An electromagnetic forming device and method for improving the limit and quality of plate turning hole

An electromagnetic forming and hole-turning technology, which is applied in the field of sheet metal forming, can solve the problems of shortening the life of molds and coils, and cannot be industrialized, and achieves the effect of reducing the pulling force, improving the service life, and increasing the height of the turning hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

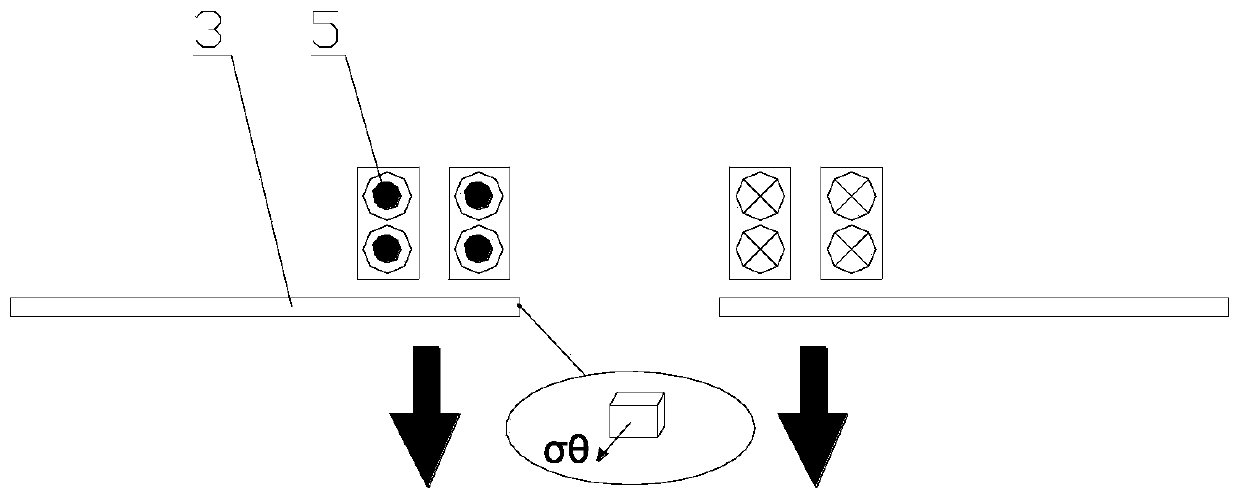

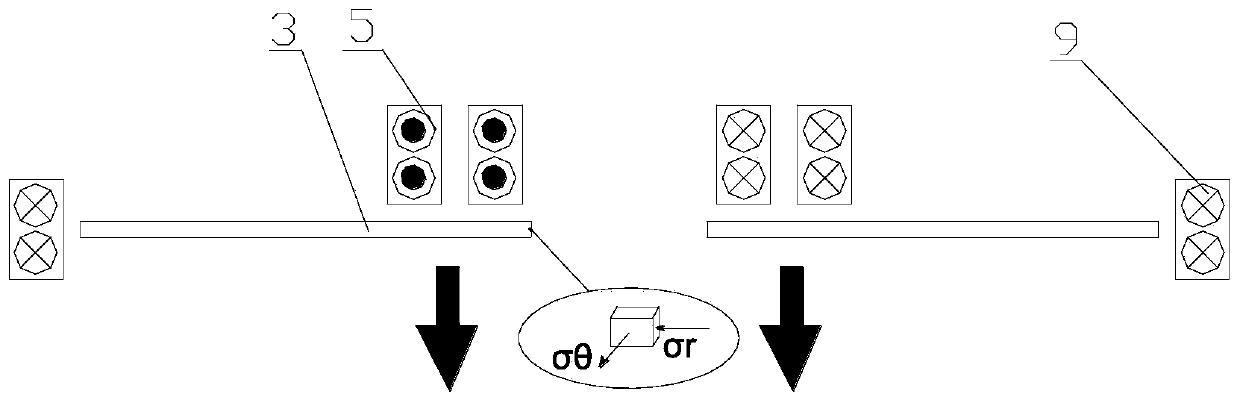

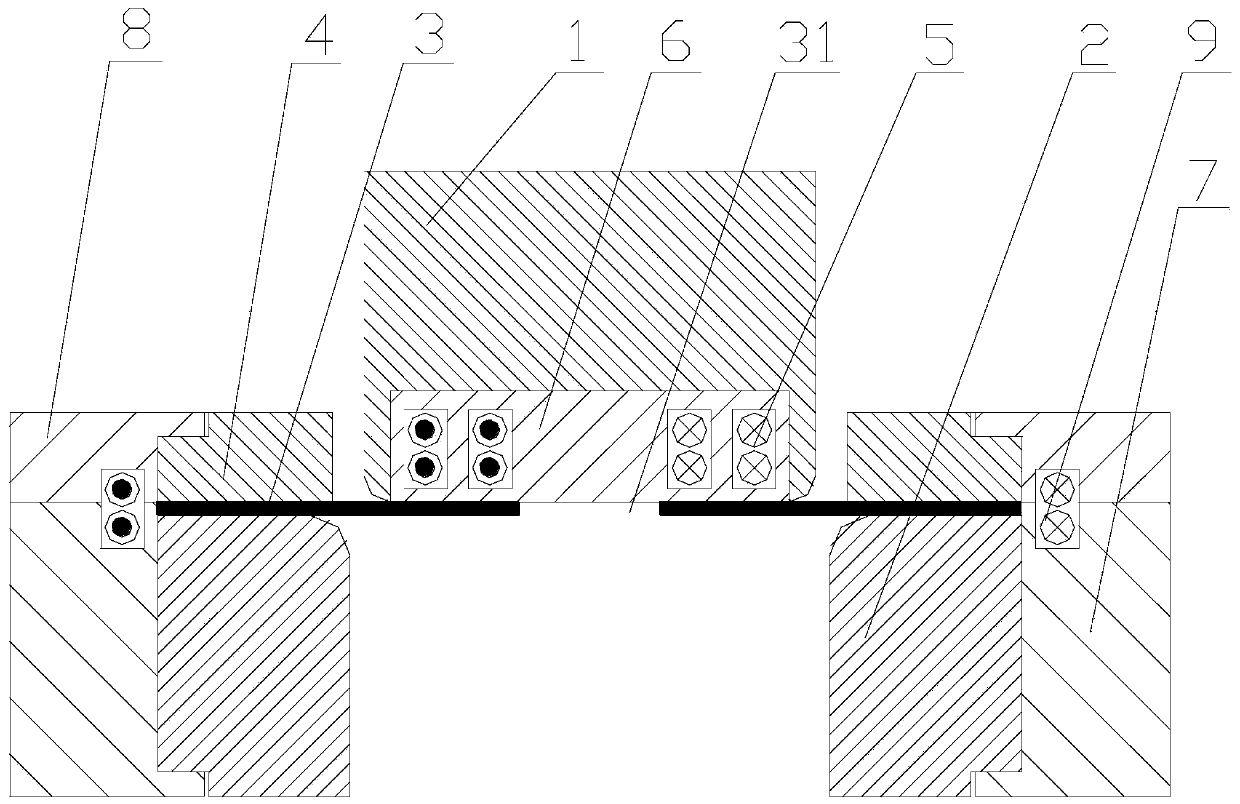

[0044] Such as Figure 3 to Figure 6 As shown in the figure, an electromagnetic forming device for improving the limit and quality of sheet material turning, including a punch 1, a die 2 used in conjunction with the punch 1, and a blank holder for pressing the sheet 3 in cooperation with the top end surface of the die 2 circle 4, prefabricated holes 31 are processed on the sheet material 3, and axial stretching coils 5 are arranged above the prefabricated holes 31. The axial stretching coils 5 are installed in the coil fixing plate 6, and the coil fixing plate 6 is installed and fixed on the punch 1, the bottom of the punch 1 includes rounded corners; the outer periphery of the die 2 is provided with a die collar 7, and the periphery of the binder ring 4 is provided with a blankholder collar 8, the die collar 7 and the blankholder collar 8 Grooves are arranged inside, and radial side push coils 9 are arranged in the grooves.

[0045] In this embodiment, the coil fixing plate ...

Embodiment 2

[0059] Such as Figure 7 to Figure 10 As shown, the difference between the forming device in the present embodiment and the embodiment 1 is that the punch 1 and the die 2 are inclined structures, and the rest of the structural features are the same as in the embodiment; the forming method in the embodiment is also the same as in the embodiment Same as in 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com