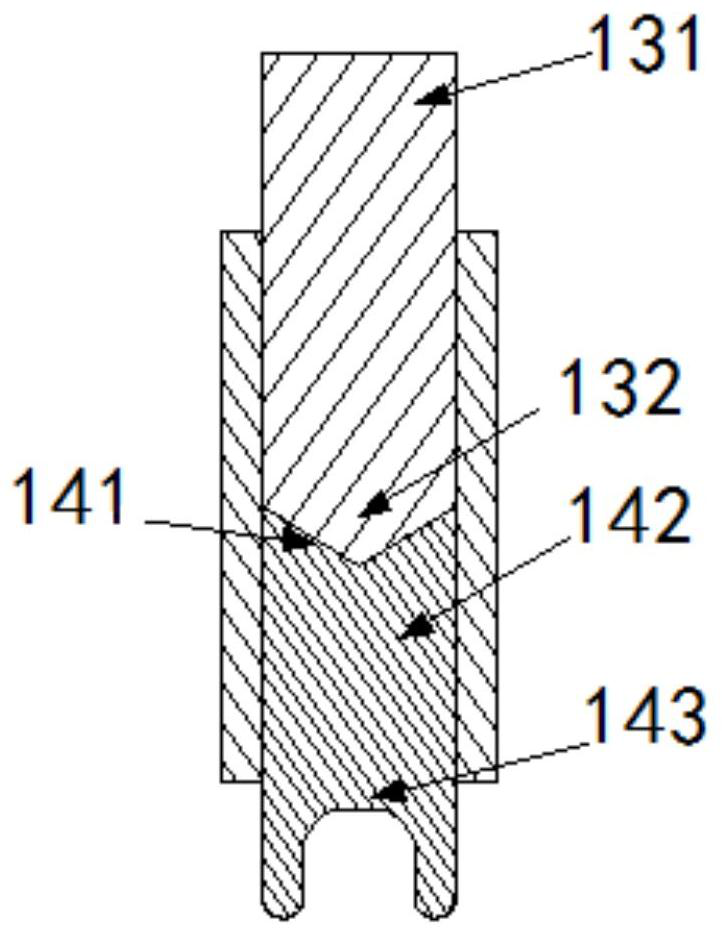

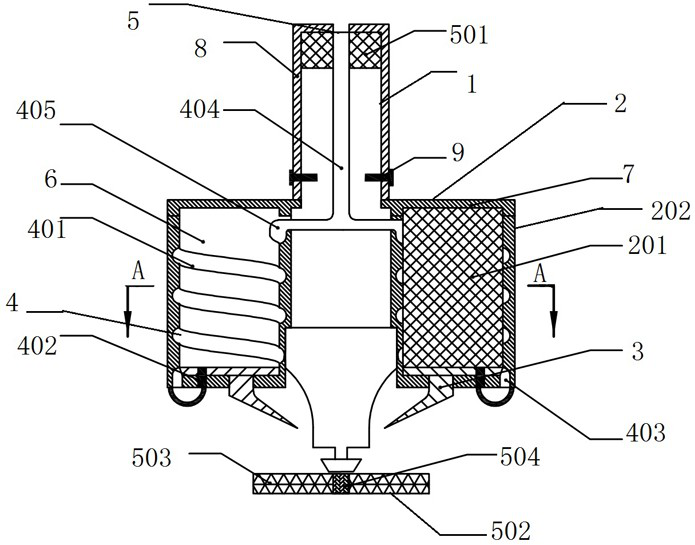

Agitating friction spot welding device and method for dissimilar metal

InactiveCN103008874AImprove plastic fluidityImprove welding qualityNon-electric welding apparatusDissimilar metalEngineering

The invention provides an agitating friction spot welding device for dissimilar metal. The device comprises an agitating sleeve, an agitating needle arranged in the agitating sleeve, a clamping sleeve clamped outside the agitating sleeve, and a welding cushion block; a welding workpiece is arranged between the clamping sleeve and the welding cushion pad; an annular electric brush is arranged at the top of the welding cushion block; a T-shaped through hole is formed in the center of the welding cushion block; a conductive rod is arranged in the welding cushion block; the conductive rod is flush with the upper surface of the welding cushion block; and the annular electric brush and the conductive rod are respectively connected with an anode and a cathode of a controllable direct current power supply through a lead. The invention further provides an agitating friction spot welding method for dissimilar metal. The method comprises the following steps of plastically softening metal material, respectively connecting the annular electric brush and the conductive rod with a direct current power supply which has the reversed polarity, so as to conduct a welding loop, and then finishing the welding by adopting a spot welding process. According to the device and the method provided by the invention, as certain welding current is applied to the welding material which is high in lower layer strength during the agitating friction spot welding process of the dissimilar metal, the material is more easily and plastically distorted, the welding pressure is reduced and the welding quality is improved.

Owner:SHANGHAI DIANJI UNIV

Drawing forming device and method of non-axisymmetric piece made of difficult-to-deform material

ActiveCN107139517ARaise the forming limitIncrease the drawing heightShaping toolsPress ramMechanical engineeringHigh conductivity

The invention discloses a drawing forming device and method of a non-axisymmetric piece made of a difficult-to-deform material. The drawing forming device comprises a male die, a female die and a blank holder. The blank holder is movably arranged on the upper side of the female die and used for clamping a plate material to be formed between the blank holder and the female die. The bottom of the male die is provided with an axial drawing coil. The female die and the blank holder are provided with an upper groove and a lower groove. Upper radial lateral push coils are embedded in the upper groove. Lower radial lateral push coils are embedded into the lower groove. The drawing forming device further comprises a high-conductivity drive punch pin and multiple high-conductivity drive bars. The high-conductivity drive punch pin is placed below the male die. The multiple high-conductivity drive bars are arranged on the outer side of the fillet end of the plate material. The drawing forming device is good in drawing uniformity, simple in structure and convenient to operate, the drawing precision is easy to control, and the drawing forming device is suitable for drawing formation of the non-axisymmetric piece made of the difficult-to-deform material.

