Plastic forming method for large complex special-shaped structural part

A plastic forming and cavity technology, applied in metal processing equipment, metal extrusion dies, etc., can solve the problems of increasing process and cost, high difficulty of pre-forming, improving plastic fluidity, solving filling problems, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A plastic forming method of non-proportional pressure loading of a PG-1 crankshaft reciprocating ejection die, the specific steps are as follows:

[0035] Step one, cutting

[0036] Step one, cutting

[0037] Will The 34CrNiMo6 steel bar is sawed as of blanks.

[0038] Step 2. Heating

[0039] The billet completed in the first step is heated in a gas furnace to the initial forging temperature of 1100°C.

[0040] Step three, mold heating

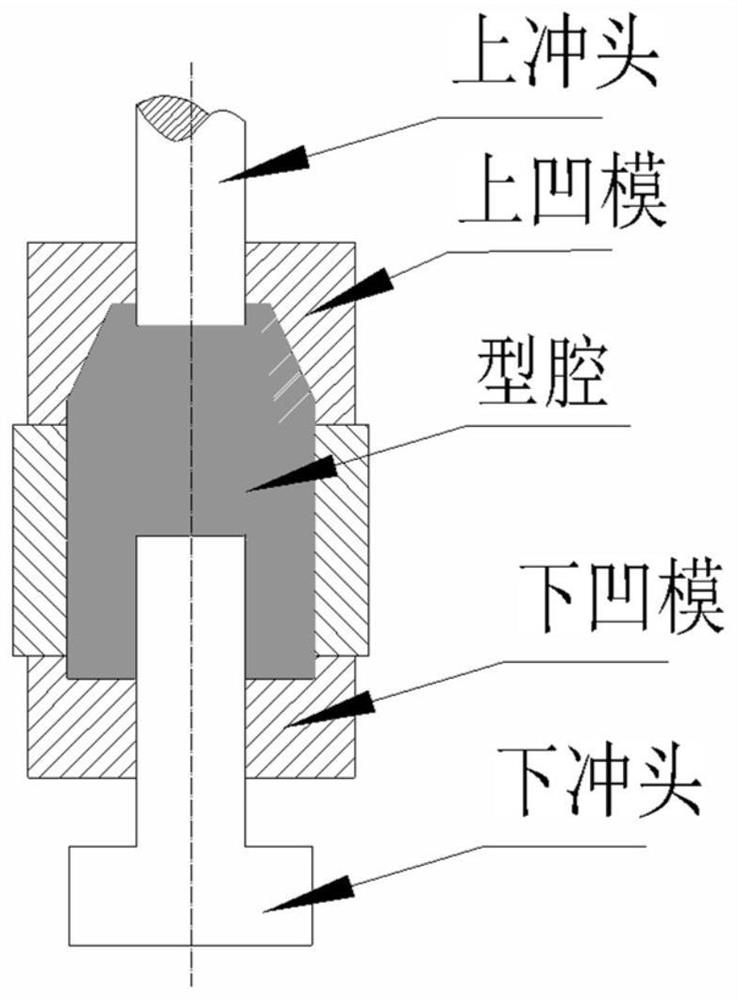

[0041] The use of induction heating equipment will be as figure 1 The upper and lower dies of the follow-up cavity shown are heated to 400°C and held for 30 minutes;

[0042] Step 4. Loading

[0043] Put the blank heated in step 2 into such as figure 1 In the mold cavity of the follow-up cavity shown, the follow-up cavity includes an upper punch 1, an upper die 2, a cavity 3, a lower die 4 and a lower punch 5 arranged vertically in sequence;

[0044] Step five, close the mold

[0045] After step 4 is completed, the mold is...

Embodiment 2

[0085] A plastic forming method of non-proportional pressure loading of a 7A04 aluminum alloy support body with a reciprocating ejection die, the specific steps are as follows:

[0086] Step one, cutting

[0087] Will The 7A04 aluminum alloy bar stock sawing is of blanks.

[0088] Step 2. Heating

[0089] The billet completed in the first step is heated in a gas furnace to the initial forging temperature of 430°C.

[0090] Step three, mold heating

[0091] The use of induction heating equipment will be as figure 1 The upper and lower dies of the follow-up cavity shown are heated to 400°C and held for 30 minutes;

[0092] Step 4. Loading

[0093] Put the blank heated in step 2 into such as figure 1 In the cavity 3 of the follow-up cavity shown in the figure, the follow-up cavity includes an upper punch 1, an upper die 2, a cavity 3, a lower die 4 and a lower punch 5 arranged vertically in sequence;

[0094] Step five, close the mold

[0095] After step 4 is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com