Automobile radiator hood flanging die

A technology of flanging molds and automobile water tanks, which is applied in the field of stamping dies, can solve problems such as troublesome unloading process and difficulty in pressing, and achieve the effects of good flanging quality, convenient unloading, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

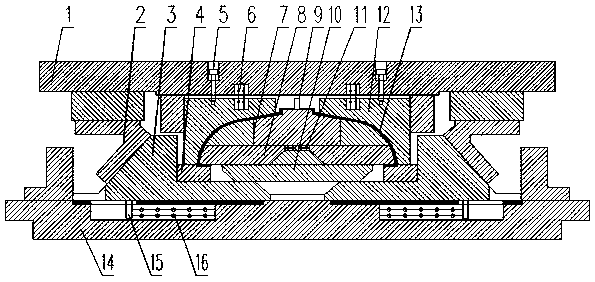

[0018] see figure 1 , a kind of automotive radiator cover flanging mold, comprising:

[0019] Sliders 3 evenly distributed along the mold centerline;

[0020] A top block 10 capable of sliding up and down;

[0021] Inner inserts 8 evenly distributed along the mold centerline;

[0022] punch 4;

[0023] It is characterized in that: the slider 3 is an L-shaped structure, the slider 3 can slide along the base 14 toward the centerline of the mold, the upper part of the outer side of the slider 3 is provided with an inclined surface, and the punch 4 is fixed on the side of the slider 3 At the bend, the end of the slider 3 is provided with an inclined surface, the inner side of the inner insert 8 is provided with an inclined surface, and the outer side is provided with a curved surface that matches the inner wall of the water tank cover top 13. The top block 10 A first truncated cone is provided at the lower end, and a second truncated cone is provided at the upper end. The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com