Owner:CENT SOUTH UNIV

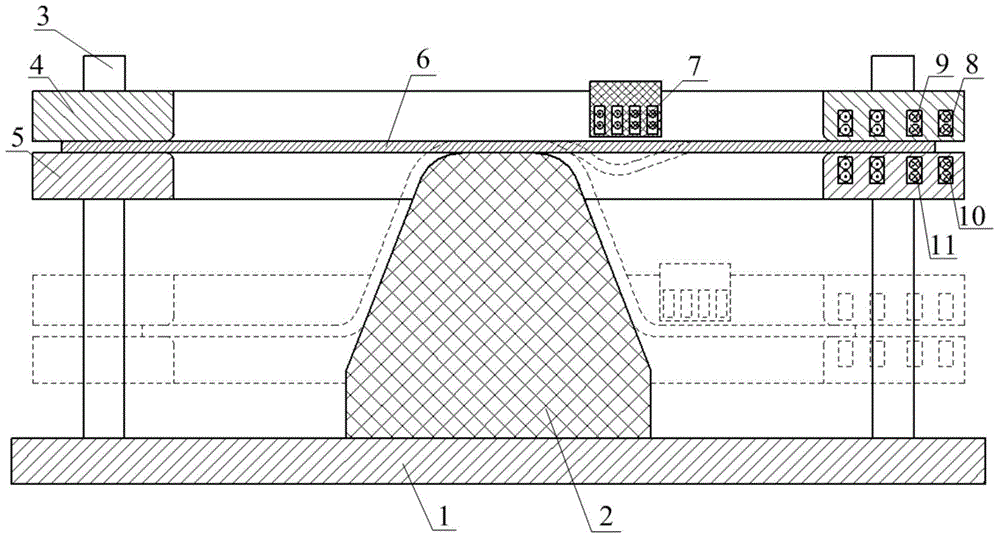

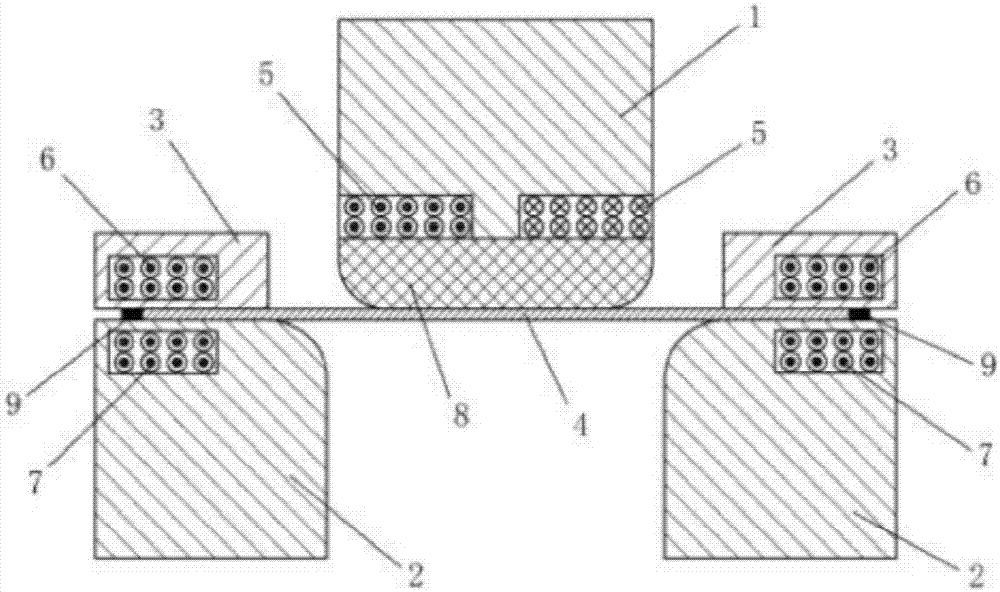

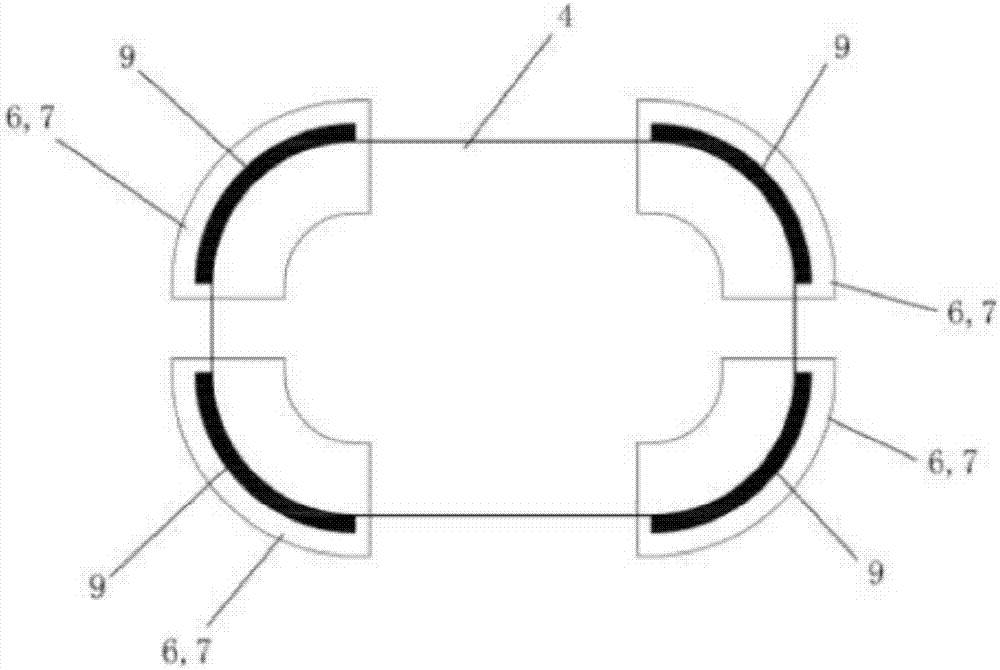

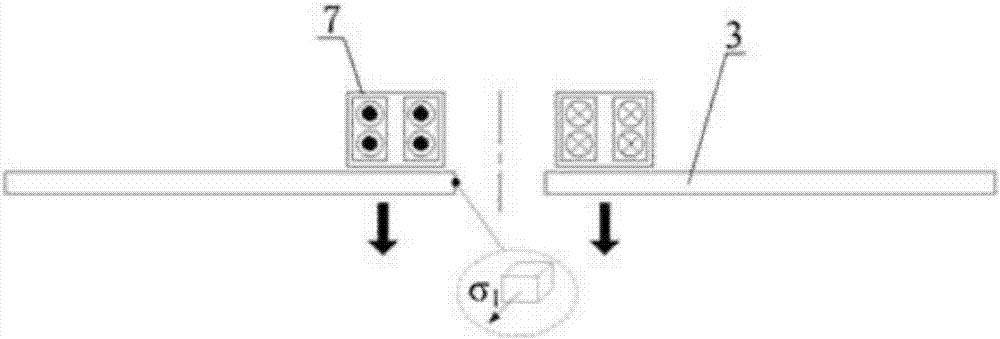

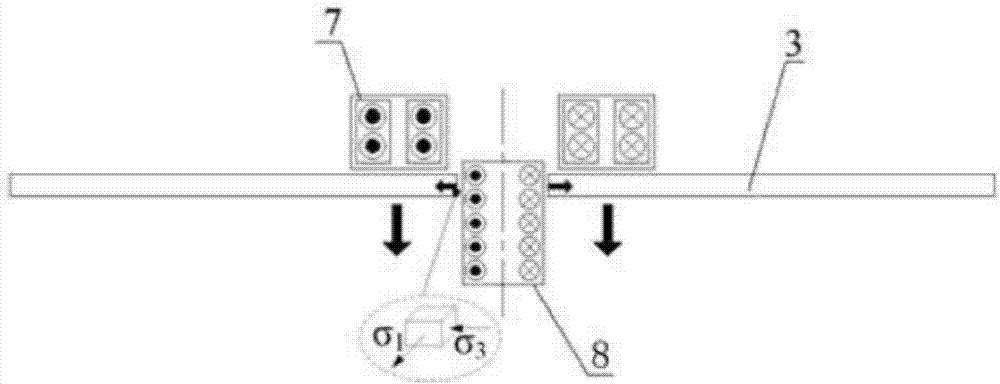

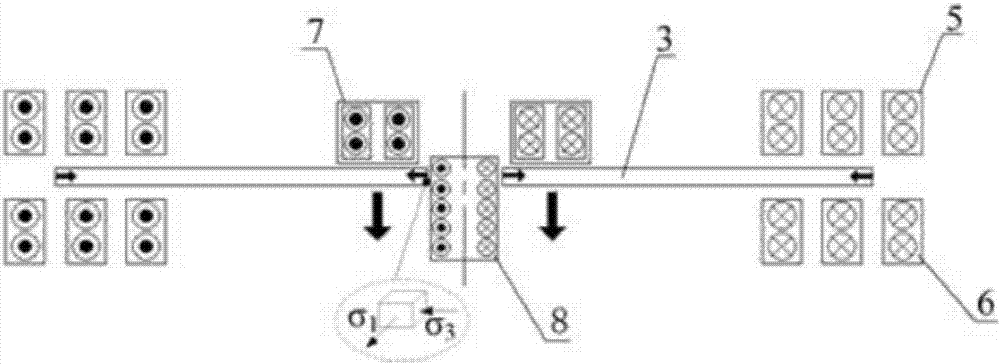

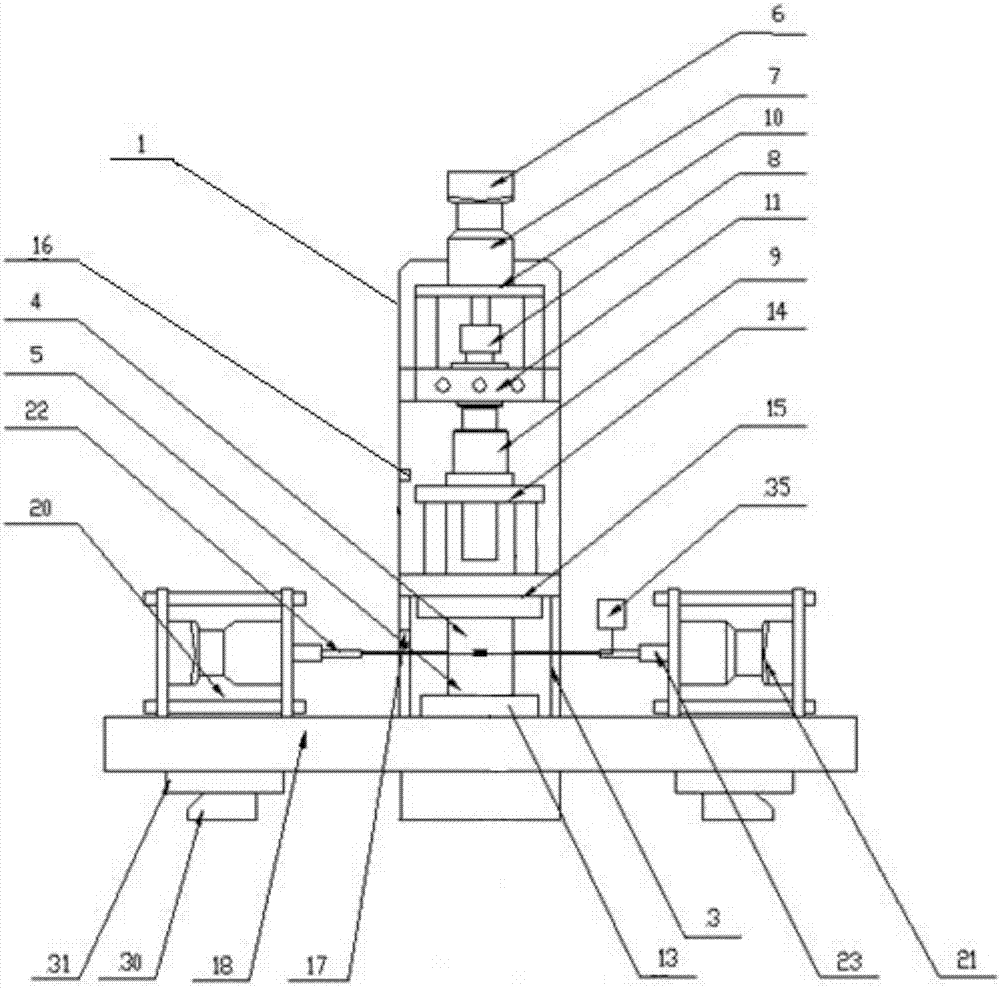

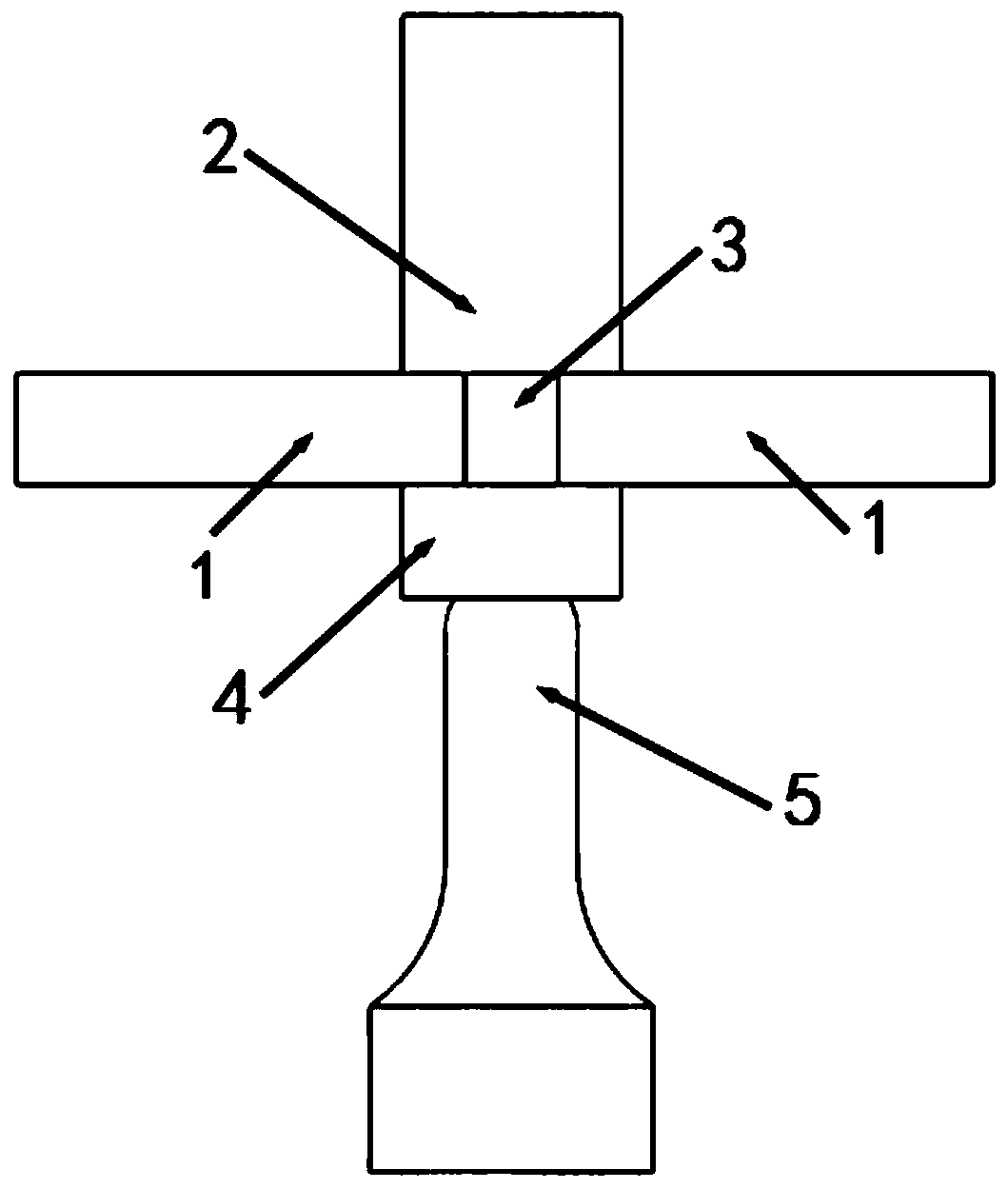

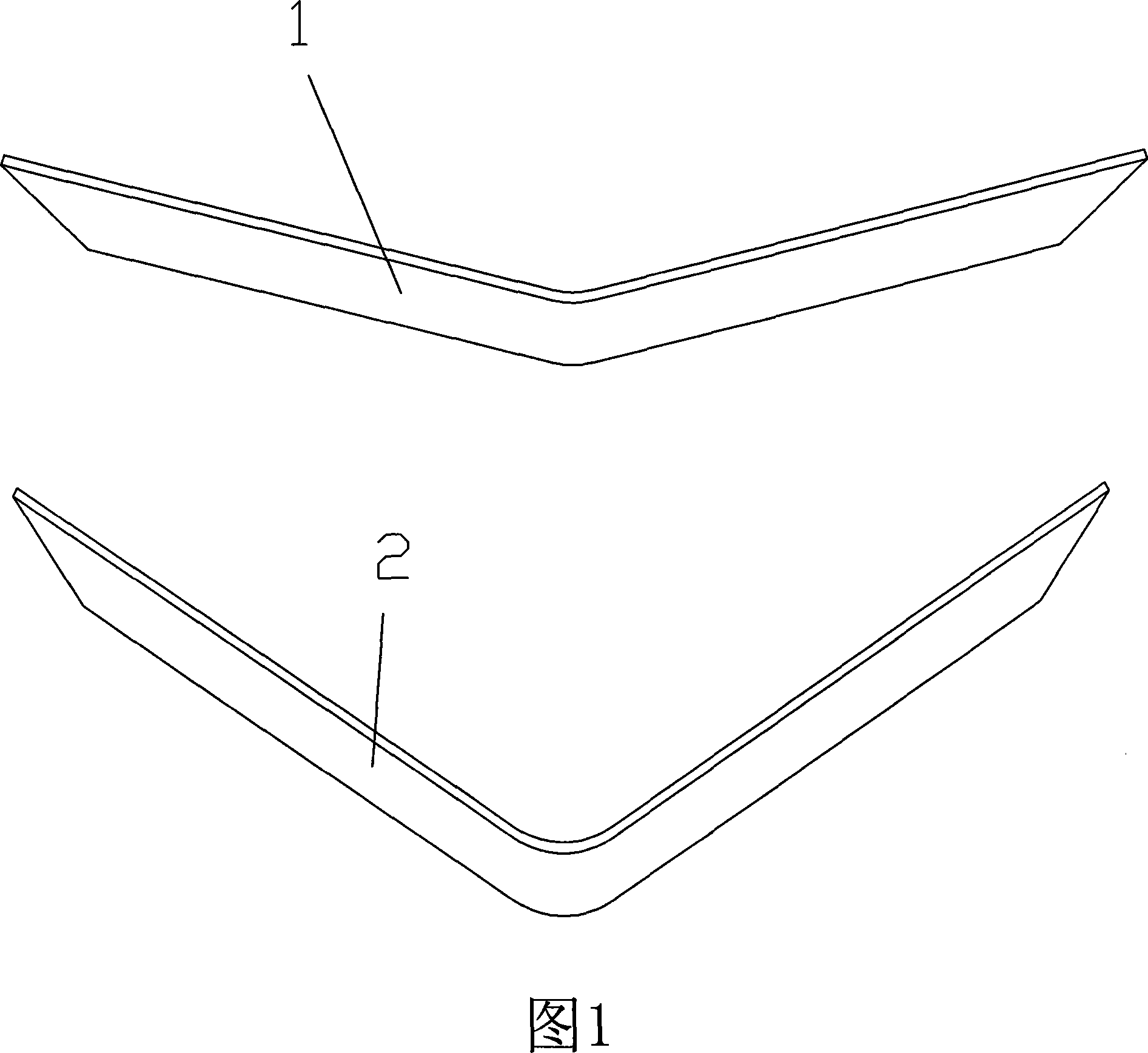

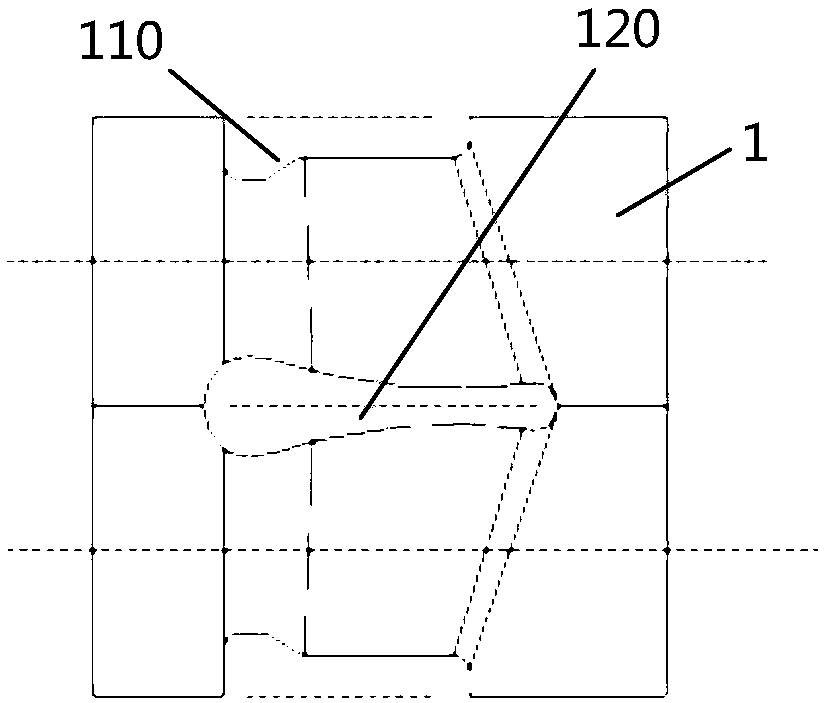

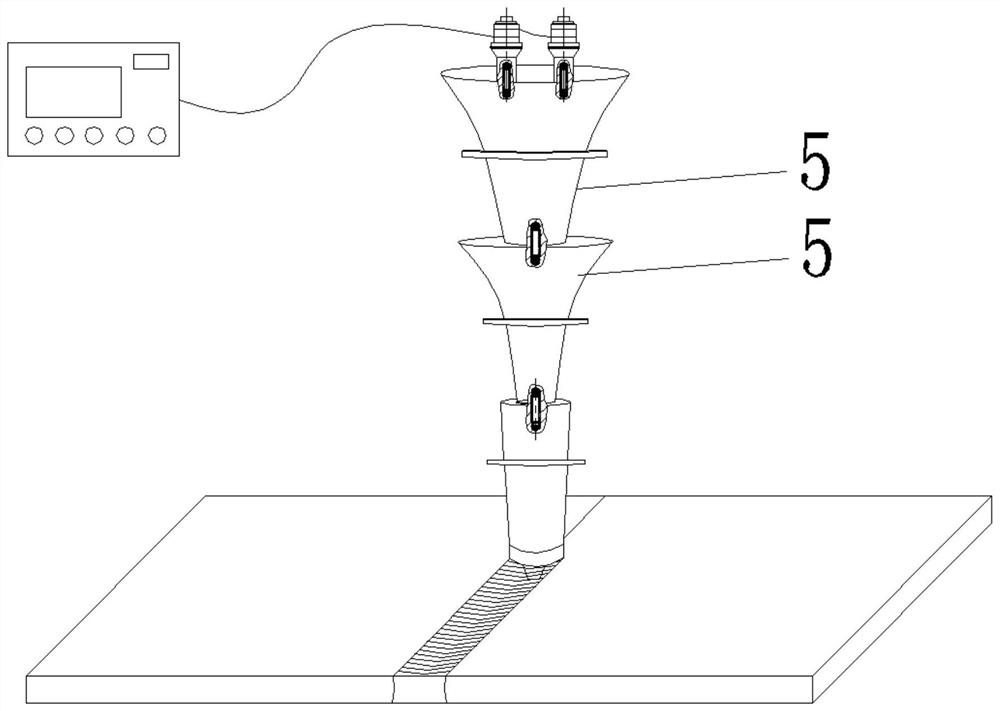

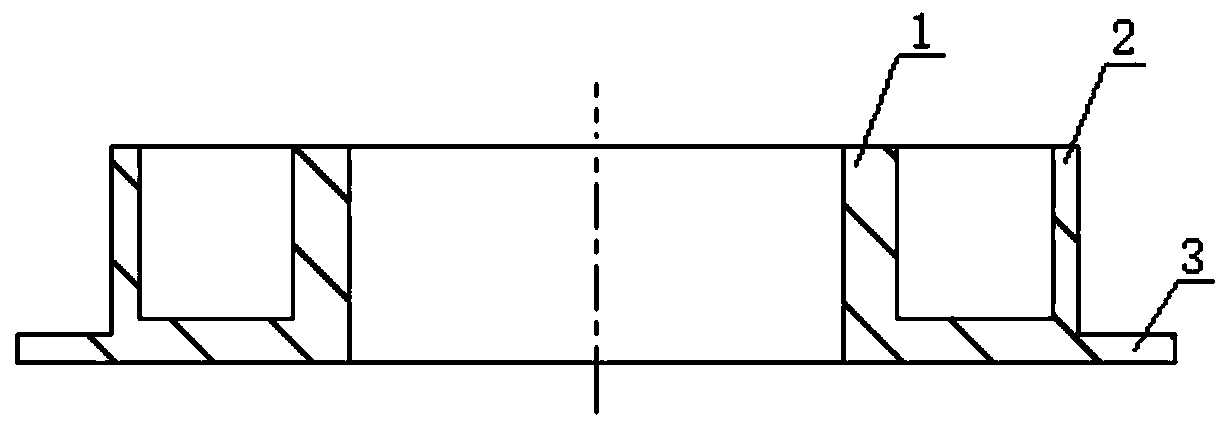

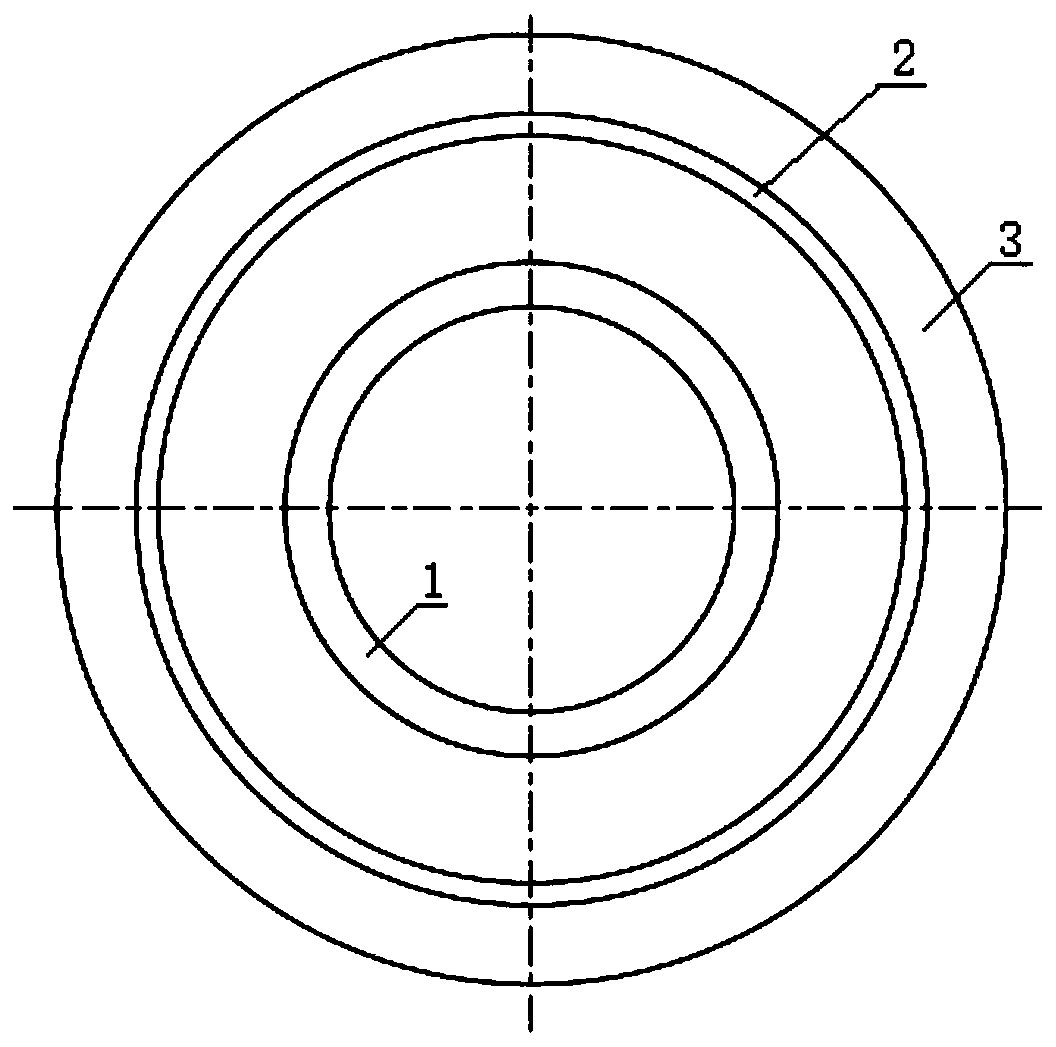

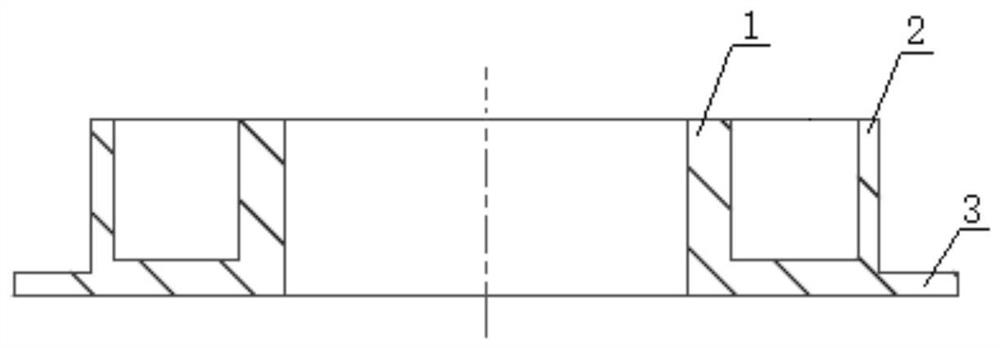

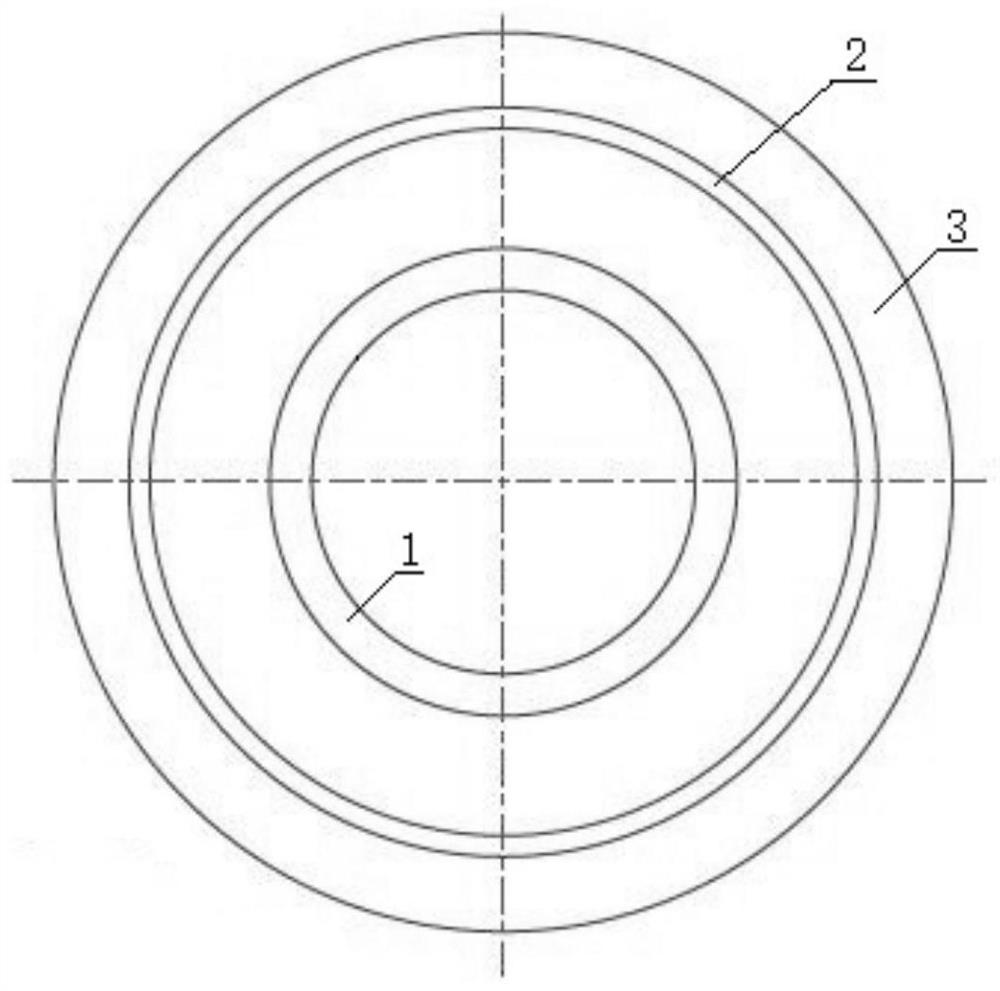

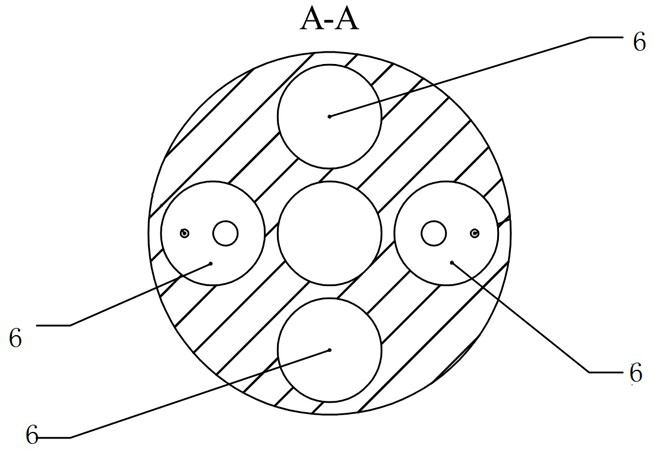

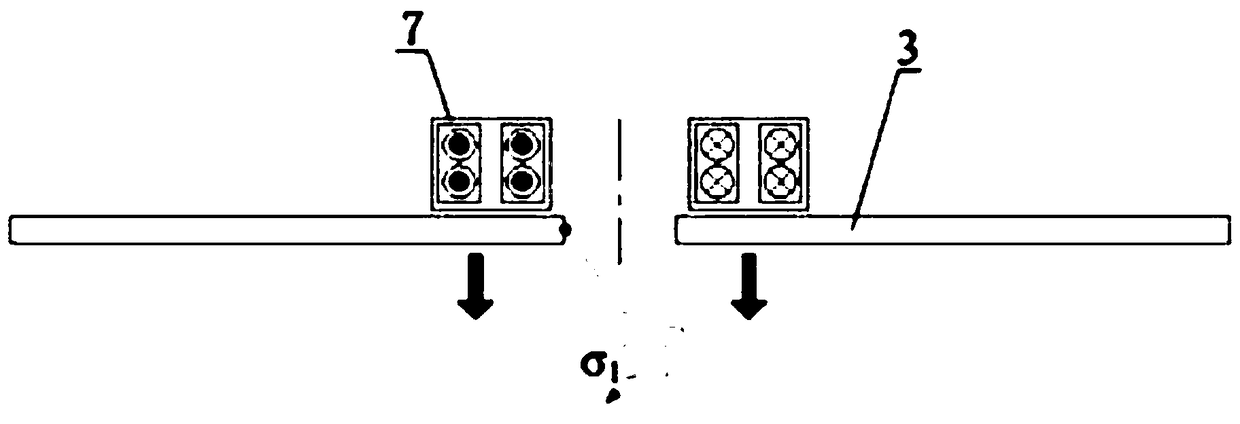

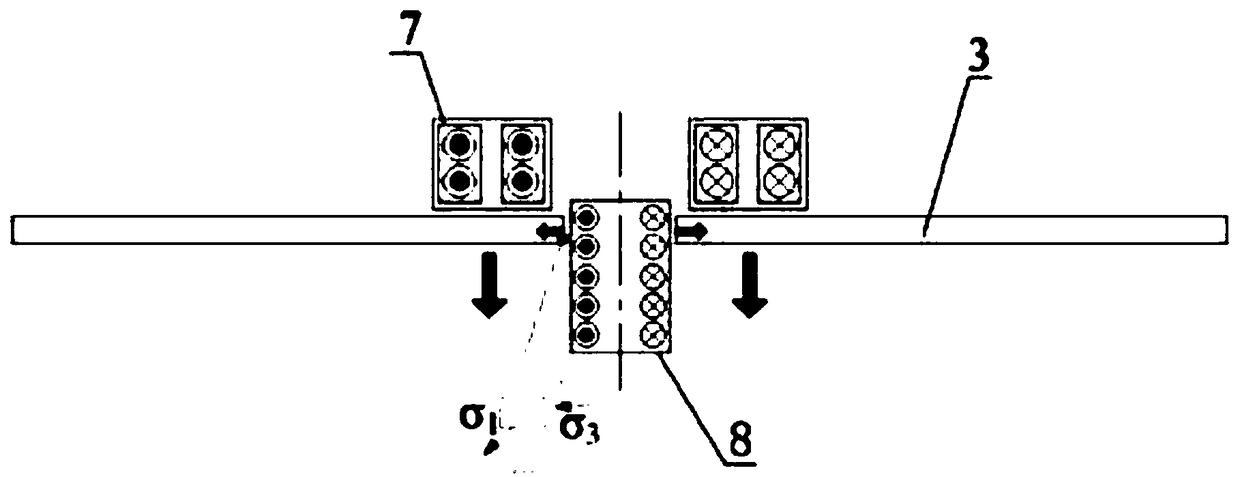

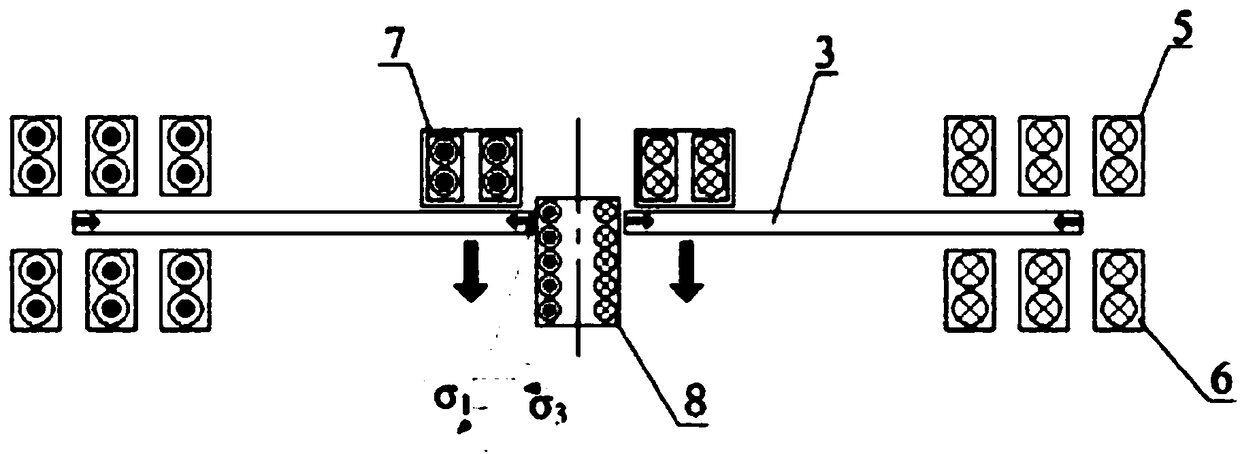

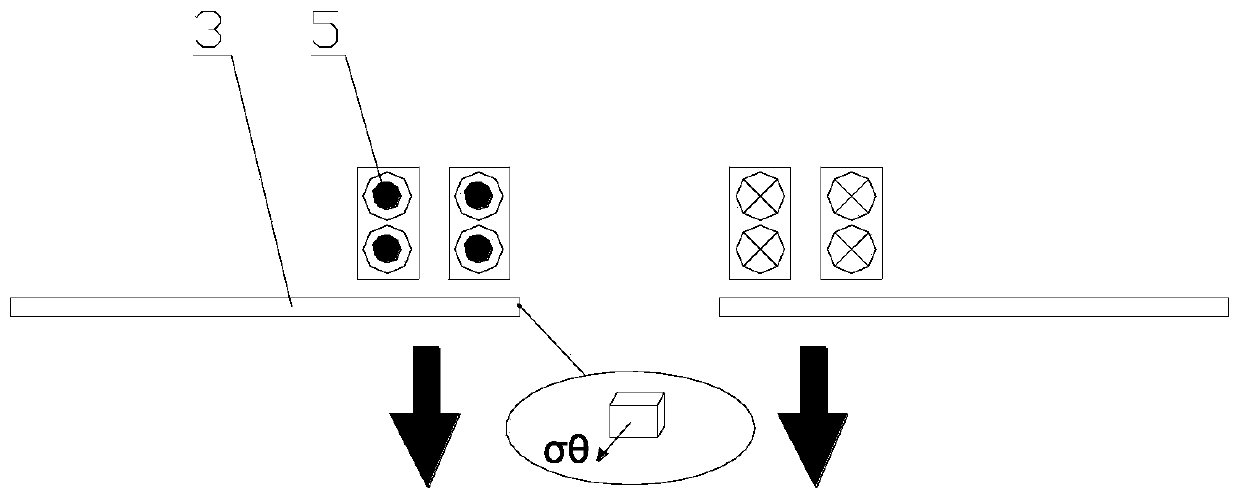

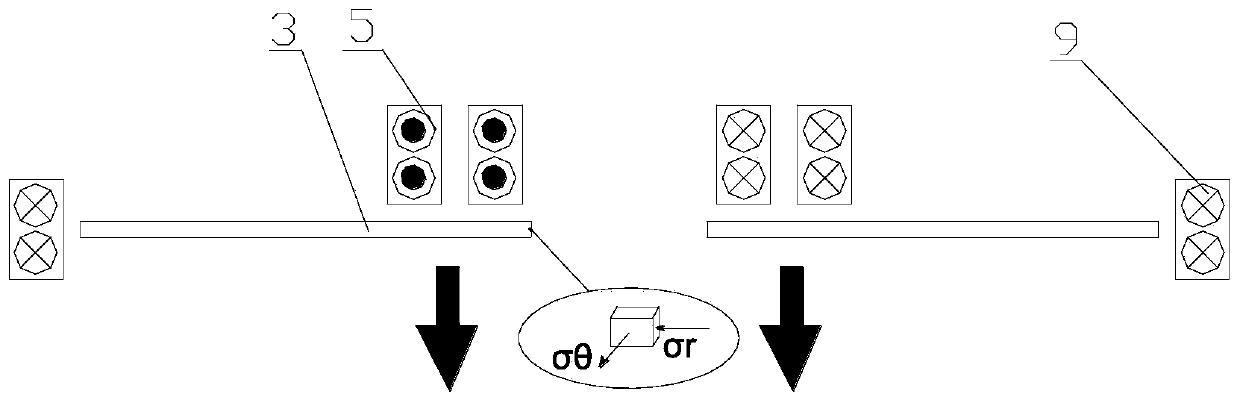

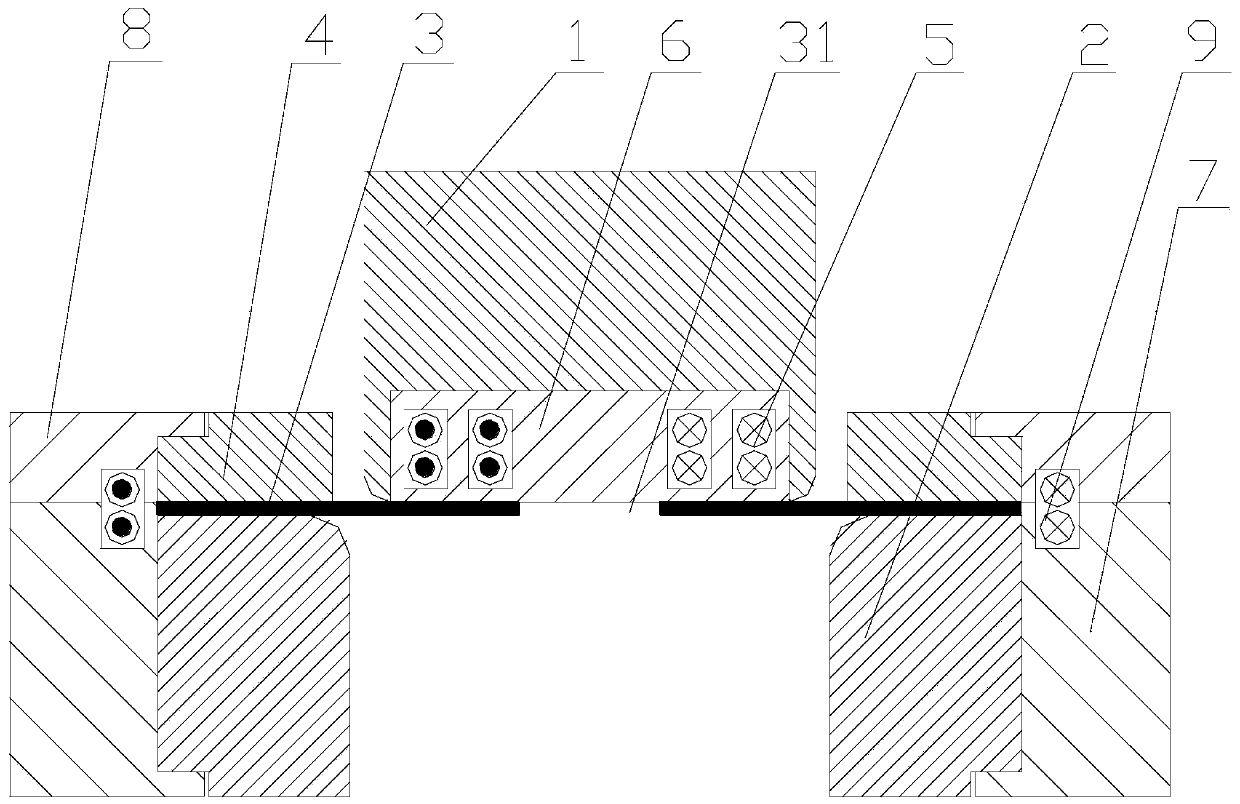

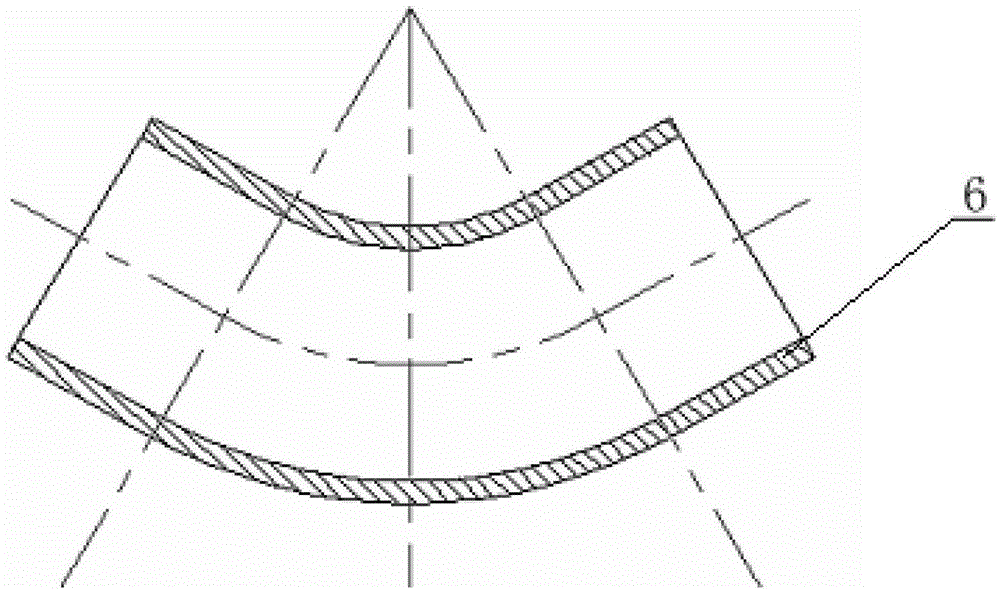

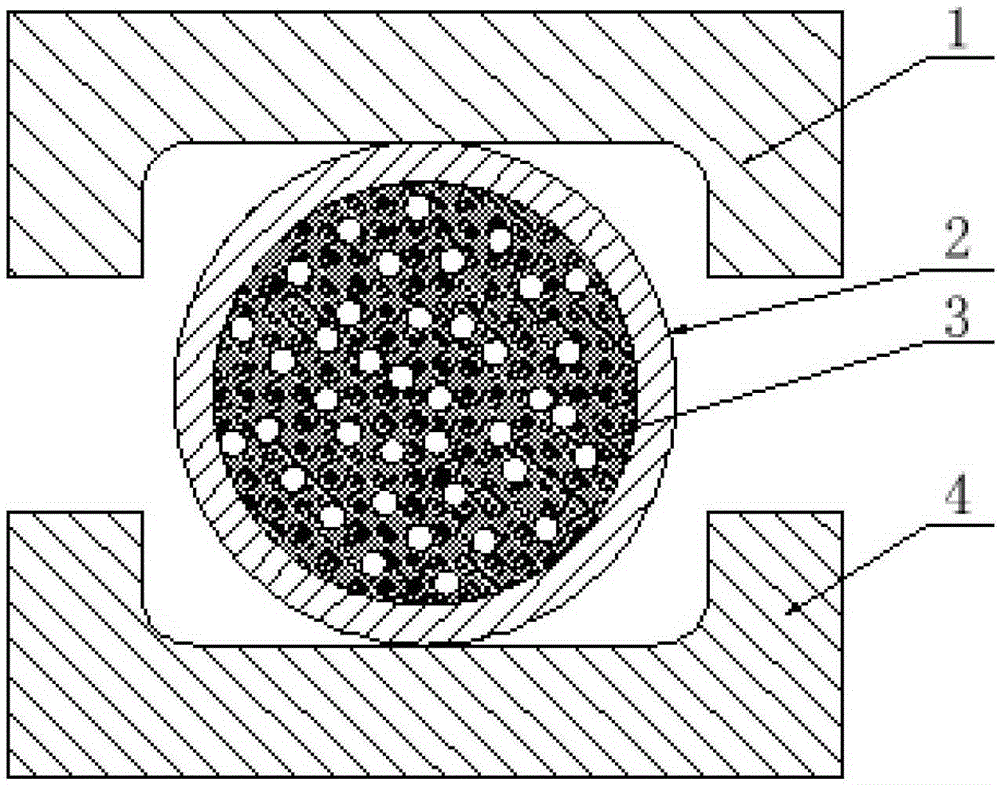

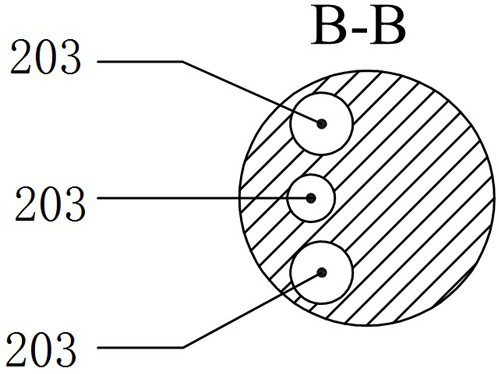

Device and method for driving plate hole flanging forming through multidirectional magnetic field force

The invention discloses a device and method for driving plate hole flanging forming through multidirectional magnetic field force. The device comprises a blank holder (1) and a concave die (2). The blank holder (1) is arranged above the concave die (2) and used for pressing a plate (3) to be subjected to hole flanging forming between the blank holder (1) and the concave die (2). A concave die cavity (4) is formed in the concave die (2). An upper coil groove and a lower coil groove are correspondingly formed in the blank holder (1) and the concave die (2). Upper end hole shrinkage coils (5) are embedded in the upper coil groove. Lower end hole shrinkage coils (6) are embedded in the lower coil groove. Axial deep drawing coils (7) are arranged above the edge of a pre-formed hole of the plate (3). An inner bulging coil (8) is arranged in the pre-formed hole of the plate (3). According to the device and method, cracks can be prevented from being generated to a round hole flanging deformation area during hole flanging forming, the product quality is good, and the forming process is simple.

