Ultrasonic friction stir welding composite welding system

A hybrid welding and ultrasonic stirring technology, which is used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of small ultrasonic amplitude, inability to obtain high-quality welds, and low ultrasonic energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

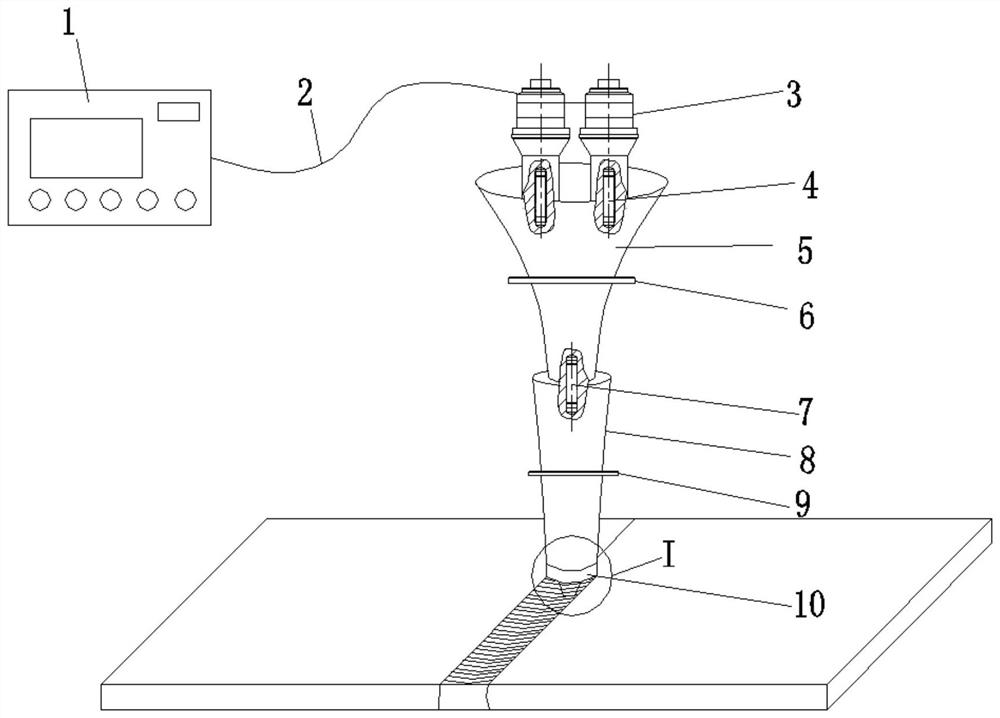

[0049] Such as Figure 1~2 As shown, an ultrasonic friction stir welding hybrid welding system includes:

[0050] A pre-stage ultrasonic horn 5, the front end of the pre-stage ultrasonic horn 5 fixes two ultrasonic transducers 3 through stud bolts I4; the ultrasonic transducer 3 is connected to the power supply 1 through a wire 2;

