Side plate overturning lifting appliance

A spreader and side plate technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of arc edge beam profiles that cannot be clamped, achieve ideal flanging effect, eliminate side plate falling off, and flanging efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

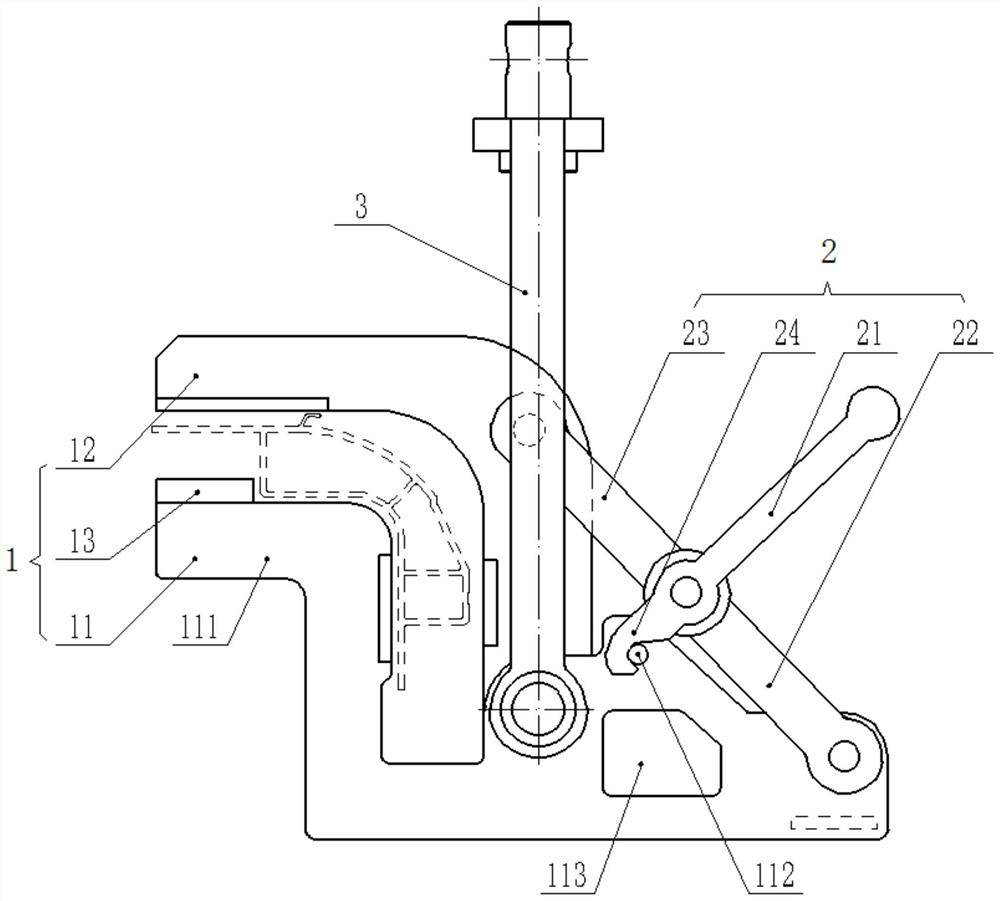

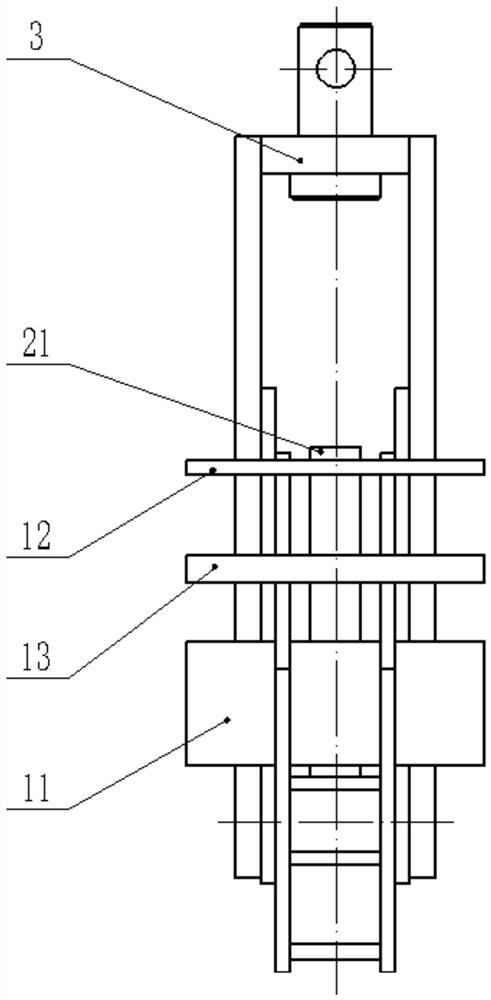

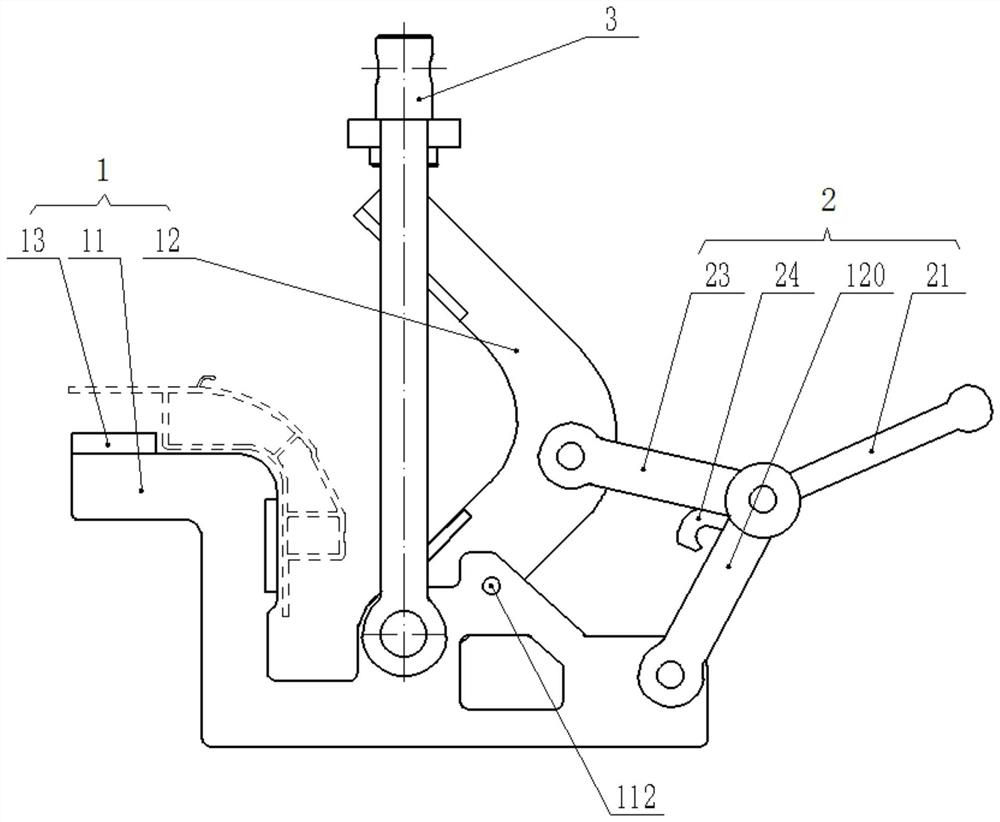

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Please attach Figure 1-3 , a side panel turning hanger, including a clamping unit 1, the clamping unit 1 includes a fixed jaw 11 and a movable jaw 12; one end of the movable jaw 12 is hinged to one end of the fixed jaw 11 , the side plate turning hanger also includes a control unit for controlling the rotation of the movable jaw 12 around its hinge with the fixed jaw 11 in a direction approaching or away from the fixed jaw 11; The movable jaw 12 is in the shape of a right-angled plate with rounded corners as a whole, and the fixed jaw 11 includes a fixed clamping end, which is a right angle with rounded corners matched with the movable jaw 12 as a whole. plate shape.

[0023] In this embodiment, the structure of the fixed jaw 11 and the movable jaw 12 is copied according to the shape of the arc edge beam profile, forming an arc-shaped clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com