Owner:CENT SOUTH UNIV

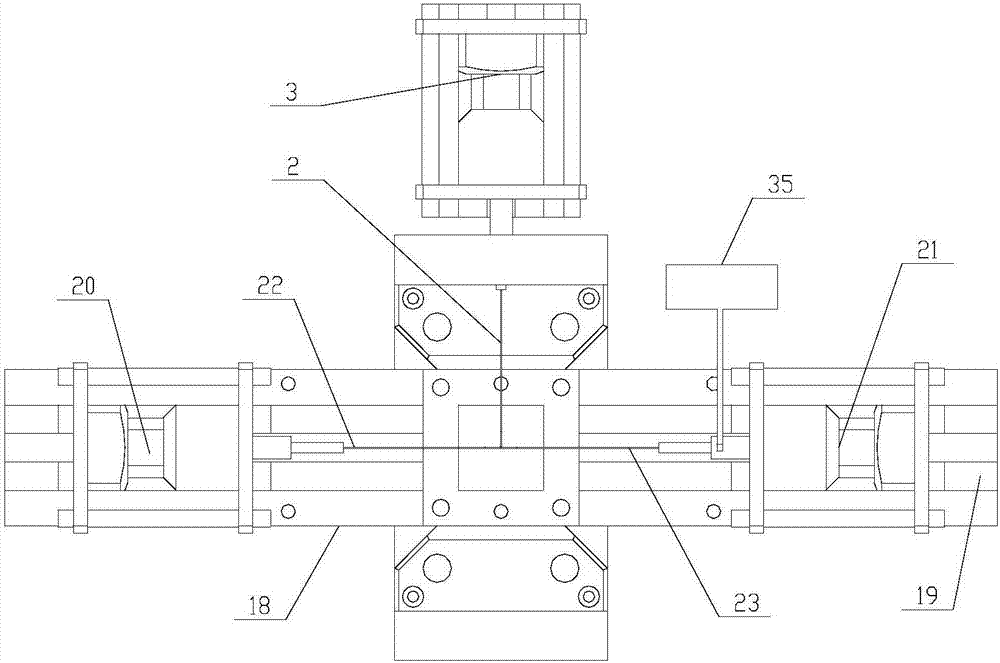

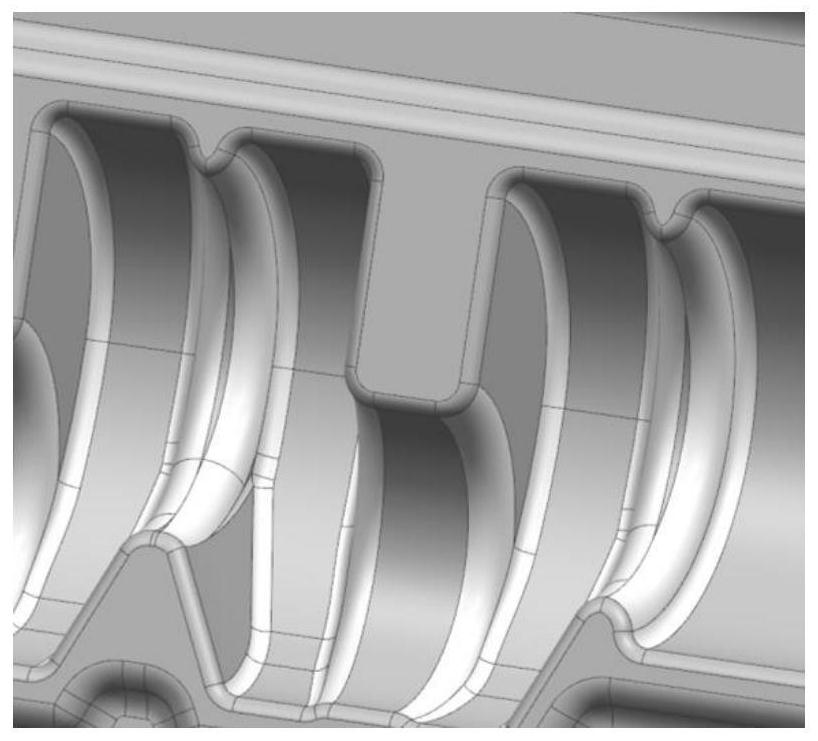

Internal high pressure forming equipment and method of micro metal T-shaped pipe

InactiveCN107030171AImprove quality and efficiencyIncrease productivityShaping toolsAtmospheric pressureHigh pressure

The invention discloses internal high pressure forming equipment and method of a micro metal T-shaped pipe and relates to the technical field of metal pipe fitting machining. The forming equipment comprises a forming mold, two linearly arranged shaft end feed punches, and a forming end balance punch for limiting the forming height of the T-shaped pipe. The forming mold comprises an upper mold and a lower mold, each of the upper mold and the lower mold is provided with a T-shaped cavity, each shaft end feed punch is connected with one shaft end feed power device, and the forming end balance punch is vertical to the two shaft end feed punches and connected with a forming end balance power device. One of the two shaft end feed punches is provided with a gas channel, the gas channel is connected with a high-pressure gas supply device, and each of the bottom of the upper mold and the top of the lower mold is provided with a heating device. Operation is convenient, the safety performance is high, air pressure internal high pressure forming of the micro metal T-shaped pipe can be achieved under the high temperature condition, the requirements on forming pressure and the requirements on the performance of the equipment are reduced, and the manufacturing cost is reduced.

Owner:NORTHEASTERN UNIV

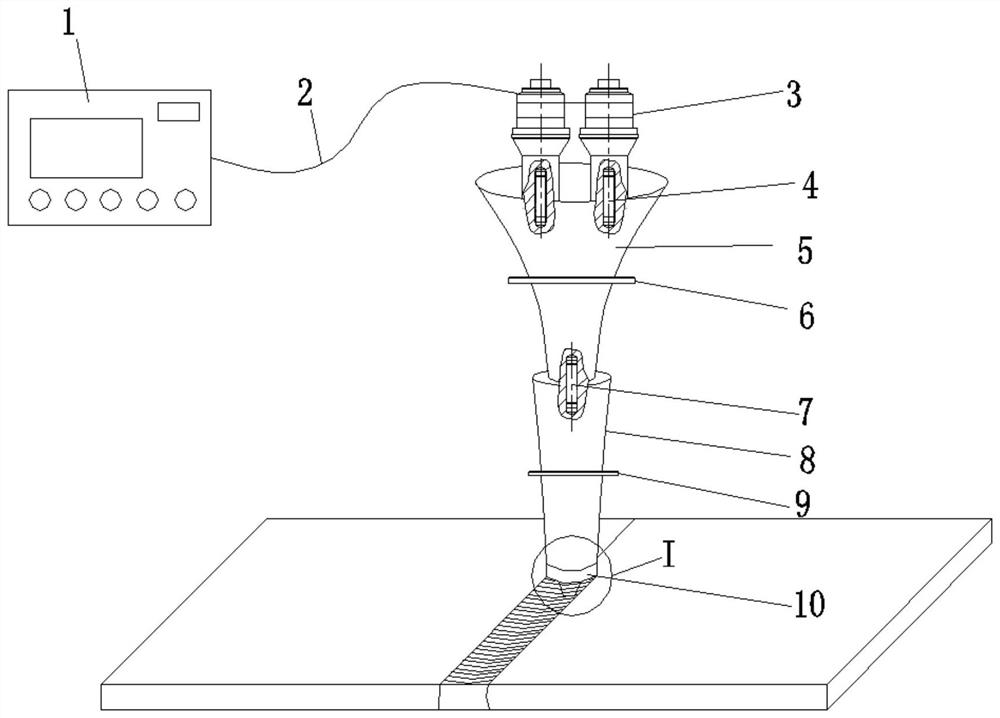

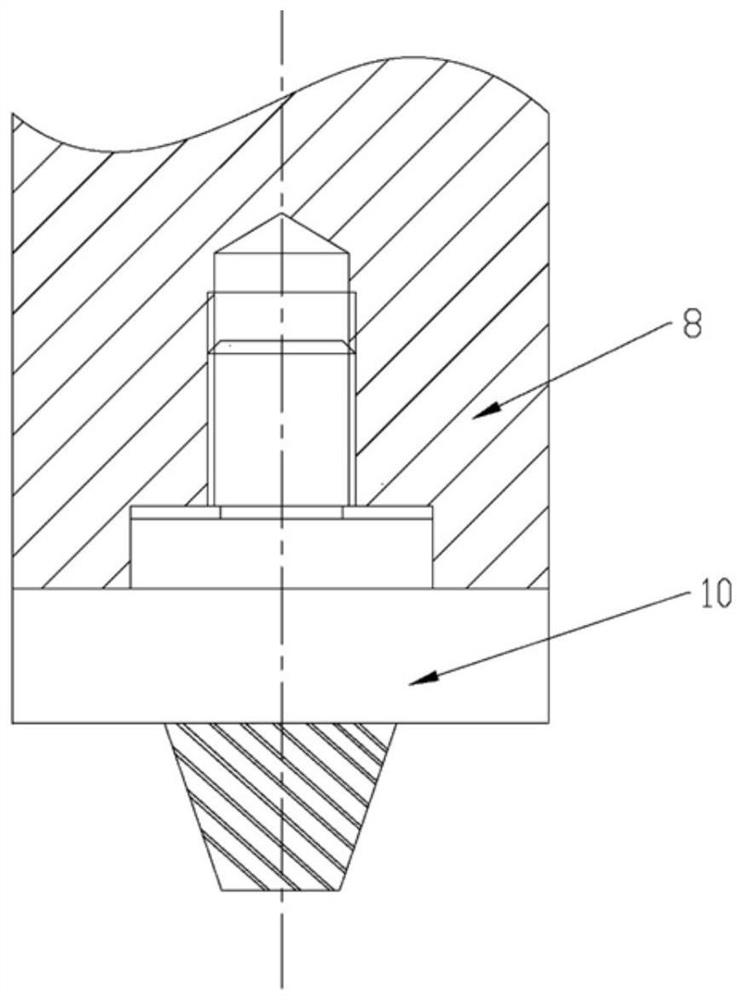

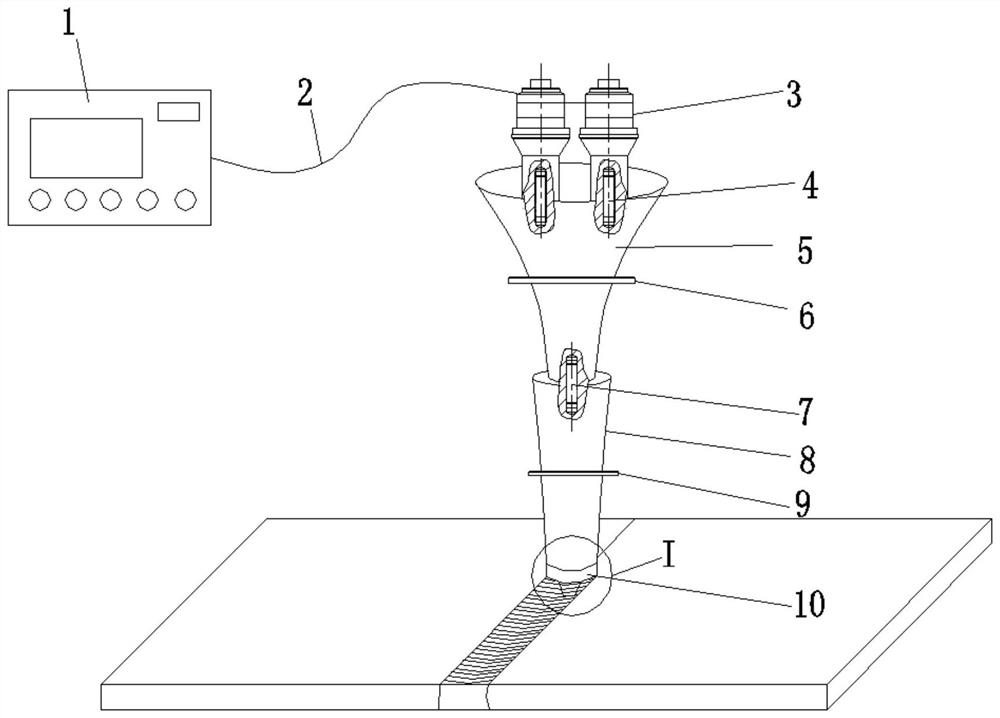

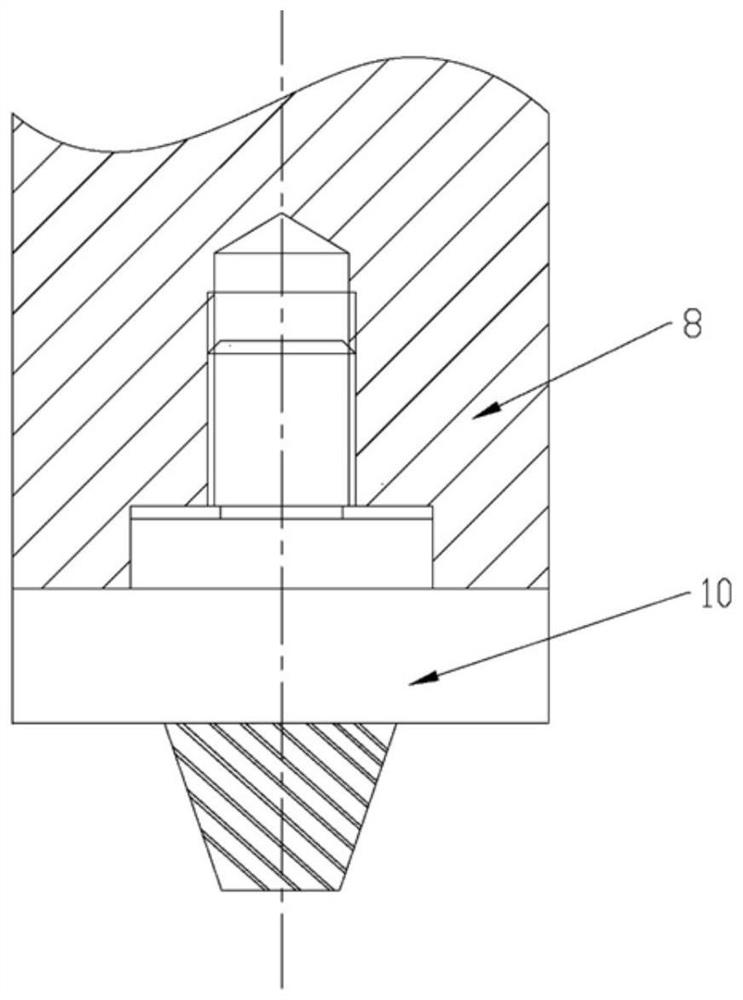

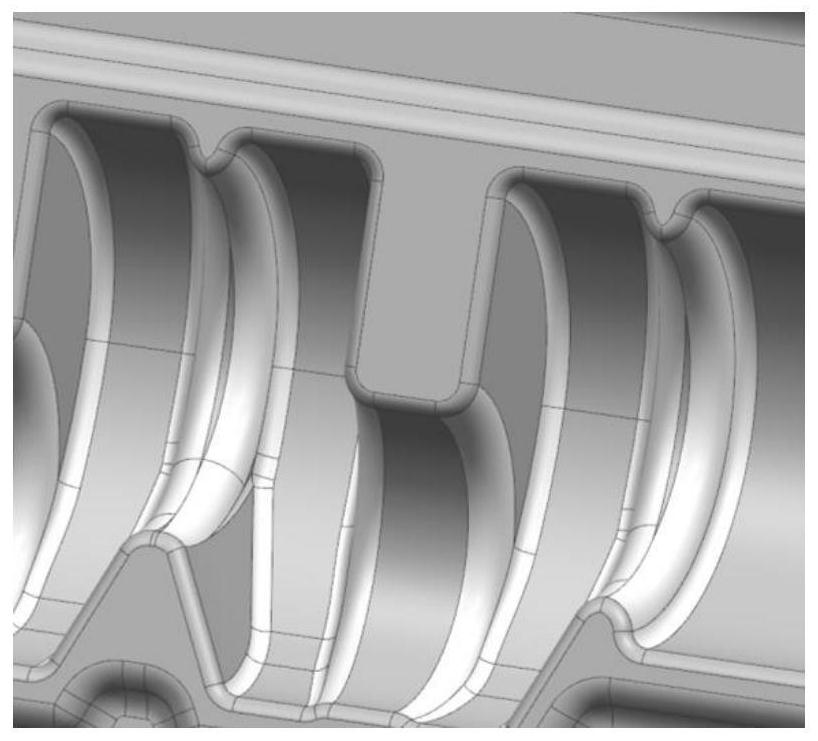

Ultrasonic coaxial assisted dual-shaft-shoulder friction stir welding method

InactiveCN110681979AIncrease profitAvoid obstructing ultrasonic vibrationsNon-electric welding apparatusTool bitFriction welding

The invention belongs to the technical field of welding, and particularly relates to an ultrasonic coaxial assisted dual-shaft-shoulder friction stir welding method. The ultrasonic coaxial assisted dual-shaft-shoulder friction stir welding method comprises the following steps: (1) placing a to-be-welded workpiece on a welding platform in a butt-joint form, and clamping and fixing a workpiece; (2)regulating a stirring needle of a dual-shaft-shoulder friction stir welding head to align to the butt-joint position of the workpiece, regulating an ultrasonic tool bit and a lower shaft shoulder to be on coaxial positions, and enabling the ultrasonic tool bit and the lower shaft shoulder to be in a pressing state in a welding process; (3) firstly starting the dual-shaft-shoulder friction stir welding head, then, starting the ultrasonic generator, and enabling the dual-shaft-shoulder friction stir welding head and the ultrasonic generator to synchronously move relative to the workpiece to forma friction stir welding seam to realize welding while the stirring needle and the ultrasonic tool bit are in a stable coupling state. A way of applying coaxial ultrasonic vibrations to the bottom ofthe lower shaft shoulder of the dual-shaft-shoulder friction stir welding head is adopted, so that the method increases an ultrasonic energy utilization rate and guarantees quality of a welded joint.