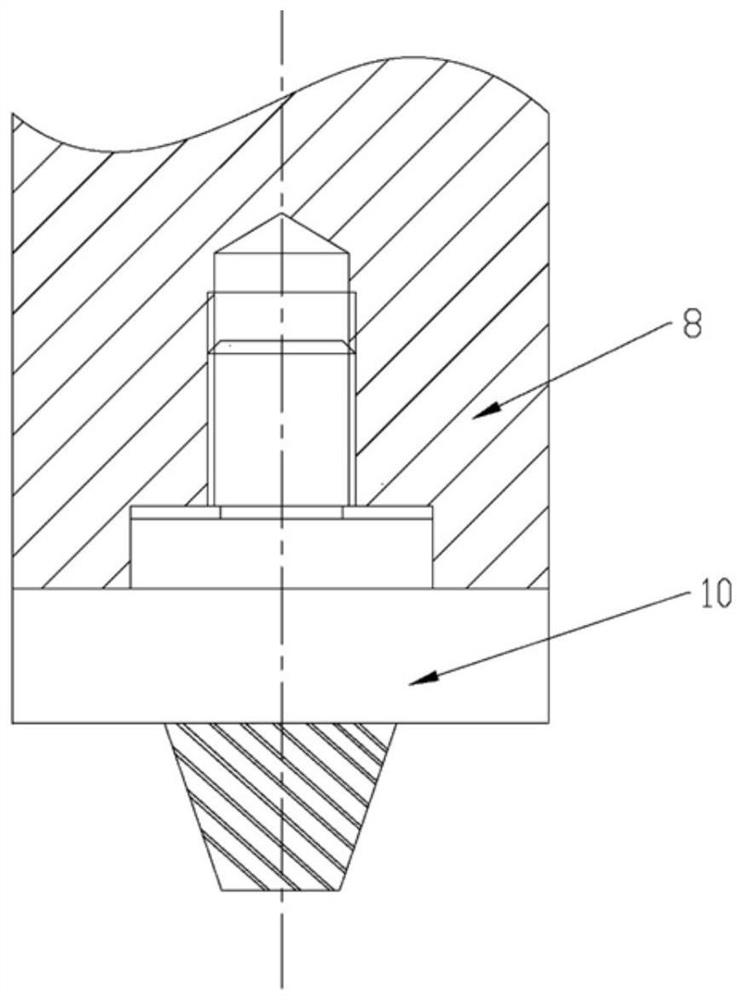

[0051] A rear-stage ultrasonic horn 8, the front end of which is tightly fixedly connected to the rear ends of all the preceding ultrasonic horns 5 through stud bolts II7;

[0052] The stirring head 10 is fixedly connected to the rear end of the rear-stage ultrasonic horn 8; the circular end face of the stirring head 10 is closely connected with the end face of the rear-stage ultrasonic horn 8, and the front end of the stirring head 10 The cylindrical section enters the shaft hole at the rear end of the rear-stage ultrasonic horn 8 to achieve radial positioning and is fixedly connected by bolts.

Embodiment 2

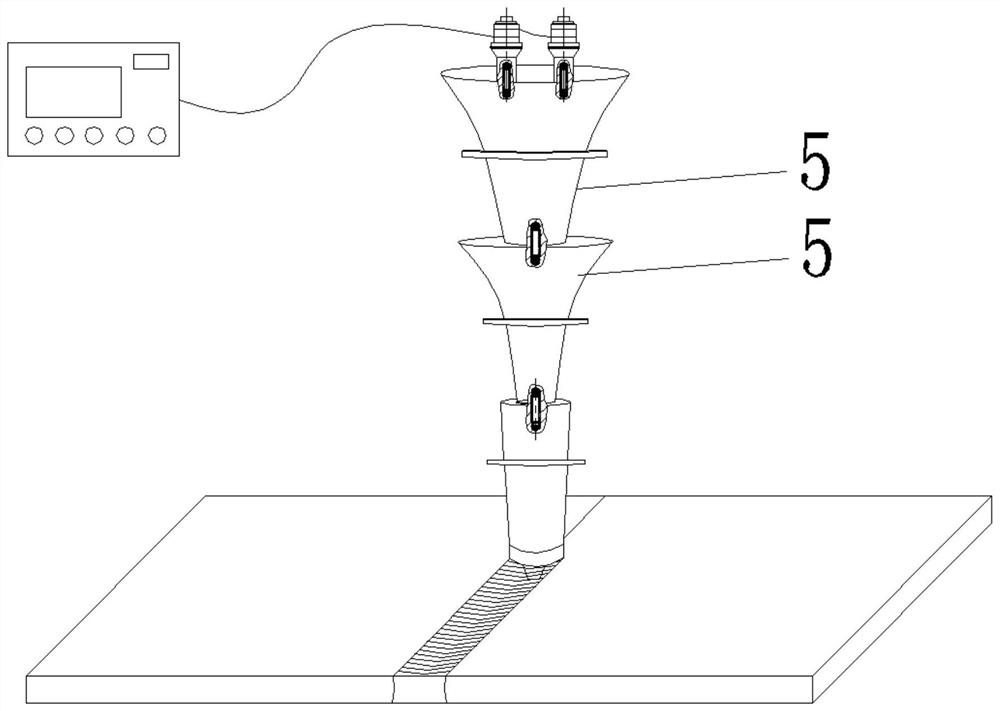

[0070] Such as image 3 As shown, an ultrasonic friction stir welding composite welding system, the difference between this embodiment and Embodiment 1 is that there are two front-stage ultrasonic horns 5 connected in series in this embodiment, and the front-end ultrasonic horn 5 is located at the front end The front end of the front-stage ultrasonic horn 5 is fixedly connected to the ultrasonic transducer 3, and the rear end of the front-stage ultrasonic horn 5 positioned at the rear end is fixedly connected to the front end of the rear-stage ultrasonic horn 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com