Owner:JIANGSU UNIV OF TECH

Method for preparing fiber-reinforced metal matrix composites by multi-channel needle-free friction stir processing

InactiveCN102319954BImprove plastic fluidityFast central heatingNon-electric welding apparatusFiber bundleMetal matrix composite

The invention discloses a large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites. Firstly, metal matrix sheets are ground and cleaned in advance; secondly, a preprocessed fiber net or unidirectional fiber bundle is clamped between the two metal matrix sheets in a prearranging manner, and needs to be completely covered and sufficiently protected by the covering sheets; meanwhile, a pin-less friction stir tool is slightly inclined and mounted; the pin-less stool is started to rotate to rub the surface of the covering sheet and move, a plastic deformation gradient field generated by the forging and torsional effects of the shoulder is utilized, consequently, not only can the oxide skin of the metal matrix interface be broken, but also the metal matrix which heats to be softened can plastically flow around the fibers to wrap the fibers, and thereby the fiber / matrix and the matrix / matrix interfaces can be compactly combined. A pin-less stir head with a large diameter more than 40mm to 50mm is adopted to carry out multi-pass multi-layer friction stir processing, and thereby a large, thick fiber-reinforced metal matrix composite plate can be produced. The addition of brazing filler metal can solve the contradiction between fiber injury and interface bonding improvement.

Owner:XI AN JIAOTONG UNIV

Point heat source composite formation method for bending

InactiveCN101101481AOvercome the disadvantage of damage or even destructionImprove plastic fluidityElectric programme controlComputer control systemMachining

The invention discloses a bending point heat source combined shaping method, comprising the steps of: 1). making simulated machining on blanks by computer platform and prejudging local region difficult to shape; 2).by step 1), obtaining point heat source machining parameters; 3). As machining, controlling point heat source for combined machining by computer control system according to the parameters in step 2); 4). during machining in step 3), blank state sensor feeds stress, strain and other real-time monitored data back to the control system. And it can overcome the defect of possibly damaging shaped pieces, even destroying them.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

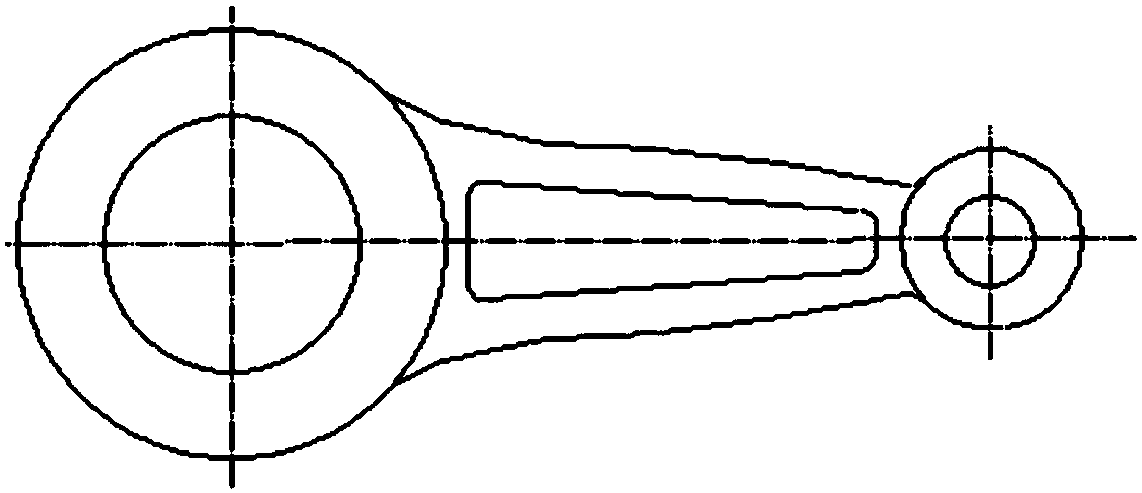

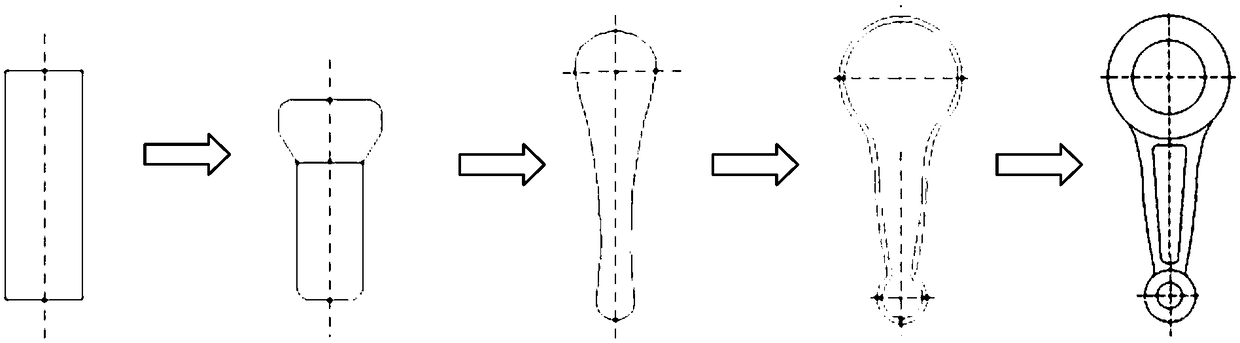

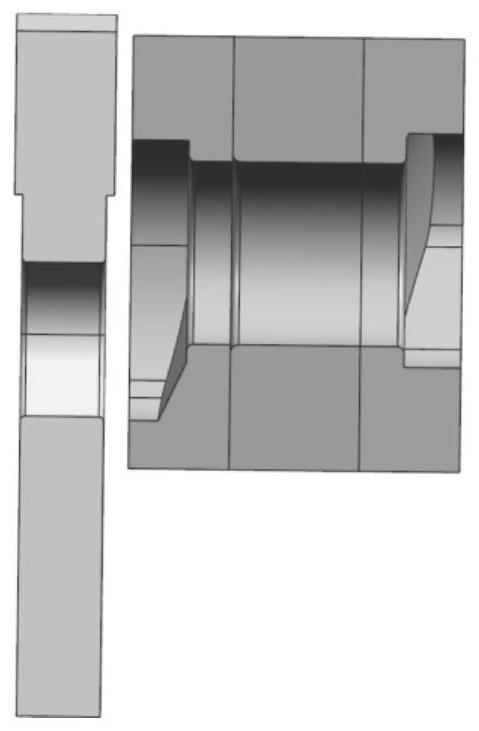

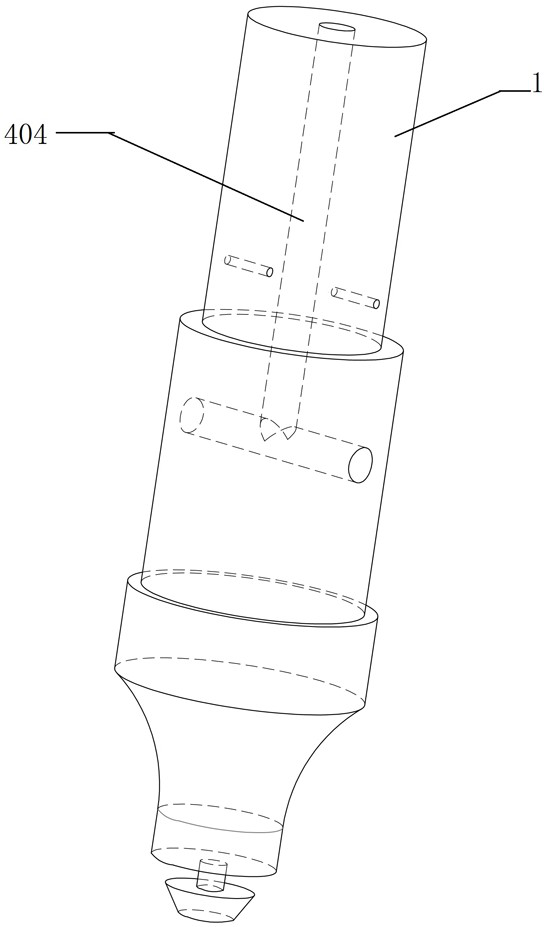

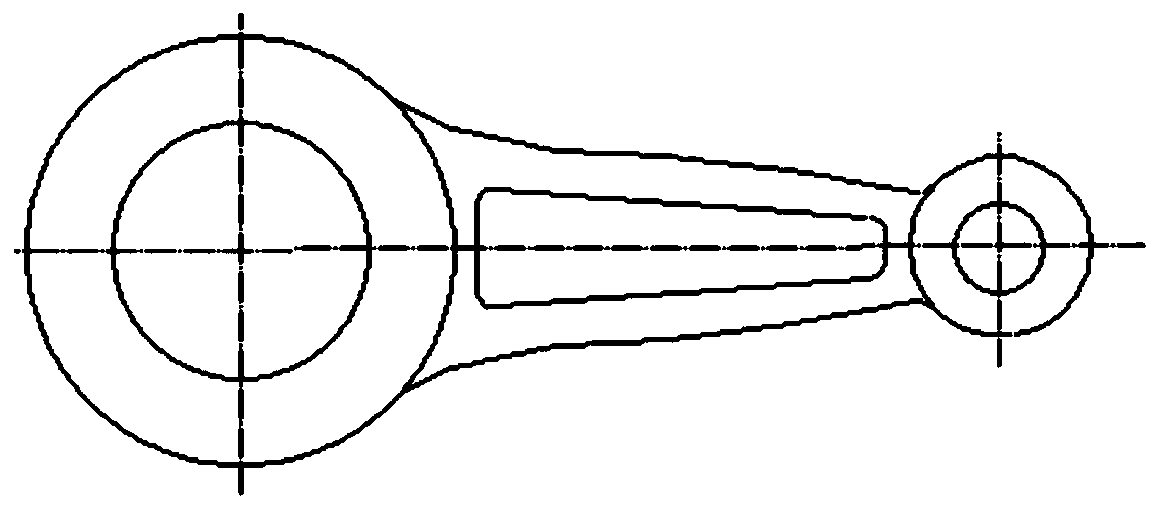

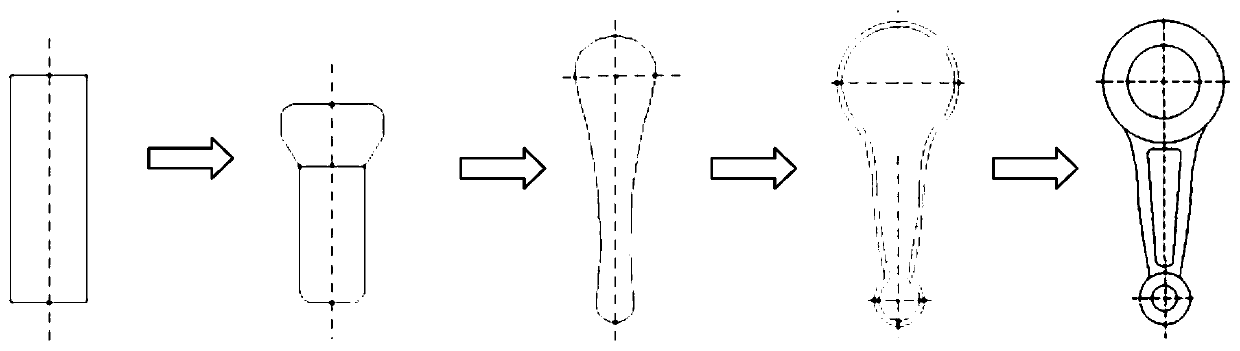

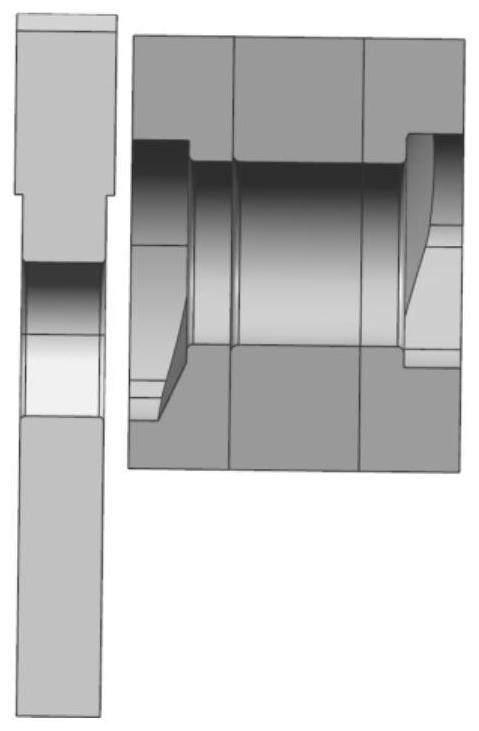

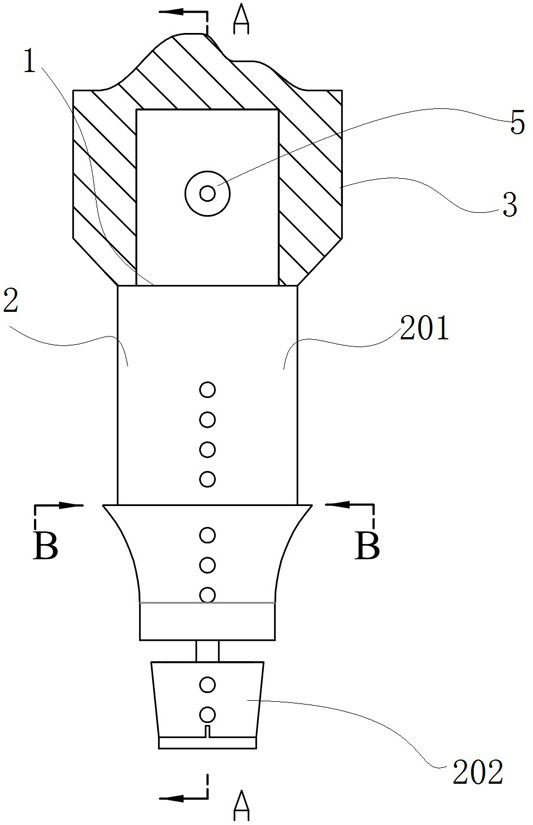

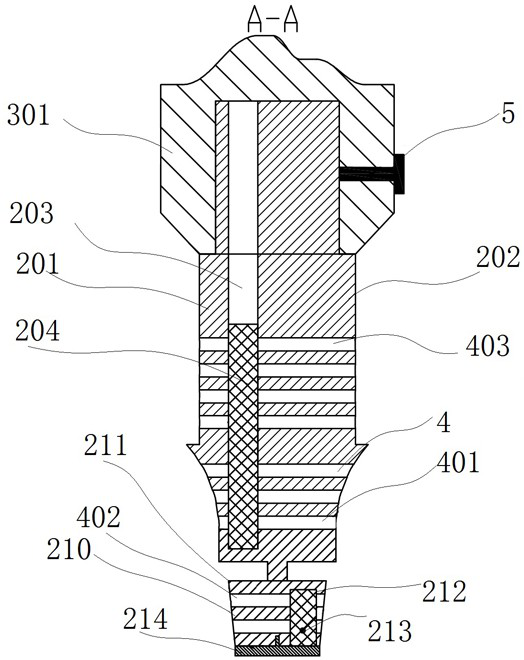

Precise thermal machining method for an engine piston connecting rod

ActiveCN108188336AIncrease profitImprove plastic fluidityExtrusion diesEngine componentsMetallic materialsEngineering

The invention discloses a precise thermal machining method for an engine piston connecting rod, and belongs to the technical field of metal material plastic machining. The method comprises the following steps that S101, a round blank is heated; S102, a precise pre-forming combination process is adopted, wherein a local upsetting process is adopted at first, a box-type variable-cross-section hole type transverse rolling forming process is adopted secondly, and thirdly, flattening and forming is carried out on the rolled blanks in a flattening mode so as to obtain a precisely-blocked extruded blank; and S103, reunion blocking and precise extrusion forming are carried out. According to the precise thermal machining method, the precise pre-forming combination process is adopted, and the process comprises the local upsetting process, the box-type variable-cross-section hole type transverse rolling forming process and a flattening and blocking precision extrusion forming process, so that precise hot working forming of the engine piston connecting rod is realized, the strength and the rigidity of the engine piston connecting rod meet the use requirements, wherein the sizes of a small head, the size of a rod body and the size of a large head of the engine piston connecting rod are close to the size of a finished product, the utilization rate of the material reaches more than 98%, and compared with an existing open type die forging, the material utilization rate is remarkably improved.

Owner:宣城市安工大工业技术研究院有限公司

Press-bending laser composite forming method

InactiveCN101140449AOvercome the disadvantage of damage or even destructionImprove plastic fluidityComputer controlLaser beam welding apparatusComputer control systemLaser processing

The present invention discloses a laser compounding and forming method for bending, which includes steps below: 1) Simulating processing is carried out to billets through a computer platform and partial area hard to be formed is prejudged; 2) Laser processing parameters are obtained according to step 1); 3) Lasers are controlled to realize composite processing through a computer control system according to parameters in step 2) during mechanical processing; 4) Synchronous with the processing in step 3), a sensor for billet state measuring feeds stress, strain and other real-time monitoring data back the control system; 5) As for a fine adjustment scheme, a fine adjustment scheme is firstly confirmed according to step 1), 2), 3) and 4) and then the scheme is controlled by a computer to complete processing. The present invention applies lasers to achieve laser compounding and forming for bending during large-sized piece forming of traditional machinery, well processes parts hard to be reshaped during mechanical forming, thus eliminating possible formed piece flaw and even damages due to mechanical forming.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Shaping method of safety air bag gasifier pressure cover

InactiveCN101284300AEvenly heatedImprove plastic fluidityMetal-working apparatusEngine componentsProduct gasAirbag

The invention discloses a method for forming a gas generator gland of an air bag, which comprises the steps of pre-heating an aluminum alloy blank to 160 DEG C-190 DEG C, dipping in sticky lubricant, drying and heating the aluminum alloy blank to 440DEG C-460DEG C, keeping the temperature, and putting in a forging die for press forming. In the forming process, the outer ring of the workpiece bears additional external force in a direction opposite to the plastic flow direction of the workpiece. The additional external force is applied by a hydraulic or pneumatic or spring mechanism through controlling a gliding block on the bottom of a die cavity. The method is applied to processing the gas generator gland of the air bag, improves product precision and production efficiency, prolongs the service life of dies, reduces production cost, and is particularly suitable for automatic production on a large scale.

Owner:JIANGSU AIRSHIP GEAR

Auxiliary incremental forming device heating metal plate by using electrical discharges

InactiveCN109365631AImprove plastic fluidityReduce tensile stressMetal-working feeding devicesPositioning devicesThick plateHigh intensity

The invention relates to an auxiliary incremental forming device heating a metal plate by using electrical discharges. The auxiliary incremental forming device is characterized in that a workpiece isfixed on a support, and the support is fixed on a machine tool. During forming machining of the metal plate, a vibrator drives an electrical discharge anode to vibrate together, then the electrical discharge anode is in contact with the plate frequently and alternately, the high-strength electrical discharges are generated, then the plate is locally heated, so that machining conditions are greatlyimproved, and the auxiliary incremental forming device is especially used for a thick plate; and the auxiliary incremental forming device has the advantages that the structure is simple, the work isreliable, the installation operation and the maintenance are convenient.

Owner:HARBIN UNIV OF SCI & TECH

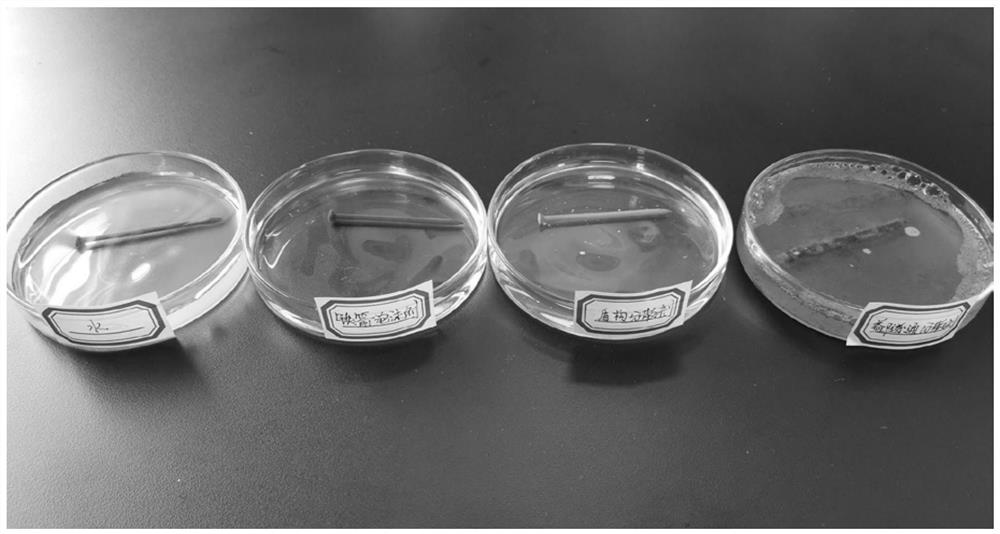

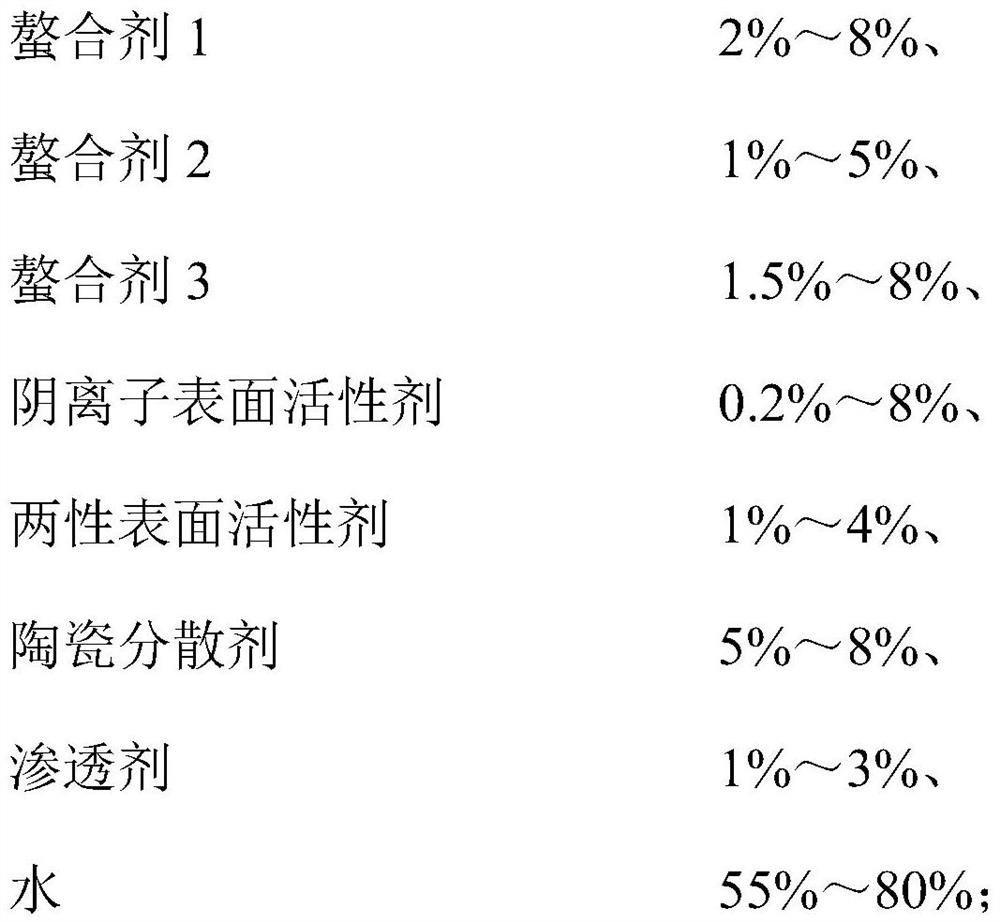

Shield dispersant and its preparation method and application

ActiveCN112342028BImprove surface activityImprove adhesionBuilding constructionsOrganic fertilisersSodium phosphatesActive agent

The invention relates to a shield dispersant and its preparation method and application. The shield dispersant is prepared from raw materials including the following mass percentages: 2%-8% chelating agent 1, 1%-5% chelating agent 2, 1.5%-8% chelating agent 3, 0.2%-8% anionic surface Active agent, 1%-4% amphoteric surfactant, 5%-8% ceramic dispersant, 1%-3% penetrating agent, 55%-80% water; the chelating agent 1 is selected from citric acid, sodium citrate , at least one of gluconic acid and polyacrylic acid; the chelating agent 2 is selected from at least one of ethylenediaminetetraacetic acid and disodium edetate; the chelating agent 3 is selected from sodium tripolyphosphate, At least one of sodium pyrophosphate and sodium hexametaphosphate. The shield dispersant is very environmentally friendly, and has good wettability, permeability, dispersibility, and low temperature resistance, which can effectively alleviate the phenomenon of "cake formation" on the shield cutterhead, and at the same time, it is low in corrosion and will not damage the equipment. cause damage.

Owner:中铁建华南建设(广州)高科技产业有限公司

Ultrasonic friction stir welding composite welding system

ActiveCN112809219AStrong load resistanceLarge effective amplitudeNon-electric welding apparatusEngineeringUltrasonic vibration

The invention provides an ultrasonic friction stir welding composite welding system. The system is characterized in that the ultrasonic friction stir welding composite welding system comprises at least one front-stage ultrasonic amplitude-change pole, a rear-stage ultrasonic amplitude-change pole and a stirring head, and at least one ultrasonic transducer is fixed to the front end of each front-stage ultrasonic amplitude-change pole; the front end of the rear-stage ultrasonic amplitude-change pole is fixedly connected with the rear ends of all the front-stage ultrasonic amplitude-change poles; the stirring head is fixedly connected with the rear end of the rear-stage ultrasonic amplitude-change pole; the front-stage ultrasonic amplitude-change poles are high-order polynomial type half-wavelength ultrasonic amplitude-change poles, and the amplification factor of the front-stage ultrasonic amplitude-change poles is a large amplification factor; and the rear-stage ultrasonic amplitude-change pole is a half-wavelength ultrasonic amplitude-change pole, and the amplification factor of the rear-stage ultrasonic amplitude-change pole is a small amplification factor. According to the system, a high-power multi-vibrator ultrasonic vibration system is used for increasing the driving power of the system, improving the ultrasonic energy density in the welding process and improving the welding efficiency, and the high-power ultrasonic vibration system achieves the effects of increasing the ultrasonic amplitude and enhancing the anti-load capacity of the system by designing a multi-stage amplitude-change pole.

Owner:DALIAN JIAOTONG UNIVERSITY

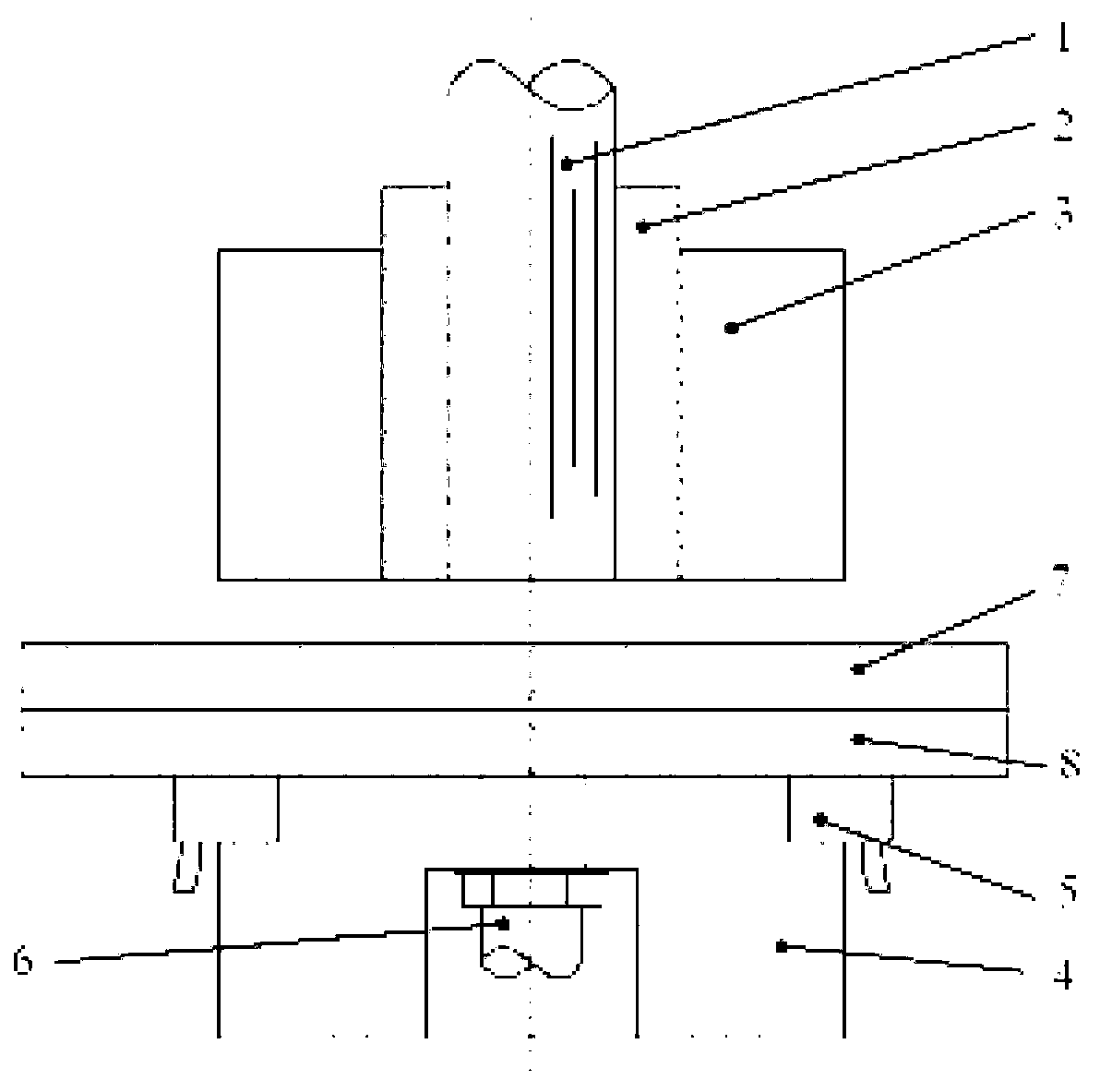

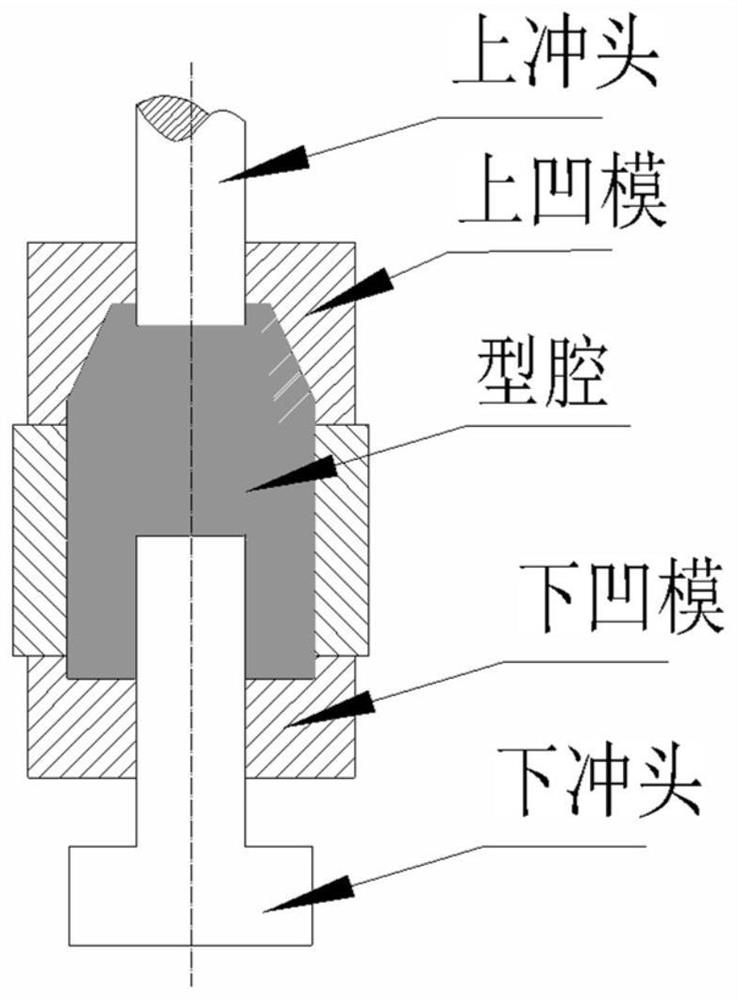

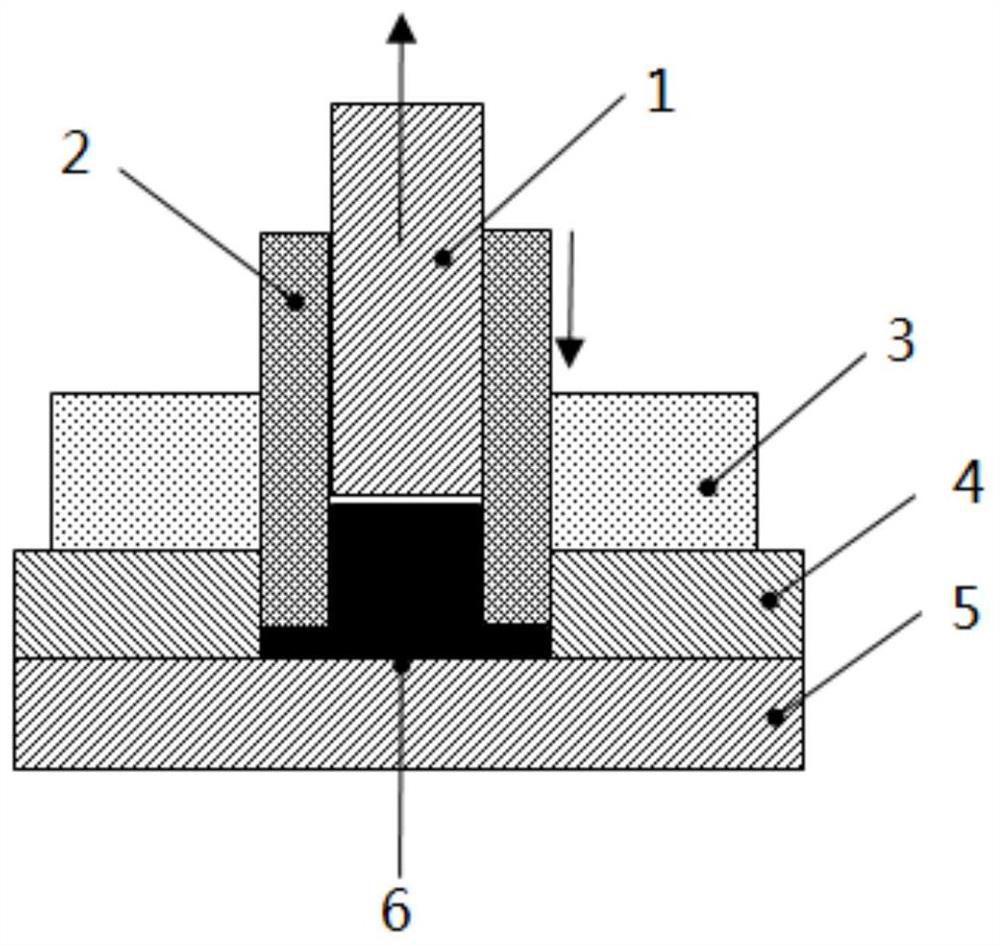

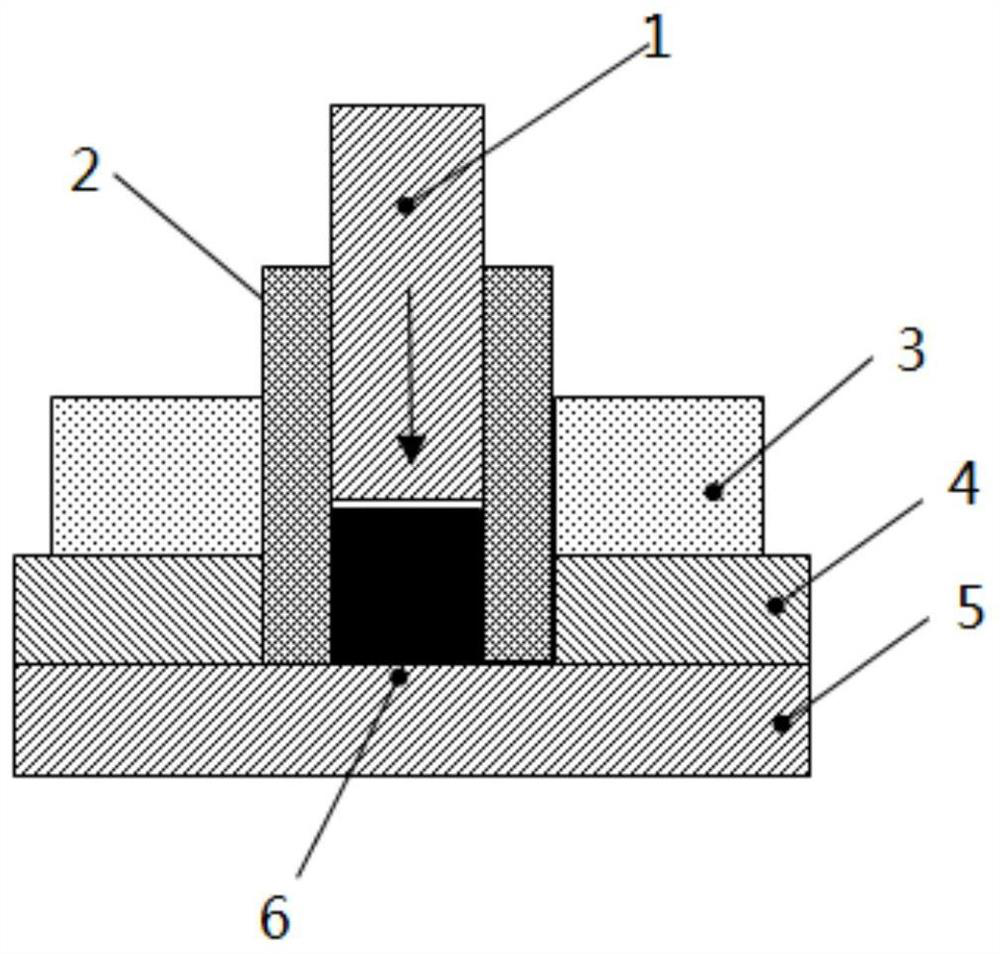

Flange type magnet yoke precision hot working method for electromagnetic brake clutch and die

ActiveCN110523899AHigh strengthIncrease stiffnessExtrusion diesForging/hammering/pressing machinesPunchingButt joint

The invention discloses a flange type magnet yoke precision hot working method for an electromagnetic brake clutch and a die, and belongs to the technical field of metal material plastic working. Theprecision hot working method comprises the following steps of S01, heating a round billet; S02, pre-forming a combined process, wherein, the first step is an upsetting process, the second step is a pre-upsetting forming process, and the third step is a punching process; S03, carrying out the closed precision extrusion forming; and S04, shaping and deburring. According to the process, forging is used for replacing casting, the magnetic conductivity of the electromagnetic brake and the clutch magnet yoke is improved, and the use requirement is better met; and the size of a forge piece is close to that of a finished product, and the material utilization reaches 98% or above. The related die comprises an upper extrusion female die, a lower extrusion female die and an extrusion male die, the space formed by the butt joint and closing of the upper extrusion female die and the lower extrusion female die is a cavity, a single-ring-shaped boss is arranged at the lower end of the extrusion maledie, and the size of the cavity is equal to the sum of the size of a magnet yoke blank and the size of the portion, stretching into the cavity, of the extrusion male die.

Owner:宣城市安工大工业技术研究院有限公司

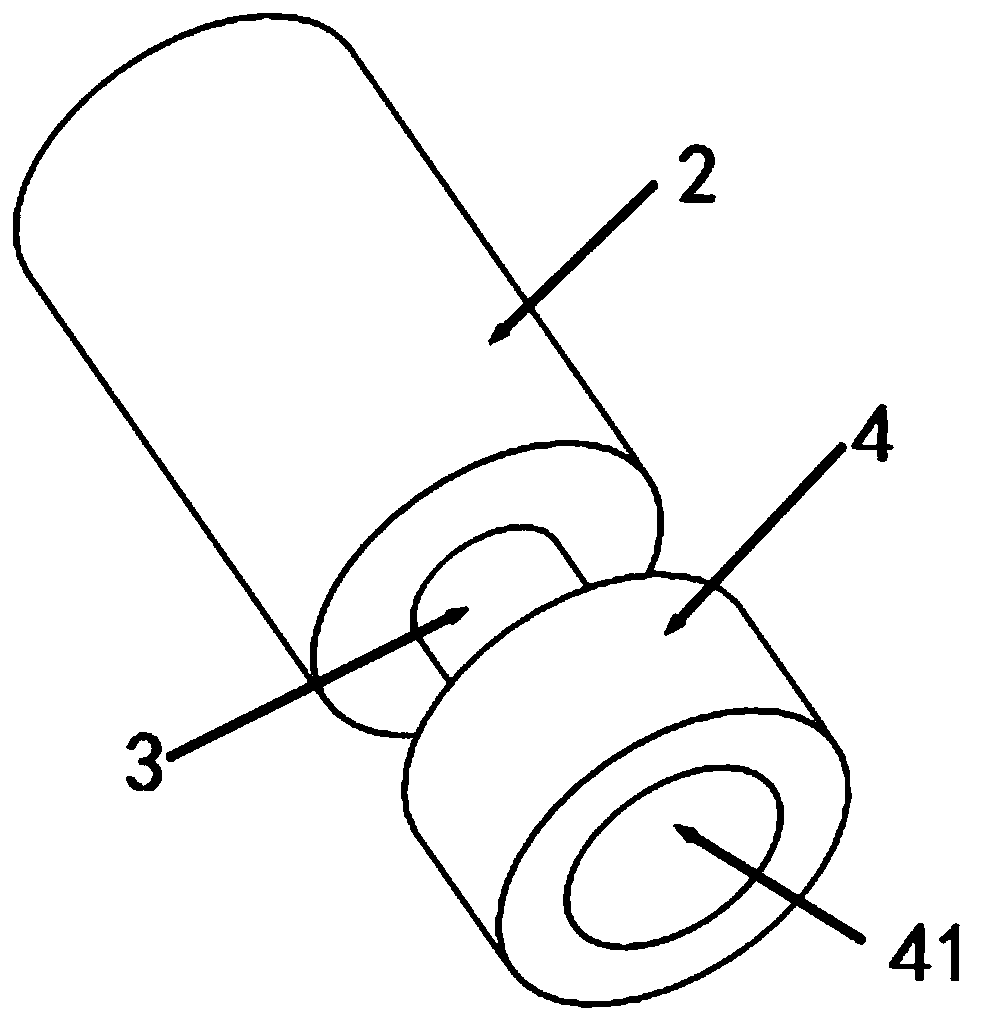

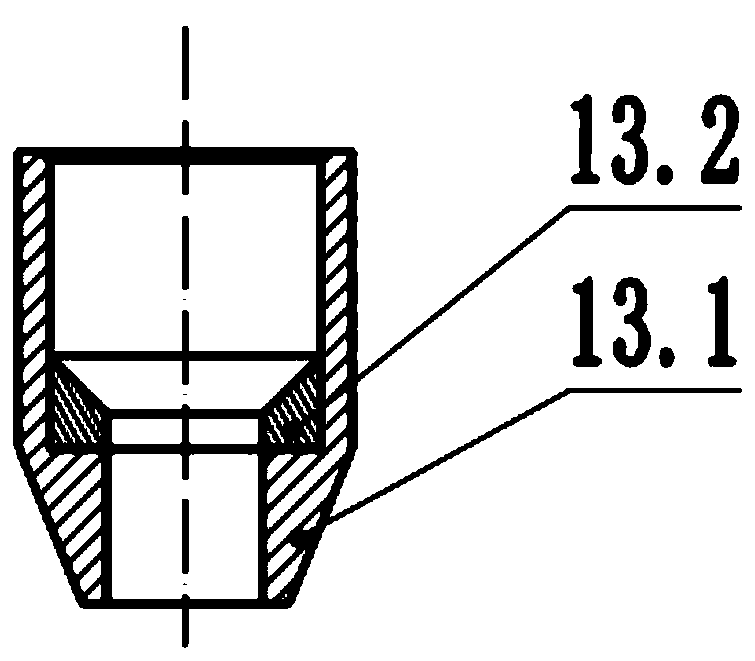

Friction riveting device for thermoplastic carbon fiber composite material and aluminum alloy and riveting method of friction riveting device

PendingCN112810169AImprove plastic fluidityGood formabilityDomestic articlesFibrous compositesUltimate tensile strength

The invention discloses a friction riveting device for a thermoplastic carbon fiber composite material and an aluminum alloy. The friction riveting device comprises a female die, a blank holder and a driving rod. The lower part of the female die is of a solid cylindrical structure, the center of the upper part of the female die is provided with a circular groove, and the bottom face of the circular groove protrudes upwards to form a conical shape. The blank holder is of a cylindrical structure, a cylindrical center hole is formed in the center of the blank holder, and the blank holder is arranged above the female die and is coaxial with the female die. The driving rod is coaxially arranged in the center hole and can perform rotary motion and axial feeding motion along the center hole. The invention further discloses a riveting method of the friction riveting device for the thermoplastic carbon fiber composite material and the aluminum alloy, heat is generated through rotating friction, meanwhile, the rotating speed and the axial feeding speed of the rivet are adjusted, and therefore the optimal rivet welding state value between the thermoplastic carbon fiber composite material plate and the aluminum alloy plate can be achieved, and the joint strength and the joint forming effect are improved.

Owner:JILIN UNIV

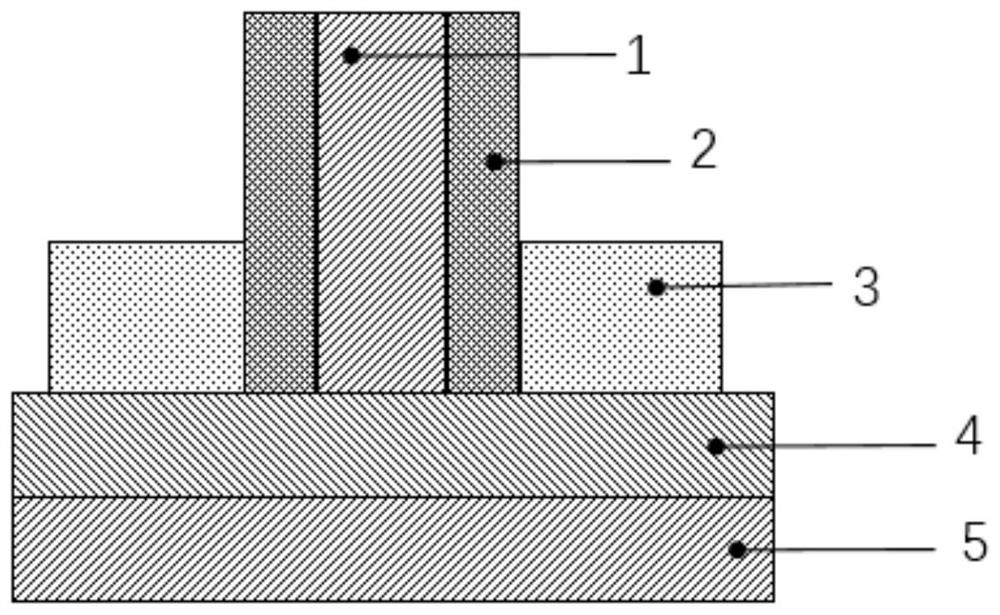

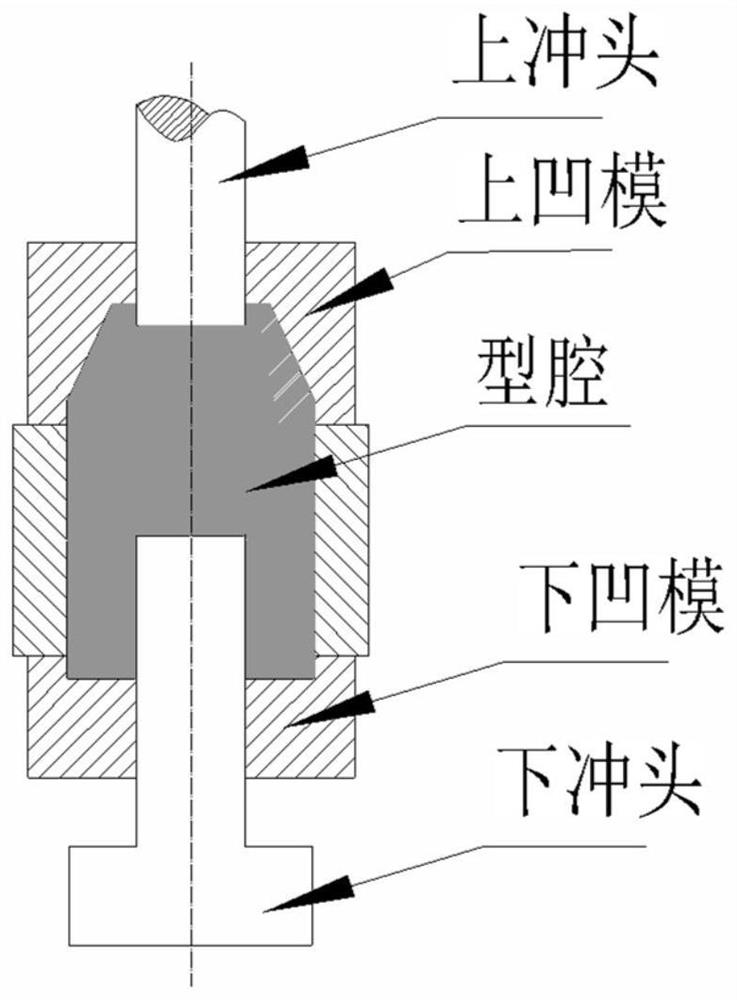

Plastic forming method for large complex special-shaped structural part

ActiveCN112296111AOvercome the problem of low life expectancyImprove plastic fluidityExtrusion diesMold fillingMechanical engineering

The invention belongs to the technical field of manufacturing of specific metal articles, and particularly relates to a plastic forming method for a large complex special-shaped structural part. The plastic forming method sequentially comprises the procedures of discharging, blank heating, feeding, die assembly and reciprocating ejection extrusion, and is characterized in that the feeding comprises the following steps that a heated blank is put into a cavity of a follow-up cavity, and the follow-up cavity comprises an upper punch, an upper female die, a cavity body, a lower female die and a lower punch which are sequentially arranged. According to the method of the invention, the problem that the service life of a die is short in extrusion forming of a complex component can be solved; andthe plastic fluidity of a large complex special-shaped component can be remarkably improved, and the mold filling problem of the complex component is solved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Bending and point heat source composite formation method

InactiveCN100468244COvercome the disadvantage of damage or even destructionImprove plastic fluidityElectric programme controlComputer control systemMachining

The invention discloses a bending point heat source combined shaping method, comprising the steps of: 1). making simulated machining on blanks by computer platform and prejudging local region difficult to shape; 2).by step 1), obtaining point heat source machining parameters; 3). As machining, controlling point heat source for combined machining by computer control system according to the parameters in step 2); 4). during machining in step 3), blank state sensor feeds stress, strain and other real-time monitored data back to the control system. And it can overcome the defect of possibly damaging shaped pieces, even destroying them.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

A flange-type magnetic yoke precision thermal processing method and mold for electromagnetic brake clutch

ActiveCN110523899BHigh strengthIncrease stiffnessExtrusion diesForging/hammering/pressing machinesPunchingMetallic materials

Owner:宣城市安工大工业技术研究院有限公司

Magnetic surrounding type double-shaft-shoulder friction stir welding tool and mounting method thereof

ActiveCN114083107AExtended service lifeIncrease temperatureMetal-working hand toolsNon-electric welding apparatusMagnetic tension forceEngineering

The invention discloses a magnetic surrounding type double-shaft-shoulder friction stir welding tool and a mounting method thereof, and relates to the technical field of friction stir welding tools. The magnetic surrounding type double-shaft-shoulder friction stir welding tool comprises a stirring head; a surrounding type magnetic field device is sleeved with the stirring head; a magnetic line guiding device is installed at the bottom of the surrounding type magnetic field device; a water cooling device is arranged in the surrounding type magnetic field device; and magnetic field enhancing devices are fixedly arranged at the upper end and the lower end of the stirring head. Under the condition that the welding speed and the rotating speed are fixed, the surrounding type magnetic field device, the magnetic line guiding device and the magnetic field enhancing devices are additionally arranged, so that the size of a weld nugget area can be increased, and the metal flowability at the bottom of a weldment is improved so as to make up the defect of dispersively distributed cavities when a cavity behind the stirring needle is filled. The process is simple, the cost is low, the welding efficiency is high, the service life of the stirring head is long, weld structure grains can be refined, and the comprehensive performance is remarkably improved. The process is simple, the cost is low, the welding efficiency is high, the service life of the stirring head is long, weld structure grains can be refined, and the comprehensive performance is remarkably improved.

Owner:南京雷尔伟新技术股份有限公司

A precision thermal processing method for an engine piston connecting rod

ActiveCN108188336BIncrease profitImprove plastic fluidityExtrusion diesEngine componentsMetallic materialsEngineering

The invention discloses a precise thermal machining method for an engine piston connecting rod, and belongs to the technical field of metal material plastic machining. The method comprises the following steps that S101, a round blank is heated; S102, a precise pre-forming combination process is adopted, wherein a local upsetting process is adopted at first, a box-type variable-cross-section hole type transverse rolling forming process is adopted secondly, and thirdly, flattening and forming is carried out on the rolled blanks in a flattening mode so as to obtain a precisely-blocked extruded blank; and S103, reunion blocking and precise extrusion forming are carried out. According to the precise thermal machining method, the precise pre-forming combination process is adopted, and the process comprises the local upsetting process, the box-type variable-cross-section hole type transverse rolling forming process and a flattening and blocking precision extrusion forming process, so that precise hot working forming of the engine piston connecting rod is realized, the strength and the rigidity of the engine piston connecting rod meet the use requirements, wherein the sizes of a small head, the size of a rod body and the size of a large head of the engine piston connecting rod are close to the size of a finished product, the utilization rate of the material reaches more than 98%, and compared with an existing open type die forging, the material utilization rate is remarkably improved.

Owner:宣城市安工大工业技术研究院有限公司

A device and method for driving plate hole turning and forming by using multi-directional magnetic field force

The invention discloses a device and method for driving plate hole flanging forming through multidirectional magnetic field force. The device comprises a blank holder (1) and a concave die (2). The blank holder (1) is arranged above the concave die (2) and used for pressing a plate (3) to be subjected to hole flanging forming between the blank holder (1) and the concave die (2). A concave die cavity (4) is formed in the concave die (2). An upper coil groove and a lower coil groove are correspondingly formed in the blank holder (1) and the concave die (2). Upper end hole shrinkage coils (5) are embedded in the upper coil groove. Lower end hole shrinkage coils (6) are embedded in the lower coil groove. Axial deep drawing coils (7) are arranged above the edge of a pre-formed hole of the plate (3). An inner bulging coil (8) is arranged in the pre-formed hole of the plate (3). According to the device and method, cracks can be prevented from being generated to a round hole flanging deformation area during hole flanging forming, the product quality is good, and the forming process is simple.

Owner:CENT SOUTH UNIV

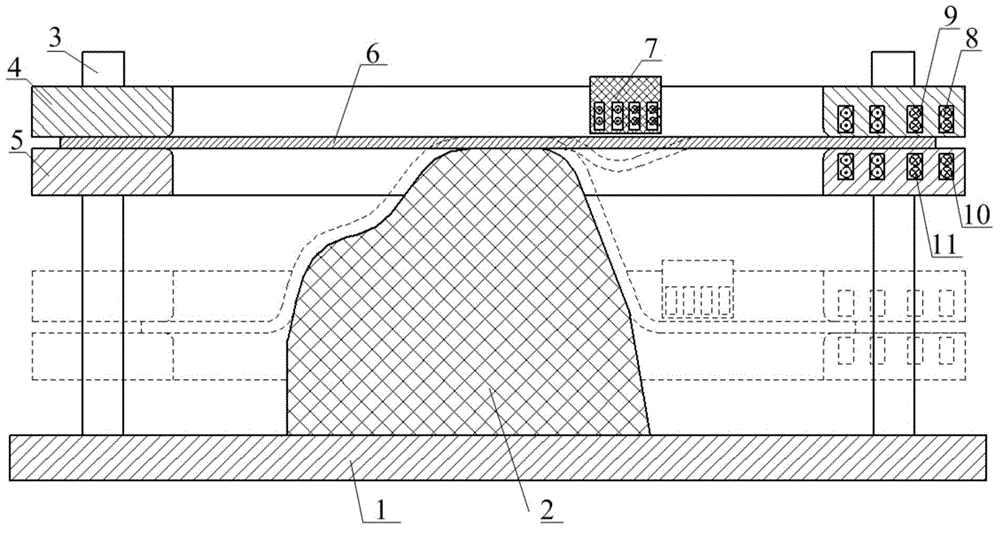

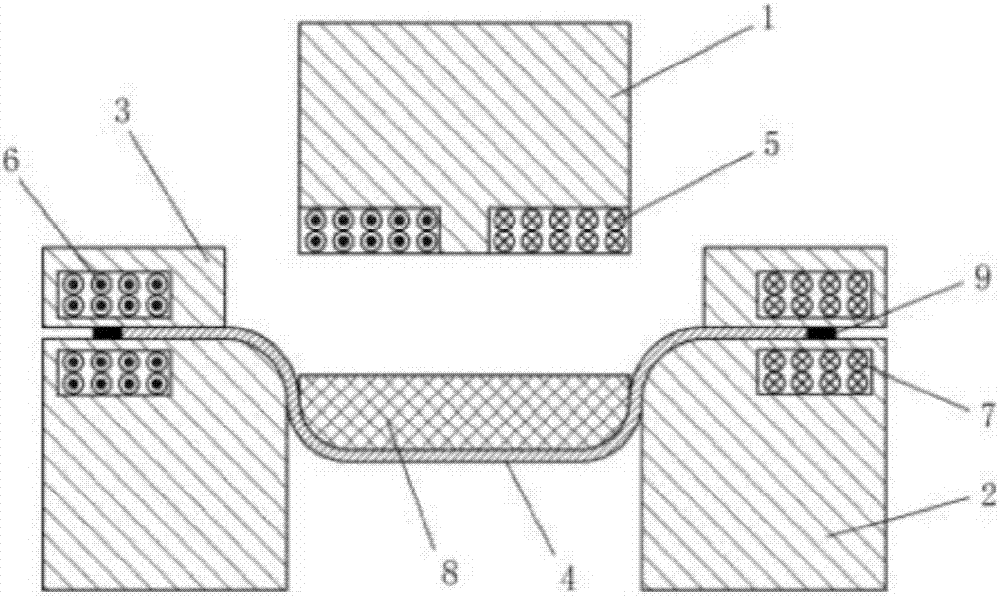

An electromagnetic forming device and method for improving the limit and quality of plate turning hole

The invention discloses an electromagnetic forming device for improving the panel hole-flanging limit and quality. The electromagnetic forming device for improving the panel hole-flanging limit and quality comprises a male die, a female die matched with the male die, and a blank holder matched with the top end surface of the female die so as to press a panel veneer, wherein a pre-manufactured holeis processed in the panel veneer; an axial tension coil is arranged above the pre-manufactured hole and is arranged in a coil fixing plate; the coil fixing plate is arranged and fixed to the bottom part of the male die; a circular bead is arranged on the bottom part of the male die; a female die sleeve ring is arranged on the periphery of the female die; a blank holder sleeve ring is arranged onthe periphery of the blank holder; grooves are formed in the female die sleeve ring and the blank holder sleeve ring; and radial side pushing coils are arranged in the grooves. The invention providesthe composite die which is capable of greatly prolonging the service lives of the coils and the dies during electromagnetic pulse hole-flanging; and meanwhile, only one tool is required during the whole forming process, and electromagnetic pulse discharge and die reshaping can be carried out synchronously, so that the production efficiency is greatly improved.

Owner:CENT SOUTH UNIV

An Ultrasonic Friction Stir Welding Hybrid Welding System

ActiveCN112809219BStrong load resistanceLarge effective amplitudeNon-electric welding apparatusEngineeringUltrasonic vibration

Owner:DALIAN JIAOTONG UNIVERSITY

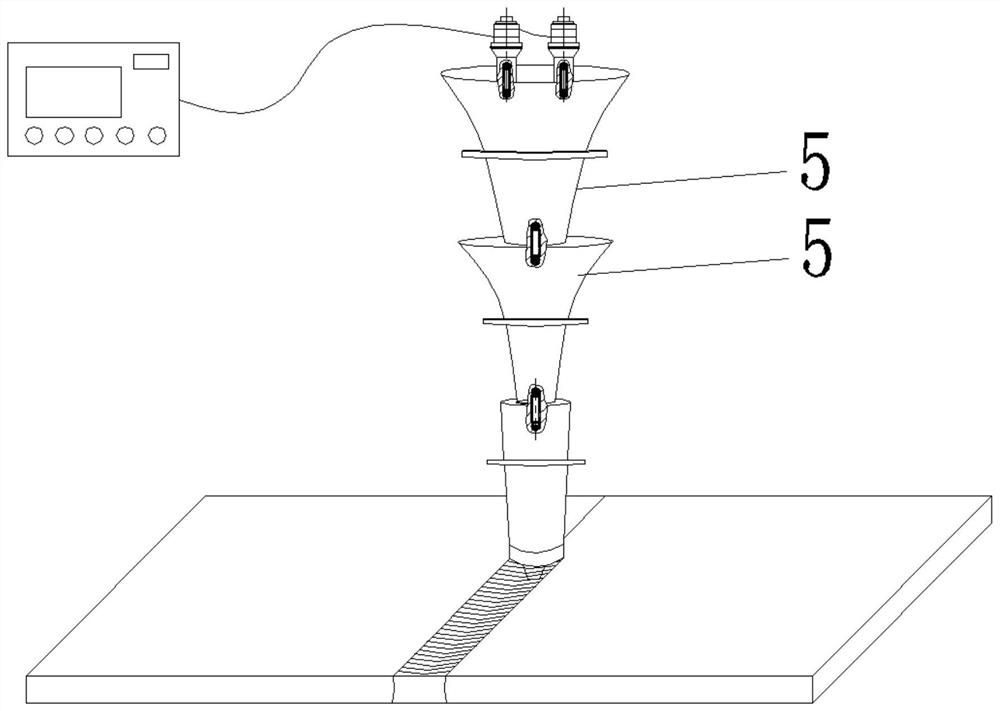

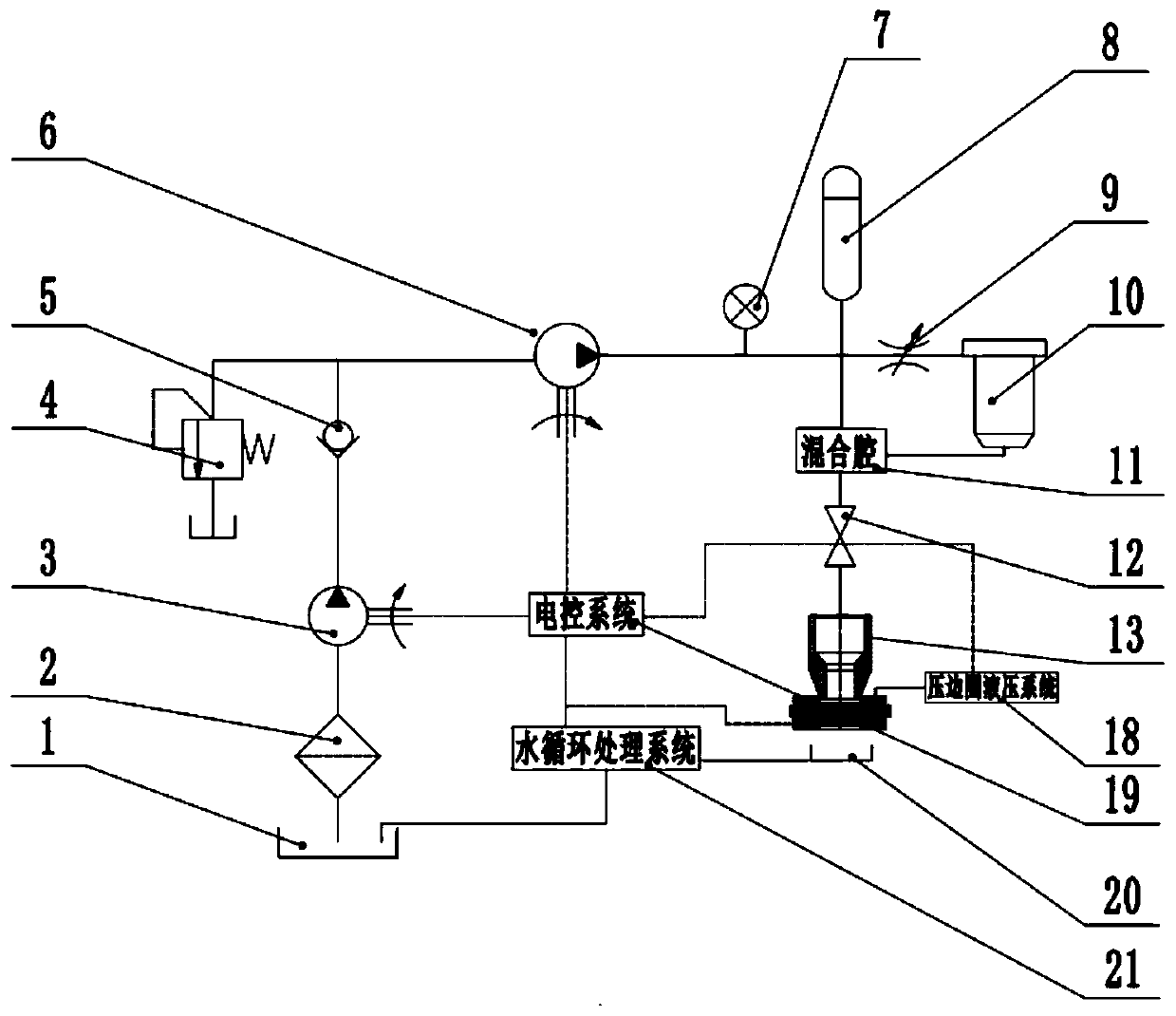

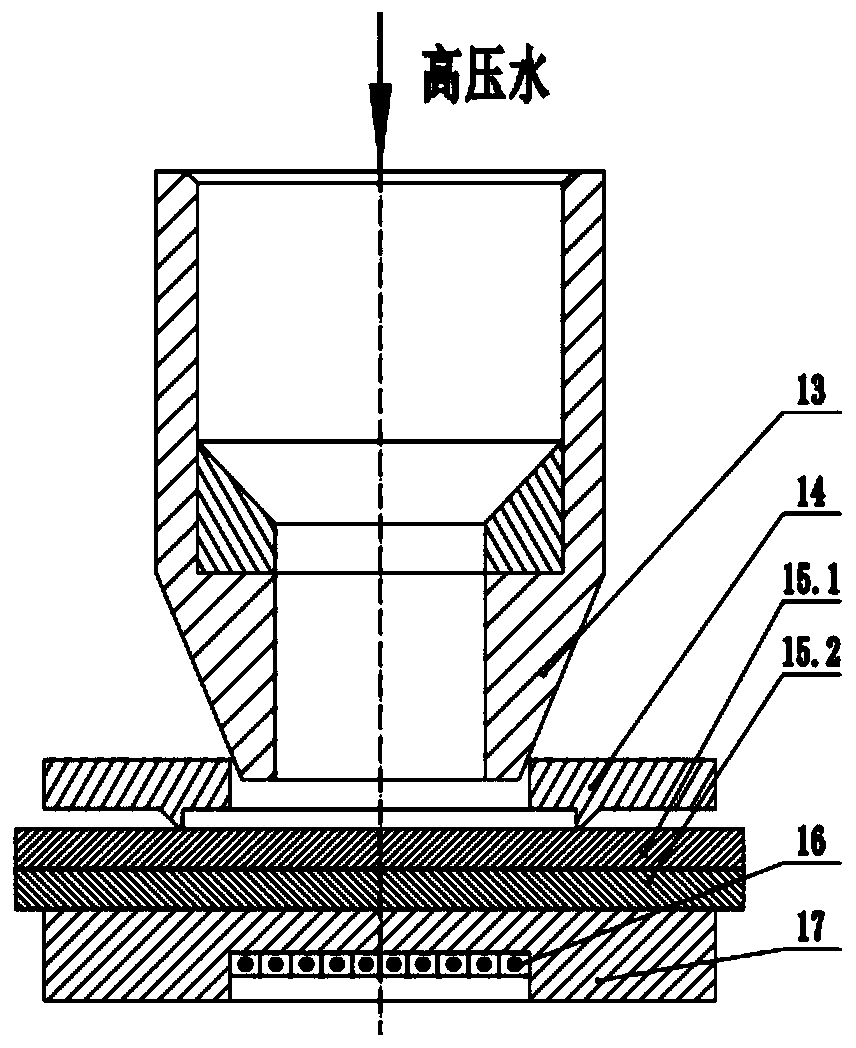

Integrated anti-extrusion connecting system and method thereof for water knife forming, strengthening and quenching

The invention provides an integrated anti-extrusion connecting system and a method thereof for water-knife forming, strengthening and quenching. The system comprises a connecting device, a water-knifepower system, an electric control system and a water circulation treatment system, wherein the connecting device comprises a spray head and a connecting tool; the water-knife power system comprises awater tank, a filter, a low-pressure water pump, a check valve, a high-pressure water pump, an energy accumulator, a throttle valve, a hard particle tank, a mixing cavity and a stop valve, and the stop valve is located above the spray head; the electric control system is electrically connected with the high-pressure water pump, the low-pressure water pump, electromagnetic coils and a blank holderhydraulic system; and one end of the water circulation treatment system is connected with the water tank of the water-knife power system, and the other end of the water circulation treatment system is connected with a water collector. The system is used for connecting multi-layer plates, forming, quenching and strengthening are integrated, the production efficiency is high, the connection reliability is high, and the connection position has the advantages of compact metal structure, high strength, strong wear resistance, high hardness and the like.

Owner:CENT SOUTH UNIV

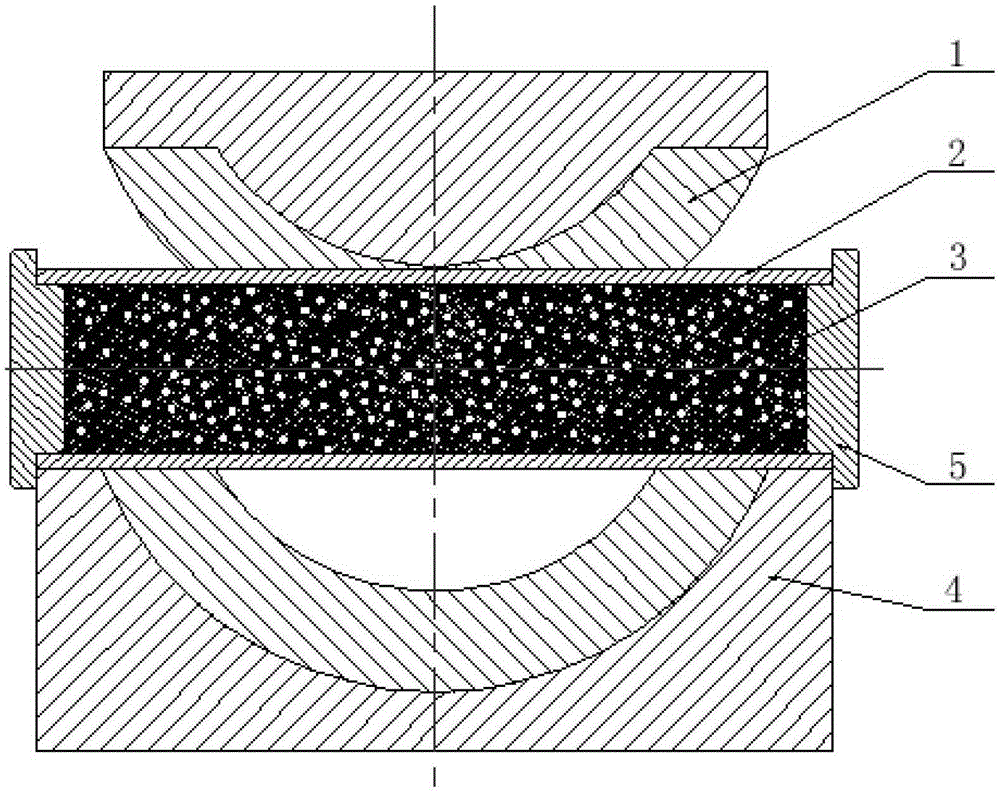

A medium forming method for improving the formability of thick-walled metal pipe fittings

The invention relates to a medium forming method for improving the forming property of thick-wall metal pipe fittings. The method comprises the following steps: S1, preparing composite medium, namely, granular medium is uniformly mixed with fusible alloy under molten state, wherein the melting point of the fusible alloy is lower than the melting temperatures of a tube blank and the granular medium; S2, filling composite medium, namely, a fluid-shaped composite medium is filled in a hollow tube blank and then cooled until the composite medium is solidified; S3, forming pipe fittings; and S4, taking out the granular medium, namely, the solidified fusible alloy in a pipe is converted into molten fusible alloy, so that the molten fusible alloy drives the granular medium to be separated from the pipe fittings. The invention overcomes the defects that when the traditional rigid mould method is used for thick-wall metal pipe fitting forming, good forming quality is hard to achieve, avoids multi-step molding of metal pipe fittings, greatly saves the die cost, shortens the production period, and achieves the purpose of environmental-friendly and rapid production.

Owner:WUHAN UNIV OF TECH

A pre-filled friction stir spot welding method for eliminating hole defects

ActiveCN108941880BExtend the mixing timeImprove plastic fluidityNon-electric welding apparatusPlastic materialsSpot welding

The invention discloses a prefilling friction stir spot welding method capable of eliminating hole defects. The method comprises a zeroing phase, a pressing phase and a prefilling phase; a stirring sleeve is maintained to rotate in situ; meanwhile, a stirring needle is rotated to downwards prefill by a certain depth to eliminate a gap between a plastic material and the stirring needle; and meanwhile, a certain filling forging force can be applied to the plastic material under the stirring needle. The method further comprises a filling phase and a finishing phase. Through the prefilling actionof the stirring needle, the gap between a welding material and the stirring needle caused by the material loss is eliminated; and a certain filling forging force can be applied to the welding materialon the lower side, so that the welding material can be quickly extruded and filled in a cavity formed by extraction of the stirring sleeve in the filling phase, and the hole defects in the welding process are eliminated.

Owner:SHANGHAI DIANJI UNIV

Plastic forming method for large and complex special-shaped structural parts

ActiveCN112296111BOvercome the problem of low life expectancyImprove plastic fluidityExtrusion diesEngineeringMechanical engineering

The invention belongs to the technical field of manufacturing specific metal articles, and in particular relates to a plastic forming method for large and complex special-shaped structural parts. The plastic forming method sequentially includes blanking, billet heating, loading, mold clamping and reciprocating ejection extrusion processes. In the cavity, the follow-up cavity includes an upper punch, an upper die, a cavity, a lower die and a lower punch which are arranged in sequence. The method of the invention can overcome the problem of low die life of complex components during extrusion, can significantly improve the plastic fluidity of large complex special-shaped components, and solve the problem of filling complex components.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Semi-submersible underwater rotary magnetized double-shaft-shoulder friction stir welding tool and mounting method

ActiveCN114289852AExtended service lifeIncrease temperatureNon-electric welding apparatusMagnetic tension forceEngineering

The invention discloses a semi-submersible type underwater rotary magnetization friction stir welding tool and an installation method, and relates to the technical field of underwater rotary magnetization double-shaft-shoulder friction stir welding tools, the semi-submersible type underwater rotary magnetization friction stir welding tool comprises a stirring head body, the stirring head body comprises a magnet bias device, a clamping assembly and a water cooling assembly, one end of the magnet bias device is sleeved with the clamping assembly, and the other end of the magnet bias device is sleeved with the water cooling assembly; a water cooling assembly is arranged in the magnet bias device; the magnet bias device comprises a stirring head upper shaft shoulder assembly and a stirring head lower shaft shoulder assembly connected with the stirring head upper shaft shoulder assembly through a motor rotating main shaft, under the condition that the welding speed and the rotating speed are fixed, the asymmetric bias magnetic field magnetic force adjustable stirring head is additionally arranged, the size of a nugget area can be increased, and the welding quality is improved. The metal flowability at the bottom of a weldment is improved to fill a cavity behind the stirring needle, the defect of dispersively distributed cavities is overcome, the process is simple, the cost is low, the welding efficiency is high, the service life of the stirring head is long, weld structure grains can be refined, and the comprehensive performance is remarkably improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com